What are the Well Control Equipments?

Well control equipment refers to the tools, systems, and devices used in the oil and gas industry to maintain control over the well during drilling, completion, and production operations. These equipment are crucial for preventing blowouts, controlling the flow of fluids, and managing well pressures. Some common well control equipment includes:

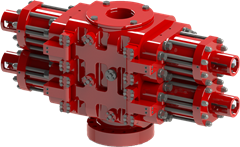

Blowout Preventer (BOP): A blowout preventer is a large, specialized valve that is installed at the top of the wellhead to control the flow of fluids and prevent uncontrolled releases of oil or gas. It consists of various ram and annular preventers that can be activated to seal the wellbore in case of an emergency.

Choke Manifold: A choke manifold is a system of valves and pipes located near the BOP stack. It is used to control and regulate the flow of fluids from the well. The choke manifold includes a choke valve that restricts the flow, allowing pressure control.

Kill Manifold: A kill manifold is a system of valves and pipes that is used to pump heavy fluids (mud or kill fluids) into the wellbore to control the well's pressure. It is typically used during well control operations such as well kicks or blowouts.

Mud Pumps: Mud pumps are large, high-pressure pumps used to circulate drilling mud or fluids into the wellbore during drilling operations. They help to control the pressure and stabilize the well by removing cuttings, cooling the drill bit, and providing hydraulic pressure to the wellbore.

Mud Gas Separator: A mud gas separator is a vessel that separates gas from drilling mud. During drilling operations, gas may be encountered in the wellbore, and the separator allows for the safe venting of gas while retaining the drilling fluid for recirculation.

Diverter System: A diverter system is used to redirect the flow of fluids away from the rig during an emergency, such as a blowout. It diverts the flow to a designated area, away from the drilling equipment, providing a safer environment for the personnel on the rig.

Surface Safety System: The surface safety system consists of various valves, sensors, and controls that monitor and manage the pressure and flow of fluids at the surface. It includes devices such as pressure gauges, alarms, emergency shutdown systems, and interlocks to ensure safe operations.

These are just a few examples of well control equipment used in the industry. The specific equipment and configurations may vary depending on the well type, operational requirements, and regulations in different regions.

8613371530291

8613371530291