wire rope inspection course in stock

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

This course will provide delegates with an understanding of wire rope inspection requirements for a range of wire ropes. Covering a range of fundamental topics, including legislative requirements and the manufacturing processes the course develops an understanding of inspection requirements of a range of wire ropes and the discard criterion. This course consists of a range of theoretical and practical sessions where delegates will be required to confirm and demonstrate their knowledge of the course through theoretical and practical assessment.

By the end of this training programme the delegate will be:Aware of the relevant legislation applicable to wire ropes, including British Standards and other industry best practice

Personnel who are involved in the inspection, and/or safe use of wire rope. This course is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment.

This interactive online course is designed to provide certification on CMCO’s chain and wire rope hoist repair and service procedures for a variety of hoists, including CM, Budgit, Coffing and Yale , and Shawbox chain and wire rope, electric, air and manual hoists. It will measure the skills necessary for competent job performance by testing the technician’s knowledge of diagnostics and repair procedures per the latest industry standards and CMCO repair and service guidelines.

After registering and paying for the course, you will be automatically directed to our new LearnUpon LMS where you will be asked to create a password to set up your account.

Highly interactive and available to undertake from the comfort of your own home, this Rigging Gear Inspection training course from Columbus McKinnon has been specifically designed to provide the requirements of OSHA regulations and ASME guidelines for proper and correct inspection procedures and documentation.

OSHA requires inspections to only be carried out by competent personnel, selected by the employer, and this in-depth training course will assist employers/managers in deeming their employee as a competent person.

Any wire rope in use should be inspected on a regular basis. You have too much at stake in lives and equipment to ignore thorough examination of the rope at prescribed intervals.

The purpose of inspection is to accurately estimate the service life and strength remaining in a rope so that maximum service can be had within the limits of safety. Results of the inspection should be recorded to provide a history of rope performance on a particular job.

On most jobs wire rope must be replaced before there is any risk of failure. A rope broken in service can destroy machinery and curtail production. It can also kill.

Because of the great responsibility involved in ensuring safe rigging on equipment, the person assigned to inspect should know wire rope and its operation thoroughly. Inspections should be made periodically and before each use, and the results recorded.

When inspecting the rope, the condition of the drum, sheaves, guards, cable clamps and other end fittings should be noted. The condition of these parts affects rope wear: any defects detected should be repaired.

To ensure rope soundness between inspections, all workers should participate. The operator can be most helpful by watching the ropes under his control. If any accident involving the ropes occurs, the operator should immediately shut down his equipment and report the accident to his supervisor. The equipment should be inspected before resuming operation.

The Occupational Safety and Health Act has made periodic inspection mandatory for most wire rope applications. If you need help locating the regulations that apply to your application, please give our rigging experts a call.

The Rigging, Part 1 course concentrates on the design and characteristics of wire rope. It covers wire rope construction and the different types of rope lay used. This course identifies the classification of wire ropes. It explains how to install wire ropes correctly and reviews the importance of inspection and lubrication.

Wire ropes undergo constant stress and wear through daily use. So, wire rope requires monthly inspection in accordance with this section to reduce the risk of failure and potential resulting injury or property damage. In addition, this section covers criteria to use in determining when to replace rope, and requires inspection of rope on equipment that has been idle for a month or more, before the rope and equipment can be returned to service.

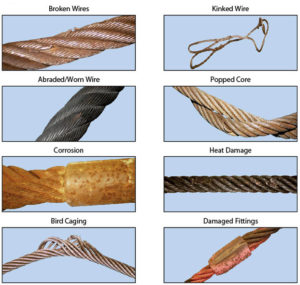

A thorough inspection of all ropes shall be made at least once a month and a certification record which included the date of inspection, the signature of the person who performed the inspection and an identifier for the ropes which were inspected shall be kept on file where readily available to appointed personnel. Any deterioration, resulting in appreciable loss of original strength, shall be carefully observed and determination made as to whether further use of the rope would constitute a safety hazard. Some of the conditions that could result in an appreciable loss of strength are the following:

All rope which has been idle for a period of a month or more due to shutdown or storage of a crane on which it is installed shall be given a thorough inspection before it is used. This inspection shall be for all types of deterioration and shall be performed by an appointed person whose approval shall be required for further use of the rope. A certification record shall be available for inspection which includes the date of inspection, the signature of the person who performed the inspection and an identifier for the rope which was inspected.

Wear and damage to wire rope can’t always be seen on the surface. Konecranes RopeQ Magnetic Rope Inspection pairs visual inspection with non-destructive testing to detect internal broken wires that may escape detection through traditional inspection methods.

The aim of the course is to provide delegates with a thorough grounding of the legal requirements and safe working practices pertaining to resin socketing of wire ropes and to teach them the practical skills involved.

The course is presented by fully qualified, multi-skilled engineers and technicians all of whom have many years experience of wire rope production and maintenance.

The course focuses on customers’ specific requirements i.e. Type of wire rope to be socketed and experience of trainees attending. Trainers employ the practical methods of instruction, explanation, demonstration, imitation and practice with ongoing assessment leading to certification on successful completion.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

Cranes and their associated rigging require pre-use, monthly, quarterly, and annual inspections. These inspections will include the wire rope, drum, blocks, sheaves, rollers and other rigging hardware that may come into contact with the wire rope and subject it to wear.

Your crane"s wire rope works hard. (Almost as hard as you do.) It can deteriorate more quickly than you might think, posing a real danger for you and your crew. In this article, we"ll answer the following questions.

Before we get into that, let"s take a brief moment to go over the proper wire terminology. Understanding the make-up of the wire rope allows you to have a clear understanding of when the rope needs to be replaced.

Flexible steel wire rope is made up of individual wires that make up a strand; these strands are then wrapped around a central core to make up a rope.

Understanding the difference between a wire and a strand is critical. If a strand (grouping of wires) in the rope breaks, the crane wire would need to be replaced. However, if a single wire in the strand breaks, the rope itself may still be usable.

Rag & Visual Inspections: In this method, you use a rag in your inspection, pulling it slowly across the strand, stopping for a closer and more detailed inspection wherever the rag gets caught on a wire.

The Diameter Measurement Method: This method involves comparing the diameter of your rope at various intervals with the rope"s official diameter per the manufacturer"s guidelines. A variation in the rope"s diameter can alert you to potential interior damage that a visual inspection would miss.

Localized Flaw Inspections (LF) vs. Loss of Metallic Area Inspections (LMA) - Both methods use electromagnetics to search for a wire rope"s internal damage.

According to OSHA"s safety regulations, you"re required to inspect your crane"s wire ropes at least every 12 months by qualified professionals. However, OSHA and other experts also recommend inspecting your wire ropes more frequently, such as after every initial installation or repair, or daily before each shift to ensure a safe work environment.

As discussed at the very beginning of this article, we can break down wire rope into three parts. First, wires, which make up strands, and then the strands wrapped around the central core make the rope. Of your total number of wires, you never want more than 10% to be damaged before you need to look into crane wire rope replacement.

According to OSHA, only "trained personnel should carry out inspections," and according to the Crane Manufacturers Association of America, a certified crane inspector should get 2,000+ hours of field experience and training.

We at Americrane & Hoist Corporation are just the experts you need, qualified to offer OSHA inspections and provide operator safety training classes to your employees. Contact us today!

8613371530291

8613371530291