union wire rope co for sale

We pride ourselves on providing robust solutions to our customers in the most demanding and diverse applications; with unmatched support, innovation and quality. When customers come to Union they are not just looking for a product, they are looking for our expertise and hands on approach to understand and resolve the issues they encounter in the field.

We want to create value, we want to solve problems, and we do that together. Our people are an extension of your team to overcome challenges and create solutions for you.

Union wire ropes reflect the people who make it. People of character, full of grit and determination. Tough-minded individuals who never cut corners or take shortcuts. We’ve matched science of design with the art of skillful manufacturing craftsmanship to build the best wire rope in the world.

No matter where you are in the world, Union delivers hard-working products, exceptional service and unmatched support. At Union, we’re with you in the field, on the rig and in the mine, getting our hands dirty to supply tough ropes that help you get the job done - better. Being part of the global leader, WireCo WorldGroup, our expertise is unmatched. Whether it"s manufacturing, design, troubleshooting or logistics, Union wire rope support is unsurpassed.

These 3 strand ropes are ideal for pulling lines in electrical transmission line construction. Rotary swaging the rope results in an exceptionally compact rope cross-section. This increases surface area, which improves rope contact with sheaves and on drums, thereby providing greater resistance to surface wear and abrasion while reducing wear on sheaves. The smooth surface also helps reduce wear on underground conduits. Lengths may be fitted with flemish-eye ends.

Since 1951, the family at Union Sling Company in Dallas, Texas has provided rigging products and services to the North Texas area. Our experience allows us to provide dependable, quality service. We sell strong, safe rigging products.Our experience means we have worked with a variety of industries. We don"t just sell products. We can answer questions too. We have the know-how to provide the right rigging for the job.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

Since 1951, the family at Union Sling Company in Dallas, Texas has provided rigging products and services to the North Texas area. Our experience allows us to provide dependable, quality service. We sell strong, safe rigging products.

Union Sling Company sells wire ropes, chain and nylon slings, fittings, pendants, chokers, safety harnesses, tie-down straps, and custom architectural railing assemblies.

Union Sling Company in Dallas, Texas has provided rigging products and services to the North Texas area since 1951. Our experience allows us to provide dependable, quality service and sell the safest, strongest products. Our experience means we have worked with a variety of industries. We don’t just sell products; we can answer questions too. Our family-run business has staff with the background to help you with your project. We have the know-how to provide the right rigging for the job.

We represent and distribute rigging products from many of the top manufacturers in our industry. These include, The Crosby Group, Gunnebo Industries, Peerless Chain, Columbus McKinnon, Cooper Tools / Apex Tool Group, Chicago Hardware, and Pewag.

Nothing speaks to the level of precision and performance we can offer than our continued success in medical wire and cable. With full process control from wire rod to finished cable assembly, our focus is providing full compliance with the most exacting specification used in today’s medical devices. We offer the complete line of austenitic, ferritic, duplex, martensitic, and super duplex stainless steel alloys; cobalt and nickel based alloys, copper, silver plated copper, brass, bronze, and resistance alloys in diameters from 0.001″ (0.0889mm) up to 1.00” (25.4mm) on the industries widest range of packages including bobbin, carrier, coil, reel, spool, or your custom packaging requirement. Learn more by visiting ourLoos & Co., Inc. Medical Technologies Division. Alloys: 304, 304L, 304V, 316LVM, MP35N®, L605, 17-7, Copper, Cobalt & Silver Plated Copper, and more.

Our wire and cable are manufactured and processed to meet the most stringent aerospace industry requirements. “Seam Free” material can be finished with our full range of wire coatings. No other company can provide more military specification wire and cable products than the CWI family of companies. From specialty alloy bar stock for fasteners, to rescue hoist cable and flight control applications, CWI is the global leader in aerospace wire and cable product support. Most Mil-Spec products are stocked or available to quickly turn. We provide quick delivery, exceptional service, and technical knowledge to support your processing and product requirements. Our common alloys for the aerospace industry include: 302HQ, 316L, 13-8Mo, A286, Monel® 400, Monel® K500, Inconel® 600, 718, and Invar 36.

