mud agitator vs desander brands

Mud cleaner used in oilfield means the equipment processing drilling mud. It is combined with desander cone and desilter cone as well as bottom shaker. It is called 2nd and 3rd phase solids control equipments.

The first mud cleaner was a combination of two 12-inch-diameter and twenty 4-inch hydrocyclones mounted above a specially built, 5-footdiameter, stainless steel, round Sweco shaker. Even though the mud cleaner was invented for use with a weighted drilling fluid, the first application was on a well drilled using one of the first unweighted, potassium chloride drilling fluids, in a shallow, 2200-foot research well near Houston, Texas, in 1971. An API 80 screen was mounted on an unbalanced elliptical motion Linkbelt shale shaker to process the fluid as it left the well bore. The fluid was then pumped to the hydrocyclones. The well was to be used, initially, to evaluate the use of air injection into risers to reduce annular pressure at the seafloor and, subsequently, as a research test well.

The second mud cleaner was a bank of twenty 4-inch Pioneer hydrocyclones mounted above another specially built 4-foot-diameter, doubledeck, stainless steel, round Sweco shaker. The screens could be arranged in parallel or in series to process the underflow from the cones. This unit was placed on an exploration well in South Louisiana. A gas-bearing formation at about 11,000 feet contained an 11.0-ppg pore pressure. The gas-bearing formations between 11,300 feet and 16,000 feet had been depleted to pore pressures as low as 2.2 ppg. Plans were to drill through this interval with the 11.0-ppg water-base drilling fluid, set casing, and drill the exploration part of the hole. Through this interval, differential pressures, between the fluid in the well bore and the formation pressure, varied up to 6000 psi. A centrifuge was used along with the mud cleaner and dilution to keep the drilled-solids concentration very low to make a compressible filter cake. While drilling this interval, no lost circulation or stuck pipe was experienced. Torque and drag on the drill string were minimal. After reaching about 80 feet above the predicted casing depth, the mud cleaner was shut down. (Actually, the company man suggested that the research team go home for Christmas because they were having no problems and the new experimental equipment was not really needed.) As the last 80 feet was drilled, considerable drill string

drag and torque developed. The casing point was actually 120 feet below the predicted depth. The drilled-solids concentration in the drilling fluid greatly increased. Wiper trips were needed between each logging run prior to setting casing. So much drill string torque and drag were experienced that the research team was asked to return to the rig and turn on the mud cleaner. So many solids were discarded by the desilters and presented to the mud cleaner screen that an API 200 screen could not handle all of the flow. An API 150 screen was mounted on the mud cleaner to reduce the drilled solids during two circulations. Then a final cleanup was made with two circulations using an API 200 screen. The drilled-solids concentration could not be returned to the lower levels achieved during earlier drilling, but a sufficient number of drilled solids were removed to allow casing to be run without incident and cemented in the borehole.

Note that this lucky event of turning off the mud cleaner was probably the reason that mud cleaners became commercial. No drilling program schedules stuck pipe. None was programmed here. The research plan should have included a procedure to validate the mud cleaner performance. Since no problems were encountered and none were expected (although stuck pipe and lost circulation are common with 6000-psi overbalance in a well bore), no comparative data were acquired to prove that the mud cleaner was performing properly—until the machine was luckily shut off. This was also a great lesson in planning research for the drilling processes. The research team concentrated on keeping the drilling fluid in good shape and minimizing the impact of drilled solids; unfortunately, the primary function should have been to prove the machine beneficial. At that time, not all drilling personnel believed that drilled solids were detrimental or evil.

The mud cleaner’s U.S. patent—No. 3,766,997 (October 23, 1973), granted to J. K. Heilhecker and L. H. Robinson and assigned to Exxon Production Research Company—was found to be invalid because of prior art later discovered in the British Patent Office. A German inventor had been granted a patent on a similar device in the late 1800s. Although his invention had never been reduced to practice or used in the oil patch, and screens were much coarser in those days, the existence of the information in the public domain prevented collection of royalty for application of this technology. (As an interesting note, all of the companies providing mud cleaner service had offered to pay a nominal $5 a day per unit as a technology transfer fee for help in developing the product. This offer had been rejected and the service companies had been told that a much larger royalty payment would be required when the patent was issued. With an invalid patent, the service companies never had to pay a royalty and certainly did not pay a technology transfer fee.)

