what size hydraulic pump do i need for sale

High pressure can do much damage if something bursts. Bursting the pump case or hose is possible. Take this seriously and always use Personal Protective Equipment around high pressure.

The information here as far as I know correct, but it is provided with no guarantees of any kind what so ever. You need to verify your application with the supplier or other competent source.

The maximum pressure a pump is specified for varies somewhat from pump to pump but is generally in the 2500-3500 psi area. The flow per revolution varies enormously from pump to pump, so when searching for a pump, first look at the flow per revolution or GPM (gallons per minute). Higher is better.

Your car/motorcycle/kart will loose power through its drive train too. 15% loss is a good starting point, which means you can dimension the max HP lower than your actual engine HP. This is of course not true for a dyno connected directly to the engine crankshaft.

Small capacity gear pumps are very cheap. For example tractor pumps works well for a go-karts/crosskarts or other lower hp applications. You can get them from $30 and up on alibaba.com or eBay. You can also buy more expensive versions in high-end hydraulic shops.

They work well up to about 3000psi, sometimes 3500psi, have few moving parts and operate smoothly. Flow is moderate (= moderate horsepower capacity) for the cheap units.

Max RPM rating can normally be exceeded somewhat without problems for gear pumps. Efficiency will go down above the rated RPM, but we don’t care about that in dyno applications.

Here is an pump series where the highest capacity pump is rated for almost 200hp. At these power levels you will need to think about cooling, and check that the flow control valve is compatible with the generated flow and pressure.

Hydraulic vane pumps are another option. They operate with very low flow pulsation. As such, vane pumps produce less noise while maintaining a high flow and quite high pressures. They are a good choice for higher horsepower applications. They are often somewhat more expensive than gear pumps.

Piston pumps can be had with very large flow and high pressures. Piston pumps pulsate more than gear pumps or vane pumps and are for that reason not recommended.

Make sure the hose between the pump and the valve can take the pressure and flow rate too. Many online shops have what you need, for example FlowfitOnline.

Gear pumps have very few moving parts. They consist of two intermeshing gears. These pumps have a constant flow rate. They operate at pressures generally between 50 and 210 bar. Gear pumps operate at the highest speeds of any pumps at up to 3000-6000 rpm.

In an external-gear pump, only one of the gear wheels, the drive gear, is connected to the drive. The other gear wheel, the driven gear, rotates in the opposite direction, so that the teeth of the rotating gear wheels interlock.

There are also double external-gear pumps, which combine two gear pumps driven by the same coupling shaft. A double external-gear pump has the advantage of supplying two independent hydraulic circuits, and also provides more flow to one circuit.

For the people who have absolutely no idea about what these log splitters are, in simple terms, they can be called machines that chop wood using automation (or manual) power.

The primary purpose is to break these logs into pieces to aid their transport. The purpose of designing the log splitter is to simplify log splitting via automation (or manual) power.

Log splitters are phenomenal in their work, and the design aspect of log splitters is their main highlight. To achieve this automation, efficiency, and effectiveness, all these log splitters use hydraulics.

This two-stage hydraulic log splitter pump is the base of the hydraulic system. The hydraulic system is used to pressurize and create the force for splitting the wood.

This makes the log splitter pump the essential part of the log splitter. Whether you are well-versed with log splitters or have hardly heard about them, go through this article, and you will surely understand what size of log splitter pump you should use.

Log splitter pumps, as previously discussed, are a very crucial element. Thus, choosing the right kind of hydraulic log splitter pump becomes very important. The best way to go with this is by choosing the right size and quality materials for the log splitter pump. This will ensure high efficiency and effectiveness.

Before you make the decision, do analyze accordingly concerning your needs and log splitter. The size of log splitter pumps influences not only the performance but also the cost. Thus, the decision of choosing the size of hydraulic log splitter pumps depends upon three major factors:

Before deciding the size of log splitter pumps, it is essential to understand the hydraulics to determine the correct size based on the principle of log splitter pumps.

Hydraulic log splitter pumps work according to the phenomenon of hydraulics. Pascal’s law (Principle of hydraulics) governs hydraulics. It states that if you apply pressure to a particular point of a fluid (closed/confined), the pressure transmits to every other fluid point (with no losses).

Pumps convert one form of energy to another. As the name suggests, hydraulic pumps convert mechanical energy to hydraulic energy. For this conversion, hydraulic pumps use flowing water.

Using flowing water, these hydraulic pumps create a hydraulic system. This system is complicated, but in simpler terms, it provides force in a specific area, basically what we call pressure.

