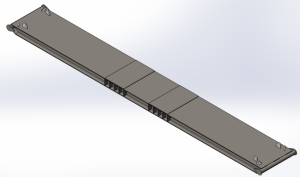

workover rig base beam made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A Base Beam is used on a workover rig for stabilization. They are used in place of ground anchors. Guice Base Beams set the standard for internal guying solutions. They are designed to meet requirements of API RP 4G 14.3. Our beams are proven to decrease rig up and rig down times and will endure the rigorous stresses of the oilfield. We manufacture in-house at GEI Welding. Each beam comes with an assigned serial number to prove it’s a Guice Base Beam.

Guice Base Beams come in 3 standard widths, 2 different variations and can be customized and painted to your specific needs. Base Beam certification is free when manufactured by GEI Welding!

Main Features Name: traveling hook Brand: KH Original: China Domestic famous fluid end, strong driving force, low fuel consumption, high economic benefits. Machine Parts Name: derrick platform Brand: KH Original: China Domestic famous, strong driving force, low fuel consumption, high economic benefits. After-Sales Service * Training how to instal the machine, training how to use the machine.

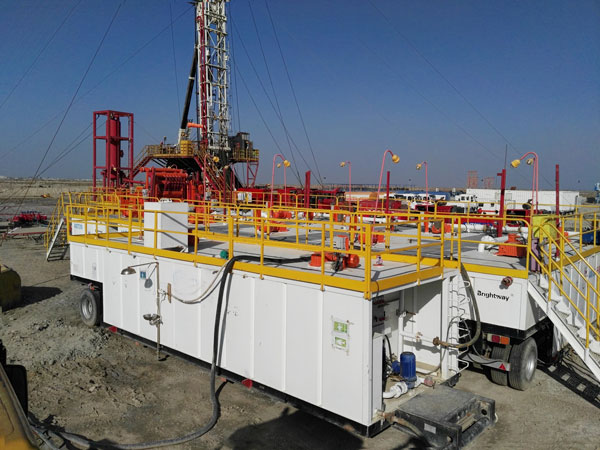

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

11” 3K Annular BOP, 11” 3K Double Ram (Blind Type Lower, 5” pipe upper), Drilling Spool, BOP Test Pump, (air powered) with hoses and chart recorder. BOP Test Base. BOP Stack Lifting device. Transport Skid. BOP Control Unit. BOP Control Unit remote Panel, (For Drill floor) Transport Skid for above control units. Choke and Kill Manifold 3-1/16” X 3K. 3-1/16” X 3K Manual and Hydraulic valves. Remote Choke panel. Non-return Valve. All high pressure fire proof hydraulic hoses, hand wheels etc. Stack up height = 73.6” (1.87m)

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

WILSON SUPER 38(Ref#3307R) Double drum drawworks, friction clutches, Foster makeup and breakout catheads, Cummins 250 disel engine, Spicer 4 speed transmission, 70’ cantilever mast, 4-sheave crown block, racking board, mounted on 8’W x 22’L tandem axle trailer with folding walkways, mast base, 4 manual jacks, Budd wheels, National Ideal 75 ton 3-sheave block with hook, Price: $45,000

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

KSM550 DOUBLE DRUM WORKOVER RIG(Ref#8731R) mounted on 5 axle carrier, tandem steer, tri-drive rear powered by Seres 6-0 with Allison 5860 transmission, 104" x 240,000# hook load (8 lines) mast,

HUBBARD C500 WORKOVER RIG(Ref#654T) Built 2012, 42 x 12 drawworks, Cat C15 (475 hp) engine, 112’ x 300,000# derrick, mounted on 5 axle carrier. Includes skid mounted Gardner Denver PAH mud pump with Detroit 8V92 engine (gear end is good, but needs fluid ends machined or replaced). Package Price: $270,000

