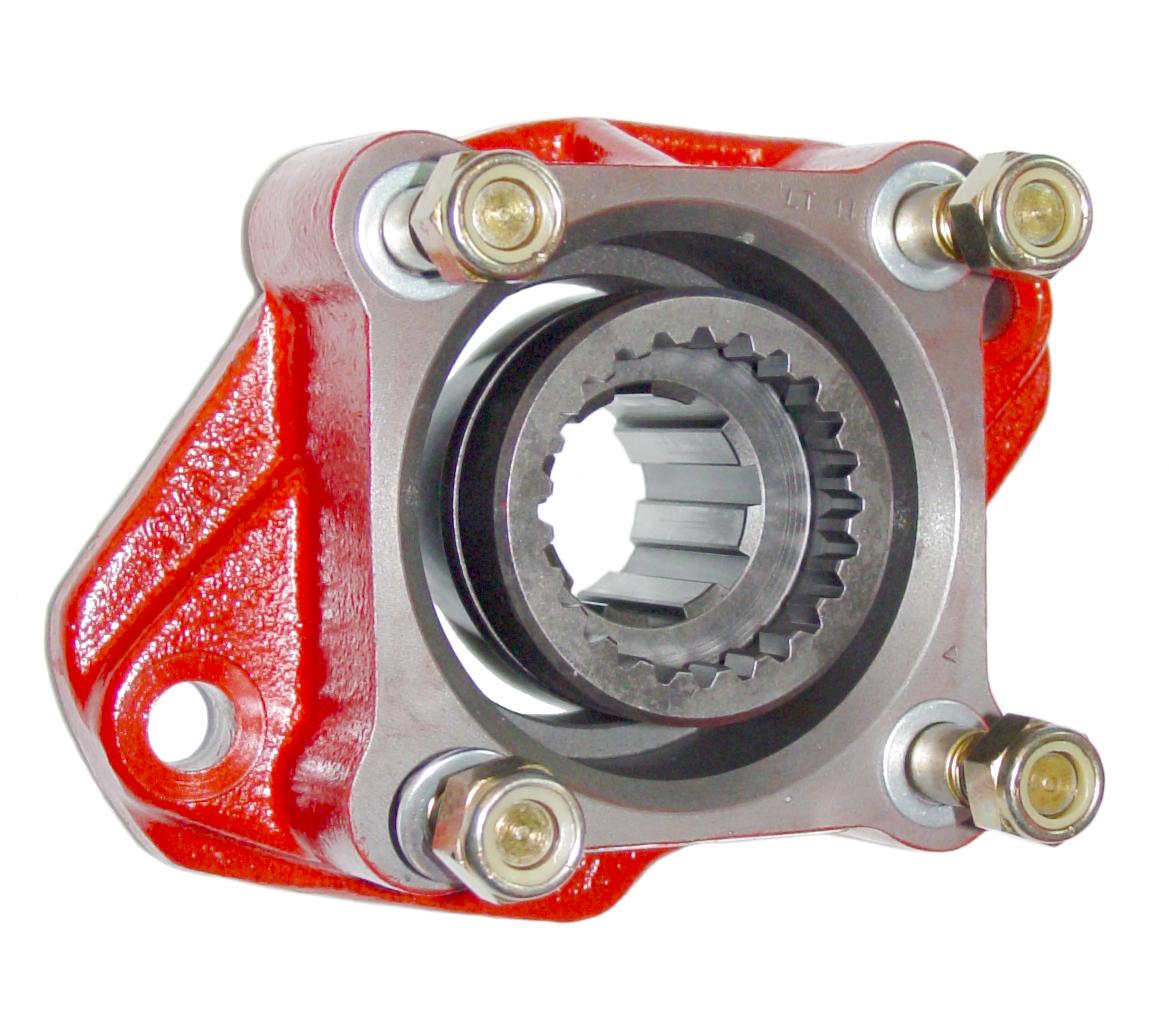

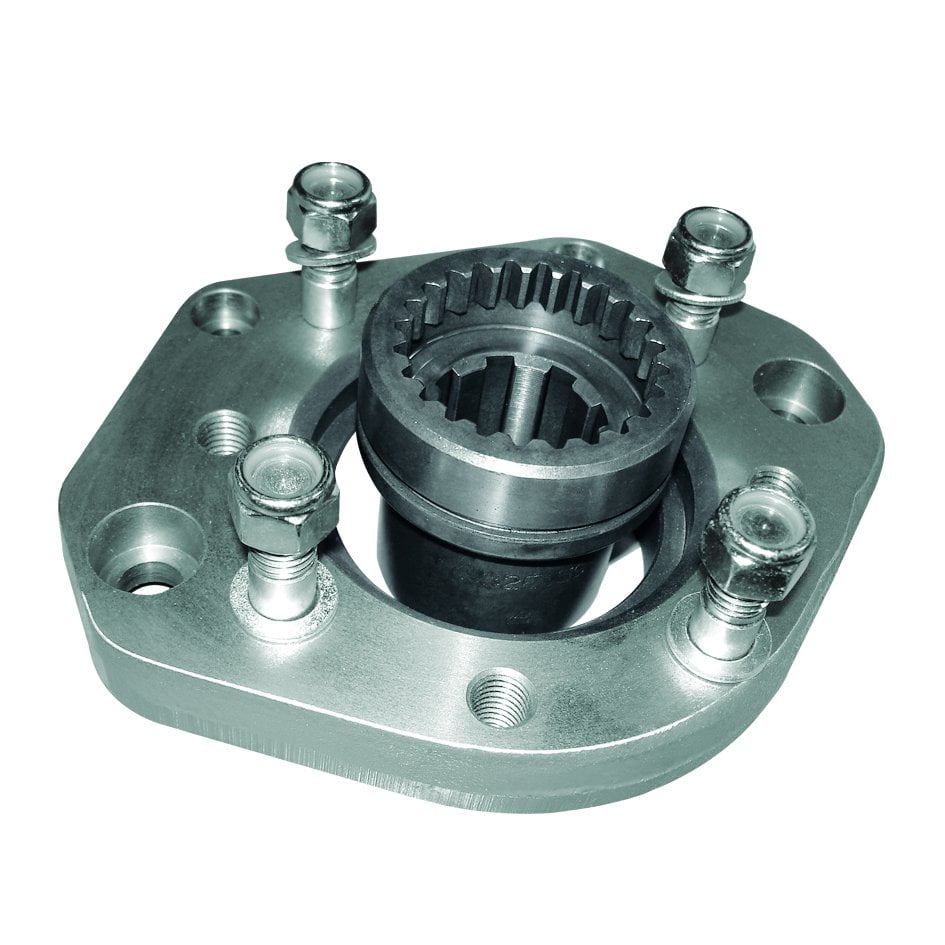

pto hydraulic pump adapter factory

In an industrial capacity, the need for heavy-duty components that can handle transmitting the power required for machinery to operate translates into one specific part: the power take-off. The Power Take-Off (PTO) is an essential element that transfers an engine’s power to another mechanical device. However, there isn’t just a single type of engine driven PTO, and each unit is uniquely suited for various, specific industrial applications.

Parker Chelsea is a market leader in Power Take-Off products for the truck and mobile vocational markets. Our PTOs are designed with a wide range of internal speeds, torque capacities and output options to match up with virtually all driven equipment requirements. We offer a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, countershaft, split-shaft and front engine mount applications. Features include mechanical shift, powershift, constant engaged shift options, overspeed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators. Bottom line is if you need a reliable and rugged performer, think Parker Chelsea.

