workover rig elevators manufacturer

KET is a leading manufacturer of Drill Pipe Elevators. We design and precision-machine all of our elevators to meet and exceed API Standards (API 8C or API 7K Standards), with KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

We understand the critical requirements of the oil and gas industry and the need for high-quality tools and parts. Our elevators include Safety Latch Lock Pins – designed to keep the elevator’s safety latch locked in place, preventing the elevator from being accidentally released

Single Joint Elevator also called Auxiliary Elevator. Lake Petro provides Single Joint Elevator with SJ type, SP type and SJX type. All of these elevators are designed and manufactured according to 8A/8C spec.

SLX auxiliary elevators are hoisting tools for handling single pipes or working together with the professional tools CRT to move the tubulars from gate to well centre.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The World Petroleum Supply Becket & Bails manufactures build two different beckets. The standard that can be used with standard drill pipe elevators from 3 ½” – 5 ½” and the Extended shank especially designed for tall hydraulic elevators from 5” – 6 5/8”. Perfection Links are also offered in lengths 36” – 42” in ratings of 100 & 150 ton capacity.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Company covers an area of more than 40,000 square meters, registered capital 50.8 million Yuan. And its main products include manual tongs series, slips series, elevators series, elevator links series, bushing series, casing spider series and pneumatic slips series etc. There are 12 products won the national utility model patent product, one invention patent products, five high-tech products, 2 in Nantong famous brand product.

Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions. Equipped with excellent equipment, strong technique force and completed test facilities, the company constantly innovate and expand market. Now the company has become a first-level supply member of Chinese Petroleum & Natural Gas Consortium, as well as the member of China Petrochemical Material Resources Market. We have obtained the Production License issued by the nation. Strict quality control has allowed us to gain the ISO9001-2008 certificate of quality management system, ISO1400:2004 environment management system certification and GB/T28001-2011 occupational health and safety management system certification and have the right to use API Spec 7K, 8C monogram. Since 2004 and has become a network members Petrochina, CNOOC, Sinopec level, won the "private technology enterprises in Jiangsu province" title, and won the "enterprise credit AAA level" and Nantong "contract" AAA level enterprise title Exploring the way forward in practice and surpassing self in innovation, our ‘Zero Defect and Zero Distance’ service purpose is bringing us more and more business partners.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

Rack-and-pinion elevators are an ideal choice for construction and industrial applications. Century Elevators provides rack-and-pinion elevators and hoists that are self-contained and install directly to an existing or emerging structure, making them ideal for commercial and industrial sites of all types including new construction, restorations, building additions, renovations and maintenance. We specialize in vertical access equipment designed for outdoor use in harsh environmental conditions - including hazardous-area elevators and hoists suitable for NEC and IEC explosive-dust environments.

The team at Century Elevators includes dedicated safety personnel, designers and installers allowing for a turnkey design and installation experience. Equipment can be provided with custom capacities, dimensions, material selections and configurations.

Offshore Drilling Derrick elevators are custom engineered to be permanently installed to meet the needs of various types of platform derricks including drill ships, fixed platforms, jackups, and semisubmersibles. GEDA personnel elevators are designed to withstand the mechanical stresses of the derrick structure continuous natural heave, pitch, and roll movement.

GEDA Elevators are ISO 9001-2008 Certified, and meet ANSI A17.1, EN-81 code requirements, and can are certified to meet DNV, ABS, NORSOK, Inmetro, and USCG requirements.

The FMS 375 is mounted flush with the rig floor, allowing the casing connection height to be lowered 1 meter (3 feet), thus eliminating the need for scaffolding.

