splice wire rope end to end made in china

Experience the health benefits of natural, high-quality splice rope end as culinary ingredients or healthcare supplements available at Alibaba.com for affordable prices. Other versatile applications include herbicides, cosmetics and engine fuel and lubricants. Key considerations when choosing splice rope end include the source, processing method, ingredient quality and packaging. Explore various accredited manufacturers and distributors for quality splice rope end, essential for your needs in and out the kitchen.

Superior-quality splice rope end keep a white color when solid and are colorless in liquid form. For cooking, choose a treated and refined product to benefit from the slightly sweet complimentary flavor. Asian cooking prominently features splice rope end in sauces, stir-fries and roast meats for flavor and heat stability. The high saturated fat content prolongs the shelf life and helps maintain a solid form in room temperature. Alibaba.com also provides unrefined splice rope end that are without additional processing or ingredients for a stronger aroma and flavor.

Choose less processed splice rope end for clean eating or Paleo diets and skin and hair health. The product contains high levels of essential macronutrients and a lower smoke point for stable cooking. Other options include organic splice rope end from all-naturally grown coconuts, free from chemicals and pesticides. For large quantity applications on a budget such as dip-frying food or creating bath oils, refined splice rope end are more economical.

Browse through organic, refined and unrefined splice rope end options on Alibaba.com for the best deals and offers. Whether you are looking to apply some on your skin or cook with it, visit the site for many choices on high-quality products. Most products are stable and easy to store, with or without a refrigerator.

Rotation rope and non-rotation rope or rotation resistant rope. Round strand rope, compacted rope, swaged rope. Wire rope with fiber core, wire rope with IWRC(Independent Wire Rope Core). Galvanized wire rope, ungalvanized wire rope or bright wire rope. Wire rope with plastic insert, Wire rope without plastic insert. Wire rope covered with plastic.

The end of a single wire rope is bent back along the rope to form the eye, and strands are hand-tucked into the body of the rope in what is called a burnt end splice. With Burnt End splices, the ends of strands are left exposed and cut off with a torch. Upon special request, a premium splice known as a tapered and concealed splice can be provided. Slings with rope bodies larger than 1" diameter are made only with Burnt End splices. All have the same rated capacity, size for size.

The tapered and concealed splice utilizes tension in the rope body to secure strands where they are tucked back into the rope. Needs no metal sleeve to assure firm anchoring. When "tapered" and "concealed", ends of strands are tucked inward and concealed inside the rope.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

