mud agitator pdf in stock

Comes Complete with a "C" Face Explosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Derrick Mud Agitator

MUD AGITATOR All Derrick agitators feature a "C" face motor coupled to a rugged oilfield gearbox, which eliminates misalignment and troublesome couplings. This configuration promotes longer motor and gearbox bearing life. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. Helical-Bevel gearboxes are preferred over worm gear arrangements because of their power efficiency, reliability, and lower operating temperatures.

The Derrick agitator is available in both horizontal (model DE-AG-H) and vertical (model DE-AG-V) configurations sizes range from 5 to 30 HP. Derrick agitators carry a two year warranty.

Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller (size, type and quantity), and shaft length to meet your requirements.

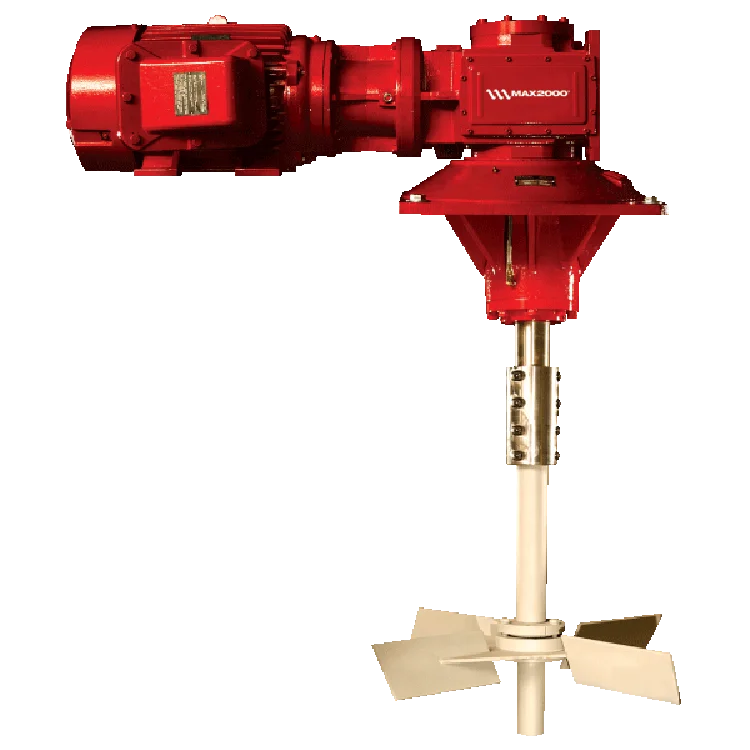

Vertical Mud Agitator Model DE-AG-V (shown with a turbine impeller)

DE-AG / SSCP 9/03 Copyright 2003 Derrick Corporation. All products indicated by trademark symbols are trademarked and/or registered by Derrick Corporation. DE-AG Mud Agitator

Comes Complete with a "C" FaceExplosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Mud Agitator

Derrick DE-AG mud agitators come complete with an explosion proof "C" faced motor, a highly efficient gear box, impeller and shaft complete with bushing. Available motors range from 5 HP to 30 HP. The motor is attached directly to the gear box assembly, which helps prevent premature bearing failure due to misalignment. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. This allows the DE-AG to do the same amount of work with less horsepower. The noise level of the DE-AG has been reduced to less than 75 dBA. Agitator model, horsepower, impeller diameter, and shaft length are customized to specific tank dimensions and maximum mud weights. Available horsepowers: 5, 7.5, 10, 15, 20, 25, and 30. Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller diameter and shaft length to meet your requirements. The DE-AG gear box has a two year warranty.

DIMENSIONS (IN,MM) WEIGHT WHEN ORDERING SPECIFY: MODEL HP Minimum Shaft Dia. Shaft Agitator (lbs / kgs) 1) Model Number Impeller Dia. (lbs/ft / kg/m) (Less Shaft & Impeller) 2) Motor Voltage DE-AG 3 3 24 610 2 1/4 57 13.5 / 20 350 / 159 3) Shaft Length DE-AG 5 5 28 711 2 1/4 57 13.5 / 20 450 / 204 DE-AG 7.5 7 1/2 32 813 2 1/4 57 13.5 / 20 575 / 261 4) Impeller Size DE-AG 10 10 40 1016 3 1/4 83 28 / 42 875 / 397 5) Impeller Orientation DE-AG 15 15 40 1016 3 1/4 83 28 / 42 1000 / 454 (Straight or Canted) DE-AG 20 20 44 1118 3 1/4 83 28 / 42 1300 / 590 DE-AG 25 25 48 1219 3 5/8 92 35 / 53 1800 / 816 6) Tank Depth DE-AG 30 30 48 1219 3 5/8 92 35 / 53 1850 / 839