Oilfield casing elevators and spider are used to grip tubulars and API-sized pipes vertically lifting and lowering the string into or out of the wellbore as part of the casing running process. These elevators can be set up on your drilling rig as an actual elevator, meaning thefre hoisted by bails, link extensions and the top drive, or they can be configured as a spider, meaning they are mounted on the rig floor gripping the string and holding it in place. Depending on which configuration works best for your drilling site, you will need to utilize different accessories like a

We sell elevators with capacities from 250 tons to 750 tons, link extensions to hang the elevators and flush mounted spiders to eliminate the need for scaffolding. Our elevators and spiders will give your rig crew more room to work, creating a safer work environment.

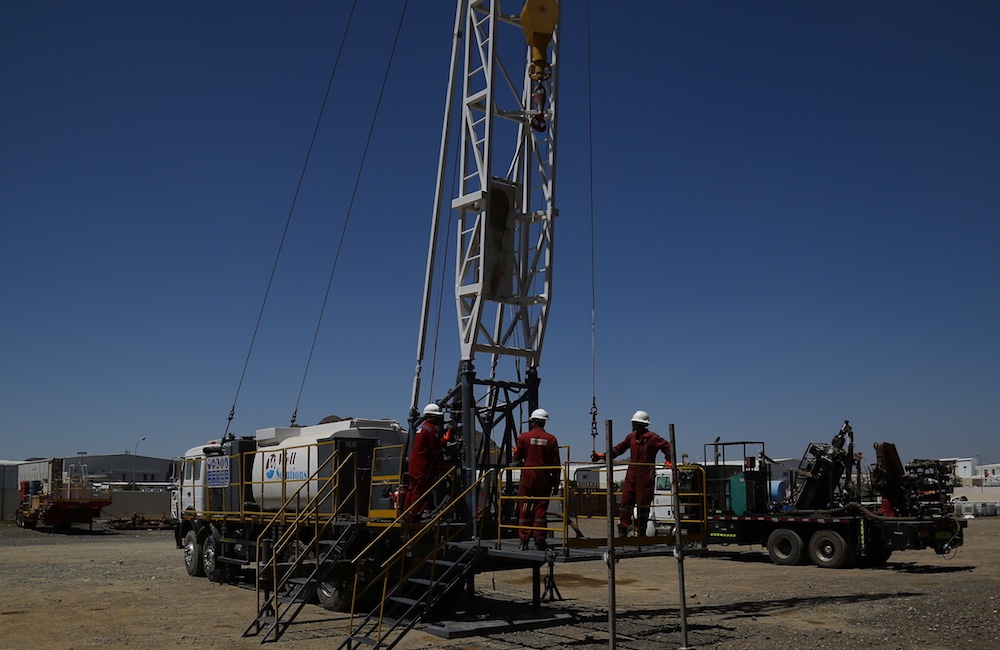

The Floor hand is responsible for assisting in setting up and taking down of the Workover Rig and equipment, handling, sorting, and moving tools, pipe, cement, and other materials in addition to maintaining a clean and organized work environment.

Attached to the hook or top drive with bails, our elevators help you to handle singles or strings of casing, tubing, risers, and high corrosion-resistant-alloy completion tubing. These elevators—including automated, flush joint, remote operated, and spider/elevator combinations—offer various operating methods, from manual to remote, and they enable running pipe with or without collars.

Unlike conventional elevators, our remote-operated single-joint elevator lifts single joints of tubing and casing without manual handling. The elevator accommodates pipe sizes between 3-1/2 and 20 in. and has a weight load limit of 6 tons (5,443 kg).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Our products cover 12 series with over 200 kinds, including truck-mounted drilling rigs, skid-mounted drilling rigs, trailer-mounted drilling rigs, work over rigs, logging equipments, etc. Especially, RG PETRO-MACHINERY GROUP CO., LTD. firstly proposed an idea for portable drilling equipments with characteristic of quick-carrying and operation automation in China, and put it into the development of portable drilling equipments. RG PETRO-MACHINERY GROUP CO,. LTD. developed the first 3000m truck-mounted drilling rig in China and was awarded the state-level second-class award of advance science and technology, awarded the national recognition with the Shenzhou V Spacecraft, and the award is the highest science and technology award in the petroleum equipments industry till now. 4000m truck-mounted drilling rig and 4000m trailer-mounted drilling rig developed by RG PETRO-MACHINERY GROUP CO., LTD. is the largest self-propelled drilling equipment in the worldwide, with high-competitive in the international market, providing the advanced drilling equipment for factory drilling.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The oil and gas industry has a history of collaboration between organizations, including operators, contractors, manufacturers and distributors, in efforts to continuously improve efficiency and safety. Incidents are often triggers that lead to this type of collaboration. This article highlights an example where an incident led to a drilling contractor, manufacturer and distributor to work together to design, produce and put in place a tool that will greatly reduce the chances of similar incidents reoccurring and, thus, improve safety on the job.

