viper wire rope lubricator price supplier

The Viper WRL was developed with safety and the environment in mind. When used correctly the Viper WRL has a number of Health, Safety and Environment benefits.

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE"s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

The manual lubrication of wire ropes via the drip, brush, spatula or rubber glove method has always been a difficult maintenance task. Typically employed are messy asphaltic or “blackjack” type products, which have coating abilities but very little lubrication or penetration properties.

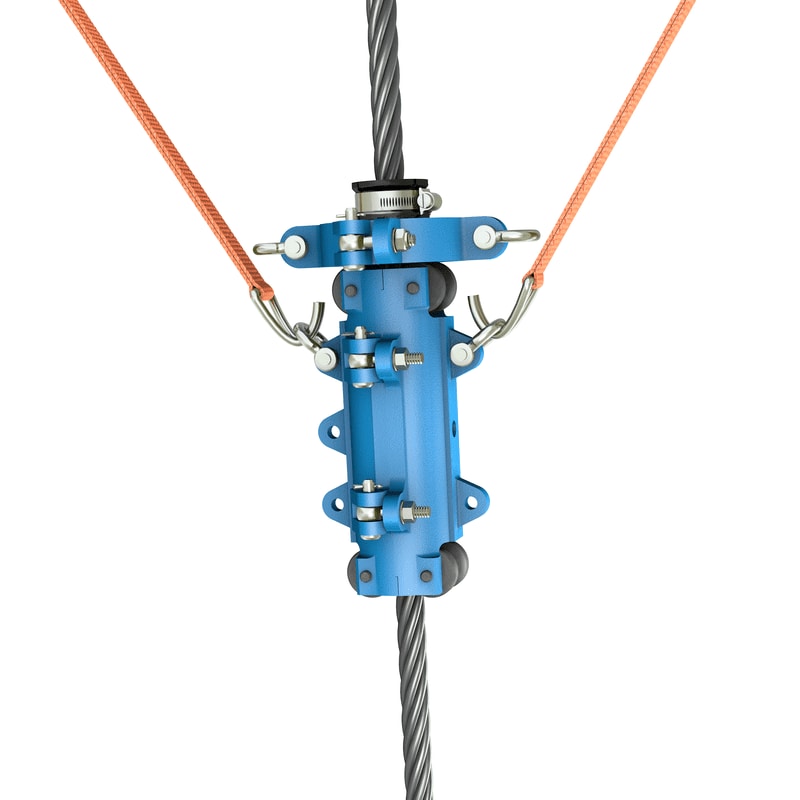

The VIPER Mid MK II Wire Rope Lubricator provides fast and effective lubrication of wire ropes from 5/16 in (8mm) to 2–5/8 in (67mm) in diameter, at speeds up to 6,670 ft (2,000 m) per hour. It eliminates the slow and labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing quality lubricant under high pressure right through to the core of the wire rope.

The system consists of the lubricator Collar assembly, which houses the polyurethane seals to suit the specific size rope. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar as the lubricant is applied with a high pressure grease pump, forcing lubricant between the strands to the center or the rope. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The benefits over conventional drip and brush or spray systems are substantial. The Viper MK II Wire Rope Lubricator operates at a higher pressure than most other lubricator collars on the market; this combined with the robust construction guarantees fast, safe and effective wire rope lubrication.

For lubricating larger rope sizes 2 in (50mm) to 6 1/2 in (165mm), you will need the Viper Maxi MK II. Viper Mini MK II lubricates rope sizes 15/64 in (6mm) to 1 13/32 in (36mm.)Please contact us for more information about these solutions.

Proper lubrication of wire rope will extend operational life and increase safety. Done correctly, it lubricates exterior surfaces as well as the inside wires and core. Proper lubrication will help reduce friction as the individual wires move over each other, and provide corrosion protection.However, lubricating wire ropes can be difficult. Manual lubrication via drip, brush, spatula or rubber glove method is a messy, time-consuming maintenance task and can be hazardous to the environment.

The Viper Wire Rope Lubricator is a much better solution. The Viper Mid MK II provides fast, effective one-pass lubrication of wire ropes from 5/16 in (8 mm) to 2 5/8 in (67 mm) in diameter, at speeds up to 6,670 ft (2,033 m) per hour. It eliminates the slow, labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing LE’s robust wire rope lubricant under high pressure (up to 5,500 psi) right to the core of the wire rope.

