what size hydraulic pump for log splitter manufacturer

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

If you plan to replace the hydraulic pump in your log splitter or build your log splitter, you should know the size of the hydraulic pump that fits your log splitter. Log splitters are designed to split logs efficiently.

The machine uses a hydraulic system to power the splitting wedge to split logs efficiently. The hydraulic pump is an integral component of gas and electric splitters to provide the necessary power to do the job properly.

A log splitter is a powerful machine that splits logs of various sizes using hydraulic pressure. All log splitters – whether electric, gas, or manual – use hydraulics to feed the splitting wedge to cut the logs to just about any size you prefer.

The hydraulics system found in a log splitter consists of an engine, a hydraulic cylinder, a valve, an oil pump to create oil pressure, and a tank to hold and feed oil through the system.

Since the log splitter pump is one of the most important components of the machine, choosing the right kind of hydraulic pump for your log splitting machine becomes crucial when you need to replace the pump or plan to build your own log splitter.

Hydraulic pumps work according to the theory of hydraulics. The Principle of hydraulics or Pascal’s law governs how hydraulics work. Pascal’s law states that when you apply pressure to a specific point of a closed or confined fluid, the pressure will transmit to all other fluid points without any losses.

The hydraulic pump converts mechanical energy into hydraulic energy by using flowing water. The hydraulic pump uses flowing water to create a hydraulic system.

Even though the system is quite complicated, the operation is simple. Hydraulics provide force in a specific area. This force is what we call pressure which helps the log splitter perform its job effectively.

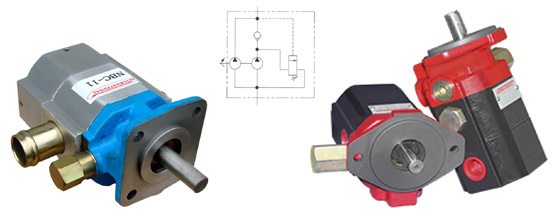

Log splitter pumps are two-stage hydraulic pumps. The entire splitting system is dependent on the pump. The pump consists of two pumping sections as well as an internal pressure sensing valve. One section of the pump helps generate the maximum flow rate at a lower pressure, and it is used to draw the piston back for the system to reset after splitting the log.

It takes very little force to draw the piston back into the cylinder after splitting the log. But, it should happen quickly. That is why you need the highest possible flow rate at low pressure.

When pushing the piston into the log, you need the highest possible pressure to generate maximum splitting force to split the logs efficiently. The flow rate is not a big issue here. Hence, the pump will switch to a high-pressure and low-volume stage to split the log.

When the size of the pump increases, it requires more fluid. But when there is more fluid in the cylinder of the pump, the speed & force of the pump decrease. That is why you need to choose the right size pump for your log splitter.

You can split logs more efficiently when opting for the correct size hydraulic pump for your log splitter. There are different sizes of hydraulic pumps in the market today. You should do your homework properly and opt for the right size pump for your log splitter.

The latest hydraulic pumps available in the market are based on GPM (Gallons per minute). The higher the GPM, the smaller the cylinder. The splitting force of the pump depends on the cylinder.

The pump that your log splitter needs will be dependent on the engine size of the machine. For example, a 5.5-6 hp engine can handle an 11 GPM 2-stage hydraulic pump, while an 8 hp or bigger engine can handle a 16 GPM 2-stage pump.

The engine of a log splitter works on hydraulics. While the pump will create the driving force, the hydraulic cylinder will work in unison with the valves, influencing splitting power and speed. If your log splitter has a 6-7 Horsepower engine, you should opt for a two-stage hydraulic pump (about 3000 PSI) with 11 GPM.

To get more speed, the pump either needs more flow (GPM) or a smaller cylinder. Smaller cylinders don’t require more power but will produce less force. More flow comes from a larger hydraulic pump. You will get the same force with a larger pump but supply more horsepower to the new hydraulic pump.

Are you planning to replace the hydraulic pump in your log splitter or build your own log splitter? If so, you should understand the basics of how a hydraulic pump works and what size pump to choose for your log splitter. To achieve automation, efficiency, and effectiveness, all log splitters rely on hydraulics.

Therefore, you should not worry too much as the size of the pump is only one aspect to look at. But the right decision about the size of the hydraulic pump is always useful in usage.

Log splitters are designed with a simple process in mind: to split logs efficiently. To do so, almost all use a hydraulic system to pressurize the driving force of the splitting wedge. When you purchase a log splitter, you don’t have to worry much about the individual parts other than for basic maintenance needs and cleaning purposes.

But if you are interested in building your own log splitter, which is a very realistic option due to the simplicity of the machinery, then you do need to know what parts are best for effective splitting power. Gas and electric splitters utilize a hydraulic pump which is the integral component of hydraulic power. If you were wondering what size hydraulic pump for a log splitter you need, this article explains below its use and what to look for.

Log splitters are powerful machines that provide a splitting pressure to logs of various sizes. Almost all splitters use hydraulics whether it is pressurized via an electric, gas, or manual power source. These hydraulics feed a splitting wedge of your model of choice to make short work of just about any size log you you need to cut down to size.

One of the simplest hydraulic systems you can find in use is a log splitter. The basics of hydraulic pressure utilize an engine, oil pump to create oil pressure, a hydraulic cylinder that works with a valve for splitting power, and tank to hold and feed oil through the system.

If you are serious about making your own backyard log splitter, then you want to have, at a minimum, the following components to provide the right amount of force and power for basic splitting of averaged sized, seasoned logs:

But you may want a bit more force for heavier workloads, which is why I’ve explained below how a pump can help determine your splitter’s speed, and influence the cutting force. Read more about how a log splitter works, how to care for it, and what you need to build your own.

Mentioned multiple times above is the use of a two-stage pump that is most common for a hydraulic log splitter system. This is because it uses two different sets of gears doing the pumping to keep you machine running smoothly and providing the power you need at the speed you desire.