When the mud cleaner was first introduced, many would try to decide whether to use a mud cleaner or a centrifuge. The problem with this decision is that mud cleaners do not compete with centrifuges in solids removal. In weighted drilling fluids, mud cleaners are designed to remove drilled solids larger than barite (larger than 74 microns). Centrifuges remove solids mostly smaller than most barite (less than 5 to 7 microns).

GN Solids Controlis a world famous turnkey provider of solids control equipmentfor oil and gas drilling fluids. GN Solids Control has rich experience on design, development, and manufacture solids control equipment includes but not limited to shale shaker and shaker screen, decanter centrifuge, desander, desilter, mud cleaner, mud agitator, cuttings dryer, centrifugal pump, screw conveyor and mud tank etc.

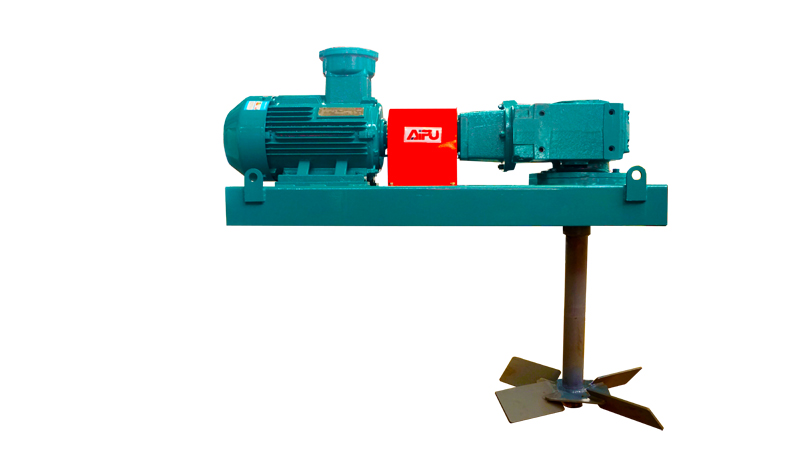

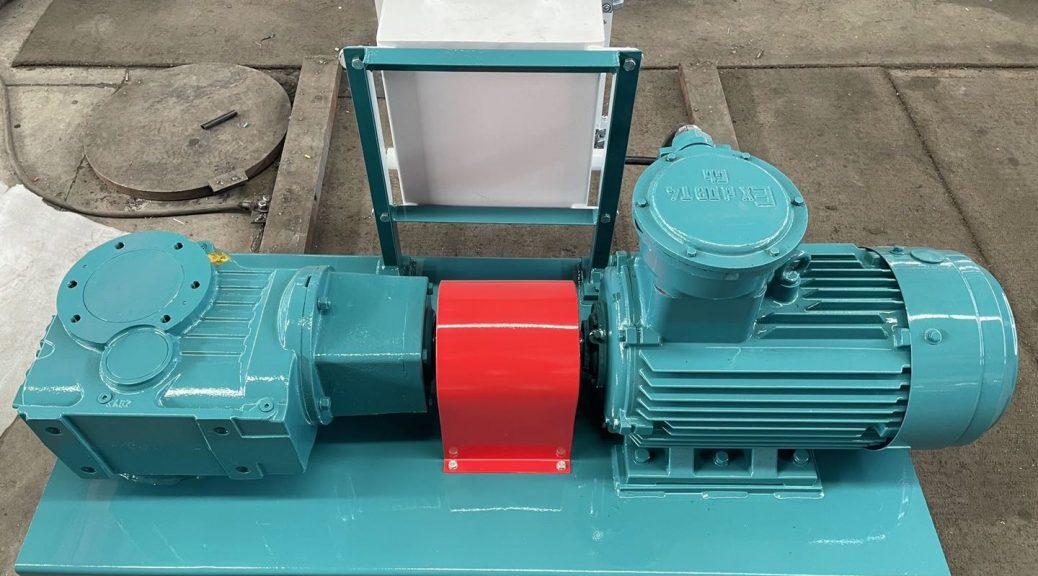

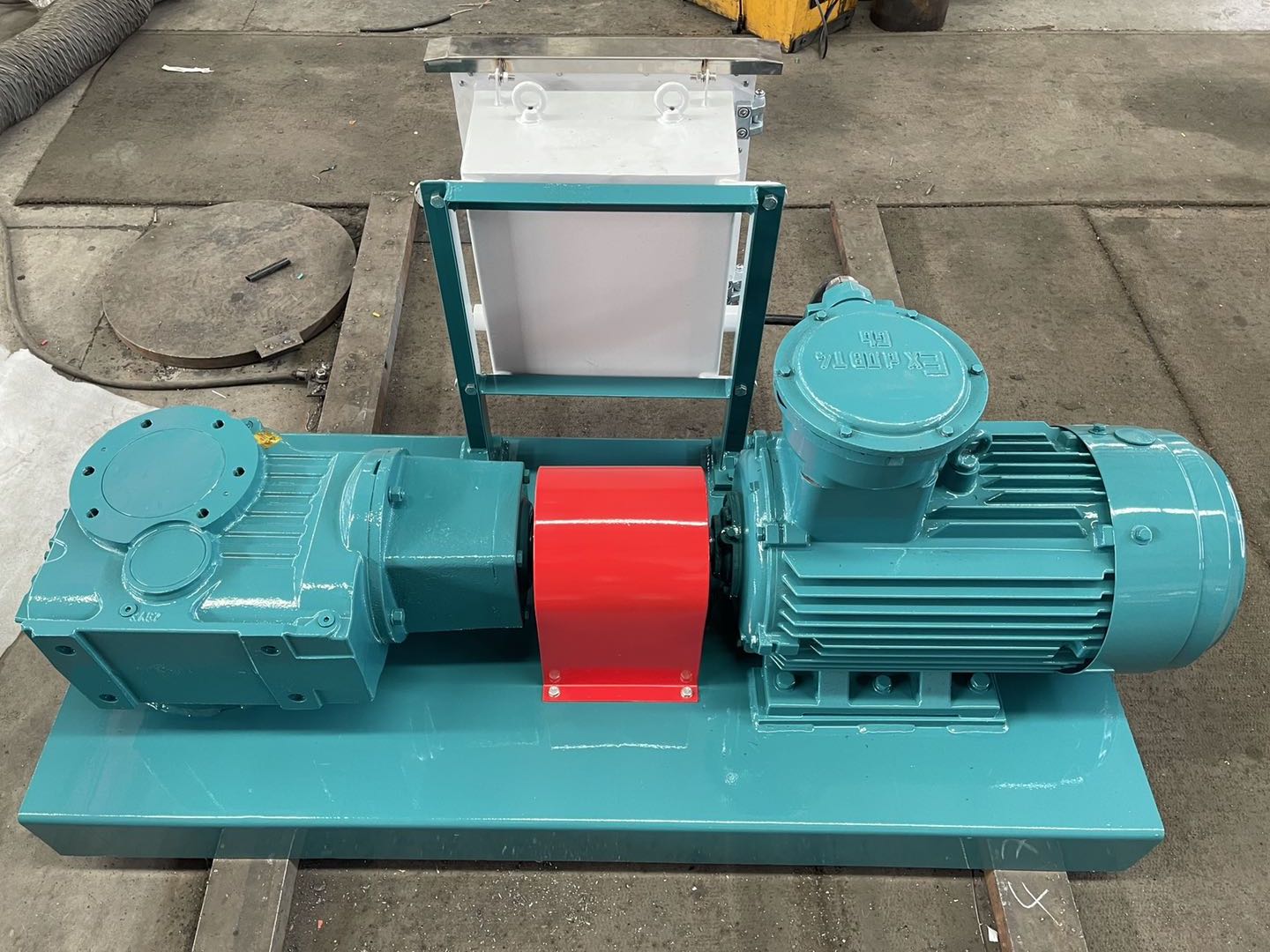

Last month, GN Solids Control finished manufacturing of one batch mud agitators for one offshore drilling rig platform. Consider the heavy duty mud, GN Solids Control provides helical bevel gerabox reducer for these mud agitators.