HUBBARD C400 SERVICE RIG(Ref#274Tb) Manufactured 2014, 72’ x 180,000# derrick on 4-line (250,000# on 6-line), mounted on 5 axle carrier, Detroit Series 60, Allison transmission, all hydraulic, 8000’ of 5/8” sandline, 100 ton McKissick casing blocks, 1” line 42” x 12” casing drum, 42” x 12” sand drum, disc assist on casing drum, 1500 hours, 3000 miles. Westco power tongs 1-1/2”, 2”, 2-7/8” and 5-1/2”, set of bails/links, tubing elevators 1-1/2” – 2”, rod hook, elevators, wrenches, swab tools, Martin Decker weight indicator, stored inside Price: $645,000

IRONTECH SR42 SERVICE RIG(Ref#970Tb) Built 2005, 104’ x 225,000# telescopic double free-standing mast, 42” x 10” drawworks, 38” x 8” sandline, Detroit Series 60 engine, Allision 5860 transmission, mounted on 5 axle carrier tandem steer/tri-drive, Level IV completed in 2014 (16,270 CAODC mast hours remaining) Price: $755,000 CDN (approx. $600,000 USD)

SERVICE KING 675 DRILLING RIG(Ref#6830T) Manufactured 2008, 104’ x 315,000# derrick, single drum with 8 lines 1-1/8” wire, dual 6’ hydro breakout, Ideco 7-1/4 x 15” duplex mud pump with 353 Cat engine, 150 ton swivel, 4-1/2” x 40’ kelly, (8) 6-1/4” collars (new), 5000’ of 4-1/2” 1660 X-hole drill pipe Double White, (2) 300 bbl mud pits, 150 bbl water tank, doghouse, 12’ substructure with 18” rotary table, center tub with v-door, (2) pipe tubs, 42” x 30’ pipe rack, (2) landing mats for rig and sub, (2) 6’ elevator links, 4-1/2” 150 ton elevators, (2) sets of slips, rat hole digger with boot, (2) Type B BJ tongs Price:$390,000

SERVICE KING SK 375 (REF#6121R) Manufactured 2011, 475 hours, 3750 miles, 42 x 10 – 38 x 8 drawworks, “like new", 96" x 180,000# hydraulically raised mast, 4 axle carrier w/ 60 series Detroit engine, 4500 OFS Allison transmission, 500hp right angle box, 4 hydraulic leveling jacks.

SERVICE KING SK-175 WORKOVER RIG(Ref#274Ta) Manufactured 2008, 72’ x 150,000# derrick, Detroit Series 60 engine, mounted on 4 axle Crane Carrier, tooled out, Guiberson T60 air slips 100 ton casing blocks, Westco power tongs, currently working Price: $445,000

ZJ70LDB2000HP DRILL RIG(Ref#15720T) Manufactured 2009, well-maintained by large international contractor, currently stacked in Asia. (Cost $10,000,000 USD new). This is a complete turnkey package including tubulars and is ready for shipment. Full inventory and photos available on request. Price: $4,000,000

XJ650 WORKOVER RIG(Ref#15410N) New, Double drum, 24,600" service depth, 18,400" workover depth, 111 x 330,470# mast, CAT C18 700HP diesel engine, TC-680 transmission, 6 axle carrier 37mph, Right angle gear box, Price:$1,700,000

PETRO XJ400 WELL SERVICE RIG(Ref#6016Ta) Built 2005, 104" x 225,000#, double drum, Detroit Diesel 60 Series engine, Ellis Williams 440 Triplex mud pump, 150 bbl mud tank, gas buster, base beam, double BOP, 8 x 20 doghouse and related support equipment, missing tongs, missing slips and hand tools Price: $355,000

PETRO SXJ400 WELL SERVICE RIG(Ref#6016Tc) Built 2012, 104" x 225,000# capacity, double drum, Detroit diesel Seriel 60 engine, base beam, double BOP, 8 x 20 doghouse and related support equipment, Missing Ellis Wiliams 440 triplex pump, 150 bbl mud tank, gas buster, tongs, slips and handling tools, fair condition Price: $357,500