Although a two-stage pump is the best option for your log splitter, you can manipulate the amount of force it exerts through which size cylinder you choose. To calculate your own splitter’s force and speed based on the choices you make, you can use this handy calculator tool.

The entire splitting system is dependent upon the pump that consists of two pumping sections and an internal pressure sensing valve. One of these sections generates the maximum flow rate rated at at lower pressure that is used to draw the piston back for the system to reset after splitting. The other section provides the highest possible pressure to generate maximum splitting force.

Knowing the maximum pressure generated by a pump determines the splitting powerof the pump, and one thing you will notice is that most companies are fairly generous in their tonnage claims and round up more often than not. To figure the tonnage provided by the splitter, simply multiple the maximum pressure of the pump (a two-stage pump applies about 3,000 PSI), by the total surface area of the piston in square inches. The resulting number is the total available pressure.

You also can determine the cycle time of a piston to figure how quickly you can work through a pile of logs. To move a 4 inch piston 24 inches (the common piston length) you need 301 cubic inches of oil. Since a gallon of hydraulic fluid takes up 231 cubic inches, you need to pump, at a minimum, 1.5 gallons of fluid to push the piston in one direction.

The flow rate of the pump is dependent on the size of the engine powering the system. If your engine is capable of providing an 11 gallon per minute rate, then it will take approximately 20 to 30 seconds to cut, and around 10 seconds to reset. Common horsepower minimum requirements for a two-stage pump are:

For a dependable machine, you want to incorporate a two-stage pump to work with whatever size engine and cylinder you decide upon for cutting wood. These keep your splitter working smoothing and efficiently, and allow you to dictate speed and force to handle whatever size job you have in mind. If you have any further questions, or want to add to this information, please do so below. And, as always, please share.

Are you trying to buy a new hydraulic pump for your log splitter or do you need a perfect replacement pump kit for your wood splitter? Then, you should start your buying journey by reading this post. In this article, we’ll review the six best log splitter hydraulic pumps in 2022.

We compiled our list of the best gear pumps available after considering thoroughly their construction, splitting power, the flow rate for cycle time, operating speed, safety features, and overall benefits. We also included a buyer’s guide, FAQs, and summary to help you make a well-informed choice that suits your log splitter’s requirements and needs.

Log splitters are powerful machines designed to split logs efficiently. The machines offer effective splitting power to logs of various sizes. Almost all log splitters (including electric and gas types) use a hydraulic pump which is the integral component of a hydraulic machine that helps achieve the basic splitting of logs. The major components of a log splitter include an engine, hydraulic oil pump, valve, and hydraulic oil tank.

A typical hydraulic pump used for a log splitter is designed to feature a 5 hp gasoline engine, two-stage pumping sections, a hydraulic cylinder (4” diameter, 24” long), a 20 tons rated splitting force, and a 3-5-gallon hydraulic oil reservoir. Log splitters often use a two-stage pump to generate the right amount of pressure and flow rate required for splitting logs.

It’s tough to pick one product when you have many products from different brands making similar claims. So, we’ve done the hard work for you. Here are the best six pumps for a log splitter on the market. After reading this review, making a decision will become easier for you.

The RuggedMade 11 GPM 2-Stage Hydraulic Log Splitter Pump is perfect for log splitters with a rated force not up to 35 tons. It’s built with aluminum material for a longer service lifespan.

This hydraulic pump boasts up to 3000 PSI capable of powering log splitters and outdoor power requirements that range from 5 to 37 tons, depending on the hydraulic cylinder diameter (inner).

The two-stage pump operates at a maximum speed of 3600 rpm for faster cycle times during unloading. It’s preset to gear down mode at 500 PSI to help relieve the pump’s pressure; thus, ensuring the proper functioning of your splitter hydraulic system.

The Yaegoo 11GPM 2-Stage Hydraulic Log Splitter Pump is suitable for any log splitters application. It features a flow rate of 11 GPM capable of creating a stream of high-pressure oil required for generating maximum splitting force.

This two-stage hydraulic pump works at 3000 PSI to ensure effective splitting power without a loss of pressure. It’s built to automatically switch from high-pressure to low-pressure at 500 PSI for quick drawing back of the piston after splitting the log.

This log splitter hydraulic pump is ideal for log splitters with a rated splitting force of about 35 tons. It supports both vertical and horizontal applications.

The Bestauto Log Splitter Pump Kit is a suitable replacement pump kit for log splitters. It’s built with extrusion aluminum material that can resist wear and tears for an extended service life cycle.

This kit comes with a two-stage hydraulic pump, pump bracket, and jaw coupler. The 2-stage hydraulic pump works at 3600RPM maximum to ensure the fastest possible cycle times. The pump offers 13 GPM flow at 3000PSI maximum operation pressure to provide quick oil output.

The pump bracket and jaw coupler make lifting, pressure type, elbow, bending row, straightening, cutting, assembly, and more possible for a hydraulic log splitter. It’s compatible with a wide range of engine sizes.

The RuggedMade 16 GPM 2 Stage Hydraulic Log Splitter Pump features a body built with aluminum material for longevity. It’s designed to contain two pumping stages and a bypass valve to allow for efficient log splitting.

The first stage of the pump generates 16 GPM at 650 PSI required to reset the entire splitting system back after splitting. The second stage of the pump delivers 3.5 GPM at 2500 PSI to generate the maximum splitting force required to push the piston into a log for effective splitting performance.

The TooTuff Log Splitter Build Kit is a perfect kit for a DIY splitter project. It provides two-stage pump action to allow for maximum log splitting efficiency. The 1st pumping stage operates with a maximum flow rate (13 GPM) at a lower pressure of 650 PSI to help ensure a quicker cylinder return position.

In the second stage, the pump switches to a lower flow rate (3 GPM) and higher pressure (2500 PSI) to generate the maximum effective splitting power to split the log.

This hydraulic pump provides faster cycle times (16 GPM at 3600RPM) and higher possible pressure (up to 4000 PSI) with a small engine or most 8-14HP gas engines.