Two-stage hydraulic pumps are usually used as log splitter pumps. This complex system can be explained using an analogy. Consider the working of a vehicle, and it displaces itself irrespective of the heavyweight. It uses power for displacement.

This is precisely what happens in a log splitter, except that it happens at a smaller scale. Thus, the pump utilizes the conversion of the energy for running the log splitter.

Now that you know the log splitter and hydraulic pump details, we can discuss the size of the log splitter pump. Why should we be bothered about the size of the log splitter pump? The reason is that the size affects the speed and force (splitting).

Bigger the size of the log splitter pump (basically the pump cylinder’s size), the bigger the splitting force. This helps in the useful splitting of more extensive woods. But with the increase in the size of the hydraulic pump, it also requires more fluid. The requirement of more fluid decreases the speed.

This is the reason why the size of log splitter pumps becomes so essential. You can either choose the speed of splitting force. If you choose to increase one of the two-parameter, then the other one decreases.

To choose the best and correct size of your log splitter, you need to decide to improve either pump speed or splitting force. There are different size pumps available in the market according to your requirement.

Pumps available in the market are based on GPM (Gallons per minute). The higher the GPM, the smaller is the cylinder. The splitting force depends upon the cylinder. The higher the GPM, the smaller is the splitting force. To make it more transparent,

If you are interested in making a log splitter, which is possible as the calculations required for designing, parts required, and technique to make a log splitter is available. It can be employed if one shows interest in it. Only go for the DIY option if you are well-versed with machinery.

The engine of the log splitter works on the basics of hydraulics. The pump creates the driving force, and the hydraulic cylinder works in unison with the valves influencing splitting power and speed.

The engine used must be of 6-7 Horsepower. A two-stage hydraulic pump (about 3000 PSI) must be employed of 11 GPM. The standard hydraulic cylinder of 4-inch diameter and 24-inch length/height. Around 10-12-gallon capacity of the oil tank.

Note: If you want to play around with the values and choose the best according to your requirement, then use this calculator tool by international hydraulics.

Finally, it is your choice! As you know that you can either have a good speed or high splitting force, you must make your own decision with the size of log splitter pumps. You do not need to worry a lot as the size is only one aspect to look at, but the right decision about the size is always useful in usage.

The choice of DIY or buying one from the market is also your choice. If you are well-versed with calculations and machinery, then go for it as log splitters are expensive in the market.

If you know why you are employing a log splitter, it will help you make a better decision. For example, if you are one of those campers who requires a log splitter in his camps for firewood, go for the speedy ones (small cylinder size). The reason is that you would want to split wood faster instead of splitting larger pieces.

Irrespective of whether you buy a branded log splitter or DIY, they require regular maintenance and cleaning. For better results, go for the two-stage hydraulic pumps (even if they are a bit expensive).

If you follow the above tips, then the log splitter works effectively and efficiently. Taking the right decisions can help you enforce the right speed and optimum splitting force required for your log splitting.

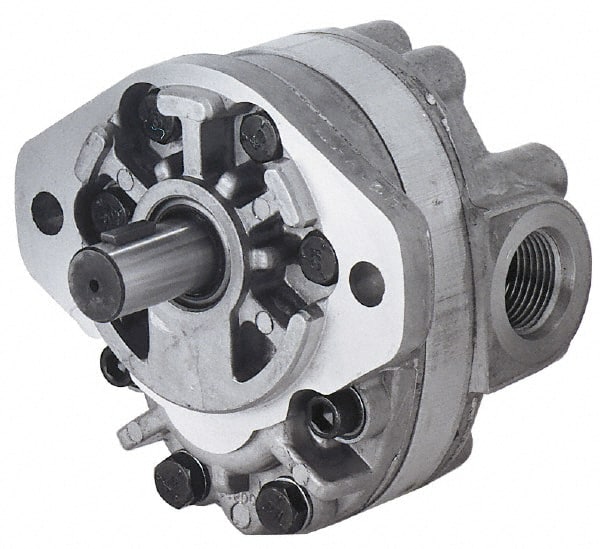

The goal of a hydraulic pump is to move hydraulic fluid through a hydraulic system, acting much like the beating heart of the system. There are two things that all hydraulic pumps have in common: (1) they provide hydraulic flow to other components (e.g., rams, hydraulic motors, cylinder) within a hydraulic system, and (2) they produce flow which in turn generates pressure when there is a resistance to flow. In addition, most hydraulic pumps are motor-driven and include a pressure relief valve as a type of overpressure protection. The three most common types of hydraulic pumps currently in use are gear, piston, and vane pumps.