PRINCE PTO HYDRAULIC PUMPS Up to 40 gallons per minute and up to 2250 psi UNIQUE FEATURES: PLUS STANDARD FEATURES: • Self-adjusting wear plates on both sides of the gears. • Proper size hose adapters are provided for inlet ports. • Two outlet ports are provided with a NPT adapter for one port and a plug to seal unused port. • Center section available in high strength aluminum alloy for std. duty cycle or in high strength cast iron for high duty cycle use. • Tractor front end loaders • Pull-type cotton pickers • Cotton balers (module builders) • Reliable • Efficient • Roller Bearings • Run fitted body • Internally splined drive shaft. • High-tensile cast iron end plates. • Slips onto tractor PTO shaft (no gear box required). • Two-bolt installation on farm tractors of all sizes. • Tractors imported without integral hydraulics • Landscape equipment • Rotary mowers • Street Sweepers • Back hoes MODEL FEATURES ALUMINUM CENTER HOUSING • Standard duty cycle • Reduced weight • Smaller housing CAST IRON CENTER HOUSING • High duty cycle • Use in circuits with motors • Better at higher temperatures • Increased wear resistance REAR PORTED • Higher flows • Simplified hose connections • Higher flows at reduced engine rpm as compared to other PTO pumps Prince PTO pumps are specifically designed for PTO drive operation on all sizes of farm tractors. No additional gear box is required. Pumps are mounted by sliding the internally splined pump onto the PTO splined shaft and restraining rotation with a torque arm. See page P6 for the PTO pump torque arm kit. • FILTRATION The pump must be used in a clean system with clean oil. The fluid cleanliness should meet the ISO 4406 17/14 level. As a minimum, 10 micron filtration is recommended. • HYDRAULIC FLUID A good quality mineral base hydraulic fluid with a viscosity in the 70-250 SUS range at operating temperature is recommended. • OPERATING TEMPERATURE Oil operating temperature should not exceed 180°F. If it does, the reservoir may be too small or a heat exchanger may be needed. • SHAFT SPEEDS Prince PTO pumps are designed to operate at up to 110% of standard PTO shaft speeds. Standard speeds are 540 rpm for the 6 tooth shaft and 1000 rpm for the 21 tooth shaft. CATP 3-01-20-01 • CLOSE RUNNING CLEARANCE FOR HIGH FLOW RATE Another feature that contributes to the excellent and long-lived efficiency of the PTO-Series pump is the minimum clearance between the gears and the center housing. Each pump is assembled with zero clearance between the housing and the tips of the gear teeth, then test run until the teeth establish a proper wear path in the housing. The result is a much tighter clearance than found in traditional pumps. • PRESSURE RATING Pumps are designed for 2250 PSI max. relief valve setting. A relief valve, external to the pump, must be provided in the system. • PORTS All pumps are provided with an inlet port adapter (SAE O-ring boss to hose barb) and outlet port adapter (SAE O-ring boss to female pipe thread) sized appropriately for the ports and required line sizes. A steel plug is provided for the second outlet port. • RESERVOIR As a guideline, a reservoir size in gallons should equal the pump output in gallons per minute. A larger reservoir and/or an oil cooler may be needed for high duty cycle applications. PRINCE MANUFACTURING CORPORATION/WORLD HEADQUARTERS • NORTH SIOUX CITY, SOUTH DAKOTA 57049 URL: www.princehyd.com • E-MAIL: prince@princehyd.com O.E.M. CUSTOMER SERVICE: (605) 235-1220 • FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 • FAX (712) 233-2181 • SELF ADJUSTING WEAR PLATES Prince PTO pumps have self-adjusting wear plates that seal around the two unequal size gears. T

PTO Drive is 6 Tooth DriveActual displacement: 5.7 CI/Rev, Porting location: Side, Center Section: Cast Iron, RPM: 540A feature that contributes to the excellent and long-lived efficiency of the Prince PTO pumps is the minimum clearance between the gears and the center housing. Each pump is assemblied with zero clearance between the housing and the tips of the gear teeth, then test run until the teeth establish a proper wear path in the housing. The result is a much tighter clearance than found in traditional pumps or imported pumps.

Pump Gas Engine Adapters (Bell Housings) are designed to assure proper shaft alignment between the gasoline engine and your hydraulic pump. They also reduce assembly cost over using a foot mounting bracket or riser.

8613371530291

8613371530291