The Viper Wire Rope Lubricator can be used in any application where wire rope can be drawn through the collar of the lubricator, including the following typical applications:

The Viper Wire Rope Lubricator consists of a lubricator collar assembly that houses polyurethane seals suited to a specific wire rope size. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar. The steel scraper plates pre-clean the rope by scraping dirt, debris and old lubricant from the rope and protect the seals from loose strands, flattening them out before new lubricant is applied.

As the lubricant is applied with the high-pressure, high-flow grease pump, it forces the lubricant between the strands to the wire rope core. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The collar is the heart of the Viper MK II. Constructed from high-grade cast aluminum with a robust protective coating, the collar is completed with stainless steel hardware to provide maximum corrosion protection. The MK II collar has built-in handles, making it easy to carry in one hand. One person can easily attach the Viper to the rope.

LE carries the complete standard kit and all necessary components for operation. Configuring the kit is simple. The selection of the seals and scraper plates is based on wire rope size. If you have more than one wire rope size, additional scrapers and seals can be purchased.

We also carry some of the best wire rope lubricants found in the market to provide you with an entire solution. We recommend that you use Wirelife® Almasol® Coating Grease (452-453) with the Viper Wire Rope Lubricator

Wirelife Almasol Grease is available in NLGI 00 (452-PL, 452-QD, 452-DR) and NGLI 0 (453-PL, 453-QD, 453-DR) grades, both of which are extremely tacky and water resistant and have exceptional penetrating ability. They provide EP protection and exceptional corrosion protection, even in underwater applications

In addition to wire rope lubrication, LE is happy to offer lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all of our items to help you make the right decision.

To learn more about the Viper Wire Rope Lubricator or about LE’s enhanced lubricants, lubricant training, oil analysis, filtration, lube rooms, breathers, sight glasses or other lubricantreliability solutions, please contact us today.

We are proud to have been part of the Viper Wire Rope Lubricator (WRL) team for the past decade – helping to develop and grow the worldwide sales of this safe, simple & efficient lubrication system.

A&S International has a group of distributors who actively and successfully market & sell the Viper WRL range to clients in their own territories as part of the wider global Viper distributor team. And in the ten years to date, our Viper WRL distributors have sold more than 800 units!

The unique Viper seal design is at the heart of the Viper WRL package. The selected polyurethane material is wear-resistant to ensure long service life but still flexible enough to mould to the rope. This flexibility helps reduce leakage but more importantly massages the lubricant into the rope, increasing penetration of the lubricant and the protection from corrosion that this provides. Other wire rope lubricators tend to simply coat the outside of the rope. The length of the Viper Mid and Maxi collar / seal combination also increases the dwell time that the rope has with the lubricant, which also helps with application and ultimately leads to longer rope life and extended lubrication intervals

The Viper MkII Wire Rope Lubricator range provides fast and effective cleaning and lubricating of wire ropes. Wire ropes from 8 mm (5/16” ) to 165 mm (6-1/2”) in diameter can be automatically greased at speeds up to 2,000 mt per hour. NEW member of the growing Viper family. Smaller but equally effective. SAFE, SIMPLE, EFFECTIVE.

The Viper MkII with the new cast Aluminium collar is 32% lighter and combined with the unique inbuilt carry handles and shoulder strap enables single person wire rope lubrication. Ideal for use on all cranes, towing lines and mooring lines, the Viper MKII eliminates the HS&E risks associated with manual lubrication. Use of the Viper MKII provides improved wire rope lubrication by forcing wire rope lubricant under pressure into the wire rope.

Other lubricators just coat the surface of the ropes but the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer. This longer dwell time means greater lubricant penetration which leads to increased rope life and extended relubrication intervals.

The Viper wire rope lubricator is an Australian designed and built lubricator. It provides fast and effective lubrication of wire ropes, eliminating the slow and arduous task of manual lubrication. Lubrication of wire ropes with the Viper Wire Rope Lubricator provides superior protection by forcing lubricant into the core of the rope at pressures of up to 6,000 psi.

Yes, there is a significant increase in Rope life due to the penetration of the lubricant to the core of the rope. Typically wire rope users are manually applying lubricant to the outer strands or using a low pressure applicator that only fills the wire rope valleys. The VIPER Wire RopeLubricator will apply lubricant to the core of the wire rope sealing out moisture and protecting the strands against fretting, corrosion and fatigue failure. In marine applications such as ROV umbilical wires, ship deck winches, oil rig applications and wharf cranes the ropes typically corrode from the inside out.

