pressure compensated hydraulic pump how it works factory

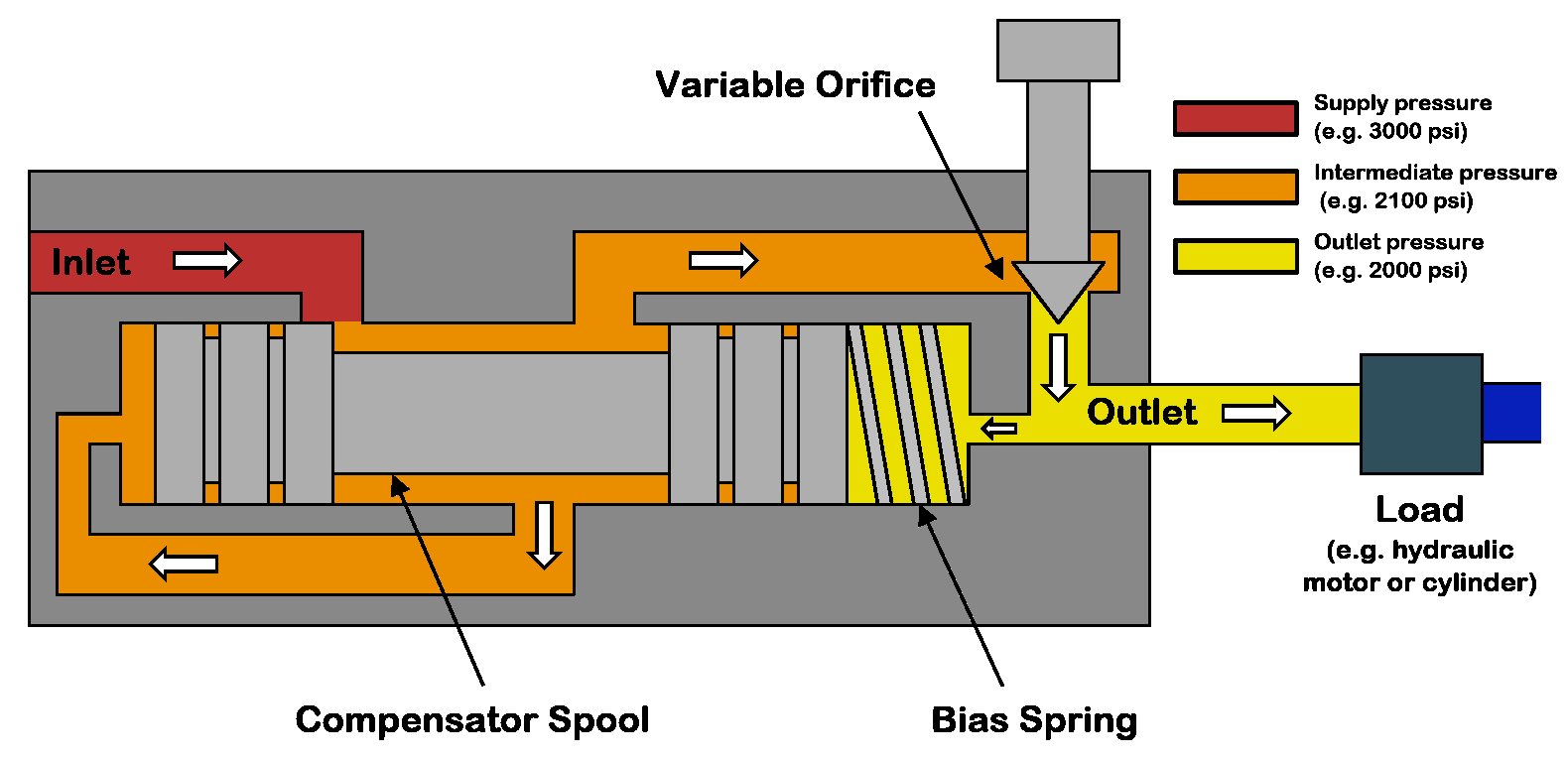

A pressure compensator is a device built into some pumps for the purpose of automatically reducing (or stopping) pump flow if system pressure sensed on the pump outlet port, should rise above a pre-set desired maximum pressure (sometimes called the "firing" pressure). The compensator prevents the pump from being overloaded if an overload is placed on the hydraulic system.

A compensator is built into the pump at the factory and usually cannot be added in the field. Any pump built with variable displacement can be controlled with a compensator. These include several types of axial piston pumps and unbalanced (single lobe) vane pumps. Radial piston pumps can sometimes be built with variable displacement but do not lend themselves readily to this action. Most other positive displacement pumps including internal and external gear, balanced (double lobe) vane, gerotor, and screw types cannot be built with variable displacement.

Figure 1 is a schematic of a check valve axial piston pump, variable displacement, controlled with a pressure compensator. The pistons, usually 5, 7, or 9 in number, are stroking inside a piston block which is keyed to and is rotating with the shaft. The left ends of the pistons are attached through swivel joints, to piston shoes which bear against and slide around on the swash plate as the piston block rotates. The swash plate itself does not rotate; it is mounted on a pair of trunnions so it can swivel from neutral (vertical) position to a maximum tilt angle. The angle which the swash plate makes to the vertical causes the pistons to stroke, the length of stroke being proportional to the angle. Normally, at low system pressures, the swash plate remains at its maximum angle, held there by spring force, hydraulic pressure, or by the dynamics of pump construction, and pump flow remains at maximum. The compensator acts by hydraulic pressure obtained internally from the pump outlet port. When pump pressure rises high enough to over-come the adjustable spring behind the compensator piston, the "firing" pressure has been reached, and the compensator piston starts to pull the swash plate back toward neutral, reducing pump displacement and output flow. The spring in the compensator can be adjusted for the desired maximum or "firing" pressure.

Under working conditions, on a moderate system overload, the compensator piston reduces the swash plate angle just enough to prevent the system pressure from exceeding the "firing" pressure adjusted on the compensator. On severe overloads the compensator may swing the swash plate back to neutral (vertical) to reduce pump flow to zero.

Maximum Displacement Stops. Some pumps are available with internal stops to limit the tilt angle of the swash plate. These stops limit the maximum flow and limit the HP consumption of the pump. They may be fixed stops, factory installed and inaccessible from the outside, or they may be externally adjustable with a wrench.