PETRO SXJ400 WELL SERVICE RIG(Ref#6016Td) Built 2012, 104" X 225,000# capacity, double drum, Detroit diesel 60 series, Ellis Williams 440 triplex mud pump, 150 bbl mud tank, gas buster, base beam, double BOP, tongs, slips, 8 x 20 doghouse, handling tools and related support equipment, missing tongs, slips and handling tools, good condition Price: $510,000

PETRO SXJ 400 WELL SERVICE RIG(Ref#6016Te) Built 2013, 104" x 225,000 capacity, double drum, Cat C15 diesel engine, Ellis Williams 440 triplex mud pump, 150 bbl mud tank, gas buster, base beam, double BOP, tongs, slips, 8 x 20 doghouse, handling tools, related support equipment, missing BOP, tongs, slips and some handling tools, fair/good condition Price: $410,000

PETRO SXJ 400 WELL SERVICE RIG(Ref#6016Tf) Built 2013, 104" x 225,000# capacity, double drum, Cat C15 diesel engine, Ellis Williams 440 triplex mud pump, 150 bbl mud tank, gas buster, base beam, double BOP, missing tongs, slips and doghouse, good condition Price: $525,000

750 HP WORKOVER RIG RIG MANUFACTURED(Ref#8942R) Manufactured 2011, used 6 months, 750hp double drum drawworks, CAT C15 540hp each, rated 3000M w/ 5" DP, 6m rig floor, 27-1/2" rotary table, 2 section telescopic mast, 38m x 2250 kn hook load, Rg swivel, Volvo Penta (2) 430kw, mud system, (2) x 800hp Bomco F-800 mud pump, 2x liner shakers, desander, desilter, mud system capacity 300m3, water tanks capacity 40m3, Located Middle East. PRICE: $6,300,000

At first referring to Fig. 1, the utility model is made up of derrick epimere 2, derrick hypomere 8, telescopic hydraulic cylinder 3, hydraulic cylinder top holder 4, cylinder lower holder 9, base 10, connection bearing pin 11, stepless adjustable sleeve pipe stabbing board 12, should provide during work and satisfy required other facility of derrick operation, as overhead traveling crane 1, quadruple board platform 5, standpipe maintenance platform 7.That the utility model adopts is upright, open front, no guy wire, trussed construction, and derrick epimere 2 and derrick hypomere 8 adopt rectangular steel pipes or the angle steel material as column, diagonal brace, crossbeam, stull.Before hoisting, derrick epimere 2 is sleeved in the derrick hypomere 8, the support that the support structure 6 of derrick hypomere 8 is realized derrick epimere 2, telescopic hydraulic cylinder 3 is separately fixed on derrick epimere 2 and the derrick hypomere 8 by hydraulic cylinder top holder 4, cylinder lower holder 9.Telescopic hydraulic cylinder 3 upper ends are fixed on the derrick epimere 2 with U bolt by hydraulic cylinder top holder 4, and are detachable; Telescopic hydraulic cylinder 3 lower ends are by cylinder lower holder 9 usefulness bearing pins fixedly on the derrick hypomere 8, detachably.Hydraulic cylinder top holder 4 is made up of gusset 41, clamp 42, fixed head 43, gusset 44.Cylinder lower holder 9 is made up of riser 91, pin 92, connection base plate 93.Telescopic hydraulic cylinder 3 fixed forms of this structure, making telescopic hydraulic cylinder 3 tops is Open architecture, after pin 92 is removed in telescopic hydraulic cylinder 3 bottoms, also becomes Open architecture, two all can be extracted out, and is easy to maintenance.