Also in many highly loaded applications such as large cranes and mine winders the ropes suffer fatigue failure due to the wire rope having friction from the strands rubbing against each other as the rope travels over sheaves and onto the drum. When using a Wire Rope Lubricant the rope is protected against corrosion and internal friction is reduced and therefore the Wire Rope life is improved. Major wire rope manufacturers such as Bridon suggest that lubrication with a pressure lubricator may increase wire rope life by up to 300% compared to unlubricated wire ropes.

In comparison to manual lubrication the VIPER Wire Rope Lubricator delivers a significant reduction in labor and downtime, once the VIPER Wire Rope Lubricator is set up and the wire rope speed versus pump speed is adjusted then the operation is virtually automatic. Lubrication can occur at speeds of up to 6,670 feet per hour (2,000 meters per hour). Back to FAQ’s.

The VIPER Wire Rope Lubricator Kit includes a complete suite of proven accessories that allows for rapid on-site deployment and enables the manufacturer to offer a standard 12 month warranty on all parts (excluding normal wear & tear). When the VIPER Wire Rope Lubricator is used in conjunction with Lubrication Engineers LE453 Wirelife coating lubricant the equipment warranty is doubled to 24 months. Back to FAQ’s.

The VIPER Wire Rope Lubricator Collar weighs approximately 16kg / 35lbs with Scraper plates. The fact the unit is one piece with quick tighten toggles means it is more maneuverable and easier to set up than other two piece units. Back to FAQ’s.

Please refer to the document “VIPER Wire Rope Lubricator Seal & Scraper Selection Guide”. The seals and scrapers are installed into the collar to achieve the most effective sealing of lubricant between the collar and wire ropes. Seals are made in approximately 1/16″ (2mm) increments and are interference fit depending on the size rope. Scrapers are supplied 2mm / 5/64″ larger than the actual wire rope size to allow for Rope flexing. It is recommended that wire ropes be physically measured prior to ordering seals and scrapers as ropes in service can stretch and sizes may vary.

This depends on a number of factors including the condition of the wire ropes being lubricated and whether there are abrasive contaminants on the ropes prior to them entering the seal. However as an example a marine customer recently lubricated 7,000 metres / 4.3 miles of 1-3/8″ (34mm) wire ropes while their ship was in dry dock. At the end of the lubrication session the customer feedback was that there was no leakage from the seal and that the seal had virtually no wear visible. It is estimated that in normal use VIPER Wire Rope Lubricatorseals will last 40,000 — 50,000 feet (12,000 to 15,000 meters). Back to FAQ’s.

These types of wire ropes have extremely tightly wound strands with little space between the strands for wire rope lubricants to penetrate. While it cannot be guaranteed that the VIPER Wire Rope Lubricator will enable penetration of lubricant to the core with these types of ropes, it can be guaranteed that it will provide significantly improved lubrication compared to traditional manual lubrication methods. It is even more important with these types of ropes to select an effective wire rope lubricant such as LE453 WireLife coating lubricant. Back to FAQ’s.

The VIPER Wire Rope Lubricatorcan be used in any application where wire ropes can be drawn through the collar, please refer to the applications listed below:

Dof Subsea– ROV umbilical wire lubrication /BHPB Petroleum– Oil and Gas rigs at sea /Woodside Petroleum– Oil and Gas rigs at sea /Alcoa Aluminum– Ship loader /Xstrata Coal– Mine winder cable /Mentrade– OEM – Deck winch manufacturer /BHPB Iron Ore– Iron ore ship loaders /MOL Tankships– Ship Management Company – Oil tanker /Cervan Marine– Ship loader /Clough Engineering– ROV umbilical wire lubrication /OSG Ship Management Company– Ship mooring lines /SeaTrucks– Marine pipe laying ship /Acergy– Marine Engineering Company /LMS Ship Management– Ship Cranes /Mermaid Marine– New vessel with submersible /Marine Equipments Pte Ltd– OEM Winch Supplier /BHPB Olympic Dam Uranium Mine– Mine Winder /Waterway Constructions– Bridge Building Crane Ropes /VSL – Cable manufacturers– Pre-coating of cables to the core. Back to FAQ’s.

Support for the VIPER Wire Rope Lubricatoris available via email, phone or fax. The VIPER Wire Rope Lubricator is a proven, high quality unit that features only the best standard of accessories to ensure long term reliable service. VIPER distributors worldwide are also available for onsite support and demonstration. Back to FAQ’s.