Manual Control Lever. Some pressure compensated pumps, especially hydrostatic transmission pumps, are provided with an external control lever to enable the operator to vary the swash plate angle (and flow) from zero to maximum. On these pumps the pressure compensator is arranged to override the manual lever and to automatically reduce the swash plate angle if a system overload should occur even though the operator control lever is still shifted to maximum displacement position.

Basically the pressure compensator is designed to unload the pump when system pressure reaches the maximum design pressure. When the pump is unloaded in this way, there is little HP consumed and little heat generated even though pressure remains at the maximum level, because there is no flow from the pump.

Variable displacement pumps are usually more expensive than fixed displacement types, but are especially useful in systems where several branch circuits are to be supplied from one pump, and where full pressure may be required simultaneously in more than one branch, and where the pump must be unloaded when none of the branches is ill operation. If individual 4-way valves are used in each branch, each valve must have a closed center spool. The inlet ports on all 4-way valves must be connected in parallel across the pump line. However, if all branch circuits are operated from a bank valve of the parallel type, a pressure compensated variable displacement pump may not be necessary; a fixed displacement pump, gear, vane, or piston, may serve equally well because the bank valve will unload the pump when all valve handles are placed in neutral, but when two or more handles are simultaneously shifted, their branch circuits will automatically be placed in a parallel connection.

As in all hydraulic systems, more pump oil will flow to the branch with the lightest load. Bank valve handles can be modulated to equalize the flow to each branch. When individual 4-way valves are used in each branch, flow control valves may be installed in the branch circuits and adjusted to give the flow desired in each branch.

Figure 2 shows a multiple branch circuit in which a variable displacement pump is used to advantage. Individual 4-way valves, solenoid operated, are used for each branch, and they have closed center porting. Please refer to Design Data Sheet 54 for possible drift problems on a pressure manifold system. A pressure relief valve is usually required even with a pressure compensated pump due to the time interval required for the swash plate to reduce its tilt angle when a sudden overload occurs. The relief valve will help absorb part of the pressure spike generated during this brief interval. It should be adjusted to crack at about 500 PSI higher than the pressure adjustment of the compensator piston spring to prevent oil discharge across it during normal operation.

All hydrostatic transmission systems use a variable displacement pump with pressure compensator, and often combine the compensator with other controls such as the horsepower input limiter, load sensing, flow sensing, or constant flow control.

© 1990 by Womack Machine Supply Co. This company assumes no liability for errors in data nor in safe and/or satisfactory operation of equipment designed from this information.

Hydraulic pumps are an incredibly important component within hydraulic systems. IFP Automation offers a variety of pump and hydraulic system products that deliver exceptional functionality and durability. Our partner Parker’s extensive line of hydraulic pumps deliver ideal performance in even the most demanding industrial and mobile applications. In this post, we are going to spend time discussing pressure compensated and load sensing hydraulic pumps.

Do to the surface area of the servo piston and the pressure exerted on that area, a force is generated that pushes the swash plate of the pump to a lower degree of stroke angle.

The pump tries to maintain compensator setting pressure, and will provide whatever flow (up to it’s maximum flow rate) that is necessary to reach that pressure setting.

For more information on how you can make use of hydraulic pump technology in your applications, please contact us here to receive a personalized contact by an IFP Application Engineer:

IFP Automation supplies innovative technology and design solutions to the automation and mobile marketplaces. Our firm is a technology supplier specializing in the design and supply of automation and motion control products to OEM, integrator, and end user customers. Companies partner with IFP because they like the depth of our product and application knowledge and our commitment to outstanding customer service.

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/12/2023 08:49 AM UTC

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/12/2023 08:49 AM UTC

Variable-displacement pumps are used in hydraulic systems where the flow requirements vary. This usually means the system has several actuators and, depending on the current cycle of the machine, the number of actuators moving at a given time will fluctuate. The most common type of variable-displacement pump is the pressure-compensating pump.

Pressure-compensating pumps are designed to deliver only the amount of flow required by the system to maximize efficiency and avoid heat generation. The compensator is adjusted to a pressure somewhat higher than that required to move the system’s heaviest load.

A pressure-compensating pump will deliver its maximum flow until the system pressure reaches the compensator setting. Once the compensator setting is reached, the pump will be de-stroked to deliver only the amount of flow that will maintain the compensator setting in the line.

Whenever more flow is demanded by the system (such as would occur when an additional actuator begins to move), the pump will increase its stroke to meet the new flow demand. Whenever the system flow needs to decrease (such as when one or more actuators are stopped), the pump stroke is reduced.

When the system is stopped completely, the pump stroke is reduced almost to zero. It will stroke only a very small amount or whatever is required to maintain the compensator setting in the line, overcoming any system bypassing or leaks. While a pressure-compensating pump is efficient, the standby pressure remains high.

Adjusting a pressure-compensating pump is quite simple. With all flow blocked and the system idle, the compensator valve is adjusted to the desired pressure. However, some pressure-compensating pumps have two valves mounted on the pump body.

The two adjustments can look nearly identical. This type of pressure-compensating pump is called a load-sensing pump. The second adjustment is called either a “load-sensing” valve or “flow-compensator” valve.

A load-sensing pump is designed to reduce its pressure to a much lower standby level whenever the system is idle. This can conserve energy and reduce heat and wear in systems that spend a significant amount of time in an idle condition.

The two separate pressure adjustments allow setting the compensator valve to the required maximum system pressure and the load-sensing adjustment to a much lower standby pressure.

Whenever the system is moving a load, the high-pressure adjustment limits the system pressure. For instance, as a cylinder is extended, pressure in the system will build as necessary to move the load. Eventually, the cylinder reaches the end of its stroke, and flow is blocked.

When the flow is blocked in this fashion, the system pressure can build no higher than the setting of the compensator, but until another load is to be moved, there is no need for the system pressure to be kept so high.

Most load-sensing systems have a pump-loading directional-control valve of some sort that can place the system in an idle condition until it is necessary to move another load. When the pump-loading valve is shifted, the system pressure drops to the much lower load-sensing valve setting.