With thousands of available products and configurations, we support most industrial applications, no matter the size or the demand. After more than 60 years of industry experience, there are very few applications we have not seen. And for those we haven’t, we have the engineering and quality staff to ensure that your next development project, your next major job, or maybe just the rush order for tomorrow’s production goes off without a hitch. See all our available products and alloys for more detail.

No other market demands quite as much from its products. CWI has long been a participant in the manufacturing of specialty and exotic wire grades to meet the highly demanding requirements of heat resistance, strength retention, and reliability. We understand that our oil and gas customers are simultaneously pushing the limits of modern technology and battling the real life time constraints that can cost thousands of dollars per minute. This market needs professional service and product solutions. From demister pads and welding wire to downhole slicklines and cables for sour well monitoring, CWI offers a broad range of products to keep you on schedule no matter what the challenge. CWI alloys used in Oil and Gas Industries are: 316, 17-7 PH (631), Inconel® 600, Inconel® 625, 718, MP35N®, X750, GD316™, GD22™ / SUPA40®, GD31Mo™ / SUPA75®, GD35Mo™, GD37Mo™, GD50™, and SUPA®-GD100™.

Our alloys combat the extreme conditions of mining and exploration. These applications require a combination of strength and exceptional corrosion resistance, especially where saltwater is involved. We provide a full range of high strength wires for solid-strand and stranded cabling applications. CWI alloys used in Mining / Exploration Industries are: 302S, 316, 317, Monel® 400, Monel® K500, Inconel® 600, Inconel® 625, MP35N®, X750, GD31Mo™ / SUPA75®, GD50™. Grades 316, 317, Alloy 50, and 904L have increased levels of molybdenum to resist pitting and surface attack.

The marine environment is the most corrosive natural environment, and CWI has the alloys to combat this environment. Protect your investments and get longer service life by using a top quality stainless or nickel alloy to avoid corrosion or wire & cable failure. We offer a wide range of marine wire and cable – from running and stayed rigging to lashing wire and larger stainless wire ropes for trawling and buoy/recovery applications. CWI alloys used in Marine Industries are 316 317 Monel® 400 Monel® K500 GD50™. Premium alloys 400 and K-500, composed primarily of nickel and copper, are often specified for cold-formed bolts, screws and other fasteners used in saltwater applications. These offer superior corrosion resistance with K-500 offering additional strength properties by age hardening due to the addition of aluminum.

When there are difficult and demanding construction schedules to meet, look to us for your solution. CWI products for stainless reinforced concrete and masonry, and soil stabilization utilizing environmental mesh, architectural mesh panels, stainless nails, and more. Infrastructure investments and civil engineering projects benefit from filtration wires and mesh, as well as stainless wire ropes in hoisting and dam gate applications. CWI alloys used in the construction industry are: 302S, 304, 316, 430.

Central Wire provides a number of wire products for the automotive industry. We manufacture wires for springs, cold-formed fasteners, forming wire for exhaust system hangers, flat wire for wipers, slide formed wire components, stainless steel wool and other complex parts for use in a number of on and off-road vehicles. CWI alloys used in the automotive industry are 302HQ, 304, 304L, 305, 316, 409, 409CB, 410, 430, 431, 434, 17-7 PH (631), A286.

We"re sorry. AbeBooks.com is currently unavailable. Please refresh the page. If the problem persists, pick up a good book while you wait. We"ll be back as soon as possible.

Good: A book that has been read but is in good condition. Very minimal damage to the cover including scuff marks, but no holes or tears. The dust jacket for hard covers may not be included. Binding has minimal wear. The majority of pages are undamaged with minimal creasing or tearing, minimal pencil underlining of text, no highlighting of text, no writing in margins. No missing pages. See the seller’s listing for full details and description of any imperfections.See all condition definitionsopens in a new window or tab

UNITED STATES STEEL CORPORATION, The Youngstown Sheet and Tube Company, Detroit Steel Corporation, John A. Roebling"s Sons Corporation, Bethlehem Steel Company, Jones & Laughlin Steel Corporation, Union Wire Rope Corporation, Wire Rope Corporation of America Incorporated, Universal Wire Products, Inc., Defendants.