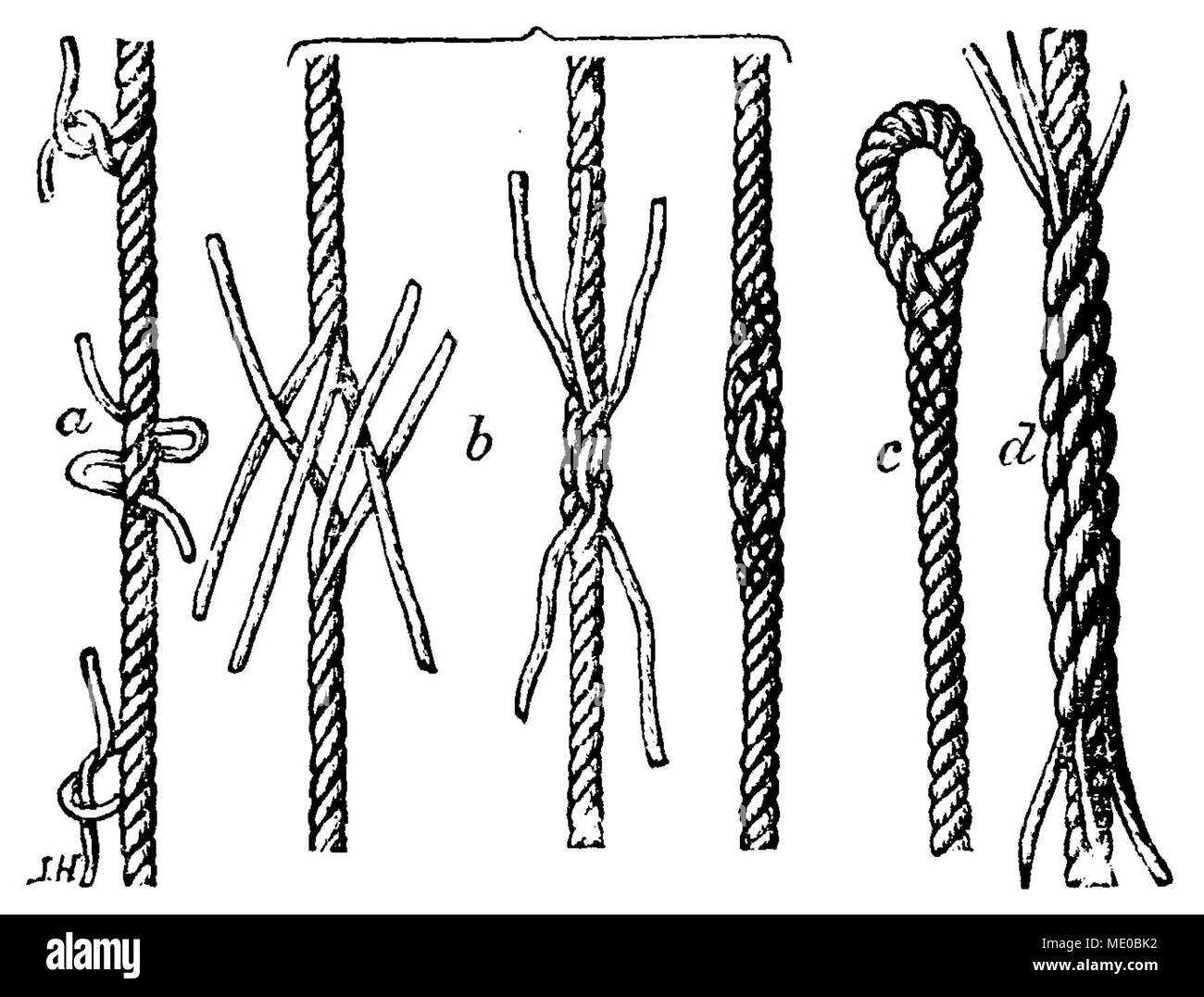

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

We are the leading supplier for wire rope end terminations to the rigging industry and in addition to ferrules, we design, manufacture and supply a full range of equipment and services. Everything engineered and manufactured in Germany.

Rope splicing in ropework is the forming of a semi-permanent joint between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together.

back splice (or end splice) – A splice where the strands of the end of the rope are spliced directly back into the end without forming a loop. It is used to finish off the end of the rope to keep it from fraying. The end of the rope with the splice is about twice the thickness of the rest of the rope. With nylon and other plastic materials, the back splice is often no longer used; the rope strands are simply fused together with heat to prevent fraying.

cut splice (originally cunt splice) – A splice similar to the eye splice. It is typically used for light lines (e.g. the log-line) where a single splice would tend to come undone, the rope being frequently wet.bowdlerised to "cut splice".

long splice – A splice used to join two rope ends forming one rope the length of the total of the two ropes. The long splice, unlike most splice types, results in a splice that is only very slightly thicker than the rope without the splice, but sacrifices some of the strength of the short splice. It does this by replacing two of the strands of each rope end with those from the other, and cutting off some of the extra strands that result. The long splice allows the spliced rope to still fit through the same pulleys, which is necessary in some applications.

short splice – Also a splice used to join the ends of two ropes, but the short splice is more similar to the technique used in other splices and results in the spliced part being about twice as thick as the non spliced part, and has greater strength than the long splice. The short splice retains more of the rope strength than any knots that join rope ends.

Splices are often tapered to make the thicker splice blend into the rest of the line. There are two main types of tapering, the standard and the "West Coast Taper".