A load-sensing valve usually is smaller than the compensator valve and typically mounted directly on top of the compensator. The compensator valve is closer to the pump. The load-sensing valve is factory preset and normally does not need to be adjusted during the initial pump setup. In most pumps, the factory preset is approximately 200-300 pounds per square inch (psi).

The most common reason to adjust a load-sensing valve is because someone unfamiliar with the pump has mistakenly attempted to set the maximum system pressure by adjusting the load-sensing valve instead of the compensator. This not only can result in unstable system pressure but in some cases can also void any warranty on the pump.

A typical configuration of a pressure-compensating pump is shown in Figure 1. A pump-loading valve is used to determine whether the system is idle or prepared to move a load. The pump-loading valve is de-energized whenever the system is idle.

Pilot pressure on the left-hand side of the load-sensing valve is then released to the tank. The pilot line on the right-hand side of the load-sensing valve is connected to the pressure line at the pump outlet. System pressure shifts the load-sensing valve and directs pressure to reduce the pump stroke so that system pressure drops to the load-sensing setting of 300 psi, as illustrated in Figure 2.

When a load is to be moved, the pump-loading valve is energized. This directs pilot pressure to the left side of the load-sensing valve, keeping it from shifting. System pressure shifts the compensator valve to de-stroke the pump exactly the amount necessary to limit system pressure to the compensator setting, 3,000 psi as shown in Figure 3.

To make the pressure settings, always adjust the load-sensing valve first. The pump should be deadheaded by closing the manual hand valve. With the pump-loading valve de-energized, pressure will build only to the current setting of the load-sensing valve. Adjust the load-sensing valve to the desired pressure.

Once the load-sensing valve is set, energize the pump-loading valve. System pressure will then build to the current compensator setting. Adjust the compensator to the desired setting. Open the manual valve, and the system can be placed back into service.

There are several variations of this design. Sometimes a throttle valve will be used to determine if a load is available. The pressure drop that results when oil moves through the throttle valve signals the need for higher system pressure.

Another common variation is to use the load-sensing valve in conjunction with a proportional relief valve connected in series. Standby pressure will then be determined by the sum of the load-sensing pressure and the electronically controlled setting of the proportional relief.

In more complex arrangements such as this, hand valves should be installed that can be opened or closed to deadhead the load-sensing valve and also to release its pressure to the tank to enable setting the pressure.

Jack Weeks is a hydraulic instructor and consultant for GPM Hydraulic Consulting. Since 1997 he has trained thousands of electricians and mechanics in hydraulic troubleshooting methods. Jack has...

You’ve been around hydraulics a while, haven’t you? With that in mind, you probably take some things for granted. There is plenty of jargon in our industry, and it isn’t learned overnight. However, if you were like me, the term pressure compensation was difficult to grasp early in your hydraulic career. If you still don’t quite get it, here’s a quick explanation of pressure compensation.

Fluid flows through components and plumbing at a rate dictated by pressure potential. If you measure pressure at point A close to your pump, and also at point B at your actuator, the difference in those two pressures is the energy available for the fluid to literally get from point A to point B. The higher this difference, the more energy there is for flow to take place. The closer point B pressure is to point A pressure, the less flow potential can take place. In hydrodynamic applications, you lose the ability to achieve velocity in your actuators because of the energy lost to flowing.

With positive displacement systems like hydraulics, which we call hydrostatics, it’s the physical force applied from the pump that pushes the oil like a physical rod. It’s literally force transfer occurring, rather than energy being contained in the inertia of the fluid moving. In this case, if fluid is pumped through one passageway, flow is not affected by pressure differential between point A and point B, except in what is lost to leakage. I should note leakage rates increase as pressure increases, but the same can occur in hydrodynamic applications.

The problem with changes in pressure at point B, is that it changes pressure differential between it and point A. This pressure differential is critical to dictate flow rates, especially when metering of fluid rate is employed. If point A is a constant 3,000 psi, and your orifice is 0.140 in., you will flow about 26 gpm. With no other changes but adding a load from a downstream motor that uses 2,000 psi flow suddenly drops to just over 15 gpm with only 1,000 psi left for flow potential (the difference between point A and point B). The rest of the 11 gpm being created by the pump would then go over the relief valve.

If you change your orifice to a pressure compensated metering valve and set it to flow about 26 gpm at 3,000 psi, it will do exactly that … always. When you run your motor using 2,000 psi of work pressure, you’re still only left with 1,000 psi to move fluid through the metering valve. Only this time, the valve self-pilots open to increase its effective diameter closer to 0.185 in., which is enough to flow 26 gpm at 1,000 psi. The valve compensates for changes in downstream pressure by opening and closing to increase or decrease its orifice.

Essentially, pressure compensation is when a hydraulic component can ready load or system pressure and adjust itself to make up for changes in those pressures. It could be a pressure compensated pump which reduces flow when downstream pressure rises too high, or a pressure compensated flow control which increases flow potential when downstream pressure rises.

A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. It generates flow with enough power to overcome pressure induced by the load.

A hydraulic pump performs two functions when it operates. Firstly, its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump. Secondly, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system.

The three most common hydraulic pump designs are: vane pump, gear pump and radial piston pump. All are well suited to common hydraulic uses, however the piston design is recommended for higher pressures.

Most pumps used in hydraulic systems are positive-displacement pumps. This means that they displace (deliver) the same amount of liquid for each rotating cycle of the pumping element. The delivery per cycle remains almost constant, regardless of changes in pressure.

Positive-displacement pumps are grouped into fixed or variable displacement. A fixed displacement pump’s output remains constant during each pumping cycle and at a given pump speed. Altering the geometry of the displacement chamber changes the variable displacement pump’s output.

Fixed displacement pumps (or screw pumps) make little noise, so they are perfect for use in for example theatres and opera houses. Variable displacement pumps, on the other hand, are particularly well suited in circuits using hydraulic motors and where variable speeds or the ability to reverse is needed.

Applications commonly using a piston pump include: marine auxiliary power, machine tools, mobile and construction equipment, metal forming and oil field equipment.

As the name suggests, a piston pump operates through pistons that move back and forth in the cylinders connected to the hydraulic pump. A piston pump also has excellent sealing capabilities.

A hydraulic piston pump can operate at large volumetric levels thanks to low oil leakage. Some plungers require valves at the suction and pressure ports, whilst others require them with the input and output channels. Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures.