GN Solids Control manufactures mud agitator with single impeller, double impellers or multiple impellers. The shaft length of the mud agitator is customized based on customer’s mud tank depth.

GN mud agitator keeps the drilling mud from sediment, and plays a very important role in mud mixing, preparing and storage. GN Solids Control also provides control boxes to match the mud agitators, explosion proof includes IEC Ex, ATEX, CNEX etc.

In order to use in the offshore platform, GN Solids Control use PPG painting to cover the mud agitators with 3 layers which can keep sea moisture rusty from long time usage.

Besides the mud agitators, GN Solids Control has also been providing the other types of solids control equipment like decanter centrifuges and shale shakers for offshore drilling platforms. GN Solids Control made DNV lifting certified equipment is able to move safely and conveniently, the DNV lifting pad and supporting frame can be added optionally.

Now GN Solids Control has many solids control equipment in stock, once we received the order, we can just buy the motors and put the control boxes, tested and get it to delivery very fast. Welcome to connect with GN Solids Control for any drilling mud solids control and drilling waste management equipment inquiries.

For desander desilter,mud gas separator,mud agitator,and other drilling mud solids control equipments,This order is the first order for GN in Argentia.Like other overseas countries,We all believe this is just a good start for our business in Argentia,GN Solids Control will keeps going faster and faster there.

GNZJ Mud Cleaner is the second stage and the third stagesolids control equipment which is a combination of Desander, Desilter and underflow shaker shaker. Comparing with traditional separate Desander and Desilter, the mud cleaner has a higher cleaning function. The Underflow Screen equals another shaler shaker which receives the waste out from the cyclone nozzle for additional processing. So that mud cleaner could recover more valuable drilling mud. Mud cleaner is the ideal device of the second class and the third class solid control to treat the drilling mud.

The manifold of standard GNZJ mud cleaner could accept one-three ea 10” desander cones and eight-sixteen ea 4” desilter cones which could offer the treating capacity various from 500GPM to 1500GPM. Anyhow, a customized quantity cone would be provided as per customer special request. GN mud cleaner can meet almost all needs for oil & gas well drilling fluids treatment system and HDD Mud Recycling System.

Mud Cleaner is also called Desander and Desilter assembly. Namely, mud cleaner consists of a two-stage separation process using a combination of hydrocyclones frame mounted over a shale shaker to operate as a single unit. Mud conditioner is effective on processing both weighted and unweighted drilling mud during mud systems in removing and drying solids while retaining the expensive drilling liquid. Used correctly, the drilling mud cleaner would greatly lower both drilling-fluid and disposal costs.

In oilfield solids control system, mud cleaner is one type very efficient device in oil & gas drilling mud cleaning system. Drilling Mud Cleaners are one of the important equipments for solids liqiud separation system

Mud agitators are indispensable in drilling fluid configuration. The mud agitator adopts the circular arc cylindrical worm reducer, the shaft section is a circular arc cylindrical worm, and the worm gear tooth shape is a circle that is conjugative to the worm. Therefore, the convex-concave meshing performance is reliable,...

In field of oil drilling mud treatment, drilling mud mixing equipment includes mud mixing agitator, mud mixing hooper, mud mixing tank. This drilling mud mixing equipment are assembled into a mud mixing system. Mud mixing equipment is used to add different chemical additives to drilling fluids and keep mud properties. Various...

What are the types of drilling mud agitators? Let’s first understand the classification method of mud agitators. Mud agitators can be classified according to different reducer motor connection methods, different impeller structures, different mixing media, and different uses. Different classifications have different...