Two monolithics 102 referring to Fig. 2 derrick base 10 are welded by rectangular steel pipe or angle steel, and foreleg 101 adopts i iron or H shape steel or assembly welding beam, and two monolithics are connected with foreleg 101, back leg truss 103 respectively by bearing pin.The base 10 intensity height of this structure, well head space are big, can directly serve as the man-like shelf that hoists.Serve as when hoisting man-like shelf, referring to Fig. 4.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

n: a wireline used on drilling rigs and well-servicing rigs to operate a swab or bailer, to retrieve cores or to run logging devices. It is usually 9/16 of an inch (14 millimeters) in diameter and several thousand feet or meters long.

n: 1. the use of water-flooding or gas injection to maintain formation pressure during primary production and to reduce the rate of decline of the original reservoir drive. 2. water-flooding of a depleted reservoir. 3. the first improved recovery method of any type applied to a reservoir to produce oil not recoverable by primary recovery methods. See primary recovery.

v: to place stands of drill pipe and drill collars in a vertical position to one side of the rotary table in the derrick or mast of a drilling or workover rig. Compare lay down pipe.

n: 1. the flat portion machined on the base of the bit shank that meets the shoulder of the drill collar and serves to form a pressure-tight seal between the bit and the drill collar. 2. the portion of the box end or the pin end of a tool joint; the two shoulders meet when the tool joint is connected and form a pressure-tight seal.

n: a procedure to ensure that the drilling line wears evenly throughout its life. After a specified number of ton-miles (megajoules) of use, the line is slipped-for example, the traveling block is suspended in the derrick or propped on the rig floor so that it cannot move, the deadline anchor bolts are loosened, and the drilling line is spooled onto the drawworks drum. Enough line is slipped to change the major points of wear on the line, such as where it passes through the sheaves. To prevent excess line from accumulating on the drawworks drum, the worn line is cut off and discarded.

n: a set of gears installed between a prime mover and the equipment it drives to reduce the running speed. For example, on a beam pumping unit, the engine may run at a speed of 600 revolutions per minute, but the pumping unit it drives may need to operate at 20 strokes per minute. The speed reducer makes it possible to obtain the correct pump speed.

n: a measurement of the electrical currents that occur in the wellbore when fluids of different salinities are in contact. The SP curve is usually recorded in holes drilled with freshwater-base drilling fluids. It is one of the curves on an electric well log. Also called self-potential curve.

n: the connected joints of pipe racked in the derrick or mast when making a trip. On a rig, the usual stand is about 90 feet (about 27 meters) long (three lengths of drill pipe screwed together).

n: a special steel pumping rod. Several rods screwed together make up the mechanical link from the beam pumping unit on the surface to the sucker rod pump at the bottom of a well. Sucker rods are threaded on each end and manufactured to dimension standards and metal specifications set by the petroleum industry. Lengths are 25 or 30 feet (7.6 or 9.1 meters); diameter varies from 1/2 to 1 1/8 inches (12 to 30 millimeters). There is also a continuous sucker rod (trade name: Corod™).

n: a method of artificial lift in which a subsurface pump located at or near the bottom of the well and connected to a string of sucker rods is used to lift the well fluid to the surface. The weight of the rod string and fluid is counterbalanced by weights attached to a reciprocating beam or to the crank member of a beam pumping unit or by air pressure in a cylinder attached to the beam.

n: a solid cylindrical tool pointed at the bottom and equipped with a tool joint at the top for connection with a jar. It is used to straighten damaged or collapsed casing or tubing and drive it back to its original shape. v: to reduce the diameter of a rod, a tube, or a fitting by forging, hammering, or other method.

The grid electricity workover rig can meet all kinds of workover operational requirements due to its safety, stability, and reliability as well as excellent technical performances. The wellsite is now completely free from exhausted gas/oil emissions, and well site noise has also been greatly reduced. We can make a new contribution to save energy in oilfields by using this kind of environmentally-friendly workover rig.

Our company founded in the Yellow River delta (Shengli Oil Field, the second large oil field in China)--- Dongying City, Shandong Province. It engages into the designing, developing, testing, manufacturing, repairing, and drilling service. Its business covers drilling rig, workover rig, solids control equipment, drilling rig supporting and drilling strings and other equipments related with petroleum.

To ensure our website performs well for all users, the SEC monitors the frequency of requests for SEC.gov content to ensure automated searches do not impact the ability of others to access SEC.gov content. We reserve the right to block IP addresses that submit excessive requests. Current guidelines limit users to a total of no more than 10 requests per second, regardless of the number of machines used to submit requests.

8613371530291

8613371530291