mud agitator parts quotation

KOSUN mud agitator is part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solids particles from depositing in the circulating tank and to stabilize the performance of drilling fluids. The motor and speed reducer, speed reducer and impeller shaft are connected by steel coupling.

LAKE MA series mud agitatoris part of the drilling fluids solids control equipment, which is mainly used to agitate and mix the drilling mud to prevent solids particles from depositing in the circulating tank and to stabilize the performance of drilling fluids.

DrillingParts.com is in no way affiliated with the companies referenced in this website. References and/or mention of company names or the accompanying computer code are for ID purposes only and are not Trade Marks or Trade Names used by or affiliated with DrillingParts.com. Although under affiliate program agreements, DrillingParts.com may earn on qualifying purchases completed through third party associates such as Amazon, eBay and our marketplace vendors.

That support includes 24/7 access to our skilled service teams and vast parts inventory. We are always here for you, because we know you do not want downtime. You want quality, dependability and the support of a long-standing oilfield equipment expert backing you up.

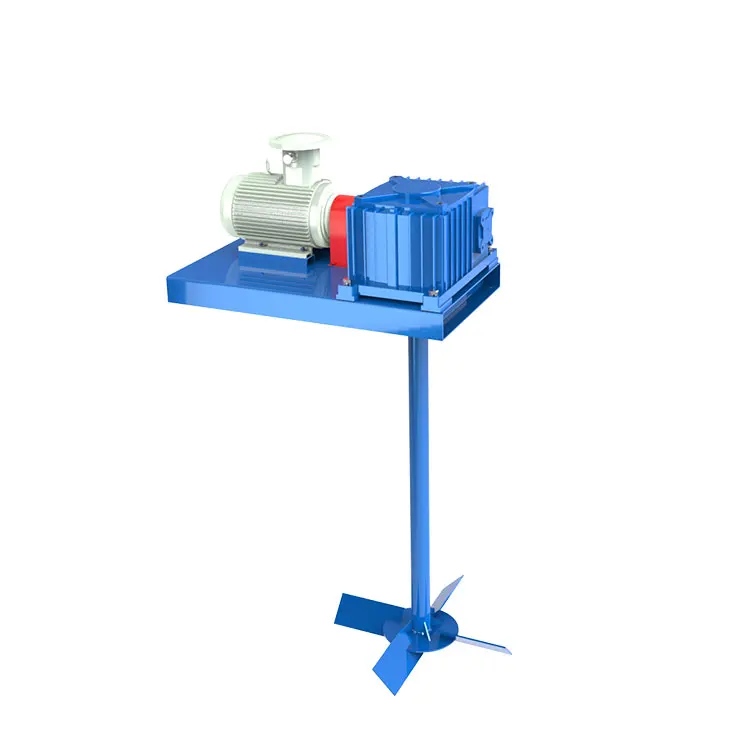

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

The direct-drive shaft assembly featured on our agitators maximizes motor efficiency which results in reduced energy consumption and greater performance. Available in vertical or horizontal configurations, all of our agitators are completely customizable and or to meet your specific tank dimensions and mud weight range.

We know just how critical downtime can be to your operations. And we’ve responded by developing an inventory system that assures ready availability of critical parts, and a delivery network that speeds those parts right to your door. ProQuip’s standard delivery system can often ship stock parts the same day as ordered. Extremely large stock orders or those requiring additional manufacturing may take longer.

To simplify repairs, ProQuip is pleased to introduce Tank Agitator Rebuild Kits – stocked with routine maintenance items, such as bearings, gaskets and seals. Order a Rebuild Kit in advance of an emergency! Plant personnel will have all the components on-hand when time is critical. Ask your ProQuip Local Sales Representative for details or contact ProQuip Customer Service.

Sometimes old machinery can no longer satisfy current application requirements. But with genuine ProQuip parts, your worn agitators or outdated drive systems can often be retrofitted with new, more efficient components. The end result for you: a cost-effective solution that gets your proven performer back in top operating condition to handle today’s demanding service conditions.

Nearly every agitator is customized to some extent. Shaft extensions are manufactured to fit into each customer’s specific vessel or tank and impellers are sized to specifically fit the application. There are also numerous other components of an agitator which, due to customer request or design requirements, were originally custom made. ProQuip maintains records on every ProQuip agitator shipped with complete design details.

These customized components must be manufactured to the application specifications to replace the original component. Delivery of these custom components is dependent on component complexity and material availability. Shafts and impellers can often be turned around in 2 weeks or less. ProQuip offers competitive prices and assurance that replacement parts are made to the same demanding standards as the original equipment. ProQuip Local Sales Representatives would be happy to provide you with a standard quote on an aftermarket customized component.

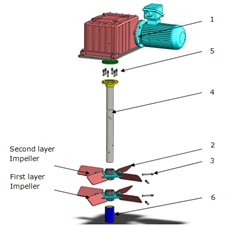

The mud agitator parts includes motor, reducer, base, stirring rod, impeller and other spare parts. Among them, the motor and the reducer, and the reducer and the pulsator shaft are all connected by a rigid coupling, and the pulsator is assembled by welding four blades. The mud agitator is generally installed on the surface of the mixing tank, and the mixing medium is mainly solid and liquid, including mud, muddy water, oil and water and other media.

In the actual use of mud agitator, often due to the quality of the motor, reducer, base, stirring rod, impeller and other spare parts will fail or be damaged, so the quality of the mud agitator parts thedirectly determines the effect and life of the agitator. When we choose a mud agitator, we need to know the daily maintenance and troubleshooting methods of the mud agitators spare parts.

The failures caused by the mud agitator parts include drive failure, transmission failure and mechanical failure. The failure of the explosion-proof motor parts of the mud agitator will cause the drive failure of the motor unable to rotate. The failure of the reducer spare parts will cause the motor torque to be unable to be transmitted to the stirring rod through the reducer, and transmission failure occurs. If the maintenance is improper, for example, the reducer is not often lubricated, it is indeed easy to malfunction; the impeller of the agitator, The material of the extension bar spare parts or improper installation may cause other mechanical failures. Therefore, the two important parts of the motor and reducer need to be specially maintained during the use of the agitator.

Hubei Craun Technology Equipment Co., Ltd (abbreviated as Craun Tec.), with the registered capital of 10 million RMB and 25000㎡ factory ground, is located in High Tech. industrial park of Xian Ning, Hubei province, which is 100 Kilometers away from Wuhan. The HQ is divided into two parts, mechanical precision processing factory and equipment manufacturing factory. We have more than 100 sets professional precision processing center, inspection equipment, heavy manufacturing equipment and complete environmental protection treatment equipment. Craun Tec. focuses on the technology R&D on the field of solid-liquid separation, and has the independent R&D and fast & efficient system solution capabilities, it is a global professional manufacturer integrating system design, technology R&D, production and sales and after-sales service.

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

• New drive shaft design allows for the maintenance, removal and replacement of the gear box with out entering the tank or vessel. Since all maintenance can be performed at the surface there is no need to drain the mud tanks or perform confined space work. This patent pending innovation will be the industry standard in the years to come.

• The Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high

• Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the Agitator is the lower bearing, which can

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

8613371530291

8613371530291