Drilling mud agitator is a special agitator for oil drilling solids control. There are different specifications and models. It cannot be simply used in chemical, petroleum refining, food and other industries. How to choose a drilling mud agitator, here are 4 aspects to pay attention to. Rotating speed of drilling...

The mud agitator is generally installed on the surface of the mixing tank, and the mixing medium is mainly solid and liquid, including mud, muddy water, oil and water and other media. The mud agitator is mainly composed of motor, reducer, base, stirring rod, impeller and other spare parts. Among them, the motor and the...

In oil and gas Industry, Brightway Solids Control Company can design and manufacture the 500-700 Barrels mud pit tanks with agitators used in offshore rig to drill. As the oil drilling mud equipment manufacturer, Brightway Company can provide various mud equipment and services and supplies, such as mud shale shaker, mud...

In the oil drilling industry, there are many drilling mud agitator companies in the world, such as brandt nov mud agitator company, derrick mud agitator company, mi swaco mud agitator company. The mud agitators they produced are used in many oil field drilling mud systems, so they are famous and profecional Drilling Mud...

Liquid Mud Agitator is used for the mud tanks, trip tanks, ship tanks, mud pit. so it also called mud tank agitator, ship tank agitator, mud pit agtator. The Liquid Mud Agitator power includes 10hp 7.5kw, 15hp 11kw, 20hp 15kw. The electric voltage is 220-240V/ 50Hz, 380-415V/ 50Hz, 440-480V/ 60Hz, 575-600V/ 60Hz. The...

Brightway is the mud agitator manufacturer in China and has the competitive mud agitator price for our customer. Mud Agitator Price is composed of two parts, one is the Mud Agitator Power you will use, and the other is the material of the impeller and length of the impeller. So if you want the details

Brighway Solids Control is one of the Mud Agitator Suppliers in the world. Mud Agitator Power includes 5.5kw Mud Agitator, 7.5 kw Mud Agitator, 11kw Mud Agitator, 15kw Mud Agitator etc. As we know, there are many good Mud Agitator Suppliers in the oilfield, such as Derrick, Brandt NOV, Swaco etc. Brightway company is also...

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

AIPU received an order for 4 sets of solids control system for 2000 meters drilling rig (ZJ20 model). The ZJ20 solids control system will including shale shaker, desander, desilter, decanter centrifuge, mud agitator, centrifugal pump, mixing hopper, mud tank etc. The client ordered 4 sets of equipments for oil drilling in China after compared 3 others solids control supplier.

1.1 set of hunter MG3 linear motion shale shaker for 800GPM max flow, the 2 sets of shale sit on a shared skid for fast moving and installation. One distribution box connected with both shaker for mud inlet.

2.1 set of vacuum degasser sit after shale shaker, the self suction vacuum degasser can save one set of centrifugal pump and power supply for the whole mud system.

3.1 set of desander with hunter mini bottom shaker for second phase cleaning. The desander cyclone can be changeable with some US brand of equipment. Hunter mini shaker is a 2 screen panel shaker with wedge type screen.

4.1 set of desilter with hunter mini bottom shaker for third phase cleaning, the desilter cone can be changeable with some US brand equipment and bottom shaker model same with desander.

5.3 sets of centrifugal pump sit on mud tank skid, 2 sets of pump work as a transfer pump for desander and desilter, the third pump work as a mixing pump with a mixing hopper on tank top.

6.4 sets of mud agitators sit on mud tank for avoid solids settling down by working 24 hours. The mud agitator cooperate with mud gun to reach a perfect agitating application. The mud gun will help flash corners of mud tanks.

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

HJBL series vertical mud agitator is mainly used for deep mixing and mixing in the mixing tank. The mixing shaft is longer than 1 meter and equipped with a stainless steel base to ensure that the mixer runs stably and does not shake during the mixing process.