In a gear pump, hydraulic fluid is trapped between the body of the pump and the areas between the teeth of the pump’s two meshing gears. The driveshaft is used to power one gear while the other remains idle until it meshes with the driving gear. These pumps are what is known as fixed displacement or positive displacement because each rotation of the shaft displaces the same amount of hydraulic fluid at the same pressure. There are two basic types of gear pumps, external and internal, which will be discussed in a moment.

Gear pumps are compact, making them ideal for applications that involve limited space. They are also simple in design, making them easier to repair and maintain. Note that gear pumps usually exhibit the highest efficiency when running at their maximum speed. In general, external gear pumps can produce higher levels of pressure (up to 3,000 psi) and greater throughput than vane pumps.

External gear pumps are often found in close-coupled designs where the gear pump and the hydraulic motor share the same mounting and the same shaft. In an external gear pump, fluid flow occurs around the outside of a pair of meshed external spur gears. The hydraulic fluid moves between the housing of the pump and the gears to create the alternating suction and discharge needed for fluid flow.

External gear pumps can provide very high pressures (up to 3,000 psi), operate at high speeds (3,000 rpm), and run more quietly than internal gear pumps. When gear pumps are designed to handle even higher pressures and speeds, however, they will be very noisy and there may be special precautions that must be made.

External gear pumps are often used in powerlifting applications, as well as areas where electrical equipment would be either too bulky, inconvenient, or costly. External gear pumps can also be found on some agricultural and construction equipment to power their hydraulic systems.

In an internal gear pump, the meshing action of external and internal gears works with a crescent-shaped sector element to generate fluid flow. The outer gear has teeth pointing inwards and the inner gear has teeth pointing outward. As these gears rotate and come in and out of mesh, they create suction and discharge zones with the sector acting as a barrier between these zones. A gerotor is a special type of internal gear pump that eliminates the need for a sector element by using trochoidal gears to create suction and discharge zones.

Unlike external gear pumps, internal gear pumps are not meant for high-pressure applications; however, they do generate flow with very little pulsation present. They are not as widely used in hydraulics as external gear pumps; however, they are used with lube oils and fuel oils and work well for metering applications.

In a piston pump, reciprocating pistons are used to alternately generate suction and discharge. There are two different ways to categorize piston pumps: whether their piston is axially or radially mounted and whether their displacement is fixed or variable.

Piston pumps can handle higher pressures than gear or vane pumps even with comparable displacements, but they tend to be more expensive in terms of the initial cost. They are also more sensitive to contamination, but following strict hydraulic cleanliness guidelines and filtering any hydraulic fluid added to the system can address most contamination issues.

In an axial piston pump, sometimes called an inline axial pump, the pistons are aligned with the axis of the pump and arranged within a circular cylinder block. On one side of the cylinder block are the inlet and outlet ports, while an angled swashplate lies on the other side. As the cylinder block rotates, the pistons move in and out of the cylinder block, thus creating alternating suction and discharge of hydraulic fluid.

Axial piston pumps are ideal for high-pressure, high-volume applications and can often be found powering mission-critical hydraulic systems such as those of jet aircraft.

In a bent-axis piston pump (which many consider a subtype of the axial piston pump), the pump is made up of two sides that meet at an angle. On one side, the drive shaft turns the cylinder block that contains the pistons which match up to bores on the other side of the pump. As the cylinder block rotates, the distances between the pistons and the valving surface vary, thus achieving the necessary suction and discharge.

In a radial piston pump, the pistons lie perpendicular to the axis of the pump and are arranged radially like spokes on a wheel around an eccentrically placed cam. When the drive shaft rotates, the cam moves and pushes the spring-loaded pistons inward as it passes them. Each of these pistons has its own inlet and outlet ports that lead to a chamber. Within this chamber are valves that control the release and intake of hydraulic fluid.

In a fixed displacement pump, the amount of fluid discharged in each reciprocation is the same volume. However, in a variable displacement pump, a change to the angle of the adjustable swashplate can increase or reduce the volume of fluid discharged. This design allows you to vary system speed without having to change engine speed.

When the input shaft of a vane pump rotates, rigid vanes mounted on an eccentric rotor pick up hydraulic fluid and transport it to the outlet of the pump. The area between the vanes increases on the inlet side as hydraulic fluid is drawn inside the pump and decreases on the outlet side to expel the hydraulic fluid through the output port. Vane pumps can be either fixed or variable displacement, as discussed for piston pumps.