Detroit Steel Corporation (Detroit) is incorporated in Michigan where it has its principal office. It has never registered to do business in Pennsylvania. It has never appointed an agent to receive service of process in Pennsylvania. It has never had an officer or a resident salesman in Pennsylvania. It has never had a telephone listing or bank account in Pennsylvania and has done no local advertising in Pennsylvania. However, as a part of its sales transactions it has delivered a substantial amount of its product in the Eastern District of Pennsylvania. As a result of sales agreements entered into outside of Pennsylvania, in 1953 it delivered $387,829.35 worth of steel in the Eastern District of Pennsylvania and in the first nine months of 1954 it delivered $206,474.23 worth of steel there. A large part of this steel was delivered to the plant of the General Electric Company in Allentown in the Eastern District pursuant to an agreement of sale between Detroit and the General Electric Company, which was negotiated and entered into at Schenectady, New York. All the rest of the steel which Detroit shipped into the Eastern District of Pennsylvania was sent to customers there by reason of agreements of sale entered into outside the Eastern District of Pennsylvania and because of allocations by the National Production Authority during the time when there was a shortage of steel resulting from the Korean war. Detroit did no soliciting of business in the Eastern District of Pennsylvania. Occasionally agents of Detroit visited its customers in the Eastern District for good will purposes, but not for the purpose of soliciting business there.

Detroit has filed a motion to dismiss the action against it contending no proper venue exists as to it in the Eastern District of Pennsylvania. Plaintiff contends that venue is proper in this District under Section 12 of the Clayton Act, 15 U.S.C.A. § 22, which provides in pertinent part: "Any suit * * * under the antitrust laws against a corporation may be brought * * * in any [judicial] district wherein it * * * transacts business".

Plaintiff contends that the activities of Detroit in the Eastern District of Pennsylvania constitute the transacting of business therein. Detroit contends that they do not. Does a corporation which delivers a substantial amount of its product into a judicial district, as a result of orders obtained outside a judicial district, "transact" business therein within the venue section of the Clayton Act when it does no soliciting there and performs no other substantial activity there?

In construing the venue clause of the Clayton Act the Supreme Court said in Eastman Kodak Co. v. Southern Photo Materials Co., 273 U.S. 359, at page 373, 47 S. Ct. 400, at page 403, 71 L. Ed. 684, "that a corporation is engaged in transacting business in a district, within the meaning of this section * * * if in fact, in the ordinary and usual sense, it `transacts business" therein of any substantial character." In United States v. Scophony Corp., 333 U.S. 795, at page 807, 68 S. Ct. 855, at page 861, 92 L. Ed. 1091, the Court said: "Refinements such as previously were made under the `mere solicitation" *427 and `solicitation plus"[1] criteria * * * [are] no longer determinative. The practical, everyday business or commercial concept of doing or carrying on business `of any substantial character" * * * [is] the test of venue."

The selling of its product is the most important part of a business. There can be a substitute for every department of a business but sales. Products or parts of them can be bought instead of manufactured, but there can be no substitute for sales. Without sales no business can exist. A sale is never complete until delivery is made, since it is the delivery which entitles the manufacturer to money and it is the earning of money which is the real purpose of business. No ordinary businessman would be likely to say that the delivery of almost $600,000 worth of a company"s product into the Eastern District of Pennsylvania within less than two years as part of sales transactions does not constitute the transacting of business in that district. Application of the "practical, everyday business or commercial concept" test of what constitutes "transacting" business causes me to come to the conclusion that Detroit Steel Corporation was transacting business in the Eastern District of Pennsylvania when the present action was filed and service was made on it.