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

LIGHTIMIIKI heavy duty pulp and paper stock agitators!-for guaranteed performance Every LIGHTNIN stock agitator is backed by the experience gained through 50 years of special- ization, with over 10,000 installations throughout the world"s pulp and paper mills. LIGHTNIN manufactures a complete range of stock agitators up to 1000 hp. Their engineering recommendations are based upon a full assess- ment of all relevant factors of the installation, and result in the selection of the most suitable design of equipment with guaranteed optimum performance —in writing, and at minimum cost. Unusual...

LIGHTIMIIM originated these agitation techniques Reduced bottom blow tanks The reduced bottom design was developed by LIGHTNIN to maximize agitator performance, reduce energy costs, and minimize capital construction costs. This efficient design concept has been applied successfully to towers containing over 1000 tons of stock. Multi stage high intensity chlorine The LIGHTNIN chlorine premixing system ensures that each fibre is uniformly contacted with chlorine. Thus a reduction in the size of the chlorination tower is achieved, chemical usage is kept below 5%, and residuals are minimized....

Bearing housing bolts A are loosened and jacking screws B are tightened to engage shutoff C. Simple bearing The modular design permits fast bearing replacement without agitator shaft removal. The agitator shaft is secured by slinger A, bearings are loosened from the adapter sleeves B and slipped off the shaft complete with bearing retainers C.

HJBL series vertical mud agitator is mainly used for deep mixing and mixing in the mixing tank. The mixing shaft is longer than 1 meter and equipped with a stainless steel base to ensure that the mixer runs stably and does not shake during the mixing process.

Vertical mud agitator can be widely used in chemical industry (fine chemicals, pharmaceutical chemicals and daily chemicals), environmental protection (sewage treatment), pharmaceuticals, cosmetics, metallurgy, food, heat treatment cooling, leather processing and other industries.

Mud gun are meant to provide supplemental or primary mixing in mud tanks depending on the number being used and the pit size. They are best used in tank corners to keep solids from settling and a mud agitator is placed in the tank center.

The mud agitators are high-efficiency mud-mixing units offered in a wide array of custom sizes and configurations to accommodate virtually any mud tank. Both horizontal and vertical drive configurations are available for all sizes of mud agitators. The horizontal drive is designed for installations having limited space above the mud tank.

The mud agitator stirs a mud slurry to maintain suspension of solids. The agitator is mounted on top of the mud tank and has one or two impeller(s) immersed in the mud slurry. The impeller shaft is directly coupled to an electric drive motor that is available in several horsepower ratings from 3 (50Hz only) to 30 (60Hz). Impellers are available in diameters ranging from 20″ to 52″ to meet the needs of various size mud tanks.

The mud agitator is operated by a 3-phase induction motor. Drive motors range from 5 to 30 horsepower for the 230/460Vac 60Hz power configuration and 3 to 25 horsepower for the 190/380 50Hz power configuration.

Though there are mud guns and mud agitator‘s, to activate the mud, there is certain portion in the mud tank which is not influenced by these activating devices. Hence this portion of mud tank is having in-activated mud. This in-activated mud promotes in settling of the chemicals at the bottom of the tank creating a differential chemical composition throughout the tank. This in-activated mud is carried to the drill string followed to the drill bit, where its functioning is severely affected. On observation, in mud tank there‘s a provision to run a horizontal shaft-blade assembly through the length of the tank. Such an arrangement at proper elevation can activate that portion of the tank which is generally a dead zone. This assembly runs horizontally along the length of the mud tank with three bearing supports at the partition. Each blade assembly consists of four blades and four such assemblies are located through out the length of the shaft.

On economic considerations, the amount of chemicals wasted due to this in-active mud is primarily calculated. The cost of chemicals wasted per tank for a location is amounting to around Rs.51,000/- (Rs. Fifty one thousand). If the drilling rig, works at least for a span of one year in five locations, the total cost of chemicals lost amounts to Rs.2,55,000/- (Rs. Two lakh fifty five thousand). To reduce this wastage of mud it is proposed in this paper to design a horizontal shaft-blade assembly

Mud with density 1668.1 kg/m3 is chosen in order to design the project for high mud weight. The Standard D.C Motor with speed reduction gear box used to mud-agitator is selected for calculation towards failure criterion.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

8613371530291

8613371530291