Vane pumps are used in utility vehicles (such as those with aerial ladders or buckets) but are not as common today, having been replaced by gear pumps. This does not mean, however, that they are not still in use. They are not designed to handle high pressures but they can generate a good vacuum and even run dry for short periods of time.

There are other key aspects to choosing the right hydraulic pump that goes beyond deciding what type is best adapted to your application. These pump characteristics include the following:

Selecting a pump can be very challenging, but a good place to start is looking at the type of pump that you need. Vane pumps have been largely replaced by compact, durable gear pumps, with external gear pumps working best for high pressure and operating speeds while internal gear pumps are able to generate flow with very little pulsation. However, vane pumps are still good for creating an effective vacuum and can run even when dry for short periods of time. Piston pumps in general are more powerful but, at the same time, more susceptible to contamination.

Whether the pump is needed for the rugged world of mining, the sterile world of food and beverage processing, or the mission-critical aerospace industry, MAC Hydraulics can assist you with selecting, installing, maintaining, and repairing the right pump to meet the needs of your hydraulic system. In the event of a breakdown, our highly skilled technicians can troubleshoot and repair your pump — no matter who the manufacturer happens to be. We also offer on-site services that include common repairs, preventative maintenance, lubrication, cleaning, pressure testing, and setting.

Star Hydraulics & Pneumatics, LLC. builds three types of manually operated pumps - single piston pumps, two-speed pumps, and double-acting pumps. Pumps with 4-way valves are also offered. Your application determines which type of pump to select. At Star Hydraulics, LLC our pumps are robust, solidly built by combining established designs with some of the latest equipment meticulous workmanship and high quality standards. In fact, one of our customers was kind enough to return a pump to us after being used for more than 40 years and it looks like it was almost new.

If there is initially little or no resistance, but high force is needed later, use the two-speed dual piston pump. An example of this would be a press in which a cylinder advances until it contacts a load and then applies a much greater bending or cutting force. The dual piston pump supplies high volume, low pressure flow until the increased force is needed, at which time it automatically switches to high pressure, lower volume.

Light hydraulic oil is recommended for use with Star Hydraulics, LLC pumps. Oils with SUS viscosity of 75 to 150 at 100°F will give satisfactory performance (ISO grade 15, 22, or 32). In an emergency situation when above oils are not available, use 5w or 10w motor oil or automatic transmission fluid. Unless there is a specific need to do so, Star pumps are shipped without oil.

A Star pump is well-made and robust. It is expected to work in tough environments. Because of that exposed surfaces of standard pumps are painted with industrial quality paint. Pumps painted with special colors with two coat finishes, or with prime coat only, and pumps with special plated or polished parts are also available.

In order to provide for continuing product improvement, Star Hydraulics,LLC may make design changes that affect the data provided on this web site. Contact the factory for the most current specifications.

It is important to keep the pump clean and well-maintained and follow operating guidelines for best operation and longevity. It is best to keep the pump clean and keep foreign materials away from the piston area so that the surface does not get damaged. Use the proper oil and do not let the reservoir run dry. Do not exceed the pressure ratings on pumps that do not have an overload relief valve and take care when adjusting or re-setting pumps that have an overload valve.

If you find that you need to replace the seals on a pump, Star provides repair/replacement kits for each pump along with service instructions on how to replace the seals. If you find that you need assistance during this process, please call us.

Star Hydraulics also provides a repair and rebuilding service for all of our pumps. Just call our customer service to get the return information to send the pump(s) back to our factory.

In addition to the standard pumps that are shown in this catalog, Star will also customize our pumps to meet your requirements. Some general types of customization are:

Star works closely with distributors of our hydraulic products and can put you in touch with a distributor in your area to purchase the accessories necessary to set-up your hydraulic system. If you have special requests, we will be happy to assist you with these accessories.CALCULATING PUMP PRESSURE AND RESERVOIR VOLUME

Sudenga Industries is a leading manufacturer of durable ag equipment for grain, feed and seed handling applications. Products can be found in farm and commercial agriculture installations as well as industrial material handling applications worldwide. Sudenga was founded in 1888 in the northwest corner of Iowa where it is still located today.

Log splitters are designed with a simple process in mind: to split logs efficiently. To do so, almost all use a hydraulic system to pressurize the driving force of the splitting wedge. When you purchase a log splitter, you don’t have to worry much about the individual parts other than for basic maintenance needs and cleaning purposes.