The axial piston pump is possibly the most widely used variable displacement pump. It’s used in everything from heavy industrial to mobile applications. Different compensation techniques will continuously alter the pump’s fluid discharge per revolution. And moreover, also alter the system pressure based on load requirements, maximum pressure cut-off settings and ratio control. This implies significant power savings.

Two principles characterise the axial piston pump. Firstly the swash plate or bent axis design and secondly the system parameters. System parameters include the decision on whether or not the pump is used in an open or closed circuit.

The return line in a closed loop circuit is under constant pressure. This must be considered when designing an axial piston pump that is used in a closed loop circuit. It is also very important that a variable displacement volume pump is installed and operates alongside the axial piston pump in the systems. Axial piston pumps can interchange between a pump and a motor in some fixed displacement configurations.

The swivel angle determines the displacement volume of the bent axis pump. The pistons in the cylinder bore moves when the shaft rotates. The swash plate, in the swash plate design, sustain the turning pistons. Moreover, the angle of the swash plate decides the piston stroke.

The bent axis principle, fixed or adjustable displacement, exist in two different designs. The first design is the Thoma-principle with maximum 25 degrees angle, designed by the German engineer Hans Thoma and patented in 1935. The second design goes under the name Wahlmark-principle, named after Gunnar Axel Wahlmark (patent 1960). The latter features spherical-shaped pistons in one piece with the piston rod and piston rings. And moreover a maximum 40 degrees between the driveshaft centre-line and pistons.

In general, the largest displacements are approximately one litre per revolution. However if necessary, a two-litre swept volume pump can be built. Often variable-displacement pumps are used, so that the oil flow can be adjusted carefully. These pumps generally operate with a working pressure of up to 350–420 bars in continuous work

Radial piston pumps are used especially for high pressure and relatively small flows. Pressures of up to 650 bar are normal. The plungers are connected to a floating ring. A control lever moves the floating ring horizontally by a control lever and thus causes an eccentricity in the centre of rotation of the plungers. The amount of eccentricity is controlled to vary the discharge. Moreover, shifting the eccentricity to the opposite side seamlessly reverses the suction and discharge.

Radial piston pumps are the only pumps that work continuously under high pressure for long periods of time. Examples of applications include: presses, machines for processing plastic and machine tools.

A vane pump uses the back and forth movement of rectangle-shaped vanes inside slots to move fluids. They are sometimes also referred to as sliding vane pumps.

The simplest vane pump consists of a circular rotor, rotating inside of a larger circular cavity. The centres of the two circles are offset, causing eccentricity. Vanes slide into and out of the rotor and seal on all edges. This creates vane chambers that do the pumping work.

A vacuum is generated when the vanes travel further than the suction port of the pump. This is how the oil is drawn into the pumping chamber. The oil travels through the ports and is then forced out of the discharge port of the pump. Direction of the oil flow may alter, dependent on the rotation of the pump. This is the case for many rotary pumps.

Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. Higher viscosity fluids on the other hand, may cause issues for the vane’s rotation, preventing them from moving easily in the slots.

Gear pumps are one of the most common types of pumps for hydraulic fluid power applications. Here at Hydraulics Online, we offer a wide range of high-powered hydraulic gear pumps suitable for industrial, commercial and domestic use. We provide a reliable pump model, whatever the specifications of your hydraulic system. And we furthermore ensure that it operates as efficiently as possible.

Johannes Kepler invented the gear pump around year 1600. Fluid carried between the teeth of two meshing gears produces the flow. The pump housing and side plates, also called wear or pressure plates, enclose the chambers, which are formed between adjacent gear teeth. The pump suction creates a partial vacuum. Thereafter fluid flows in to fill the space and is carried around the discharge of the gears. Next the fluid is forced out as the teeth mesh (at the discharge end).

Some gear pumps are quite noisy. However, modern designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles are much quieter. On top of this, they can mesh and un-mesh more smoothly. Subsequently this reduces pressure ripples and related detrimental problems.

Catastrophic breakdowns are easier to prevent with hydraulic gear pumps. This is because the gears gradually wear down the housing and/or main bushings. Therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear causes the unit to seize or break down.

Can hydraulic gear pumps be reversed? Yes, most pumps can be reversed by taking the pump apart and flipping the center section. This is why most gear pumps are symmetrical.

External gear pumps use two external spur gears. Internal gear pumps use an external and an internal spur gear. Moreover, the spur gear teeth face inwards for internal gear pumps. Gear pumps are positive displacement (or fixed displacement). In other words, they pump a constant amount of fluid for each revolution. Some gear pumps are interchangeable and function both as a motor and a pump.

The petrochemical industry uses gear pumps to move: diesel oil, pitch, lube oil, crude oil and other fluids. The chemical industry also uses them for materials such as: plastics, acids, sodium silicate, mixed chemicals and other media. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry.

Mathematical calculations are key to any type of hydraulic motor or pump design, but are especially interesting in the gerotor design. The inner rotor has N teeth, where N > 2. The outer rotor must have N + 1 teeth (= one more tooth than the inner rotor) in order for the design to work.

Why would we want to add this extra complication to our hydraulic systems?Having a hydraulic pump which reduces its output to near zero when the system pressure reaches maximum saves the system from pointlessly forcing oil over a relief valve.

Whenever a system is at maximum pressure, and the pump is a fixed displacement model, like a gear pump, then the system is at maximum displacement as well.

The combination of these two maximums also means that the power requirement from the prime mover (diesel engine or electric motor) is at maximum as well.A prime mover at maximum power is consuming maximum energy (fuel or electricity). Much of this energy is being used for nothing other than a conversion to heat.

You could compare this to operating a truck at maximum throttle while it is parked against a solid wall of rock. You"ll burn a lot of fuel but you won"t be doing any useful work!

The following is an unedited transcript from a recent Fluid Power World Webinar:Load Sense Hydraulics Simplified. FPW Associate Editor Mike Santora moderates with the presenter, Carl Dyke.

Mike Santora: Hello and thank you, everyone, for attending today’s webinar, Load Sense Hydraulics Simplifiedbrought to you by Fluid Power World magazine, Ametek, and Higginson. We would like to thank our presenter, Carl Dyke, for being here today. I’m Mike Santora Associate Editor for Fluid Power World Magazine and I’ll be your moderator.