Standard tapers progressively remove a portion of each remaining strand – one-third at a time is typical, resulting in a taper of two additional tucks beyond the splice – thus making each successive tuck produce a narrower splice. This is only practical with laid-lines – those made up of numerous strands laid side by side.

A fid is a hand tool made from wood, plastic, or bone and is used in the process of working with rope. A variety of fid diameters are available depending on the size of rope being used. Styles of fid designs include:

A Marlinspike is a tool, usually made of steel and often part of a sailor"s pocketknife, which is used to separate strands of rope from one another. They can range in size anywhere from 3 inches to 5 feet long, with a round or flattened point.

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

Referring to fig. 1-3, a splicing steel wire rope comprises a steel wire rope body 1 and a splicing mechanism arranged on the steel wire rope body 1; the splicing mechanism comprises a first splicing assembly and a second splicing assembly; the first splicing assembly and the second splicing assembly are respectively arranged at two ends of the steel wire rope body 1; the first splicing assembly and the second splicing assembly are matched at one end far away from the steel wire rope body 1; the second splicing assembly comprises a splicing head 6 and a connecting component 7, and the splicing head 6 is installed at one end of the steel wire rope body 1; the connecting part 7 is arranged on the splicing head 6; the connecting component 7 comprises a connecting rod 71, a movable sleeve 72, a limiting rod 73 and a spring 74, wherein the connecting rod 71 is arranged inside the splicing head 6; and both ends of the connecting rod 71 are provided with movable sleeves 72; the non-adjacent ends of the two movable sleeves 72 are respectively provided with a limiting rod 73, and the non-adjacent ends of the two limiting rods 73 are respectively extended to the outer surface of the splicing head 6; the spring 74 is sleeved on the connecting rod 71, and two ends of the spring 74 are respectively connected with one adjacent side of the two movable sleeves 72.

Wherein, four spouts 2 have been seted up to the lateral wall of wire rope body 1, and the interval value between every two spouts 2 of four spouts 2 is adjacent equals, and splice 6 is all kept away from to four spouts 2.

The first splicing assembly comprises a splicing sleeve 3 and a limiting block 5; the splicing sleeve 3 is sleeved at one end of the steel wire rope body 1 far away from the splicing head 6; the outer side wall of the splicing sleeve 3 is provided with two limiting holes 4; four stoppers 5 are installed to the inner wall of splice cover 3, and four stoppers 5 all are located the inside of four spout 2, and its effect is realized linking together the both ends of wire rope body 1.

Wherein, two spacing grooves are provided in the splice 6, and the two spacing grooves are communicated with the inside of the splice 6, and the two movable sleeves 72 are respectively located in the two spacing grooves, and the elastic range of the spring 74 is limited by the action of the movable sleeves.

Wherein, the one end that the gag lever post 73 kept away from movable sleeve 72 matches with spacing hole 4, and its effect is convenient for the one end of better assurance gag lever post 73 gets into the inside of spacing hole 4 smoothly, has realized the concatenation to splice joint 6 and splice sleeve 3.

During operation, at first press the gag lever post 73 on the splice 6 to the inside of splice 6, insert the inside of splice 3 with the one end of splice 6 after that, rotate splice 6 simultaneously and make gag lever post 73 correspond with the position of spacing hole 4 each other, the movable sleeve 72 pops out under the effect of spring 74 simultaneously, and prescribe a limit to movable sleeve 72 under the effect of spacing groove, thereby ensure that wire rope can splice together, simultaneously under the effect of spout 2 and stopper 5, make wire rope can carry out the regulation of minim.

The above description is only for the purpose of illustrating the preferred embodiments of the present invention and is not to be construed as limiting the utility model, and any modifications, equivalents, improvements and the like that fall within the spirit and principle of the present invention are intended to be included therein.

Manufactured in Calgary this cable is made by coating offshore aircraft cable with a tough and durable PVC coating. The colour is flat black to best fade into the background.