The Bestauto Log Splitter Pump Kit consists of a powerful hydraulic pump and hydraulic tools such as a jaw coupler and pump bracket. This hydraulic pump is built with sturdy and durable materials that can withstand even harsh environments.

The pump offers two-stage hydraulic actions to keep your log splitter running correctly. The 1st stage of the pump is preset to operate with a maximum flow rate of 16 GPM at 650 PSI for quicker withdrawing of the piston after the log has been split.

While the 2nd stage of the pump operates with the lower flow (3.5 GPM maximum) at higher pressure (2500 PSI maximum) to ensure excellent splitting efficiency.

The materials used in the construction of a hydraulic pump for log splitters would determine the longevity and performance of such a pump. Log splitter pumps built with high-quality materials such as aluminum have a longer service lifespan.

It’s important to ensure that all the components of the pump you intend to buy are built with materials of high strength and hardness that can resist wear and tear over multiple uses. It’s also important to check if the pump’s quality is well-assured by the manufacturer so that you can have a great user experience.

The splitting power of a hydraulic pump for log splitters is largely dependent on the maximum pressure that such a pump can generate. The amount of pressure that a pump generate vary from brand to brand.

However, the higher the pump’s maximum pressure, the more effective its splitting power. We don’t recommend more than 3000 PSI, which is the practical maximum pressure that most 2-stage gear pumps required for excellent log splitting.

The flow rate of the hydraulic pump determines the periods of time the pump would take to work through a pile of logs. The pump’s flow rate is largely dependent on the size of the engine powering the system.

A two-stage hydraulic pump for log splitters often requires minimum horsepower such as 5-7 hp engines with 11 GPM pump, 6hp engine with 13 GPM pump, 8 hp with 16 GPM pump, and 11 hp with 22 GPM pump.

You don’t have to worry too much when choosing a hydraulic pump based on the flow rate as virtually all log splitter pumps out there are rated for the same pressure.

It’s important to know that the operating speed of the hydraulic pump is hugely dependent on the hydraulic flow rate (GPM). Generally, larger pumps produce more flow which means more operating speed. However, bigger gear pumps require larger engines or powerful engines to drive them. Small pumps produce less flow but don’t require more horsepower to function properly.

The safety valve ensures smooth operation and performance of the hydraulic pumps. It helps to control the maximum pressure created by the hydraulic pump. Without a safety valve, most hydraulic pumps will build pressure up to a point that something break. Uncontrolled maximum pressure is likely to break your hydraulic hoses, garden hoses, hydraulic pressure hoses, the cylinder, or the pump itself.

To ensure the entire safety of your hydraulic system, you should go for 2-stage pumps with features such as a hydraulic relief valve, check valve, directional control valve, unloader valve, or hydraulic valve. Any of these safety features would help keep your pump’s pressure in check.

Besides, you should check if the pump you want to buy comes with a return filter, filter element, or filter head. Any of this would function to keep dirt out of its hydraulic reservoir (fluid reservoir).

Most simple wood splitters use a 2-stage gear pump for efficient log splitting. The two-stage pumps give log splitters effective splitting power using small engines. They can help generate the highest possible pressure required to keep most log splitters working smoothly and efficiently.

The approved fluid types for the hydraulic system of most wood splitters are AW-32 10-Weight (ISO 32) and AW-46 20-Weight (ISO 46). These hydraulic fluid types help lubricate your gear pumps and other hydraulic parts for protection against corrosion and weariness during extreme cold and heat.

We recommend changing the hydraulic oil in your log splitter every 100 hours of work. Regular changing of the hydraulic oil in your log splitter would help improve the performance of your log splitter hydraulic system. In addition to replacing your log splitter hydraulic oil as recommended, you also need to change your filter to keep dirt away.

A single-stage hydraulic pump features only a single pumping section or setting. It’s designed to generate just one flow rate (maximum GPM) at one maximum pressure to create the maximum splitting force. While a two-stage hydraulic pump features two pumping sections or settings. It’s designed to generate two flow rates at two different pressure levels.

A two-stage pump automatically switches to its ‘high-pressure/low-flow stage to split the blog (something that can’t be achieved with a single-stage pump). Two-stage pumps generally save splitting time than its counterpart (that’s one-stage pumps).

Look no further than this review if you would like to try out the best hydraulic pumps for log splitters out there. Any of the review gear pumps are capable of giving your splitters the power required to split log efficiently. We’re certain that you won’t go wrong with choosing to buy any of the above products. They are the best anyone can find on the internet at the moment.

For the people who have absolutely no idea about what these log splitters are, in simple terms, they can be called machines that chop wood using automation (or manual) power.

The primary purpose is to break these logs into pieces to aid their transport. The purpose of designing the log splitter is to simplify log splitting via automation (or manual) power.

Log splitters are phenomenal in their work, and the design aspect of log splitters is their main highlight. To achieve this automation, efficiency, and effectiveness, all these log splitters use hydraulics.

This two-stage hydraulic log splitter pump is the base of the hydraulic system. The hydraulic system is used to pressurize and create the force for splitting the wood.

This makes the log splitter pump the essential part of the log splitter. Whether you are well-versed with log splitters or have hardly heard about them, go through this article, and you will surely understand what size of log splitter pump you should use.

Log splitter pumps, as previously discussed, are a very crucial element. Thus, choosing the right kind of hydraulic log splitter pump becomes very important. The best way to go with this is by choosing the right size and quality materials for the log splitter pump. This will ensure high efficiency and effectiveness.

Before you make the decision, do analyze accordingly concerning your needs and log splitter. The size of log splitter pumps influences not only the performance but also the cost. Thus, the decision of choosing the size of hydraulic log splitter pumps depends upon three major factors:

Before deciding the size of log splitter pumps, it is essential to understand the hydraulics to determine the correct size based on the principle of log splitter pumps.

Hydraulic log splitter pumps work according to the phenomenon of hydraulics. Pascal’s law (Principle of hydraulics) governs hydraulics. It states that if you apply pressure to a particular point of a fluid (closed/confined), the pressure transmits to every other fluid point (with no losses).

