workover rig elevators supplier

The global elevator and escalator market size is estimated at around USD 79.9 billion in 2021. This huge figure is expected to increase at a compound annual growth rate (CAGR) of 6.4% up till 2028. With such promising current market size and market growth rates, it can be a good idea for businesses to enter the industry. One way to capitalise on this market is by buying wholesale elevator links for drilling rig and reselling them to installation and repair service businesses, malls and landlords. You can also use them directly as part of your own business.

When buying or selling wholesale elevator links for drilling rig, it is important to understand the different types of elevators there are. Hydraulic elevator components are different from traction elevator components. Hydraulic elevator components include a tank, motor pump, valve, and actuator. Meanwhile, a standard traction elevator will have a motor, drive sheave, brake and machine bed plate.

Understanding the type of elevator links for drilling rig your customers use or are looking for can help you to recommend the correct elevator links for drilling rig for them. Sometimes, even if all the elevator door parts and other elevator links for drilling rig are perfectly fine, it may be good for your customers to have elevator spare parts in case of emergency.

KET is a leading manufacturer of Drill Pipe Elevators. We design and precision-machine all of our elevators to meet and exceed API Standards (API 8C or API 7K Standards), with KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

We understand the critical requirements of the oil and gas industry and the need for high-quality tools and parts. Our elevators include Safety Latch Lock Pins – designed to keep the elevator’s safety latch locked in place, preventing the elevator from being accidentally released

Single Joint Elevator also called Auxiliary Elevator. Lake Petro provides Single Joint Elevator with SJ type, SP type and SJX type. All of these elevators are designed and manufactured according to 8A/8C spec.

SLX auxiliary elevators are hoisting tools for handling single pipes or working together with the professional tools CRT to move the tubulars from gate to well centre.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Rack-and-pinion elevators are an ideal choice for construction and industrial applications. Century Elevators provides rack-and-pinion elevators and hoists that are self-contained and install directly to an existing or emerging structure, making them ideal for commercial and industrial sites of all types including new construction, restorations, building additions, renovations and maintenance. We specialize in vertical access equipment designed for outdoor use in harsh environmental conditions - including hazardous-area elevators and hoists suitable for NEC and IEC explosive-dust environments.

The team at Century Elevators includes dedicated safety personnel, designers and installers allowing for a turnkey design and installation experience. Equipment can be provided with custom capacities, dimensions, material selections and configurations.

Workovers rank among the most complex, difficult, and expensive types of well work. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

World Petroleum Supply, Inc. stocks the top Workover/Well Servicing Tools in the industry from leaders like Cavins Oil Well Tools, Westco International, NOV, BVM Corp., and Keystone Energy Tools. Their designs have been field-proven with features, and design to save money, time and enhance safety.

Drillform’s 820 Workover Rig Catwalk offers fast cycle time and a high lift capacity. The unit has a simple set up, and features hydraulic kickers, indexers, and skate. The “no deck” design reduces overall weight and increases personnel safety by reducing fall risk. For ease of transport, there is a simple transition into transport mode with a pintle hitch. A telescoping ramp extends from 8’ to 20’ (optionally higher) floor heights, while an extended pipe channel accommodates Range II and Range III tubulars with up to 2,200 lb. lifting capacity, handling 2 ⅜” to 6” OD. The catwalk includes a pintle hitch for easy towing and is available in skid and towable versions. Now available in both skid and towable versions from World Petroleum Supply, Inc. located near Houston, TX.

The team at Drillform have been leading industry efforts to automate pipe handling since the late 1990s with their introduction of the TM series of Iron Roughnecks and PC series of catwalks, sold to Canrig/Nabors Industries in 2006. Drillform’s modern iron roughnecks are geared to address the challenges¬¬ facing drilling contractors associated with more powerful rigs, and the drilling of deeper and more horizontal wells.

