mud agitator calculator quotation

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

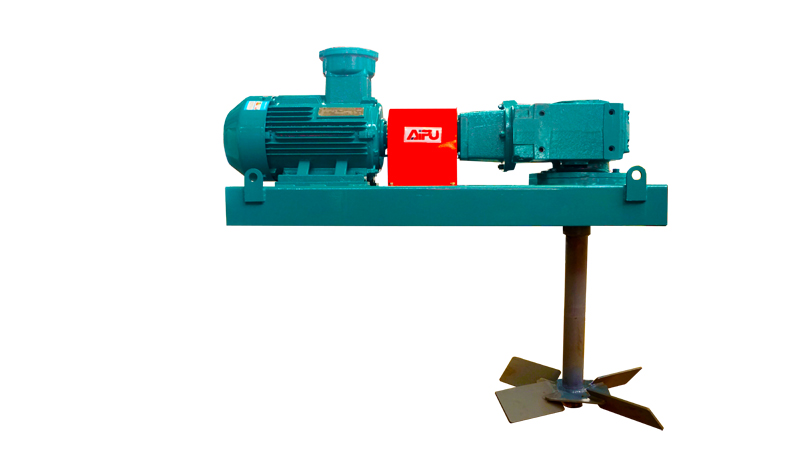

There are different models APMA7.5 and APMA11, APMA15, etcetera. Presently, the helical bevel geared ones are usually APMA7.5. While the APMA15 geared with a helical worm reducer. For mud agitators, we produce a gearbox driven by a 5.5kw, 7.5kw, 11kw, 15kw, 18.5kw, 22kw, and 30kw motor.

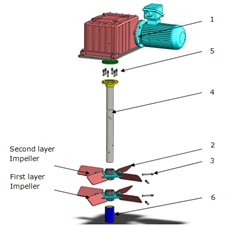

And the agitators can be the horizontal type or the vertical type. According to users’ preferences, we’ll provide different customization services. The impellers can be a single layer or double layer. The blades are the canted type for better agitation performance.

Drilling mud agitators are popular auxiliary equipment used in drilling mud system. In the oilfield, mud tanks are the platform for a whole solids control system. On tanks, there are shakers, mud cleaner, centrifuge, pumps, agitators, and so on

Mud tanks are used to reserve drilling fluids. During whole well drilling, we need drilling mud and we maintain and process drilling mud for better property and save drilling cost. Mud agitators will help us to mix or agitate the drilling fluids. Under the impellers’ rotation, the useful solids will suspend without sediment

We know the agitator is consisting of a motor and a reducer. Combining them together will get a proper turn speed. Under proper TOR the drilling fluids will be at a high property for better circulation throughout the mud system

Horizontal worm gear type agitator, this is the most popular agitator used in oil and gas mud tank because it’s cost-effective. There are coupler options for agitators to protect gear or options without a coupler for saving cost.

A horizontal bevel gear type agitator is a very good option for larger torque and minimum footprint. The bevel gear is much higher torque compares to the worm gear. Better performance, higher cost.

AIPU supply mud agitator for the above options as per buyer’s request and cost budget. Other than an agitator, AIPU supply a series of equipment for mud tank or a whole tank with all tank attachment.

Starting torque: A number of factors can influence the amount of starting torque needed to get agitators in motion. The sheer volume of materials to be mixed, and their density, can place a lot of stress on vessel mixing components. Tank design also influences this – factors such as tank geometry, agitator design, baffle design and geometry, hub arrangement, motor power output, and tank temperature control all can affect the torque needed to begin a mixing cycle. And of course, batch variability also is a critical factor.

Mixing dynamics:Often, precise control is needed to ensure consistent batches, as the consistency of the batch can vary during processing. Viscosity or density can change drastically as mixing proceeds, which means that forces on the agitators can swing wildly.

8613371530291

8613371530291