But if you are interested in building your own log splitter, which is a very realistic option due to the simplicity of the machinery, then you do need to know what parts are best for effective splitting power. Gas and electric splitters utilize a hydraulic pump which is the integral component of hydraulic power. If you were wondering what size hydraulic pump for a log splitter you need, this article explains below its use and what to look for.

Log splitters are powerful machines that provide a splitting pressure to logs of various sizes. Almost all splitters use hydraulics whether it is pressurized via an electric, gas, or manual power source. These hydraulics feed a splitting wedge of your model of choice to make short work of just about any size log you you need to cut down to size.

One of the simplest hydraulic systems you can find in use is a log splitter. The basics of hydraulic pressure utilize an engine, oil pump to create oil pressure, a hydraulic cylinder that works with a valve for splitting power, and tank to hold and feed oil through the system.

If you are serious about making your own backyard log splitter, then you want to have, at a minimum, the following components to provide the right amount of force and power for basic splitting of averaged sized, seasoned logs:

But you may want a bit more force for heavier workloads, which is why I’ve explained below how a pump can help determine your splitter’s speed, and influence the cutting force. Read more about how a log splitter works, how to care for it, and what you need to build your own.

Mentioned multiple times above is the use of a two-stage pump that is most common for a hydraulic log splitter system. This is because it uses two different sets of gears doing the pumping to keep you machine running smoothly and providing the power you need at the speed you desire.

Although a two-stage pump is the best option for your log splitter, you can manipulate the amount of force it exerts through which size cylinder you choose. To calculate your own splitter’s force and speed based on the choices you make, you can use this handy calculator tool.

The entire splitting system is dependent upon the pump that consists of two pumping sections and an internal pressure sensing valve. One of these sections generates the maximum flow rate rated at at lower pressure that is used to draw the piston back for the system to reset after splitting. The other section provides the highest possible pressure to generate maximum splitting force.

Knowing the maximum pressure generated by a pump determines the splitting powerof the pump, and one thing you will notice is that most companies are fairly generous in their tonnage claims and round up more often than not. To figure the tonnage provided by the splitter, simply multiple the maximum pressure of the pump (a two-stage pump applies about 3,000 PSI), by the total surface area of the piston in square inches. The resulting number is the total available pressure.

You also can determine the cycle time of a piston to figure how quickly you can work through a pile of logs. To move a 4 inch piston 24 inches (the common piston length) you need 301 cubic inches of oil. Since a gallon of hydraulic fluid takes up 231 cubic inches, you need to pump, at a minimum, 1.5 gallons of fluid to push the piston in one direction.

The flow rate of the pump is dependent on the size of the engine powering the system. If your engine is capable of providing an 11 gallon per minute rate, then it will take approximately 20 to 30 seconds to cut, and around 10 seconds to reset. Common horsepower minimum requirements for a two-stage pump are:

For a dependable machine, you want to incorporate a two-stage pump to work with whatever size engine and cylinder you decide upon for cutting wood. These keep your splitter working smoothing and efficiently, and allow you to dictate speed and force to handle whatever size job you have in mind. If you have any further questions, or want to add to this information, please do so below. And, as always, please share.

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/07/2023 04:56 AM UTC

Knowing how to right-size an electric motor for your hydraulic pump can help reduce energy consumption and increase operational efficiency. The key is to ensure the pump motor is operating at peak continuous load. But how can you know how much power is needed?

Before you can choose the correct electric motor, you must know how much horsepower (Hp) is required to drive the pump shaft. Generally, this is calculated by multiplying the flow capacity in gallons per minute (GPM) by the pressure in pounds per square inch (PSI). You then divide the resulting number by 1714 times the efficiency of the pump, for a formula that looks like this:

If you’re not sure how efficient your hydraulic pump is, it is advisable to use a common efficiency of about 85% (Multiplying 1714 x 0.85 = 1460 or 1500 if you round up). This work-around simplifies the formula to:

The above formula works in most applications with one notable exception: If the operating pressure of a pump is very low, the overall efficiency will be much lower than 85%. That’s because overall efficiency is equal to mechanical efficiency (internal mechanical friction) plus volumetric efficiency.

Internal friction is generally a fixed value, but volumetric efficiency changes depending on the pressure used. Low-pressure pumps have high volumetric efficiency because they are less susceptible to internal leakage. However, as the pressure goes up and internal fluids pass over work surfaces such as pistons, port plates, and lubrication points, the volumetric efficiency goes down and the amount of torque required to turn the pump for developing pressure goes up.