Detroit"s counsel contends that delivering $600,000 worth of steel into the Eastern District of Pennsylvania does not constitute transacting business there because the activity is not sufficiently substantial in view of Detroit"s large overall business, which amounts to almost $100,000,000 a year in sales. This contention must be rejected. Whether or not a defendant is "transacting" business in a particular district should not and does not depend on whether or not a defendant corporation or its overall sales are large or small. The important thing is whether or not the sales would appear to be substantial from the average businessman"s point of view. In my opinion, almost $600,000 worth of business in less than two years, viewed absolutely and without reference to the sales volume of any particular corporation, would appear to be quite substantial to the average businessman as compared to the sales figures of his own business.

In the opinion filed on March 9, 1955, concerning the motion of Detroit Steel Corporation to dismiss the action against it I based my conclusion that Detroit "transacts business" in the Eastern District of Pennsylvania upon the ground that Detroit "delivered" a substantial amount of its product into this District. Detroit in its petition for reargument contends that, since all but one of the shipments of steel in question were F.O.B. Detroit"s New Haven, Connecticut, mill or warehouse, "deliveries" to Detroit"s customers in the Eastern District of Pennsylvania were made in New Haven where the steel was physically delivered to a common carrier. In effect Detroit is urging the Court to view the word "delivery" as it is used in the law of sales. However, the term "delivery" referred to in my previous opinion was not used in the same technical sense as it is used in the Uniform Sales Act (see 69 P.S. § 256) or in the new Uniform Commercial Code (see 12A P.S. § 2-509), the provisions of which are addressed to the question of risk of loss as between buyer and seller. In my previous opinion the term "delivery" was not used in any technical sense, but was *428 used in its "practical, everyday business or commercial concept." From the average businessmen"s point of view the shipments in question were delivered into the Eastern District of Pennsylvania and these deliveries constituted the transacting of business in this District.

[1] The earlier reported cases on this point were concerned with the question of whether a defendant"s activities amounted to "soliciation" or "solicitation plus" in a particular judicial district. The present case is unique in that the defendant, which is moving for dismissal, engaged in "plus" activities (delivery) but not in "solicitation."

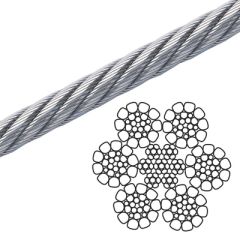

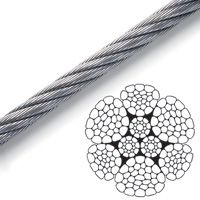

The 6 x 26 WS has better resistance to abrasion than a 6 x 25 FW. It features a compact construction with solid support for the wires; therefore it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue-resistance comparable to a 6 x 25 FW. A standard 6 x 26 WS construction provides the best rope for a wide range of applications. In general, we recommend the use of the 6 x 26WS in any application where a 6 x 25 FW is used.Fatigue resistance comparable to a 6 x 25 FW

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For customers who require peak rope performance levels in mission critical applications, Casar manufactures and supplies highly-engineered ropes that exceed industry standards while providing record-setting service life.

Our proprietary and innovative German-engineered rope designs deliver the highest levels of performance and safety, superior breaking strength values, the highest bending fatigue resistance, superior crushing resistance, and the best rotational resistance characteristics for high lifts.We have decades of global experience and on-site engineering support in the crane, OEM and underground mining sectors.

CASAR has an extensive range of products available and we can customize to your application.Our wire rope specialists will assist customers in design, selection, installation and operation to improve rope performance and maximize service life.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Two months after United Auto Workers Local 960 ended its strike against Macwhyte Co., union member Jeff Wiegert is still waiting to be called back to work.

Wiegert, one of about 280 employees who walked off the job last October, expects to return to the payroll of the Kenosha wire-rope maker, but others won"t be so lucky. Macwhyte has eliminated more than half the hourly jobs at its Kenosha plant.

The jobs cuts are just one result of a strike that left Wiegert and many fellow picketers bitter and disillusioned, not only at management but also at UAW leaders. The union gained little, if anything, from seven-and-half months on the picket lines.

"We just rolled up. We caved in," Wiegert said. The labor contract that workers ratified in May "was the same offer that (the company) gave three to four months prior to that."