AN thimbles come in either cold-rolled steel (zinc plated) or stainless steel (natural finish). Fit cable diameters from 1/16” to 3/8” to meet the most demanding marine, aircraft or industrial requirements. AN Thimbles meet all Military Specifications.

Often generically referred to as Crosby clips and occasionally as bulldogs we offer both forged and malleable wire rope clips. Forged clips are required for use in overhead lifting. The malleable clips are recommended for non critical light duty applications such as guard rails, guy wires etc. The efficiency rating on the proper number of properly applied wire rope clips is 80% of the strength of the wire rope. We offer both offshore and Genuine Crosbie Wire Rope Clips. Fist Grips have a couple of advantages over Wire Rope clips in that they are impossible to apply incorrectly and they damage the rope less in situations where the clip will be removed.

Wire rope clips must be re tightened after applying load. In accordance with good rigging practice wire rope and its terminations should be regularly inspected.

Unfortunately, polyester melts at approx. 250°C (~480°F). Research has shown that a 2k luminair-housing can reach temperatures of about 190°C (~370°F), with the truss-chord straight over it being almost 140°C (~280°F). Accidents have been reported of round slings being melted by spots, pyro or the heat of the rays, and as a result, trusses have fallen. When round slings are used, a safety backup must be applied such as a wire rope or chain sling.

So rather than have a backup steel sling why not make the sling out of steel but softer than a single cable. A steel round sling has a normal outside webbing for soft slings, but instead of the polyamide core, the steel round sling has a core made of many small steel cables, which makes it resistant to high temperatures. The steel wires within the steel round are as flexible as a normal soft sling, but have a much better fire resistance. The steel round can be used in circumstances where the normal soft slings are not allowed.

The outside webbing is black, including an identification label and a hidden inspection window to inspect the steel wires within the sling. The wire-rope core has better heat resistance than the truss itself.

Down Stage Right can supply most of your rope and cordage requirements from twill tape and black cotton tie line to large diameter manila and polyester ropes and braids. To make life very very confusing the synthetic fibre ropes are all available in either a 3 strand, solid braid, double braid or parallel core configuration in nylon, polyester or more exotic materials. Polyester ropes are available in a spun or non spun finish. Due to the huge number of different sizes, colours, materials and braid types combinations (and to simplify things) Down Stage Right Industries stocks several favourites that we have found the theatrical industry usually purchases. If you need a particular rope we are happy to bring in the particular configuration and colour that you want. Please call for details or recommendations for a particular product.

Twill tape is a flat twill-woven ribbon of cotton, linen, polyester, or wool. Used in attaching soft goods and electrical cables to pipes we offer both cotton and polyester twill in 100 yard rolls.

Used as a general purpose tie line for drops or cables it is offered in 1000 and 3000" spools. Available in cotton and polyester. Size 4, #4.5 or 1/8” and #5.

The primary advantage of sash cords are their handling characteristics and their knot holding ability. It does not have the strength or durability of double braids. Available in white as a cotton polyester blend or in black as spun polyester. Sash braid is generally a coarser cousin of solid braid.

Often mislabeled as hemp, manila is significantly stronger and is used in for hand lines in counterweight rigging and as general purpose spot line rope. We only carry #1 grade sea worthy manila. Manila has generally been replaced by synthetics in our industry

Working loads are guidelines only. Once put into service rope is continually deteriorating. Manila rope will deteriorate in storage even under ideal conditions.

Solid braid ropes are sometimes referred to as “sash cord” because this pattern was used to raise sash windows. It is formed by braiding 8 to 18 strands in a reasonably complicated pattern with all the strands rotating in the same direction on the braider. The individual stitches are oriented in the same direction as the rope. The center may contain a filler core. These ropes maintain their round shape well and therefore work exceptionally well in pulleys and sheaves. They tend to have high elongation and are generally less strong than other forms of construction, and are difficult to splice.