Pumps convert one form of energy to another. As the name suggests, hydraulic pumps convert mechanical energy to hydraulic energy. For this conversion, hydraulic pumps use flowing water.

Using flowing water, these hydraulic pumps create a hydraulic system. This system is complicated, but in simpler terms, it provides force in a specific area, basically what we call pressure.

Two-stage hydraulic pumps are usually used as log splitter pumps. This complex system can be explained using an analogy. Consider the working of a vehicle, and it displaces itself irrespective of the heavyweight. It uses power for displacement.

This is precisely what happens in a log splitter, except that it happens at a smaller scale. Thus, the pump utilizes the conversion of the energy for running the log splitter.

Now that you know the log splitter and hydraulic pump details, we can discuss the size of the log splitter pump. Why should we be bothered about the size of the log splitter pump? The reason is that the size affects the speed and force (splitting).

Bigger the size of the log splitter pump (basically the pump cylinder’s size), the bigger the splitting force. This helps in the useful splitting of more extensive woods. But with the increase in the size of the hydraulic pump, it also requires more fluid. The requirement of more fluid decreases the speed.

This is the reason why the size of log splitter pumps becomes so essential. You can either choose the speed of splitting force. If you choose to increase one of the two-parameter, then the other one decreases.

To choose the best and correct size of your log splitter, you need to decide to improve either pump speed or splitting force. There are different size pumps available in the market according to your requirement.

Pumps available in the market are based on GPM (Gallons per minute). The higher the GPM, the smaller is the cylinder. The splitting force depends upon the cylinder. The higher the GPM, the smaller is the splitting force. To make it more transparent,

If you are interested in making a log splitter, which is possible as the calculations required for designing, parts required, and technique to make a log splitter is available. It can be employed if one shows interest in it. Only go for the DIY option if you are well-versed with machinery.

The engine of the log splitter works on the basics of hydraulics. The pump creates the driving force, and the hydraulic cylinder works in unison with the valves influencing splitting power and speed.

The engine used must be of 6-7 Horsepower. A two-stage hydraulic pump (about 3000 PSI) must be employed of 11 GPM. The standard hydraulic cylinder of 4-inch diameter and 24-inch length/height. Around 10-12-gallon capacity of the oil tank.

Note: If you want to play around with the values and choose the best according to your requirement, then use this calculator tool by international hydraulics.

Finally, it is your choice! As you know that you can either have a good speed or high splitting force, you must make your own decision with the size of log splitter pumps. You do not need to worry a lot as the size is only one aspect to look at, but the right decision about the size is always useful in usage.

The choice of DIY or buying one from the market is also your choice. If you are well-versed with calculations and machinery, then go for it as log splitters are expensive in the market.

If you know why you are employing a log splitter, it will help you make a better decision. For example, if you are one of those campers who requires a log splitter in his camps for firewood, go for the speedy ones (small cylinder size). The reason is that you would want to split wood faster instead of splitting larger pieces.

Irrespective of whether you buy a branded log splitter or DIY, they require regular maintenance and cleaning. For better results, go for the two-stage hydraulic pumps (even if they are a bit expensive).

If you follow the above tips, then the log splitter works effectively and efficiently. Taking the right decisions can help you enforce the right speed and optimum splitting force required for your log splitting.

Looking for log splitter hydraulic pump purchase guide? A lot of people ask Google this question every day, and it’s no wonder if you have found yourself asking that same exact question. I mean this is an important decision that could affect your home for years to come. There are so many log splitters for hydraulic pump on the market today that choosing the right one can be a bit overwhelming.

Hydraulic pump wood splitter is a machine that splits logs by compressing them between two wedges. The log is inserted into the wedge between the two cylinders and then compressed until it splits into two pieces.

Hydraulic pump log splittingmachines are ideal for splitting large pieces of wood, such as logs from trees and branches from fallen trees. They are also used to split firewood that cannot be split by hand. The hydraulic pump log splitter is powered by an electric motor or gasoline engine, which turns a gear box that drives the hydraulic pump. The hydraulic fluid is pumped through hoses to two cylinders that compress the wood between them until it splits.

A hydraulic pump log splitter can be used outdoors or in an enclosed building such as a garage or workshop. They come in different sizes and power options depending on how much wood you need to process at once.

Log splitters are machines that are used to split logs into firewood. They work by using hydraulic pressure to drive a wedge through the wood. The machine consists of a hydraulic piston pump that is connected to a ram, which is connected by a jackshaft to the splitting wedge (or “blade”). The pump uses hydraulic fluid under pressure from an electric or gas-powered engine, which pushes the ram forward and forces it against the wedge. This causes the log to be pushed down onto a splitter bed and split in two.

There are different types of log splitters, including manual and electric versions. Each type has its own pros and cons: Manual models offer better control over how long you want each log to be split, while electric models are easier to use but require more maintenance.

Pressure is basically how much force can be exerted on an object. In this case, we’re talking about how much force is required to move the ram forward. This is where things get tricky. There are a lot of variables that go into determining how much pressure will be needed for a given application. The first thing to consider is what kind of wood you’ll be splitting with your log splitter. Generally speaking, more dense woods require more pressure to split them (which means more power). But there are other factors at play as well. For example, if you’re splitting wet logs or if you have a poor quality hydraulic pump, then it may not be able to produce enough pressure for your needs even if it has enough power capacity available.

Flow refers to how fast the oil can flow through the pump at any given time. A bigger pump has more flow capacity than a smaller one does by default (because it has more pistons inside). However, if a larger pump has too much flow capacity for its application then it may not operate as efficiently as it could because oil won’t be getting pushed through its cylinders fast enough to make them work properly.

The 11 GPM Log Splitter Pump is great for any gas log splitter. The pump has a 1/2″ diameter discharge hose with an adjustable flow control valve to allow you to adjust the flow rate to your desired setting. The 11 gpm log splitter pump is also equipped with a pressure regulator that will ensure that you don’t over-pressurize your log splitter, which can cause damage to the engine or damage to any nearby structures. The 11 gpm log splitter pump comes complete with all necessary mounting hardware, two filter screens and brass fittings.