Ametek Factory Automation has been supplying linear displacement transducers to the hydraulics industry for more than 30 years, under the brand name Gemco. The technology they use to help solve cylinder positioning needs is called magnetostriction. Magnetostriction transducers are the preferred feedback in hydraulic cylinders. They are absolute and can survive conditions associated with hydraulic cylinders. Whether it is high temperature, pressure or high cycle rate, there’s simply nothing to wear out. Ametek transducers are known for their flawless operation in the most demanding and hostile environments.

Just a couple of house-keeping details before we get started, you will see several boxes on your desktop, all of which can be moved around to suit your preferences. Initially, the Q&A box is at the lower left; this is where you will enter your questions for the Q&A session. Another box to note is the additional resources, initially at the lower right-hand corner of your desktop. These resources are for your information needs. We also have a tweet box right on the desktop, so feel free to tweet any interesting points right from there. There’s a list of hashtags for you to use as well.

Carl Dyke is the founder and chief educational officer of CD Industrial Group, a company focused on fluid power education for technicians. Carl’s company created the eLearning site LunchBoxSessions.com. Carl is an industrial mechanic whose career began as a boy in the lumber and logging industry. He spends much of his time each year in the classroom and on the shop and factory floor helping technicians with their hands-on skills development. And so, without further ado, here’s Carl Dyke.

Carl Dyke:Thank you, Mike. It was good to meet you and the entire Fluid Power World team at the recent Fluid Power Technology Conference there in Milwaukee. That was a great time. Thanks for hosting and moderating this morning, Mike.

Load sense hydraulic is a deep topic to try and cover inside of a one-hour session. There are so many design and engineering perimeters for manufacturers of machinery that integrate a load sense type of system. In this particular webinar, we’re going to try and stick to the basics and illustrate them as best we can for practical purposes.

A load sense system, if you think about the typical pressure compensated pump, the type of pump that might only have three hoses, the type of pump that has a high-pressure cutoff only, that’s the type of pump that can match the flow demand that occurs as you open a throttling valve, a proportional directional valve. But as we’re going to find out, a load sense system adds a fourth hose, a control hose to that pump. It allows the pump also to match the pressure needs and the pressure demands. We’re going to find out more about that as we go.

We’re going to start with a video. We’ve prepared a video to help simplify the understanding of some of the most important features and components in a load sense system. The video’s about 15 minutes long. It’s narrated. In the very last three minutes, the climax, if you will, that’s where we’re going to get into some of the most key features of what happens in a load sense system as it’s multi-functioning.

CD:All right, well I hope that your opportunity to fly through a load sense system in 3D helps a little bit with what is the sometimes slightly dryer, more obscure terminology that goes with load sense systems. Why is a load sense system so attractive? Primarily because of the opportunity to save input energy, which also translates in so many circumstances into a reduction of heat, but how is that done? Well, for a moment, let’s go backward to a time of simpler hydraulic systems, systems that are still in place for some simpler machinery, consider the gear pump and the relief valve.

A gear pump is always pumping at its maximum flow. If we’re using a proportional valve to meter the flow rate to an actuator, then we’re always operating this hydraulic system at maximum energy consumption. What you see here on a cut-away model with the gear pump and a relief valve, you will also see that the proportional valve is only set to half open in order to control speed as desired to the cylinder. Well, if that’s the case, our gear pump is pumping at full volume, of course, but also we are pumping over the relief valve, the unused fluid that is not desired at the cylinder. Therefore, we’re also pumping at maximum pressure.

The energy consumption is what you see by the horsepower line, which is the dark blue diagonal, all the way across the red zone. That’s a picture of our input energy. Well right now, we’re running with an enormous amount of input energy where, at the business end of the hydraulic system over there on the right past the hydraulic cylinder, we can see the energy requirement for flow and pressure at the cylinder is actually quite low. The horsepower line in green shows energy, or the horsepower output that we actually need to move the load; so a very inefficient system. I think you get the picture there.

Then, enter the pressure compensated pump, the type of pump that has only one setting, a high-pressure cutoff point. Well, in this type of system, this pump still operates at its maximum pressure. It’s matching the flow output to the demand at the proportional valve, but we’re still operating at maximum pressure. This is still a lot better than the gear pump. Gear pumps in some systems aren’t more than 10% energy efficient, where the pressure compensated pump arrangement can possibly make it possible to get to 25% energy efficiency.

Here we see an energy picture for the pressure compensated pump. What we can see that’s changed is while the flow rates of the pump now matches the demand through the proportional valve, we see that we’re still pumping at maximum pressure, but at least that diagonal dark blue line is now shorter by at least a percentage, and those energy savings are welcomed; both from in terms of cost of input energy, and potential for building up undesirable heat in the system.

As we bring in the load sense pump, which has an additional compensator, some manufacturers refer to that second adjustment as the flow compensator. But I think really what you saw in the video, and what you’ll see as we continue here, is that, that flow compensator, that load sense adjustment is just another pressure compensator with a softer spring setting. We also bring in pressure feedback on a special signal line, as we’ll see in the next screen, that ties in from the load at the cylinder. What we’re really doing is we’re setting pressure compensation on the fly. There’s a big energy savings potential associated with that.

In this image here, that thinner, narrower, yellow horizontal line you see it going from the proportional valve back to the pump’s compensator controller, that’s our load sense signal line. That’s our opportunity to instruct the pump about what’s happening at the load in the cylinder. We could have that load sense signal line coming right from the cylinder, but it’s generally more convenient to have it pick up either the A or the B work port lines from the cylinder just inside the directional valve, as shown here.

Here’s our energy savings curve when we look at where the big potential is for energy savings and heat reduction in a load sense system. What we’re seeing now is that this system not only matches the flow rate requirement, the pressure compensated pump did that. But the load sense system is also matching the pressure issues, the pressure requirements in the hydraulic cylinder, and producing a pump outlet pressure that’s only slightly higher than what’s needed at any one time. Look how short that diagonal dark blue line is now. There is the big savings. The opportunity here to go from pressure compensated pump systems, which might reach 25% energy efficiency, right up to potentially 60% energy efficiency for a load sense system. My source on that statistic came from a parker, a pump division manual that I was looking at to verify yesterday; and just refresh on that.