"Double braid" ropes, also referred to as "Marine Ropes" or "Yacht Braid" or “2 in 1” are perhaps the most well known braided rope on the market today. They are constructed of a hollow braided rope, which acts as a core inside another braided rope. The combination of the 2 ropes in 1 results in a rope with higher tensile strength than commonly found in twisted ropes. The inner rope and outer rope are generally designed to share the load fairly evenly. Double braid ropes have a torque free construction, and are easily spliced. However, caution must be exercised where double braid ropes are run over pulleys, through hardware or in any situation where the outer rope may slide along on the inner rope and bunch up. This condition, often called "milking", will cause dramatic loss of strength by causing the entire load to go onto the inner rope, because the sheath is bunched up and therefore not under the same tension as the inner rope. Polyester double braid ropes big advantage is that they do not have the same stretch as nylon. They can also be made with a soft “spun” covering giving a better hand feel. The elasticity of nylon ropes can absorb sudden shock loads that would break other ropes.

Manufactured by New England Ropes Stage Set X is a superior replacement for manila with a longer life, much higher strength and no slivers. This rope was specially developed as a replacement for manila hand lines in counterweight rigging and we find it to be Cadillac of the synthetic hand line ropes. Multiline II is a three stranded rope with the same ideals in mind. It is more economically priced and has slightly different handling characteristics.

PRODUCT DESCRIPTION: New England Ropes" Stage-Set X is the softest, strongest and most environmentally stable product available in the theatre industry for counterweight systems. It"s parallel core of polyester fibre contained within a helically wrapped polyester tape and covered by a braided polyester jacket, remains firm and round under all load conditions and resists crushing in rope locks.

Compliance to the above specifications is based upon testing according to the Cordage Institute Standard Testing Methods for Fiber Rope and/or ASTM D-4268 Standard Methods of Testing Fiber Ropes.

Tensile strengths - Are approximate average for new, unused ropes. To estimate the minimum tensile strength of a new rope, reduce the approximate average by 15% (Cordage Institute defines minimum tensile strength as two standard deviations below the average tensile strength of the rope).

Good resistance to most minerals / organics, acids, weak alkalis, bleaches and other oxidizing agents and most solvents. Polyester is generally considered to have a better overall resistance to acids or oxidizing agents.

Good resistance to the passage of electrical current. However in rope form, dirt, surface contaminants, water entrapment and the like can significantly affect dielectric properties. Extreme caution should be exercise any time a rope is in the proximity of live circuits.

No blanket working load recommendation can be made because it depends on the application and conditions of use, especially potential danger to personnel. It is recommended that the user establish working loads and safety factors based on professional and experienced assessments of risks. The working load is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or exceptional service such as shock, sustained loading, severe vibration, etc.

The Cordage Institute specifies that the Safe Working Load of a rope shall be determined by dividing the Minimum Tensile Strength by the Safety Factor. Safety factors range from 5 to 12 for non-critical uses, 15 for life lines.

PRODUCT DESCRIPTION: Multiline II is a 3-strand composite rope, its unique construction combines filament and staple/spun polyester wrapped around a polyolefin core (smaller than 1/2" diameter does not have polyolefin core). Multiline II feels and handles like manila, yet provides greater durability, higher strength, lighter weight, and a consistent supple feel over time.

Compliance to the above specifications is based upon testing according to the Cordage Institute Standard Testing Methods for Fiber Rope and/or ASTM D-4268 Standard Methods of Testing Fiber Ropes.

Tensile strengths - Are approximate average for new, unused ropes. To estimate the minimum tensile strength of a new rope, reduce the approximate average by 15% (Cordage Institute defines minimum tensile strength as two standard deviations below the average tensile strength of the rope).

Polyester jacket protects against UV degradation. The polyolefin fibers are UV stabilized to minimize UV degradation. Can be used outside over long term if inspected regularly.

Good resistance to most minerals / organics, acids, weak alkalis, bleaches and other oxidizing agents and most solvents. Polyester is soluble in 95% sulfuric acid or strong alkaline"s at boil. Polyolefin is soluble in concentrated chlorosulphonic and sulfuric acids.