The 11 GPM Log Splitter Pump can be used on both electric and gas powered log splitters with up to 200 PSI of pressure output. This is an excellent upgrade from stock pumps and will allow you to operate at higher pressures without damaging your equipment or injuring yourself.

The 13 gpm log splitter pump is a small and portable log splitter that can be used for small or large firewood splitting projects. The pump comes with a 3,000 PSI pressure regulator which allows you to adjust the pressure of your log splitter. This means that you can use this pump on any size wood without worrying about damaging your pump or the wood.

The 13 gpm log splitter pump comes with all of the necessary fittings and hardware, so you can easily connect it to most air tanks and compressors. It also includes an air hose that is 6 feet long, so you have plenty of room to work with while using this product. This unit comes standard with a 1 year limited warranty, but customer service representatives are available 24 hours per day if you have any questions or concerns regarding this item.

The 16 gpm log splitter pump is the perfect addition to your log splitter. This high pressure pump is capable of delivering 16 gallons per minute of water, which is enough to keep your log splitter running smoothly.

This pump is made from aluminum and features a cast iron impeller. The entire unit weighs only 30 pounds, so it can be easily stored or transported without any special equipment.

The 16 gpm log splitter pump has a 1/2″ NPT male inlet and a 3/8″ barb outlet, making it compatible with most common hose connections. The pump has an adjustable flow rate that ranges from 6 gpm to 16 gpm, allowing you to customize it for your specific needs.

The 18 gpm log splitter pump is a purpose built pump and is designed to handle the rigors of frequent use. The pump is made from high quality materials and will last for years without maintenance. The 18 gpm log splitter pump has been tested and proven to work with logs and other debris up to 5 inches in diameter. The pump can be used as an inline or submersible pump and comes complete with pressure gauge, check valve and flexible hose.

The 18 gpm log splitter pump is ideal for anyone who needs to move debris from a pond to another location or for anyone who wants to split their own wood without the use of an expensive gas powered splitter.

The 19 GPM Wood Splitter Pump is a high-performance pump designed for use in residential and commercial settings. This pump is ideal for use in fire protection systems and is able to deliver 100% duty cycle air flow up to 19 gpm. The 19 GPM Wood Splitter Pump features a horizontal discharge design that makes it ideal for use with propane tanks and other applications where vertical discharge pumps would not be suitable.

The 1″ NPT male inlet thread provides a secure connection that won’t leak, while the cast iron construction provides durability and long-term performance. The 19 GPM Wood Splitter Pump also includes an integrated check valve that helps protect against backflow should the pump stop working unexpectedly, preventing dirt and debris from being sucked back into the system.

The 22 gpm log splitter pump by Rural King is a quality pump, that offers great performance at a low price. This is an ideal pump for anyone who needs to move water from a pool or pond to their garden or lawn. It can also be used for livestock watering or other outdoor uses.

The 22 gpm log splitter pump has 1/2 inch NPT female threads and comes with it’s own filter kit. The filter kit includes an inline filter housing, filter screen and cap. The filter screen is designed to keep debris out of your pump, while the cap helps prevent water from entering the intake when there are no logs to be split.

The 28 gpm 2 stage hydraulic log splitter pump features a 2 hp motor with a 1.5 GPM flow rate at 3000 PSI. The pump comes with an air cooled diesel engine, which will ensure that your equipment runs smoothly and efficiently. This pump is ideal for small to medium sized jobs, including those at home or in the workplace.

The unit comes equipped with a 12-inch stroke and a 6-inch rod lift, which means that you will have no trouble splitting even the largest logs. The 28 gpm 2 stage hydraulic log splitter pump is also very easy to operate – simply fill up your reservoir with water and oil mix, attach it to your pneumatic hose and go!

This 28 gpm 2 stage hydraulic log splitter pump also includes an adjustable pressure regulator valve so you can adjust the amount of pressure that goes into the cylinder depending on what type of material you are working on or how hard it is for you to split the material. This makes the unit very versatile since there are many different types of wood out there that require different amounts of pressure.

The 40 GPM hydraulic pump is the most common type of pump in the industry today. It is typically used for powering a wide variety of tools and machines in construction, mining, forestry and agriculture industries. This unit can be used as a portable or stationary unit and is powered by an electric motor or gasoline engine.

The 40 gpm hydraulic pump features a single stage design with a pressure rating of up to 4000 psi. This pump has been designed with high pressure relief valves that allow it to handle high pressures without damaging the pump. This pump also features an automatic start stop system which allows it to shut off automatically when no flow is detected in order to prevent overheating. The motor can be mounted on either side of the pump so they can be used horizontally or vertically depending on application needs.

The best log splitter pumps maintain their power and performance over time. If you want to get the most out of your log splitter pump, it’s important to properly maintain it.

A log splitter pump will work hard for you, but if you don’t take care of it, it won’t last long. To make sure your log splitter pump lasts as long as possible and performs well, follow these tips:

Keep the engine cool. A warm engine can cause damage to your pump, so make sure you let the engine run for a few minutes before shutting it off. This will allow the oil inside to cool down before you shut off the engine.

Clean out any debris from around the base of your log splitter pump after each use so that no dirt gets into the engine or on any moving parts inside. Make sure there are no leaves or other debris stuck in between moving parts that could cause damage if they get caught while in motion (like gears).

Adjusting the pressure on a log splitter is an easy process that can be done by anyone. The first thing you will need to do is locate the pressure adjustment knob, which is usually located on the front of the unit. If you are having trouble locating it, consult your owner’s manual or call customer service for assistance.

Once you have found the adjustment knob, turn it clockwise until there is little to no resistance when you pull on it. Next, grab a log that measures around 12 inches in diameter and place it between two of the splitting wedges. Push down firmly on the handle until you hear a click sound from inside the unit and then let go quickly. This will adjust your unit’s pressure and allow for better splitting performance for larger logs.