This variance makes it very important to know the efficiency of your pump if you’re using it at low pressure! Calculations that do not take low pressure into account will lead to a failed design.

If you calculate 20 GPM @ 300 PSI with an assumed overall efficiency of 89%, you would probably select a 5 Hp electric motor. However, if you calculate the same 20 GPM @ 300 PSI with the actual overall efficiency of 50%, you would know that you should be using a 7.5 Hp motor. In this example, making an assumption about the efficiency of your pump could result in installing a motor that is too large, driving up your overall operating cost.

There are many contributors to the overall efficiency of a hydraulic pump, and it pays to be as accurate as possible when choosing a motor. A best practice for proper sizing is to use published data from the pump vendor that shows actual input torque vs. pressure or overall efficiency vs pressure. Note that efficiency is also affected by RPM.

Identifying a right-sized motor for your hydraulic pump does not always ensure you are using the most efficient motor. Be sure to read Part 2 of this post to learn how RMS loading and Hp limiting can help you scale down the size of your electric motor to save money while maximizing efficiency.

Determining the right sized cylinder when performing a lift is critical. Whether it is a piece of equipment you need to lift or some other heavy load, if you choose a cylinder that is too small, you will not be able to lift the load and could cause a safety hazard. At a minimum, you may be headed back to the shop to get a bigger cylinder, wasting valuable time. Choosing a hydraulic cylinder should not be a guessing game, and it saves time and money if you calculate the size you need before you start your job. Figure out the load capacity of your cylinder before you start your lift attempt, and you’ll be successful every time. A simple calculation ensures that your hydraulic lift can tackle your lifting challenge, and it elevates the safety surrounding the lift. It’s a win-win situation, and the time spent calculating the size of a hydraulic cylinder needed to lift effectively will save you time and help you to get your job finished as efficiently as possible.

Step 1: Find out how much you are lifting. You need to know the approximate weight of the item you are lifting. The more accurate, the better. If you are estimating weight, overestimate! You don’t want the lift to be a failure. You also don’t want to just barely meet the load capacity of the cylinder, as any unexpected change or shift could cause the cylinder to stall in the middle of its cycle. Figuring out how much you are lifting is crucial in deciding which hydraulic cylinder to use.

Step 2: Know your available pressure. The hydraulic pressure from your pump must be sufficient to provide enough pressure to act on the cylinder and lift the required load. The size of your cylinder won’t matter if you aren’t able to supply enough pressure. At PowerX International, we specialize in 10,000 psi (700 BAR) hand pumps, air/hydraulic pumps and electric pumps. Therefore, the following examples will be based on 10,000 psi.

Step 3: Find out how many “points” you are going to lift the load. Some lifts are a simple one-point lift, but sometimes it is not feasible to balance a load with only one point, thus requiring two or more points. Once you know the amount of lift points and the total load you are going to lift. You can calculate the size of the cylinder(s) needed by dividing the total load by the amount of points. For example, a 100 ton load with one lift point would need at least a 100 ton cylinder while that same load with four lift points would require four 25 ton cylinders.

Step 4: Always have a safety factor. Most loads are never exactly what they appear to be and to be safe, you would never want to be right at the limit of the cylinder’s capacity. Because of this, it is recommended that at a minimum you use a cylinder that is 125% of the load capacity needed. And, if possible, you should have a cylinder (or cylinders) that can handle a load 1.5 times to 2 times larger than the load you are trying to lift.

Customer needs to lift a 5” concrete block with a weight of 160,000 lbs. Load shape is a rectangle 10’ x 20’ where force needs to be applied to each corner.

Lastly, it is important to keep your hydraulic cylinders clean and well-maintained. One common reason for hydraulic cylinder failure is that the seals become dry, dirty, and damaged. Make sure you are inspecting your cylinders prior to use, so you don’t end up with a non-working hydraulic cylinder when it comes time to lift.

There’s an old adage in carpentry that says, “Measure twice, cut once.” A similar notion can be applied to choosing the right size of cylinder for any lifting job. If you have been using hydraulic cylinders for many years and have repeat jobs that make you sure the cylinder will work, that’s great. However, when you are dealing with heavy loads, time and money is lost if you are off the mark. It is a better practice to measure and calculate the size of the cylinder needed. This way, you won’t have to go back for different cylinders if yours isn’t big enough. Plus, your lift won’t fail midway through the job.

Another way to determine the right sized hydraulic cylinder for your lift is to view or download our catalog. You can also call us and one of our knowledgeable representatives will help you find the right PowerX hydraulic cylinder for your application.

