What are the Advantages of Hydraulic Power Tools?

Hydraulic power tools offer several advantages over other types of power tools. Here are some of the key advantages of hydraulic power tools:

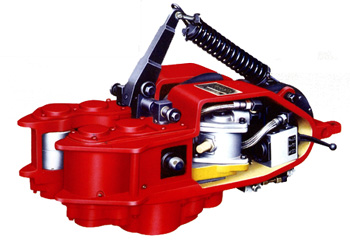

High Power-to-Weight Ratio: Hydraulic power tools are known for their high power-to-weight ratio. They can deliver a significant amount of force and power while being relatively lightweight. This makes them easier to handle and maneuver compared to traditional electric or pneumatic tools.

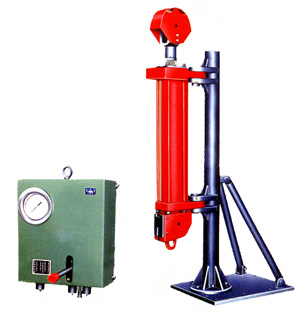

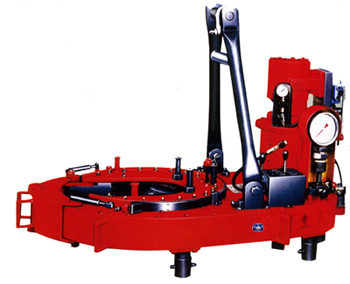

High Torque Output: Hydraulic power tools generate high levels of torque, making them well-suited for applications that require heavy-duty torque, such as loosening or tightening large bolts, nuts, or fasteners. They can handle high loads and provide consistent torque output even at low speeds.

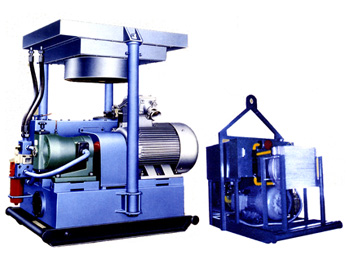

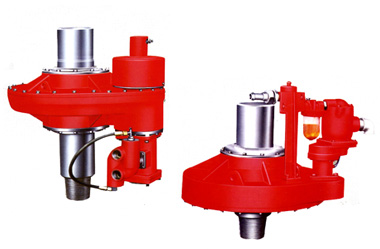

Wide Range of Applications: Hydraulic power tools are versatile and can be used in various industries and applications. They are commonly employed in construction, manufacturing, automotive, mining, and maintenance operations. Hydraulic tools are available in different configurations, including impact wrenches, breakers, drills, saws, and crimpers, allowing them to perform a wide range of tasks.

Durability and Reliability: Hydraulic power tools are designed to withstand harsh working conditions and heavy use. They are built with robust materials and are less prone to wear and tear compared to some other power tool types. Hydraulic systems are known for their reliability and longevity, ensuring consistent performance over an extended period.

Safety Features: Hydraulic power tools incorporate safety features to protect the operator and the tool itself. They often include overload protection mechanisms, pressure relief valves, and ergonomic designs to reduce the risk of accidents and injuries. Hydraulic systems also allow for precise control and gradual application of force, minimizing the chance of sudden tool failures or mishaps.

Versatile Power Source: Hydraulic power tools can be powered by various hydraulic power sources, such as hydraulic power units or hydraulic systems integrated into machinery or equipment. This flexibility allows them to be used in remote or challenging environments where access to electricity may be limited.

Reduced Vibrations: Hydraulic systems inherently dampen vibrations, reducing the transfer of vibrations to the operator. This can help reduce operator fatigue, improve comfort during prolonged use, and minimize the risk of musculoskeletal injuries.

Low Maintenance Requirements: Hydraulic power tools generally have lower maintenance requirements compared to some other power tools. They have fewer moving parts, simplified designs, and are less prone to electrical or electronic malfunctions. Routine maintenance usually involves hydraulic fluid checks and occasional seal replacements.

It's worth noting that hydraulic power tools also have some considerations, such as the need for hydraulic fluid, the requirement for a hydraulic power source, and the potential for fluid leaks. However, for many industrial applications, the advantages of hydraulic power tools outweigh the limitations, making them a preferred choice for heavy-duty tasks that demand high power and torque.

8613371530291

8613371530291