If you find that your log splitter does not have enough power for larger logs, try adjusting the pressure down again until you feel comfortable with how easily it splits smaller pieces of wood.

Log splitters are a great way to get the job done, but they can be a little bit of a pain to use. If you find your log splitter moving slow, there are a few things that could be causing this problem.

If you haven’t checked your oil in a while, it’s important to do so before operating your log splitter. This will ensure that your machine is running smoothly and safely. If you notice that there isn’t enough oil in your tank, add some more before using the machine again.

You may have noticed that your log splitter moves slower if there are large pieces of wood and debris stuck inside of it. This can be anything from small branches to larger logs or rocks. You should always check inside of your machine before using it to make sure there isn’t anything obstructing its operation. If you do find something stuck inside of it, remove it immediately so that your machine can move freely again!

There are many manufacturers of log splitters in the world, but three of them stand out as being the best. These brands are Stihl, Husqvarna, and Honda. The reason they are preferred by so many people is because they are high quality and affordable.

The Stihl brand offers a range of different models that meet most needs and budgets. The 703 is one of their most popular models for homeowners because it’s affordable and does an excellent job at splitting wood. They also offer a number of high-end professional log splitters that are used in lumberyards and other industrial applications like mining operations.

Husqvarna makes some excellent log splitters for homeowners who want to save money over the long term by getting a unit that will last for years before needing replacement parts or servicing. Their 380E is one example which has been designed to be easy to use even by beginners without any experience with this type of equipment before.

The Honda brand produces high quality hydraulic pump for wood splitter that have been proven over time to be reliable and effective at doing their job well without breaking down easily or needing repairs frequently like some cheaper models might do after only a few months use or less if used regularlyThe 380E is a great choice for anyone who needs to split wood on a regular basis and wants the best possible quality product that will last for years of use without needing repair or replacement parts.

A log splitter is a machine that helps you cut down the logs into smaller pieces. It can be used for splitting wood, but it can also be used to split firewood, tree stumps and branches.

If you want to buy a log splitter, it is important that you know what size cylinder do I need for my log splitter? There are many different types of cylinders available on the market today, so how do you know which one is right for your needs?

It is important to remember that the bigger the cylinder you select, the more power it will have. If you plan on using it for cutting logs and firewood, then it would be best if you purchased a large cylinder. However, if this is not what you plan on doing with your machine, then it would be best if you purchased a smaller one.

You should also consider whether or not there are any special features that come with your machine or not before purchasing one. For example, some machines have dual pistons which allow them to work faster than other models out there in the market today. This will save time when working with your machine so that you don’t have to spend as much time cutting down trees and splitting them into smaller pieces by hand.

The hydraulic cylinder is used in the log splitter machine. It is responsible for compressing the wood and splitting it into small pieces. The hydraulic cylinder has a piston inside, which moves up and down as you press the lever of the machine. If your log splitter does not work properly, it means there is air inside your hydraulic cylinder. In this case, you need to bleed your hydraulic cylinder to remove air from it.

Remove the cylinder cover from your log splitter by removing two bolts that hold it in place. Put these bolts aside so that they do not get lost during bleeding process.

Use a socket wrench with an extension bar to loosen three nuts at the bottom of your splitter’s hydraulic cylinder (the part where you attach a handle). Remove these nuts completely and put them aside so that you don’t lose them during bleeding process later on. Loosen two more nuts near top end of hydraulic cylinder, which will allow more air out of this part when you start bleeding process later on.

Attach one end of a plastic hose to the bleed valve on your hydraulic splitter. The other end of this hose should be attached to a bucket or container that can hold at least two quarts of water, which will catch the air bubbles released from your hydraulic splitter during bleeding process.

1.Check the hydraulic oil level in the reservoir. If it’s low, add oil to bring the level up to the “FULL” mark. Use a funnel to avoid spilling hydraulic fluid on the ground.

2.If you’re using a manual log splitter, start by removing the cap or plug from the top of the hydraulic tank and filling it with hydraulic fluid until it’s full enough to reach the “FULL” mark without spilling any excess fluid on the ground or inside your machine’s engine compartment.

3.Replace or reinstall the cap or plug on your hydraulic tank so that no air can enter and make sure that you don’t overfill your tank by allowing any excess fluid to spill out onto your driveway or garage floor while you’re working with this tool.

So there you have it—we’ve taken the time to outline several key considerations that should help you make an informed decision about your purchase. We hope that these tips have been helpful, but if you still have questions, please don’t hesitate to take a look around the rest of our site for more information. As always, happy splitting!

tags: {hydraulic pump for wood splitter,hydraulic log splitter pump,hydraulic pump wood splitter,wood splitter hydraulic pump,hydraulic pumps for log splitters,hydraulic pumps for wood splitters,log splitter hydraulic pumps,hydraulic log splitter pumps,pump for log splitter,log splitter pump,pump for wood splitter,wood splitter pump,wood splitter pumps,log splitter pumps,log splitter hydraulics,hydraulic wood splitter,hydraulic wood splitters}

A: To determine which pump to purchase, you will need to know the following: what HP engine will you be powering my log splitter with, what size reservoir capacity do you have available, what type of pump mount you will be using?

A: There are two common types of mounts used on log-splitters. There is a four-bolt mount and a two-bolt mount. The four-bolt mount pumps generally come in 5gpm-16 gpm sizes and have a ½” keyed shaft about 1-1/2” long. The two-bolt mount pumps come in 22gpm and 28gpm sizes and have a 5/8” keyed shaft that can differ in length.

A: If your log-splitter is moving slow but still capable of splitting the wood it always has, it is most likely stuck in its second stage. In the second stage (or low flow/high-pressure stage) the pump produces 25% or less of its rated GPM but it does it at a higher pressure. The transition from the first stage (or high flow/low-pressure) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

1. If the engine bogs down and stalls out, the pump is likely stuck in its first stage. In the first stage (or high flow/low-pressure stage) the pump produces its rated GPM but it does it at about 400-900psi. The transition from the first stage (or high flow/low-pressure) to the second stage (or low flow/high-pressure stage) is an automatic process achieved via internal valving with in the pump. If something within that valving has malfunctioned, and it is typically more economical to just replace the whole pump.