Vertical mud agitator can be widely used in chemical industry (fine chemicals, pharmaceutical chemicals and daily chemicals), environmental protection (sewage treatment), pharmaceuticals, cosmetics, metallurgy, food, heat treatment cooling, leather processing and other industries.

The other mixing tank is consist of mixing hopper, and 2 shear mixing pump with its individual control panel, another transfer pump is on another side of the mixing system to transfer the mud. The centrifugal pump head is interchangeable with famous brand centrifugal pump, the pump casing and impeller are made of hard ductile iron for better abrasion resistance. The mixing hopper and mixing pump installed on the other side of the mixing tank with proper pipeline fittings, the man hole, clean gate, handrails and stairs are equipped on the mixing tank. One transfer pump installed on one side of the mixing tank to transfer the mixed drilling mud to other place. Recently GN solids control shipped mud mixing system to trenchless engineering company, the technical configuration is as below:

The jet mud mixer including mud mixing hopper with different centrifugal pump, we can also install the mud mixing hopper on top of mud tank and the mixing pump installed on the tank skid or the mixing hopper and mixing pump both on the tank skid. The mud agitator motor from 3KW to 22KW to suit for different size mud mixing tank, including GNJBQ030-D, GNJBQ055-D, GNJBQ075-DD, GNJBQ110-DD, GNJBQ150-DD, GNJBQ220-DD. We have 2 phase cleaning, 3 phase cleaning system for mud mixing system, 2 phase cleaning including shale shaker and desilter cone with mud mixing unit, 3 phase cleaning system including shale shaker, desander cone and desilter cone with mud mixing unit. According to different treating capacity, we have option for 200gpm, 400gpm, 600gpm, 800gpm, 1000gpm mud recycling system. Except for mud mixing system, we also produce and design mud recycling system. We can design customized mud mixing system according to client’s requirement, normally we design square shape mud tank, the jet mud mixer are connected with mud mixing tank as independent part. The centrifugal pump can be used as trip pump, mixing pump, super charging pump, transfer pump, feeding pump, etc. The impeller and pump casing are made of ductile hard iron for better wear resistance. GN centrifugal pump is interchangeable with world famous brand centrifugal pump, including the bare pump and pump parts. The mud agitator are installed on top of the mud mixing tank for better agitating and mixing of the chemicals with the drilling fluids. It is an independent part of mud mixing tank.

The mixing pump and mixing hopper are installed on the skid with pipelines. The mud mixing tank including 2 round tank with transfer pump, electric control panel with skid, pipelines, valves. Recently one unit of mud mixing tank and 8 sets of mixing pump are shipped to engineering company. One tank is shaker tank with mixing unit, the other tank is reserve tank with only mud agitator and mud gun installed on it.Įxcept for mud tank system for workover rig, we can also design and produce mud recycling system for oil & gas drilling rig.

The painting color could be customized as per client’s requirement. The previous worm wheel type gearbox is no long used any more, the new type mud agitator are all helical type gearbox with reliable mixing performance.Ħ) Mud tank system, tank top is covered by galvanized steel grating for convenient watching the liquid level and for easy operation.

The centrifugal pump motor power could be 45 KW or 55 KW.ģ) Mixing hopper and mixing pump worked as mixing unit of the mixing tank, to prepare for new drilling fluids which can be reused by the drilling rig.ĥ) Mud agitator and mud gun, the coupling type mud agitator is required by the client, our standard model is direct connected type mud agitator, which the motor and gearbox is connected directly. The technical configuration is as below:ġ) Linear motion Shale shaker, since the workover rig operation do not need so much volume drilling fluids, one unit shale shaker treating capacity is enough, normally they will not use desander cone and desilter cone, which will need high power consumption centrifugal pump as feeding pump, only when it is required by the user, we will install the desander or desilter or mud cleaner.Ģ) Desander with its feeding pump, this is a desander unit without bottom shale shaker, the desander cone separation cut point is 45 microns, the desilter cone cut point is 25 microns. Recently one set of workover drilling rig mud system are shipping to China drilling company.

8613371530291

8613371530291