We recommend the use of a ‘Viper Rope Cleaner‘ to remove contaminants from wire ropes prior to lubricating with the Viper unit. The ‘Viper Rope Cleaner‘ is a high density polyurethane clamp which fits onto the rope prior to the lubrication collar. It is matched in size and design to each individual wire rope and can strip away hard built up lubricant and other contaminants. The angular design effectively cleans out the valleys and outer strands to assist the Viper collar to lubricate and penetrate as required. Back to FAQ’s.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

It eliminates the slow and labour-intensive task of manual lubricant application, at the same time achieving more thorough results by forcing lubricant under pressure right through to the wire rope core.

With the success of the Viper Wire Rope Lubricator, manufacturers Lubrication Engineers Australia announce the much anticipated Viper Mk II Wire Rope Lubricator launch.

Those in the marine, mining and heavy industry are already sold on the benefits of this automated, single pass wire rope lubrication technology which:

lubricates all major rope sizes, Viper MkII lubricates rope from 8mm (5/15”) to 67mm (2-5/8”) while the Viper Maxi MkII will lubricate up to 165mm (6-9/32”)

The Viper MkII Wire Rope Lubricator has many applications including wharf cranes, ship cranes, ROV cables, mine winders, mobile cranes, oil and gas platforms, anchor ropes, deck winches, overhead cranes and ship loaders.

Viper recommend the use of Viper WRL Coating Grease VCG-1 with the Viper MkII. This grease is specifically designed for the offshore industry where immersion in water occurs. Viper WRL Penetrating Grease VPG-0 has excellent penetrating ability, disperses moisture, will not drip or run plus provides extreme pressure protection for sheaves and rope drums. Both products are specifically designed for use with the Viper and for use in marine and mining applications.

Corelube designs, engineers & manufactures state-of-the-art, wire rope lubricators/lubricator & wire rope cleaning tools. Corelube has been solving wire rope maintenance problems for over 40 years.

The key to maintaining wire ropesis protecting the interior core wires from corrosion and wear with protecting the exterior from the elements and extreme wear conditions. Corelube Equipment has designed wire rope lubrication systems that address both of these issues.

We believe there is no one size fits all solution when it comes to wire rope lubrication. With 40 years of designing wire rope lubrication systems, we believe our systems are the most advanced/environmentally friendly systems out there.

Wire rope lubricants with good penetrating properties are key to preventing internal corrosion & wear. Corelube highly recommends wire rope lubricants that transition from penetrating oil to grease.

We will carry out lubrication on our 103 mm wire in the coming days. This will be the third time this has been conducted, and I am extremely satisfied with the results. No wastage due to drop off during application and very good penetration.

Bridon Ropes has used Masto machines in its factories for over 10 years, in cases where a special lubricant coating is required on particular wire ropes. Over the years the machines have given dependable service over a wide range of rope sizes and constructions, and have given satisfactory seal lives.

After having used the Masto unit for approximately 2 ½ years, we are more than satisfied with the unit. It is a clean and efficient way of greasing wires. Before we got the unit, greasing wires was a hard task, but now the unit is doing the work for us and the wires are greased properly and evenly.

The undersigned surveyor to Det norske Veritas was present when the “MASTO” wire lubricator was demonstrated on two wire dimentions. After being greased, the wires were split apart, and we can confirm that the grease had penetrated through the whole cross-section of the wires.

We have tested different types of wire rope lubricators and can ensure you that we are very satisfied with your product. We would definitely go for Masto lubricators should the need for such a product arise again.

I can confirm that the ‘Maesto’ wire rope lubricator has been in use on the vessels under my control for several years, during which time it has proved to be a highly effective tool to assist particularly in maintaining the wire ropes of the deck cranes in good order, despite the most ardous operating conditions.

After having used the MASTO unit for approximately one year, we are very satisfied with the unit. It is a safe and clean way of greasing wires. It has proved to be a timesaving tool, compared to brush, cloth etc.

Today we have used the Lubricator for the first time. One word: Amazing! 2 hours instead of two days, no backache, 60 Kg grease instead of 250 Kg, clean dungarees, no mess everywhere around. It’s a great advisable product. I will recommend the wire lubricator to my collegues.

The Viper MKII Series enable’s wire ropes to be safely, quickly and effectively lubricated and has the potential to extend their life significantly. The Viper WRL MKII eliminates manual greasing, reduces downtime and improves equipment availability. It is a safer way to lubricate wire ropes, reduces lubricant usage, has less leakage and reduces mess.

8613371530291

8613371530291