The incident occurred in April on a Sidewinder Drilling rig in Oklahoma during a routine operation. It was 9:30 p.m., and the crews were pulling out of the hole and laying down drill pipe at the end of the well. The drill pipe elevators were fitted with a piece of rope approximately 3 ft in length for the purpose of tripping the elevators open. There were scattered thunderstormsat the time with gusty winds and occasional rain and hail. The rig is equipped with a top drive with a link tilt system and a hydraulic catwalk machine.

After breaking one of the connections in the rotary table, the driller picked up on the joint, and the floormen pushed the pin end of the joint in the trough of the catwalk. The driller then started to lower the joint into the trough. After lowering the joint approximately 8 ft, the elevators tripped open, causing the joint to fall into the trough, bounce up over the V-door post and fall to the rig floor between the V-door post and stands of pipe racked back in the derrick. The floorman was standing near the setback area and was struck by the joint of drill pipe, resulting in a restricted work case injury.

It has been an accepted practice in the drilling industry to use ropes on elevators for the purpose of tripping them open while laying down drill pipe. The length and configuration of the rope varies widely from company to company and often from rig to rig.

As a result of the incident, Sidewinder began searching for an alternative to ropes as a means of tripping the elevators open for this task. During this search, the company found that a casing company employee had constructed some homemade straps out of old fall protection lanyards. He offered one of the straps to the crews on a Sidewinder rig. The company’s risk assessment matrix and MOC process were used and determined it was safe to proceed with testing it on the contractor’s elevators. The general concept appeared to be a good starting point for an alternative to ropes.

Sidewinder created a drawing of this concept with some modifications and contacted Billy Pugh Co and Dooley Tackaberry for assistance with designing and manufacturing a prototype for testing on the rigs. The first prototype, which was a strap with flexible loop style handle and swivel snap hook, was sent to the field for testing. Once feedback came in from the rig, Sidewinder and Dooley Tackaberry reviewed the findings.The information in the report was then sent to Billy Pugh for modifications, and a second prototype was assembled for testing. The new design included a strap with large plastic ring and swivel snap hook.

After the second prototype was sent to the field for additional testing, rig employees provided additional feedback, and more modifications were suggested. The third prototype consisted of a strap and a rigid metal ring and rigid snap hook.

With one more minor “adjustment,” again based on surveying employees in the field, a fourth and final design was developed. The final design change was simply to add a stronger metal ring for strength and durability of the device. This new safety product has ultimately become Part Number ELS-1A and is the standard elevator strap for use on all Sidewinder rigs.

Sidewinder’s operating procedures have been revised to include the use of the elevator strap for all drill pipe laydown operations. Ropes are no longer allowed on elevators.

In conclusion, the collaboration among Sidewinder, Dooley Tackaberry and Billy Pugh was a great example of bringing together the best resources for a common goal. By creating this new product – where employees in the field had the majority of the input in its creation – there will be multiple benefits.First, it creates a safer work environment. Second, it demonstrates to employees that their input is critical. Third, it shows that the company takes safety on the rigs very seriously. The goal is to reduce incidents to zero, and collaborations like this fit this goal and Sidewinder’s culture perfectly.

8613371530291

8613371530291