2. If the engine bogs down slightly but fails to stall out, you most likely have a bad seal on the cylinder piston. It is often more cost effective to rebuild a cylinder than to replace it depending on the extent of any internal damage. Consult with your local hydraulics shop.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. Most 2-stage Log-splitter pumps will safely create 3000 psi regardless of how quickly they transfer the fluid doing it. So, there is not actually a more “powerful” pump, just slower or faster.

A: The size of splitter is typically specified in tons of splitting force. This number is determined by the surface area of the piston multiplied by the pressure applied by the pump. The amount of tonnage that you will need depends predominately on the type and size of wood that you will be splitting. Hardwoods such as oak and hickory take more force to split than most coniferous soft woods like spruce and fir. The Janka rating is the measurement that they use to rate the hardness of wood. The higher the number, the harder the wood. Log diameter size is another important factor in the amount of force required to split the log. One of the most important factors in determining the Tonnage required to split logs is the moisture content. See below for a decent chart for tonnage requirements for seasoned wood. You will need 50-75% more tonnage for splitting green wood.

A: The tonnage rating on your log-splitter is determined by two distinct factors; piston surface area and pounds of force per square inch (psi) supplied by the pump acting upon that surface. To determine the piston surface area, you must take half of the bore diameter, and multiply that number by itself. Then take that number and multiply by pi (approximately 3.14). This will give you the surface area in square inches. Although your hydraulic pump will be rated to a certain maximum pressure rating, typically 3500psi, most log splitter hydraulic systems have a relief valve limiting the amount of pressure supplied to the cylinder and other components. To find the tonnage of your log-splitter you will take the relief valve setting in pounds per square inch multiplied by the surface area of the piston in square inches, then divide that number by 2000 pounds per ton. See example below for a 4-1/2”cylinder at 3000psi:

A: Your valve will have four ports. The IN port is supplied by the hydraulic line coming directly from the pump. The OUT port will return the flow of oil directly to the reservoir. That leaves the two work ports on the valve. The work port closest to the valve handle will be connected to the barrel port (extending) on the cylinder. Attach the other valve port to the rod port (collapsing) side. See the figure below.

A: Typical Log-splitter valves have three positions. Extend – Center – Retract. The extend position directs flow to where the cylinder expands thus forcing the wedge through the log to be split. The handle must be held in this position to maintain cylinder movement. The valve will spring to center from the extend position when the handle is released. The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal workings of the valve will force the handle back into the center position automatically.

A: The hoses on your log-splitter should have the rating printed or embossed onto the outside sheathing of the line. If it is not visible or readable it is a distinct indicator of weather damage and or rot, and you should look to have them replaced.

Your log-splitter requires multiple hoses and could potentially have three different pressure ratings (see figure below). The suction line shown in green does not see any pressure, on the contrary they usually have some sort of structure to keep the hose from collapsing. The return lines shown in orange do not typically see much for pressure, but they are typically rated to 350 psi. The actual pressure lines shown in red should be rated to at least 3500psi for your typical log-splitter application.

A: Most Hydraulic systems can be safely operated with either ATF (automatic Transmission Fluid) or a standard petroleum based hydraulic oil. Some Log-splitters have a replaceable filter assembly to help clean the oil clean. If your log-splitter does not have a replaceable filter it would be beneficial to use ATF and allow the detergents in the fluid to help keep things clean.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the seal kit.

If this is not an option for you for whatever reason, you can disassemble your cylinder and match up the seals by example with your local hydraulics shop. If you do not have a local shop, or they do not offer this type of service, you will need to measure the hard component dimensions of your cylinder. You will then need to match them with the dimensions of available seals with a seal supplier such as Seal Source, Hercules Sealing Products, or any other national seal supplier. Many of them have an online interface to help you make this selection.

A: There are many manufacturers of log-splitters out there, and just as many if not more manufacturers of cylinders. The only way to know for sure which cylinder that you have is to contact the log-splitter manufacturer with the model and serial number of your unit and ask for a parts breakdown for their part number for the cylinder that they used on that specific unit.

A: The first step in selecting a replacement cylinder for your log-splitter is identifying what style of cylinder that you currently have. While many manufacturers utilize common style cylinders, many do not. Please see the figures below for the most readily available styles.

If your cylinder has a welded body and has a short piece of pipe on each end it is a welded-cross tube style cylinder. The cylinder will have different widths on each end. You will want to place close attention to mounting widths and pin hole sizes to insure compatibility.

If your cylinder has a hole drilled through the rod end of the cylinder, this is what is called a pin-eye style cylinder. These cylinders are commonly available with either a clevis mount or a cross-tube on the barrel end. You will want to place close attention to mounting widths and pin hole sizes to insure compatibility.

If your cylinder is mounted on lugs coming out of the side of the cylinder, this is what they would call a trunnion style cylinder. Trunnion mount cylinders are almost entirely exclusive to the log-splitter manufacturer. You will need to get a replacement from the original manufacturer or contact a machine shop to recreate the mounts on a more common cylinder.

Once you have determined the style of cylinder you are looking for, you will need to determine bore size, the mounting pin to pin length (both collapsed and extended), the rod diameter, and pin hole sizes. Drawings are usually available for individual cylinders to insure a proper fit. It might be necessary to have a local shop alter your log-splitter frame to accept the cylinder, or alter the cylinder to fit your machine.

A: 2-stage log splitter pumps are sized by how many gallons per minute (GPM) they flow in the low-pressure stage. While operating below the bypass setting the pump will transfer that number of gallons per minute.

A: Availability of replacement parts for log-splitter valves depends on the manufacturer of the valve. You will first need to identify the manufacturer of the valve. Northern Hydraulics carries replacement handles and brackets for Cross MFG valves and replacement brackets and detents for the Energy MFG log-splitter valves

A:The retract position of a log-splitter valve has a feature commonly referred to as a pressure kick-out detent. Pulling the valve into the retract position detent will cause the cylinder to collapse until it is fully pulled in without holding onto the valve handle. Once the pump pressure builds to a pre-set amount, the internal passages in the valve will force the spool back into the center position automatically.