Good resistance to the passage of electrical current. However in rope form, dirt, surface contaminants, water entrapment and the like can significantly affect dielectric properties. Extreme caution should be exercise any time a rope is in the proximity of live circuits.

No blanket working load recommendation can be made because it depends on the application and conditions of use, especially potential danger to personnel. It is recommended that the user establish working loads and safety factors based on professional and experienced assessments of risks. The working load is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or exceptional service such as shock, sustained loading, severe vibration, etc.

The Cordage Institute specifies that the Safe Working Load of a rope shall be determined by dividing the Minimum Tensile Strength by the Safety Factor. Safety factors range from 5 to 12 for non-critical uses, 15 for life lines.

These are rated blocks grooved with steel sheaves fitted with Bronze bearings grooved for cable from 1/8” to 3/8” and sheave sizes from 1 ½” to 5” in diameter. Most blocks are available with single or double sheaves. Sheaves without housings are also available if you want to build your own creations.

A towing sock or wire rope puller or wire pulling grip is a device that connects to the end of a cable, such as a power cable, in order to pull it through a tube or tunnel.Chinese finger trap.eye splice.

Also similar is the strain-relief grip which uses woven wire around the end of electrical wiring just before the terminal. It is placed there to prevent the wire from breaking.

We use Talurit press dies and ferrules for complete compatibility. The ferrules are totally traceable and validated to EN13411-3 standards. This consistency in process and parts ensures that our products achieve the designed wire strength efficiencies and enjoy full coverage under Talurit’s Product Liability Insurance.

Our standard steel thimbles are manufactured according to BS 464, FF-T-276b Type III (G414) or JIS B2802 (Type A) specifications. Our solid thimbles are built to JIS B2802, JIS F3403 or DIN 3091 standard.

For crane wire ropes many different types of sockets are used: open and closed spelter sockets, open and closed swage sockets, wedge sockets and Nemag rope pear sockets.

A wedge socket termination reduces the wire rope efficiency to 80%, but the wedge socket remains a popular choice because it is easy to install and can be attached after the wire rope is reeved.

The Nemag rope pear socket when paired with the Nemag quick release link forms an unbreakable connection between two ropes. Together, they enable quick and straightforward coupling and uncoupling of grabs on cranes. Made from high grade austenitic manganese steel, these Nemag fittings generally outlast the wire rope.

Our Spelter sockets and Nemag rope pear sockets are poured with Wirelock, the original cold socketing resin and the first socketing system to meet the performance criteria of DNV for offshore wire mooring rope, currently the DNV-OS-E304 standards. Wirelock produces a void free socket for 100% efficiency and safety, and is unparallel in dependability and fatigue performance.

ESCO pioneered the design and widespread use of modern swaging materials and techniques – the press, the dies and fittings. All parts are engineered to close tolerances to work together as a total system.

ESCO stainless steel duplex sleeves provide the quickest and simplest way to make strong swaged turnback eyes in wire rope. Duplex sleeves permit easy adjustment of eye size. Grommets, plain eyes and tight thumbed eyes can be made quickly and precisely every time without splicing or die changes.

ESCO offers the strength and durability of stainless steel single sleeves specifically designed for use with the Flemish eye splice. During swaging, tough stainless steel surrounds the splice, increasing the strength of the splice and preventing unlaying when the wire rope is under load. It also protects the splice, preventing damage from accidental abuse on the job. The tapered elliptical design permits easy rope insertion and encloses the wire ends.

Cast Screwy choker ferrules feature an innovative cast Screwy contour that matches the contour of the wire rope, maximizing contact between the ferrule and rope for greater grip strength.

Screwy drumline ferrules incorporate the cast Screwy design in a shorter ferrule, designed specifically for attaching winch lines to winch drum pockets.

