wire rope inspection course free sample

ITI has been an innovator and pioneer in rigging training for nearly 30 years and conducts more rigging training for corporate clients in North America than any other provider due to its expertise, size of training staff, and deep course curriculum. Under the broader category of Rigging, courses are further classified into the following sub-categories:

The “meat and potatoes” of rigging training. ITI Rigging Applications courses cover the full gamut of skill and experience levels with options available for true neophytes to seasoned veterans and everyone in-between…

Removal criteria for wire rope, wire rope slings, synthetic web/round slings, chain slings, rigging hardware, and below-the-hook lifting devices is the focus here. Personnel qualification is available.

Designed for lift planners, crane and rigging managers, and other non-engineers who conduct lift planning activities, ITI’s Fundamentals of Rigging Engineering courses are LEEA accredited and approved by ASME.

Objective: This training is aimed at persons who directly or indirectly come into contact with wire ropes and should always be available to them. They should ease the proper handling of wire ropes and convey the necessary expertise. Compliance with the instructions in the training should ensure the safe handling of wire ropes and help to prevent dangers and minimize repair costs and downtimes.

EN10264-2: 2012-3 Steel wire and wire products - Steel wire for ropes - Part 2: Cold-drawn non-alloy steel wire for ropes for general applications. Changes to the machine as well as non-observance of the regulations from

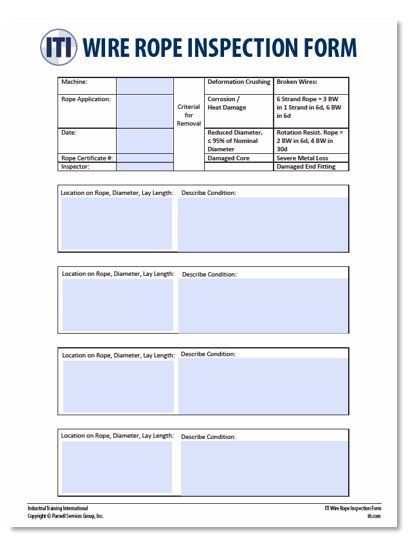

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

8613371530291

8613371530291