During the strike, Macwhyte shifted 67 jobs to its non-union plant in Sedalia, Mo., and hired 42 replacement workers to work in the Kenosha plant. The moves allowed the company to continue production, albeit at a reduced level, and gave it more leverage at the negotiating table.

Macwhyte also had the benefit of being owned by an industrial conglomerate with deep pockets, said Rudy Kuzel, former president of UAW Local 72, which represents workers at the Chrysler Corp. plant in Kenosha. Macwhyte"s parent company, privately held Amsted Industries Inc., which is based in Chicago, has estimated annual revenue of $1 billion.

"Those guys down at Macwhyte were as brave as could be and as good and strong a union as you could have," Kuzel said. "But you can"t beat a company like Amsted when they"re running all their plants, and you"ve got one little plant standing out there shut down."

Ladzinski said the company was trying to foster better communications with its employees and wanted to give that process more time before participating in an article.

Although southeastern Wisconsin has long been heavily unionized, the Macwhyte strike, some believe, offered further evidence that the area is still vulnerable to the larger economic forces that have reduced the power of unions the past two decades.

The strike showed that competitive pressures have made it extremely difficult to pass on price increases to customers, said Roger Caron, president of the Racine Area Manufacturers and Commerce. That, in turn, has compelled employers to control labor costs, especially health insurance, and resist union demands for higher compensation, he said.

Improved health insurance was one of the union"s goals when its members went on strike last Oct. 1. By March, however, strikers saw their bargaining clout slip as union members began to cross the picket line and return to work, said Local 960 president Russell Koessl.

"When the 16 ex-union people got cold feet or whatever and crossed, that killed us because they started getting production out in key areas," said Koessl, a 38-year Macwhyte veteran.

By May, it was clear to union leaders that they weren"t going to wrest any concessions out of management. UAW International officials withdrew their support for the strike, and on May 12, the union members voted 140-54 in favor of virtually the same agreement they had rejected two-and-a-half months earlier.

Today, Wiegert and other union members still believe the International turned its back on them. They say UAW planned to cut off their strike pay and health benefits if they didn"t accept the offer.

Although Wiegert, Ropp and others who are still laid off are receiving unemployment compensation and health insurance benefits from the union, the strike did not come without financial sacrifice. Ropp, for instance, spent all of his and his wife"s $3,000 in savings and sold his Harley-Davidson motorcycle to cover living expenses.

Under the three-year labor contract, the union received a 2 percent wage increase in each of the three years, but fell short in its drive for more generous health benefits. In addition, the union agreed to recognize the replacement workers Macwhyte hired during the strike.

Although he described union morale as low, Koessl said there were no open hostilities on the shop floor. He also said that there"s an undercurrent of resentment between union members and both replacements and those who crossed the picket line.

Repairing the emotional damage from a strike and rebuilding trust between the parties involved takes time, and productivity and quality often suffer in the first several months after workers return to their jobs, said Michael Rosen, chairman of the economics department at Milwaukee Area Technical College.

"It isn"t as if once the strike ends, everybody just puts everything behind them and they"re buddy-buddy," said Rosen, recalling what it was like when a union he belonged to went on strike in the 1970s. "People remember who crossed the picket line, who took their jobs, essentially who took bread off their table."

Although most of the replacement workers have stayed on after the strike, they must successfully complete a 90-day probationary period, which ends in August, to become permanent employees. By law, the UAW must allow the replacements to join the union.

Meanwhile, Macwhyte has made it clear that production levels for many of its products made in Kenosha will never return to earlier levels. The company has called back 65 union members, according to Koessl. Dozens more are either unemployed or working for different companies.

"Do I have any hard feelings against the company?" Wiegert asked. "To a point, yes, but not really. Let"s face it, they"re trying to do what all corporations are trying to do."

The 50 or so WireCo employees, some of whom survived layoffs, a strike and company bankruptcy, showed up on the last day and got the work orders out. For half of them, it was their last day of work as WireCo closed its doors last Monday.

