wire rope inspection course brands

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

This intense workshop is designed to improve the skill level of hoist service and repair technicians through comprehensive training and testing on CM, Budgit, Coffing and Yale chain & wire rope, electric, air and manual hoists. The program will measure the skills necessary for competent job performance by testing the technician’s knowledge of diagnostics and repair procedures per the latest industry standards and CMCO repair and service guidelines. Students will have the opportunity to receive certification on all CMCO brands as well as individual brands.

Students will be given CMCO Certification Exams at the end of each day to test their knowledge of electric, air and manual hoist standards related to testing and inspection.

The aim of the course is to provide delegates with a thorough grounding of the legal requirements and safe working practices pertaining to resin socketing of wire ropes and to teach them the practical skills involved.

The course is presented by fully qualified, multi-skilled engineers and technicians all of whom have many years experience of wire rope production and maintenance.

The course focuses on customers’ specific requirements i.e. Type of wire rope to be socketed and experience of trainees attending. Trainers employ the practical methods of instruction, explanation, demonstration, imitation and practice with ongoing assessment leading to certification on successful completion.

Rigging inspections are required by OSHA and ASME to be performed before use, on a periodic basis, and on a frequent basis according to language in OSHA 1910.184 and ASME B30 standards. Rigging inspections include the thorough evaluation of the condition of lifting slings, including wire rope slings, alloy chain slings, synthetic web slings, synthetic roundslings, high-performance roundslings, synthetic rope slings, and metal mesh slings. It also includes the inspection of rigging hardware including: sling hooks, shackles, eye bolts, manual hoists and chain falls, lever tools, and below-the-hook lifting devices.

The Rigging, Part 1 course concentrates on the design and characteristics of wire rope. It covers wire rope construction and the different types of rope lay used. This course identifies the classification of wire ropes. It explains how to install wire ropes correctly and reviews the importance of inspection and lubrication.

Cleveland, OH – Mazzella Companies recently launched a new online sling inspection course to complement the Lifting U™ brand of classroom and online training programs. Sling Inspections is the second addition to the library of online courses available at LiftingU.com.

Mazzella’s Sling Inspections course consists of eight lessons and focuses on OSHA 1910.184 Slings and ASME B30.9 Slings standards. Each lesson features hands-on video inspections, performed by certified Mazzella Inspectors, to demonstrate proper inspection technique and identify ASME’s removal from service criteria.

“All of the tagging, inspection, and removal from service criteria is from applicable OSHA and ASME standards. We had all of this information already available on our website, but we realized that we could package this into an online course that was engaging and easy to share with others,” says Tom Horner, Corporate Rigging Inspection Manager of Mazzella Companies.

Other topics covered in each lesson, include: inspection frequencies, sling tag requirements, inspection criteria, disposal of damaged/failed slings, and best practices for sling use and maintenance.

“Not only did we rely on information from industry standards, but also on the expertise and experience of our inspectors and trainers. The video demonstrations and real-world examples of damaged slings set this course apart from others we’ve seen,” says Mike Minissale, Director of Marketing of Mazzella Companies.

Mazzella Companies will continue to offer more online lifting and rigging courses in the future. To enroll in Lifting U™ and learn more about their classroom and job site training programs, please visit LiftingU.com.

ITI has been an innovator and pioneer in rigging training for nearly 30 years and conducts more rigging training for corporate clients in North America than any other provider due to its expertise, size of training staff, and deep course curriculum. Under the broader category of Rigging, courses are further classified into the following sub-categories:

The “meat and potatoes” of rigging training. ITI Rigging Applications courses cover the full gamut of skill and experience levels with options available for true neophytes to seasoned veterans and everyone in-between…

Removal criteria for wire rope, wire rope slings, synthetic web/round slings, chain slings, rigging hardware, and below-the-hook lifting devices is the focus here. Personnel qualification is available.

Designed for lift planners, crane and rigging managers, and other non-engineers who conduct lift planning activities, ITI’s Fundamentals of Rigging Engineering courses are LEEA accredited and approved by ASME.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

Unlike many other wire rope training courses, TENSOLOGY are able to back up the theory and application of the relevant codes, standards and regulations with experience based know-how to provide the attendee with a more comprehensive understanding of the subject.

Proper operational and safety training is essential for companies working with wire ropes, and we’re excited that we’ll soon be providing a computer-based training solution to you. As always, the completed modules will incorporate 3-D and 2-D animations, sharp and clear writing, audio narration, interactive practice screens, and tests to assess learner retention and comprehension.

Wire Rope Basics will cover: the parts of a wire rope; the different core and strand materials; different finishes; lay length, lay direction, and regular and lang lays; rotation-resistant ropes; rope classifications and rope constructions; nominal diameter; nominal strength; design factor; and maximum working load.

Wire Rope Preparation will cover: selection, transporting, storing, the importance of avoiding kinking, uncoiling, unreeling, drum winding, drum capacity, and drum spooling.

Wire Rope Use, Maintenance, and Inspection will cover: the importance of breaking in a rope, best work practices for wire ropes, lubrication, inspections, valley and crown breaks, common breaking patterns and what they signify, cutting and seizing wire ropes, and tips for extending the service life of wire ropes.

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

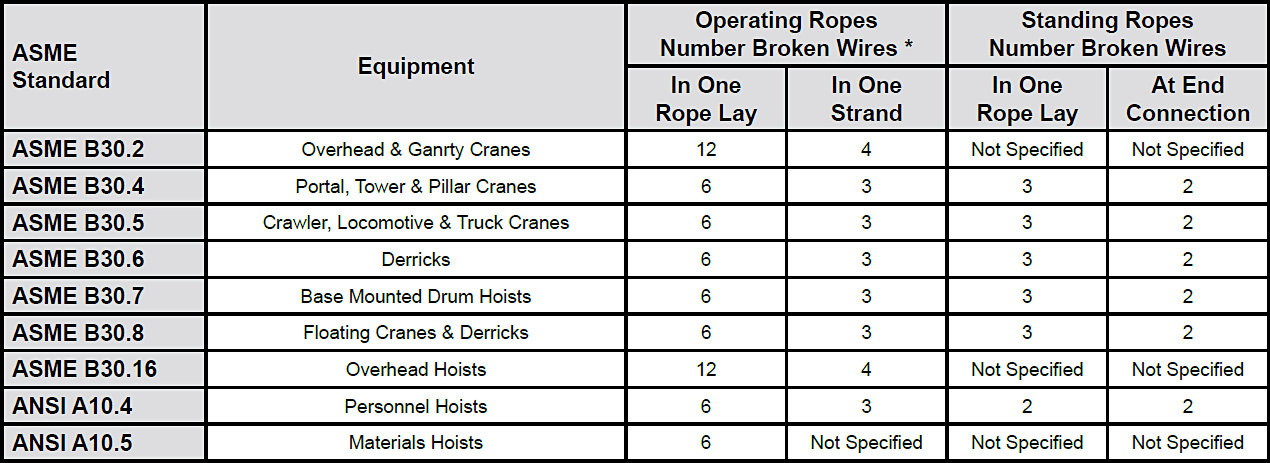

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

8613371530291

8613371530291