What is Solid Control Equipment?

Solid control equipment, also known as solids control system or mud control system, refers to a set of specialized mechanical devices used in drilling operations to manage and control the solids content in drilling fluids or mud. The primary purpose of solid control equipment is to remove unwanted solids, such as drill cuttings, from the drilling mud, ensuring that the mud remains in good condition for efficient drilling and wellbore stability.

The drilling mud plays a crucial role in drilling operations by providing hydraulic pressure, cooling and lubrication, and carrying drilled cuttings to the surface. However, as the drilling progresses, the mud gets contaminated with drilled solids, which can negatively impact drilling efficiency and the overall performance of the drilling operation. Solid control equipment helps maintain the quality and properties of the drilling mud by separating and removing these solids.

Key components of solid control equipment include:

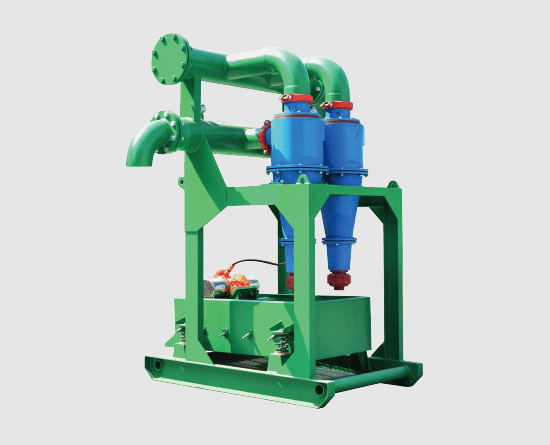

Shale Shaker: The shale shaker is the primary device used to separate larger solids from the drilling mud. It uses vibrating screens or sieves to separate cuttings and other larger particles from the mud, allowing the cleaned mud to pass through while retaining the solids.

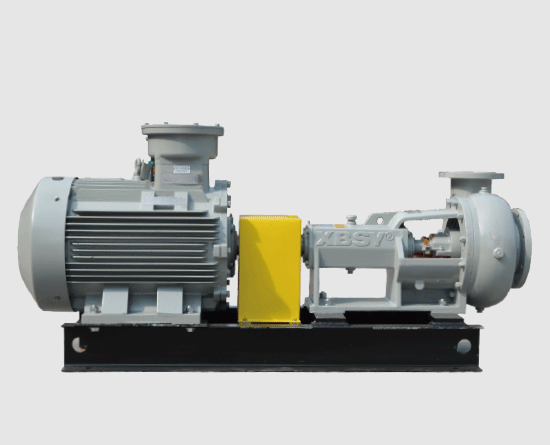

Desander and Desilter: Desanders and desilters are hydrocyclone-based units used to remove finer particles from the drilling mud. Desanders target larger-sized particles, typically in the range of 40 to 100 microns, while desilters focus on even smaller particles, usually in the range of 20 to 40 microns. These units use centrifugal force to separate and remove the solids from the mud.

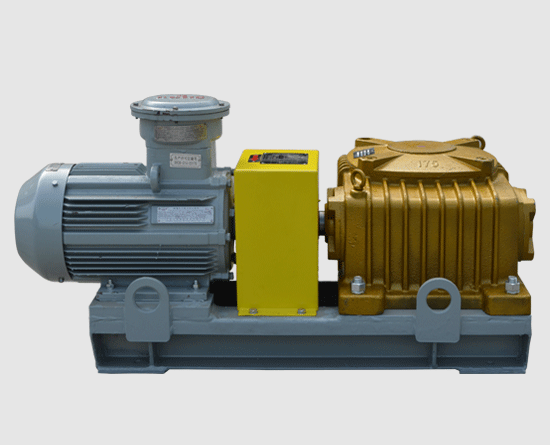

Decanter Centrifuge: A decanter centrifuge is a high-speed rotating device that uses centrifugal force to separate even finer solids from the drilling mud. It is capable of removing particles as small as 2 to 5 microns. The decanter centrifuge is particularly useful for separating barite, a weighting material, and recovering valuable drilling fluids from the solids.

Mud Cleaner: A mud cleaner is a combination of a shale shaker, desander, and desilter. It integrates these components into a single unit, providing a compact and efficient solution for solids control.

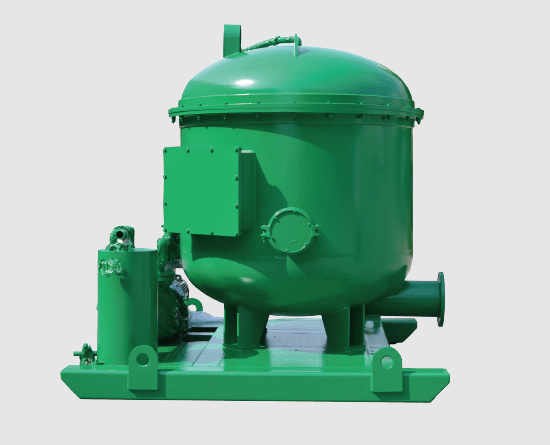

Degasser: A degasser is used to remove entrained gases, such as methane, hydrogen sulfide, and carbon dioxide, from the drilling mud. It prevents the formation of gas pockets or bubbles in the mud, which can lead to safety hazards, reduced drilling efficiency, and wellbore instability.

These are some of the main components of solid control equipment. The specific configuration and combination of equipment may vary depending on the drilling operation, the type of solids present in the mud, and the desired quality of the drilling fluid. The goal of solid control equipment is to maintain the integrity and properties of the drilling mud, improving drilling efficiency, minimizing environmental impact, and ensuring wellbore stability.

8613371530291

8613371530291