To accommodate an industry trending towards longer and deeper well profiles, Drillform has introduced a family of hydraulic and pneumatic workover rig catwalks designed to increase the speed and efficiency of tubular handling.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Company covers an area of more than 40,000 square meters, registered capital 50.8 million Yuan. And its main products include manual tongs series, slips series, elevators series, elevator links series, bushing series, casing spider series and pneumatic slips series etc. There are 12 products won the national utility model patent product, one invention patent products, five high-tech products, 2 in Nantong famous brand product.

Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions. Equipped with excellent equipment, strong technique force and completed test facilities, the company constantly innovate and expand market. Now the company has become a first-level supply member of Chinese Petroleum & Natural Gas Consortium, as well as the member of China Petrochemical Material Resources Market. We have obtained the Production License issued by the nation. Strict quality control has allowed us to gain the ISO9001-2008 certificate of quality management system, ISO1400:2004 environment management system certification and GB/T28001-2011 occupational health and safety management system certification and have the right to use API Spec 7K, 8C monogram. Since 2004 and has become a network members Petrochina, CNOOC, Sinopec level, won the "private technology enterprises in Jiangsu province" title, and won the "enterprise credit AAA level" and Nantong "contract" AAA level enterprise title Exploring the way forward in practice and surpassing self in innovation, our ‘Zero Defect and Zero Distance’ service purpose is bringing us more and more business partners.

Attached to the hook or top drive with bails, our elevators help you to handle singles or strings of casing, tubing, risers, and high corrosion-resistant-alloy completion tubing. These elevators—including automated, flush joint, remote operated, and spider/elevator combinations—offer various operating methods, from manual to remote, and they enable running pipe with or without collars.

Unlike conventional elevators, our remote-operated single-joint elevator lifts single joints of tubing and casing without manual handling. The elevator accommodates pipe sizes between 3-1/2 and 20 in. and has a weight load limit of 6 tons (5,443 kg).

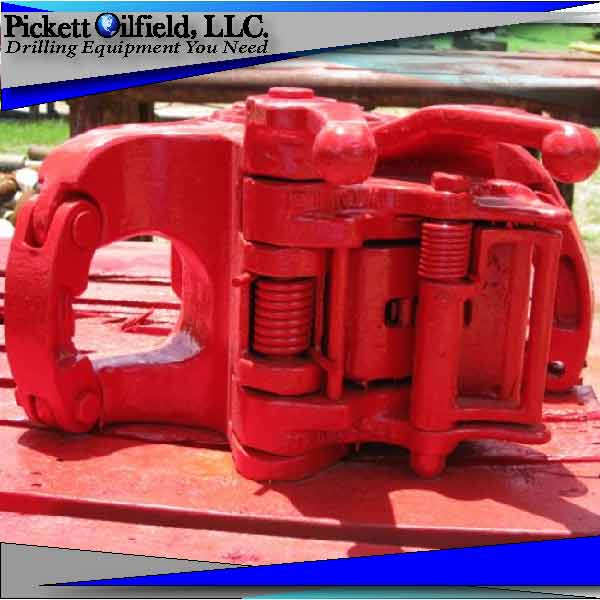

Elevators, as developed for the drilling industry, are a hinged device with handles that are used to wrap around the tool joint of drill pipe, casing (for collars) to facilitate the lifting or lowering of them singly or of the drill string as a whole.

In practical use elevators are highly stressed components and require regular careful inspection. In practice, sets of elevators and a spare duplicate are required on-site for general operations.

Texas International Oilfield Tools (TIOT) offers single joint (SJ) elevators to handle a large range of tubular. SJ elevators are used to add tubular to a string, hoisting a single casing, tubing, or collared type pipe.

Because of the internal position and diameter of the mandrel, and the normal protrusion of the gas valve in the tubing string to produce annular lift, there is often insufficient clearance to change the configuration without pulling the entire tubing string and mandrels. Consequently, a workover rig must be used. This is expensive and time consuming, resulting in a production shutdown, use of specialized equipment and increased manpower for this operation. A configuration using less intrusive side pocket mandrels is available, but that assembly is also an expensive alternative.

8613371530291

8613371530291