This product is a Hi-Lo cast iron hydraulic gear pump with max pressures of 900 PSI for the low pressure and 3000 PSI for the high pressure pump. Typical applications for this 13 GPM hydraulic pump are log splitters and presses, where alternating low and high pressures are required to move a cylinder.

Log splitters are designed with a simple process in mind: to split logs efficiently. To do so, almost all use a hydraulic system to pressurize the driving force of the splitting wedge. When you purchase a log splitter, you don’t have to worry much about the individual parts other than for basic maintenance needs and cleaning purposes.

But if you are interested in building your own log splitter, which is a very realistic option due to the simplicity of the machinery, then you do need to know what parts are best for effective splitting power. Gas and electric splitters utilize a hydraulic pump which is the integral component of hydraulic power. If you were wondering what size hydraulic pump for a log splitter you need, this article explains below its use and what to look for.

Log splitters are powerful machines that provide a splitting pressure to logs of various sizes. Almost all splitters use hydraulics whether it is pressurized via an electric, gas, or manual power source. These hydraulics feed a splitting wedge of your model of choice to make short work of just about any size log you you need to cut down to size.

One of the simplest hydraulic systems you can find in use is a log splitter. The basics of hydraulic pressure utilize an engine, oil pump to create oil pressure, a hydraulic cylinder that works with a valve for splitting power, and tank to hold and feed oil through the system.

If you are serious about making your own backyard log splitter, then you want to have, at a minimum, the following components to provide the right amount of force and power for basic splitting of averaged sized, seasoned logs:

But you may want a bit more force for heavier workloads, which is why I’ve explained below how a pump can help determine your splitter’s speed, and influence the cutting force. Read more about how a log splitter works, how to care for it, and what you need to build your own.

Mentioned multiple times above is the use of a two-stage pump that is most common for a hydraulic log splitter system. This is because it uses two different sets of gears doing the pumping to keep you machine running smoothly and providing the power you need at the speed you desire.

Although a two-stage pump is the best option for your log splitter, you can manipulate the amount of force it exerts through which size cylinder you choose. To calculate your own splitter’s force and speed based on the choices you make, you can use this handy calculator tool.

The entire splitting system is dependent upon the pump that consists of two pumping sections and an internal pressure sensing valve. One of these sections generates the maximum flow rate rated at at lower pressure that is used to draw the piston back for the system to reset after splitting. The other section provides the highest possible pressure to generate maximum splitting force.

Knowing the maximum pressure generated by a pump determines the splitting powerof the pump, and one thing you will notice is that most companies are fairly generous in their tonnage claims and round up more often than not. To figure the tonnage provided by the splitter, simply multiple the maximum pressure of the pump (a two-stage pump applies about 3,000 PSI), by the total surface area of the piston in square inches. The resulting number is the total available pressure.

You also can determine the cycle time of a piston to figure how quickly you can work through a pile of logs. To move a 4 inch piston 24 inches (the common piston length) you need 301 cubic inches of oil. Since a gallon of hydraulic fluid takes up 231 cubic inches, you need to pump, at a minimum, 1.5 gallons of fluid to push the piston in one direction.

The flow rate of the pump is dependent on the size of the engine powering the system. If your engine is capable of providing an 11 gallon per minute rate, then it will take approximately 20 to 30 seconds to cut, and around 10 seconds to reset. Common horsepower minimum requirements for a two-stage pump are:

For a dependable machine, you want to incorporate a two-stage pump to work with whatever size engine and cylinder you decide upon for cutting wood. These keep your splitter working smoothing and efficiently, and allow you to dictate speed and force to handle whatever size job you have in mind. If you have any further questions, or want to add to this information, please do so below. And, as always, please share.

This depends on your wants vs. needs, so we’ll try to help you discover what is most important. Let’s be honest. You likely want the biggest, baddest, tonnage to effortlessly split wood like it’s butter. Besides, it helps to stroke your ego too – admit it. But in reality, you likely just don’t need that much log splitter tonnage or features. Why spend more cash on log splitter parts and equipment when you just don’t need it?

Did you know the average rental size unit in the United States is a 26-ton log splitter? Most non-commercial projects just don’t need more tonnage than that.

Here’s a general guideline based on the Janka Hardness Test. This test measures the hardness of various wood species based on the necessary pounds-force (lbf) needed to embed a steel ball into the wood. Now obviously, this is just a general specification. Every piece of wood is different; different grain, temperature, dampness, dryness, etc.

Be careful. It may seem like a great deal to get a larger tonnage log splitter for about the same price or a little more than say the average 26-ton or 34-ton splitter. That’s not always the case when it comes to log splitters or log splitter parts.

It is common to find higher tonnage wood splitters from no-brand or value brands; however many have very slow cycle times compared to reputable brands that cost more. If you don’t mind splitting one log to every 4-5 logs of a better brand with faster cycling, then no worries.

Swisher log splitters have very solid 28-ton and 34-ton log splitters. Swisher has been in business over 60 years, and their prices will compete with any import on the market.

Here at Beiler Hydraulics we stock a full range of log splitter pumps. Log splitter pumps automatically switch from high-speed/low-pressure to high-pressure/low-speed to meet the load requirements. The low-pressure side is preset at 400-900 psi, and the high-pressure side has a max of 3,000 psi. These pumps are ideal for log splitters, presses, or any application where you need to automatically switch from high speed at low pressure to high pressure at low speed. Beiler Hydraulics also stocks many other Log Splitter Parts including valves, cylinders, hose assemblies, and fittings. With our multi-million dollar inventory we are more than equipped to provide a complete solution for all your hydraulic needs. Our sales team has the knowledge and expertise to make sure you have exactly what you need. At Beiler Hydraulics we believe in offering quality products at competitive prices and providing the customer service you need bef

8613371530291

8613371530291