Looking at a slightly simpler model for a moment, getting away from a fancy proportional valve. What we’re really talking about for controlling the speed of an actuator is some kind of metering device. Here we’ve just installed a very simple needle valve, just to simplify matters for a moment. While these are stills from the simulations in our lunchbox sessions, stills are all we can work with on these screens.

If you imagine for a moment that I click on the green plus button, which very gently just adds one brick to the stack on top of the cylinder; which then might perhaps increase our load pressure from 900 PSI, that’s the gauge on the right, up to 1200 PSI as we add that one brick. That pressure value is transmitted along the load sense signal line up the yellow vertical and across horizontally to the left to the pump’s controller; where that 1200 PSI would be added to the 300 PSI perhaps spring setting in the load sense compensator, to then change the left gauge reading before the flow … before the metering valve. Increasing that one to 1500 PSI, and thereby always maintaining a 300 PSI pressure drop as seen on the bottom gauge, our delta P gauge. The type of gauge that has two pressure inputs to it.

What we find out is that no matter what happens to our load at the cylinder, adding or removing bricks as a way of seeing pressure changes, our pump is constantly changing its maximum output pressure and holding a value that allows us to have steady flow through the flow controlling device without needing to work at very high pressures. Lots of energy savings there.

You might be thinking for a minute, what happens during shock load? Well yeah, that’s where things start to get a little bit more interesting. What happens if that third brick drops from the sky, let’s say, instead of being added gently? It hits down hard on the cylinder as its lifting up. Well, that might induce a pressure like what we’re showing on the right-hand gauge at the moment, 1500 PSI.

Well, if our left side gauge was still at 1200 PSI, the momentary pressure compensation value from the pump. Well, now we have a reverse delta B of negative 300 PSI. As you could imagine, for a very brief moment in time, this cylinder might grind to a halt as the new load sense pressure is transmitted to the pump, which can happen a little slowly. In some cases with shock pressure, there may be a shudder or a brief interruption in the cylinder’s motion, and enter in discussions about exactly where should the margin pressure be set on a load sense pump. Well, we’ll come back to that one in a moment.

Let’s go to the next level, one that we looked at in the video where things get most interesting. That is when we have a multifunction load sense system, where we’ve got more than one parallel application. In this case, enter in a very small little element inside the load sense system, often just a very small ball bearing, the shuttle valve; sometimes called ball resolvers. One in each section of a multi-section valve bank, and also pressure compensators in each valve section. Why are they needed?

Here is a schematic depiction of a simplified two section load sense system. On the left, you’ll see our blue return line through a cooler and filtration to tank. In the middle, we’ll see our load sense pump with its controlling compensator shown in full detail. Then over to the right, a two-section valve bank with, in each case, a hydraulic motor. We put some brake shoe brick stackers over top of those motor symbols so that we’ll be able to imagine different pressure loadings for each section.

Let’s zoom in a little bit and move that return to tank line off to the left. Now that we’re just looking at … the pump on the left, and the load sense capable two section valve crank on the right take a moment to notice down low in the middle, a line marked ‘LS.’ Leaving the valve bank in orange, and it is our load sense signal line transmitting up to port X on the pump compensator, top left. Also notice the common pump line in red entering in through the port marked ‘P’ on the lower left side of the valve bank, and moving along the bottom of the valve bank supplying two applications. Two valve sections in parallel.

The interesting features that we’re drawing some attention to here, and you saw them in 3D in the video as well in green. We see circled the load sense shuttle valves, the ball resolvers. You saw what tiny little parts those were in 3D in the video, and highlighted in purple, our pressure compensators, also very necessary. There’s a reminder of the components that we were talking about in the video.

Adjustment procedures is an area where things get kind of interesting. There’s some different terminology that can be applied here. I think one of the things that’s really important, I’m going to jump to the bottom bullet point first. That is to check with the manufacturer of your pump, or check with the manufacturer of your machine, and find out what they recommend as the best and safest procedure. Make sure you have training and guidance the first time that you’re making these adjustments to keep safe around potentially hazardous pressurized hydraulic systems.

Typically, that pressure compensator adjustment, that pressure cutoff, the one with the stiffer spring, that one will be adjusted first at the highest pressure. To make that adjustment, that may require that the load sense adjustment be tightened right down to the bottom so that it doesn’t react, or it might be recommended that the load sense signal line coming into that compensator be connected somehow to the pump’s main outlet during that first setting. Again, check with your pump manufacturer for that.

Then, the load sense adjustment is set to the required standby pressure, which is going to be a low value, often in the range of around 300 PSI. That’s the standby pressure that would be present on the main outlet of the pump when the system is in neutral; meaning that there’s really no consumption flow path through the machine, that the valve handles have been released. We’re in a neutral state.

Alternately, some manufacturers of machinery want the adjustment process to involve the measurement of pressure differential across a valve section from the inlet of the valve section to an outlet to, say, a hydraulic motor while oil is flowing. Those are the two typical procedures there. Again, we’re moving through this very briefly. It’s very difficult to cover all facets of load sense hydraulics inside of a one hour session, but hopefully this is giving you a sense of some key issues.

On the maintenance side of things and troubleshooting side, what we find in our travels is that the margin or standby pressure setting has to be set correctly. If it’s set too high, if we widen that red margin that you see there, that’s going to cause heating in the hydraulic system that wasn’t there before. That’s a waste of energy as well, which could be electricity or it could be diesel fuel. If it’s set too low, that may allow for some momentary stalling or shuddering in hydraulic cylinder action. For reasons tied to the example I was showing you earlier, where we had a shock loader, perhaps a sudden increase in pressure loading at the actuator.

In our travels over 20 years, so many problems that we end up helping to troubleshoot that tied back to contaminated flue, a flue that’s contaminated specifically with solid particles. What we haven’t shown in schematic form is that in many cases, … but I think you saw it in the video. In many cases, there is a damping orifice in the load sense signal line. The reason that orifice is often installed is so that momentary, very short lived changes in pressure loading at the hydraulic cylinder or motor, if they’re going to be very short lived changes in increases in pressure, we may not want to tell the pump’s compensator about those pressure changes; at least not tell the pump fully about them. Because by the time the pump may upstroke to react, the pressure loading at the cylinder may have gone away. We can end up into an osculation cycle where this is some unevenness in cylinder speed produced by the slow feedback that occurs as a pressure shockwave travels through the load sense signal line.