ESCO carbon steel single sleeves are manufactured from specially selected steels that are carefully formed and produced using a custom heat treating process. The result is a sleeve that provides accurate rope fit and maximum material performance during swaging and on the job. ESCO carbon steel single swage sleeves are available in sizes to fit wire rope from 1/4″ to 2-1/2″.

ESCO offers choker ferrules and end fittings machined from tough steels, engineered specifically for swaging applications. Manufactured to exacting specifications and continuously monitored to ensure the highest quality, these ferrules are available in popular sizes at competitive prices.

ESCO machined wedge-type ferrules permit the make up or repair of chokers and winch lines in minutes – no molten socket metal or swaging equipment is required. Wedge type ferrules may be applied with ESCO Socketfast® resin. Wedge-type ferrules are intended only for use with new 6 x 19 class, 6 x 37, 7 x 19, or 7 x 37 class, right regular lay, EIP, IWRC rope made to U.S. specifications.

Rugged ESCO zinc ferrules are made of shock- and abrasion-resistant alloy steel for maximum durability. These ferrules are designed to fit Bardon choker hooks, ensuring easy installation and trouble-free performance.

These thimbles protect and cradle braided sling eyes for longer service life and are cast in tough ESCO alloy material for superior performance. The unique cast tab design peens over more easily to protect and retain the rope.

through the eye of another to create a choker sling. The innovative cast tab design is easier to bend over, and the thimble supports the rope eye for greater strength. Durable ESCO alloy steel protects the rope from wear on the job.

ESCO Swagers utilize an open jaw configuration coupled with a mechanical design that leverages relatively low 2,000 PSI hydraulic force to deliver swaging force. Lower system pressure lengthens the component lifespan and reduces maintenance and operating costs.

ESCO engineers developed faster hydraulic power units to improve performance and reduce cycle time on older ESCO Swagers. The self-contained power unit stands beside the press and is controlled by an electronic foot pedal, which activates a solenoid control valve. A built-in limit switch

ESCO swaging dies are precision manufactured using premium quality tool steel. ESCO makes adapters that allow use of standard ESCO Dies and ESCO swaging systems with other brand swagers. ESCO Die Gauges provide an easy and accurate way for operators to check the condition

of their ESCO Swage Dies. Regular checking allows operators to monitor the condition of their dies and to identify when a die is reaching the end of its usable life. By ordering ahead, operators can then eliminate lost production time and maintain the highest quality swaged assembly standards.

ESCO swaging dies are made in three block sizes:2″ x 3-1/2″ end dimension. Working Load Limit (WLL) 200 tons jaw pressure. Use on ESCO Mark 75 and Mark

Have permanently affixed and legible identification markings as prescribed by the manufacturer that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one;

Have permanently affixed and legible identification markings as prescribed by the manufacturer that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one;

When U-bolt wire rope clips are used to form eyes, employers must use Table G–1 in § 1915.118 to determine the number and spacing of clips. Employers must apply the U-bolt so that the "U" section is in contact with the dead end of the rope.

Have permanently affixed and legible identification markings as prescribed by the manufacturer that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one;

All sling chains, including end fastenings, shall be given a visual inspection before being used on the job. A thorough inspection of all chains in use shall be made every 3 months. Each chain shall bear an indication of the month in which it was thoroughly inspected. The thorough inspection shall include inspection for wear, defective welds, deformation and increase in length or stretch.

Chain slings shall be removed from service when, due to stretch, the increase in length of a measured section exceeds five (5) percent; when a link is bent, twisted or otherwise damaged; or when raised scarfs or defective welds appear.

All repairs to chains shall be made under qualified supervision. Links or portions of the chain found to be defective as described in paragraph (c)(4) of this section shall be replaced by links having proper dimensions and made of material similar to that of the chain. Before repaired chains are returned to service, they shall be proof tested to the proof test load recommended by the manufacturer.

Wrought iron chains in constant use shall be annealed or normalized at intervals not exceeding six months when recommended by the manufacturer. The chain manufacturer shall be consulted for recommended procedures for annealing or normalizing. Alloy chains shall never be annealed.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291