PowerX International has the expertise to help you with your lift requirements and the high quality hydraulic cylinders, hydraulic pumps and hydraulic systems to get the job done. Contact PowerX at +1.414.988.6202 for all your high pressure hydraulic needs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We provide a variety of high-quality single and double-acting 12V hydraulic pumps. Choose from a selection of poly or steel reservoir sizing options. Our pumps are ideal for application with Dump Trailers and more. Browse our shop today and find the right hydraulic pump for your hydraulic circuit needs!

Whether gear, vane, or piston pump, there may come a time when you have to replace your hydraulic pump. When your equipment isn’t working properly and you have narrowed the problem down to a hydraulic pump that needs to be replaced, what do you need to know?

The pump may simply be worn out—they do have a natural lifespan, as they are a wearable item in a hydraulic system. Although it is not possible to give an average lifespan given the different types of pumps and widely varying hours of operation; in general, you can expect many years of good operation from a hydraulic pump in most truck-mounted hydraulic systems. However, the life of a hydraulic pump might be much longer than what you are experiencing. Here are some questions you should ask:

Has the equipment been operating acceptably with this pump for a number of years without incident, and has the decline in performance been gradual over a longer period of time?

In this case, you’ll need to get the pump make and model number so that you can make sure that your replacement will be correct—either with an exact replacement or with another make that has the same operating specifications.

In any case, when replacing a failed hydraulic pump you will want to make sure to use this opportunity to also change out your hydraulic fluid (or at the very least use a filter cart and filter your oil). In the process of failing, your pump has introduced contaminants into your hydraulic system that you want to remove before they damage your new pump or any other hydraulic component. You will want to change your filter element(s) when you install your new pump, and then change it (them) out after a break-in period on your new pump.

If not, then let’s make sure there is not something else going on, or you may just find yourself replacing pumps frequently because the underlying problem hasn’t been addressed.

Input shaft is twisted/bcanroken: This occurs due to an extreme shock load to the pump. Typically, this happens when a relief valve is missing from the system, not functioning correctly, set to a much higher value than what the pump can withstand, or is too small for the system flow and thus cannot function correctly.

Shaft fretting:Fretting corrosion occurs under load in the presence of repeated relative surface motion, for example by vibration. Direct mount pump splines can be worn away. The solutions include:

Using larger pump and PTO shafts will not eliminate fretting, but may resolve the problem because of the increased metal available before the failure occurs.

Check to see that there is a sufficient amount of oil in the reservoir. Not just when the system is at rest, but also when all cylinders are extended to their maximum length or when all the components are running.

Make sure that the pump is able to get a good flow of oil from the reservoir—pumps are designed to have the oil feed pushed to the pump by gravity and atmospheric pressure, not by “sucking” oil. If the oil level in the reservoir is lower than the inlet of the pump, or the run too long or uphill, oil may not flow adequately to the pump. You can check if the pump is receiving oil adequately by using a vacuum gauge at the pump inlet. For a standard gear pump, at maximum operating RPM, the gauge should read a maximum of 5 inches HG. Larger numbers will damage a gear pump, and if you have a piston pump, the maximum number will be lower for good pump life.

Over pressurization: Pressure relief settings may have been adjusted or changed, and are now higher than what the pump can withstand without causing damage.

Pumps don’t produce pressure, they produce flow and are built to withstand pressure. When the system pressure exceeds the pump design, failure begins—either gradually or catastrophically.

When installing the new pump, back all the relief settings off. Then with the use of a pressure gauge T’d in at the pump outlet, gradually adjust the pressure relief setting until a cylinder or motor begins to move. Once the cylinder has reached the end of its stroke, gradually increase the pressure relief setting until reaching the max system pressure (which would be the pressure rating of the lowest rated component in the system). Sometimes, if a pump has been replaced and is larger than the original (produces more flow), the relief may not be able to allow all the flow being produced to escape back to tank. When that happens, the relief valve is “saturated” and the effect is the same as having no relief in the system. Pressures can reach levels much higher than the relief settings and components can be damaged or destroyed.

Contamination: Over time, the system oil has gotten dirty or contaminated and no longer is able to lubricate the pump, or is carrying contamination to the pump.

Make sure the oil is clean, the oil filer changed on schedule, and that there are no entry points for contamination like water, dust, or dirt from a reservoir filler cap that is unfiltered or missing, seals in motors or cylinders that are allowing contaminants in, etc.

New hoses can contain leftover bits of rubber and metal particles from the cutting and crimping process and should be cleaned out before installation.