Quite often, there’s a load sense damping orifice, and that’s a very small opening. Again, doesn’t take much contaminants in there to now cause a slowdown at actuators when the work becomes harder. In other words, higher pressure.

Again with contaminated particle, contaminated fluid, a plugged bleed down orifice may be a problem. What’s the bleed down orifice? Well, all load sense systems typically have this. It’s either in the pump’s compensator, or if it’s not there, if you don’t find it in the pump’s compensator, the bleed down orifice might be in the load sense valve bank itself. Basically, why it has to be there is when you let go of the valve handles, when we say, ‘Hey, we don’t need our hydraulic cylinders or hydraulic motors to move for a period of time, that’s the time to really save input energy and allow the pump to idle down to that low standby pressure.’ If that bleed down orifice becomes plugged, then the pump’s outlet pressure may not drop down to that low standby pressure. We’ll be wasting input energy and building up unnecessary heat. …

Yes, the contaminated … again with particle contaminants, we have one example from this model of valve bank sitting in our shop where another component coming apart in the system had shed some aluminum particles. It caused the pressure compensator to become completely stuck and jammed in place. What happens in this case, if the pressure compensator can’t move, is that we’ll often see a speed up or slow down at the lower pressure actuators on the valve bank when the heavier loaded valve sections experience their pressure changes.

That’s an example or a fairly brief tour through what is a load sense system, and how does it function, and some of the trouble shooting issues that you might bump into. Again, many of the images you saw in here are simulations from our LunchboxSessions.com, where you can interact with them fully.

MS:Okay, thanks, Carl. Yeah, so we’re going to move on to some questions. The first we have coming in for you, Carl, is what is the most common load sense margin pressure value?

CD: Well, yeah, I’m not sure. I haven’t seen all of the load sense machines out there in the world that there are to see. There are some machines that are set fairly tight, may even have a steel load sense signal line on them. We’ve seen the odd one or two where the load sense value is down as low as 150 PSI or 200. In that type of machine, there’s an expectation that there really won’t be any shock loading at the cylinders, bumped into some machines set quite a bit higher. A lot of machine designers seem to sort of hone in around the 300 to 350 PSI range, seems to work out well in terms of being able to deliver consistent flow rates through most proportional valve banks. If I’m asked to say what I’ve seen from my experience about 300 to 350 PSI is the most common.

CD: Yeah, right. Sure, on many machines, the load sense signal line could be a dash six, a three-eighths, or even a dash four, or a quarter inch load sense signal line. Keep in mind that if that load sense damping orifice is in there, you will have seen it in the 3D video there just where the load sense line left the multi-section valving. That orifice is quite a bit smaller yet. It could be an O-6-0 or down to O-3-0. Considerably smaller yet.

The physical size of the load sense line, in many respects, is actually quite large. Keep in mind that the load sense line is really not carrying any noticeable amount of flow. Yes, there is flow through the bleed down orifice when the valve handles are in neutral. There is a continuous flow, but it’s very, very small. The load sense signal line is really there just to transmit a pressure value, which can move as a shock wave through the fluid, whether it’s flowing or not.

In some regards, the load sense line is actually quite large. The only time where I hear people running into any significant problems is where the load sense line might be 100 [inaudible 00:42:27] or longer on some oil field drilling machinery, and when it’s operating in arctic conditions, that can be a problem.

MS: Okay, so here’s a question that I’ve actually had myself, because I hear both terms used. Is there a difference between margin pressure and standby pressure?

CD: In most cases, the answer to that is no. Certainly, the answer is no in terms of load sense system ideals. But there is the odd machine that we bump into where all of a sudden, there is a difference where the margin pressure may be referring to the setting of that softer spring, perhaps let’s say 300 PSI, that softer spring and the compensator. Due to the way the machine works when it’s running, or perhaps when the engine is at high idol, the machine manufacturer may have allowed for a signal higher than zero PSI to be transmitted back to the load sense compensator on the pump.

They may be allowing for a 50 or a 100 PSI signal to keep the system in a higher state of readiness for the valves when they open. In that case, we’ll see that the standby pressure, which you might measure on the pump’s outlet at that moment, might actually be 50 or 100 PSI higher than the margin pressure you set earlier, which was just the spring setting itself.

MS: Okay, Carl. I have another question I want to throw at you. It looks like somebody has asked is there a difference between post and pre-compensated valves?

CD: Oh yeah, okay. The pressure compensators in the valve banks themselves, I think is what’s being asked here. Yes, there is a bit of difference. There have been other webinars on that. We followed some other valve bank manufacturers. We’re not the designers or manufacturers of any valve banks, but yes, we do notice that some mobile machinery manufacturers choose to go with the pressure compensators directly on the A and B work ports as we’re traveling out to the hydraulic cylinders, as opposed to our example where the pressure compensator was coming in before the P port on the spool.

If I understand correctly and if my memory serves, I believe that in many cases, you get a more accurate … and faster acting compensation for extremes of changes in pressure loading at the cylinders when the pressure compensators are post spools. I think there’s a couple of arguments, couple of schools of thought there, and different valve bank manufacturers argue for the benefits of one versus the other.

MS: Okay, Carl. Well, that was fantastic. Thank you so much, a great webinar. I think everybody got a lot of great content. I just wanted to remind everybody on the webinar right now that if you do have any additional questions, you can refer them to the speaker bio box containing contact information for either Carl or myself; Just contact us.

According to the application such as construction machinery and various industrial vehicles and its hydraulic control system, Kawasaki offers the most suitable axial piston pump from the wide range of variations.

Kawasaki offers high efficinecy and low noise axial piston pumps suitable for variable-speed control system. The built-in large capacity suction valve enable easy configuration of the closed circuit for various systems.

Kawasaki"s bent axis type axial piston pumps have features such as high efficniency and long life. They can operate for long periods of time under severe conditions: high-pressure continuous drive, use of fire resistant fluid, etc.

