mud agitator calculator for sale

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

When the process is not verified by previous installations PG will do a CFD analysis of the tank and agitator to verify the rheology and the required installed power.

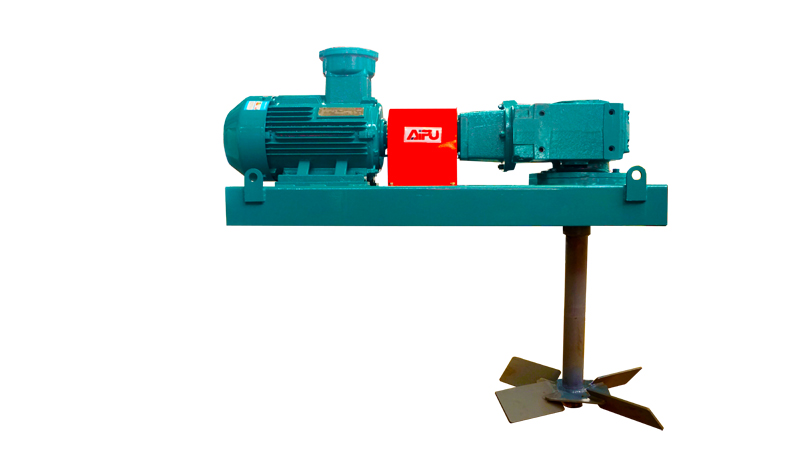

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

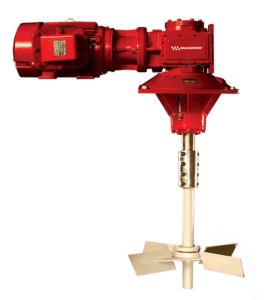

As an SPX FLOW brand, Lightnin serves the challenging waste and water treatment sector, as well as the processing of solvents, fertilizers, food/beverages, pharmaceuticals and biofuels. The mixers and agitators, that are custom designed and fabricated, are used for equalization, neutralization, flocculation, aeration, sludge mixing, flash mixing and general blending purposes. The Lightnin industrial mixer portfolio covers both portable and larger fixed-mount units. All Lightnin equipment is designed to provide prolonged trouble-free operation regardless of the specific application demands. Through the proprietary gearbox and impeller technologies developed in recent times, we can offer the market advanced mixing solutions that are far more compact and power-efficient than ever before. They also have significantly greater operational lifespans, thanks to anti-fouling mechanisms and other state-of-the-art features. Consequently, customers are able to raise their productivity levels and avoid costly downtime issues, while also keeping the energy consumption involved to an absolute minimum.

Brightway Solids Control Company (Xi"an Brightway Energy Equipment Co., Ltd.) is the professional manufacturer for the solids control equipment and complete set of solids control system. Brightway solids control equipment and system is widely used in the oil and gas drilling, HDD (Horizontal directional drilling), CBM drilling, Underground drilling, river silt cleaning, geothermal drilling., etc. Brightway solids control main equipment: Shale Shaker, Vacuum Degasser, Mud Cleaner, Desander Cleaner, Desilter Cleaner, Decanting Centrifuge, Centrifugal Pump, Submersible Slurry Pump, Screw Pump, Shear Pump, Mud Agitator, Jet Mud Mixer, Mud Gas Separator, Flare Ignition Device, Mud Gun, Oil Tank, Water Tank, Mud Tank etc. Brightway Slogan is Good Attitude, Active Action, Bright Future. Brightway provide value to customer all over the world.

Concrete, cement, render, mortar, mud brick, mixer, agitator, portable, compact, compact mixer, on-site, on-site mixer, remote, remote mixer, medium, small batch, trailer mounted, skid mounted, mixing feed, inoculate, stabilised sand, rammed earth, hire, for sale, compact mixer for hire, compact mixer for sale

Suction Tank: Mud Cleaner Tank 186bbls, Suction-1 425bbls, Suction-2 211bbls, Suction-3 220bbls, Slug Pit Equipped with: Agitator 10 HP, Agitator 5 HP, Pit Level Sensors, Desilter Pump

Reserve Tank No. 2: Reserve A= 265bbls, Reserve B= 270bbls, Equipped with: Agitator 10HP, 5 X 6 MISSION 75 HP Centrifugal Pump, TRI-FLO Hopper Skid 6 X 8 MISSION 100 HP Centrifugal Pump

8613371530291

8613371530291