Even new oil may be quite dirty if stored incorrectly, or exposed to dust and dirt. It’s always a good idea to use a filter cart and filter the system once it’s refilled with oil before turning on the system.

Hydraulic powered pumps for use in hydraulic drive and compatible power supply applications. The hydraulic pump uses a hydraulic motor to convert mechanical energy into pump output capacity that generates fluid flow. This is often in the form of a hydraulic oil hose and pump pressure system that is used to drive operation of the hydraulic pump. Hydraulic pumps come in centrifugal, transfer, roller and piston type pump models. They are engineered for customizable mounting and feature an individual motor and pump shaft that improves the ease of maintenance work. Pump types are designed for compatibility with a wide range of chemicals and applications. Hydraulic pumps are frequently used in commercial agriculture applications due to their improved power and performance. Hydraulic pumps are commonly used with tractors, sprayers and fluid transfer.

Available pumps are manufactured by ACE Pumps, Banjo, John Blue and Hypro brands. Banjo hydraulic pumps feature Gresen brand motors. Pump construction materials include cast iron, E-coated cast iron, aluminum, stainless steel, polypropylene, Ni-Resist and Silvercast. Pump seals are either Viton, EPDM or silicon carbide. Compatible max hydraulic flow rate for available hydraulic pumps range from 3 up to 24. The max flow capacity of hydraulic pumps ranges from 20 GPM up to 900 GPM. Maximum pressure output ranges from 58 PSI up to 300 PSI. Hydraulic pump inlet connections range from 1" up to 3" NPT, 220 up to 330 flange, and 5" ANSI flange sizes. Outlet connections range from 3/4" up to 3" NTP, 200 up to 300 flange, and 4" ANSI flange sizes. Operating parameters and specifications vary by pump model.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The inlet (suction) port is 1" NPT and the minimum suction hose inner diameter (ID) is 1-1/4". The inlet barbed fitting is not included but is available separately. Use a 1-1/4 ID Suction Hose and 3/4" ID high-pressure hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 37 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. The hydraulic fluid reservoir should have a capacity of at least 12 gallons to allow sufficient cooling. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least an 11.7hp 390cc engine to maintain 3,600 RPM under load.

An electric motor can be overloaded for short periods during the cycle provided the average horsepower is no greater than its nameplate rating plus service factor where this applies.

The amount of intermittent overloading is up to the user, but we suggest the overload be no more than 25% above its nameplate current rating sustained no longer than about 10% of the time required for a complete cycle.

Most A-C 60 Hz motors can be operated on a 50 Hz line and vice versa, but adjustments will have to be made in the current, HP, and speed ratings. The important thing to remember is that it is the current which causes heating. The HP which can be produced will be related to its current draw, and may be more or less than its nameplate rating.

*Voltage adjustment is to maintain current at rated value, to produce rated shaft torque. Current is always a limiting factor on a variation in rated Hz (frequency) or voltage.

Nameplate HP is based on full voltage being available. HP output is a combination of voltage times current. If voltage is too low, then to produce rated HP the current must be too high, and this overheats the motor. Motors can usually accommodate as low as 90% of rated voltage and still produce nameplate HP although temperature rise in the windings will be greater than rated rise. For permanent operation on a voltage source known to be low, the HP load should be limited, and reduced by the same percentage that the voltage is low.

If motor load does not exceed nameplate HP rating, full load current will be lower than nameplate rating and the motor will run cooler than rating. However, its starting and breakdown current (at stall) will be higher than normal. The wiring, fusing, and thermal overload protection will have to be sized accordingly. Motor noise will increase.

Using a 20 HP motor on a system which requires only 10 HP, for example, will give good results for running the pump but will consume more electricity than a 10 HP motor and will cause the power factor of the plant electric system to be poorer, especially during periods the motor is idling. Idling current of a 20 HP motor is about half the full load current of a 10 HP motor. This is an extra power waste during periods in the cycle when the pump is idling.

Using a 20 HP motor on a system which requires 25 HP for brief periods is quite possible, but during overload periods the current of such a motor maybe-about twice the current of a 25 HP motor. There will be an extra waste of power during peak periods in the cycle. But the smaller motor could more than make this up during periods in the cycle when less than 20 HP is required.

Applications include but are not limited to pumps & pumping equipment, oil royalty traders, oil & gas extraction and oil, gas field machinery, axial piston pumps, gear pumps, gerotor pumps, variable volume pumps and hydraulic power units.

8613371530291

8613371530291