Kawasaki screw pumps have been manufactured since 1936 and they are now being supplied to meet the growing demand in all industrial fields. Kawasaki screw pumps are employed for a great diversity of purposes including conveyance of heavy oils, lube oil service, pressure delivery as well as for hydraulic applications.

The Kawasaki Precision Gear Pumps are produced with the enhanced manufacturing accuracy to improve performance of the external-contact type gear pumps, which have small pulsations and good volumertic characteristics. Those pumps were originally developed for pumping and metering of polymer to the spinnerette in the production of chemical fibers, and have prevailed in many other applications.

Pressure compensation systems operate a little like feedback-based electronic systems. That’s not exactly a surprise, not when hydraulics circuits can become every bit as complex as any electronically based wiring. At any rate, the similarities are there for everyone to observe. When an output change occurs, a fraction of that change is sent back to govern the control unit, be it a preamplifier or a hydraulic actuator.

Sticking with fluid-based systems, as a load pressure varies, a fractional amount of that energy is dispatched back to the flow controlling mechanism to perform its pressure compensation duties. That’s how post-compensation hydraulics systems work. Of course, to realize this design, a load sensing pump or actuator must accept a feedback sensing line. For example, sticking with pump architectures for a moment, a piston pump would receive the feedback pressure. From here, the line would connect directly to the pump swash plate. As the equipment load varied, that signal would make the swash pate perform its pressure compensating assignment. Again, this is how post-compensation systems operate. Having become outmoded over time, pre-compensation technology has long since taken over.

Known also as “flow sharing,” post-compensation configurations have limitations. Basically, there are some disadvantages to having a fixed ratio pressure drop. Equipment responsiveness is also sometimes limited when controlled by load sensing lines and springs. Instead of the LS spring, pre-compensation devices adopt the following principle. With a different architecture, this pressure compensation circuit measures a load-generated pressure differential over individual valve spools or orifices. Sure, there’s less chance of a flow sharing issue when individual valve orifices are monitored in this way, but now each of those monitored valves is “blind” to the functions of its neighbours. No matter, when or if a system pump becomes load saturated, the pressure compensation mechanism will responsively access more pump power, perhaps by adjusting the pump swash plate, or perhaps by adjusting a pilot signal on some other hydraulic pump type.

There are two principal forms of pressure compensation. If a heavy load threatens to swamp the system pump, load sensing feedback lines and springs adjust pump performance. That’s how a post-compensation circuit operates. For pre-compensation systems, the compensator monitors pressure differentials across each valve orifice. Fortunately, new waves of advanced mobile hydraulics devices are now adding pressure compensation options, which include porting controls for pre or post-compensation controls. That leaves the designer free to weigh the pros and cons of both solutions. For one thing, does a designer really want to introduce flow sharing? If not, turn instead to pre-compensation configured load controls.

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system.

Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of Pascal"s law.

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or displacement of gear pumps for hydraulics will be between about 1 to 200 milliliters. They have the lowest volumetric efficiency (η

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. A critical element in vane pump design is how the vanes are pushed into contact with the pump housing, and how the vane tips are machined at this very point. Several type of "lip" designs are used, and the main objective is to provide a tight seal between the inside of the housing and the vane, and at the same time to minimize wear and metal-to-metal contact. Forcing the vane out of the rotating centre and towards the pump housing is accomplished using spring-loaded vanes, or more traditionally, vanes loaded hydrodynamically (via the pressurized system fluid).

Screw pumps (fixed displacement) consist of two Archimedes" screws that intermesh and are enclosed within the same chamber. These pumps are used for high flows at relatively low pressure (max 100 bars (10,000 kPa)).ball valves

The major problem of screw pumps is that the hydraulic reaction force is transmitted in a direction that"s axially opposed to the direction of the flow.

Bent axis pumps, axial piston pumps and motors using the bent axis principle, fixed or adjustable displacement, exists in two different basic designs. The Thoma-principle (engineer Hans Thoma, Germany, patent 1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the piston rod, piston rings, and maximum 40 degrees between the driveshaft centerline and pistons (Volvo Hydraulics Co.). These have the best efficiency of all pumps. Although in general, the largest displacements are approximately one litre per revolution, if necessary a two-liter swept volume pump can be built. Often variable-displacement pumps are used so that the oil flow can be adjusted carefully. These pumps can in general work with a working pressure of up to 350–420 bars in continuous work.

By using different compensation techniques, the variable displacement type of these pumps can continuously alter fluid discharge per revolution and system pressure based on load requirements, maximum pressure cut-off settings, horsepower/ratio control, and even fully electro proportional systems, requiring no other input than electrical signals. This makes them potentially hugely power saving compared to other constant flow pumps in systems where prime mover/diesel/electric motor rotational speed is constant and required fluid flow is non-constant.

A radial piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft, in contrast to the axial piston pump.

Open vs. closed center hydraulic systems can be complex to understand. So let us explain the main differences between the two systems and the pros/ cons of application use.

In open center hydraulic systems oil flows through entire system continuously . A solenoid directs flow in the component to either operate the component (ex.- compressor or crane), or to bypass the component without operating it.

In closed center hydraulic system’s the main pump is pressure compensated, which means that the flow is directed to components only when needed. When a component is not in use, the system pressure flow does not flow through the component.

The most noticeable difference in open and closed center hydraulic systems will be the addition of a “load sense line” connection on the closed center version. This connection will send a hydraulic signal back to the pressure compensated pump when the compressor is needed.

Vanair® offers both open and closed center versions of all Reliant™ Air Compressors. Reliant compressors are hydraulically driven and offer 30 to 185 CFM of air power, these reciprocating and rotary screw machines outperform the competition by offering a wider range of air power. Ideal for a variety of heavy-duty markets, these vehicle-mounted designs carry many built-in features, including cold weather packages and integrated hydraulic/compressor oil coolers.

In conclusion, for 50 years Vanair® has been trusted to provide Mobile Power Solutions® where you need it, when you need it, and how you need it. The industry demands higher dependability, greater durability, and lower lifecycle cost, and we work tirelessly to get it right. Vanair leverages its engineering expertise to design and build best-in-class product offerings to meet a variety of application and market needs. We are continually driven to evaluate new technologies and develop new products, services, and processes. Give us a call at 1-800-526-8817, we’re here to help.

8613371530291

8613371530291