Some went home and some took the opportunity to go over to the American Tavern. For years the small bar across the street from WireCo on Third Street was the unofficial Wire Rope workers gathering place. Many of the guys on swing and third shifts went there to cash their paychecks and have an early morning, after-work beer.

As Mears stood in the north side doorway of building 17 and looked out over Third Street, he reminisced about what used to be. He talked about when there were more than 500 people working there running machines on four shifts. He remembered the company-sponsored baseball games and bowling tournaments for employees. He thought of the heat from the furnaces pulling wire and the stranders running in every building. He missed the people.

“It’s a sad day. There’s a lot of friendships that have been made here. We’ve seen people get married. We’ve seen people get divorced. We’ve seen people come and go, live and die. There are many stories inside those buildings,” Mears said.

He also lamented that the St. Joseph WireCo location made the money for the company to buy all the other facilities. At one time, it was the only location in the United States, he said. Now it’s the one that’s closing.

Mears is one of about 25 WireCo employees who will still be employed at the plant for a few more months. Those who are left will finish up what little production there is, take inventory and clear the building before Hillyard Industries takes over the facilities.

Shortly after it was announced in March that WireCo was closing its St. Joseph facility, Hillyard announced plans to purchase most of WireCo’s St. Joseph properties to develop a 25-acre manufacturing and distribution center.

That closes a door on a chapter in a local manufacturing history that began almost 70 years ago when John Peter Barclay moved Wire Rope Corporation from New Haven, Connecticut, to St. Joseph in 1948.

The company purchased the old Jersey Cereal building from General Food Corporation and remodeled it and the offices to look like their old New Haven facility.

When the senior Barclay died in 1954, the leadership of the company passed on to his son Jack Barclay Jr. and his son-in-law James E. Josendale, who married his daughter Dorothy Barclay.

Their son, John Josendale Jr., is currently senior vice president and marketing director for the company. Josendale, who started in the company as a “shag driver” working in the printing department and running errands, remembered the company’s heydays in the 1960s and 1970s. During that time, it had a workforce of more than 1,500 employees.

“(These) were really boom years because we were able to pick up new lines. We got really involved in the mining industry. The roads were being constructed and a lot of this equipment that was making roads in the heyday were using wire rope back then,” he said.

“There were a lot of people there. The wire mill was a full facility. As it grew and got older, they built another wire facility and this became more of a spooling facility,” he said. “It was crowded. You had machines everywhere. You had people everywhere. You had three shifts going full speed.”

Heath remembers the softball tournaments at Walnut Park every year that the company provided for the employees. Teams from all departments — the wire mill, rope mill, sling, fabricated products, shipping and inventory — all competed in friendly competition.

Heath even invented a character for the union newspaper called “Ropey.” The image of a goofy looking guy with a turned up hat and big smile is painted on his home driveway. His garage is called “Ropey’s House.”

“It was a pamphlet that came out once a month with what was going to happen, what the union had in mind and things like that, and the caption with Ropey was ‘Ropey Sez,’ so sometimes Ropey says something cute, sometimes he just said, ‘Watch it guys; things are starting to change,’” Heath said.

Things did begin to change. In 1999, the union went on strike for a month in St. Joseph. In 2001, the company filed for bankruptcy. Shortly afterward, Wire Rope changed its name to WireCo World Group and moved its corporate offices from St. Joseph to Kansas City.

The company still maintained production plants in St. Joseph, Sedalia and Chillicothe while also pursuing a series of joint business ventures in Mexico, China, Portugal, Poland, India and the Netherlands.

Josendale said a number of things combined to cause WireCo to lose money. The public became more price-conscious as more imports were coming into the country. The manufacture of general purpose rope, which was the mainstay rope of the company, was now being made cheaper in Japan and Korea.

“We had the high-end mining rope, we had the oil field ropes which were made here, and those worked well for us,” he said. “Most of the crane ropes went to European rope, so you ended up with more of a global market and that made it more difficult to compete from this plant,” Josendale said.

For the first month after he left, Heath said he still got up at 5:30 every morning to be at work before 7 a.m. in time enough to have coffee with the guys before the day started.

8613371530291

8613371530291