mud agitator vs desander pricelist

Mud Agitator Price is composed of two parts, one is the Mud Agitator Power you will use, and the other is the material of the impeller and length of the impeller. So if you want the details of Mud Agitator Price, you need to provide your use and requirements. How much power is needed and your deepth of mud tanks.

Brightway is the famous mud agitator manufacturer and mud agitator supplier in China. and have more types mud agitators used in the mud tank of drilling mud system or other industry. such as 5.5KW 7.5kw 11kw 15kw mud agitators, or Horizontal Mud Agitator and Vertical Mud Agitator for Mud tank. Gear driven, Advanced impeller designs, Good Packed and delivered quickly. At present, Brightway BWJBQ series mud agitator had been exported to 40+ countries and service for many coustomers. Competitive Prices of Mud Agitator and good sevice is the importent factor.

If you want kown the Mud Agitator Price, please send your request to Brightway Email ( brightway@bwwell.com ) and our sales engineer will give you an Competitive Prices offer as soon as possible.

For desander desilter,mud gas separator,mud agitator,and other drilling mud solids control equipments,This order is the first order for GN in Argentia.Like other overseas countries,We all believe this is just a good start for our business in Argentia,GN Solids Control will keeps going faster and faster there.

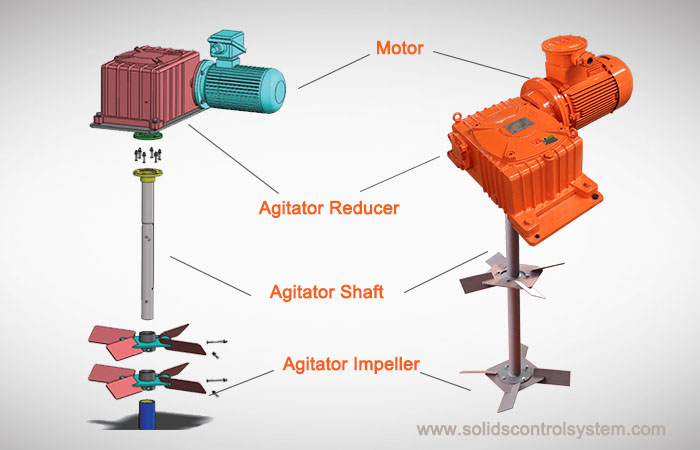

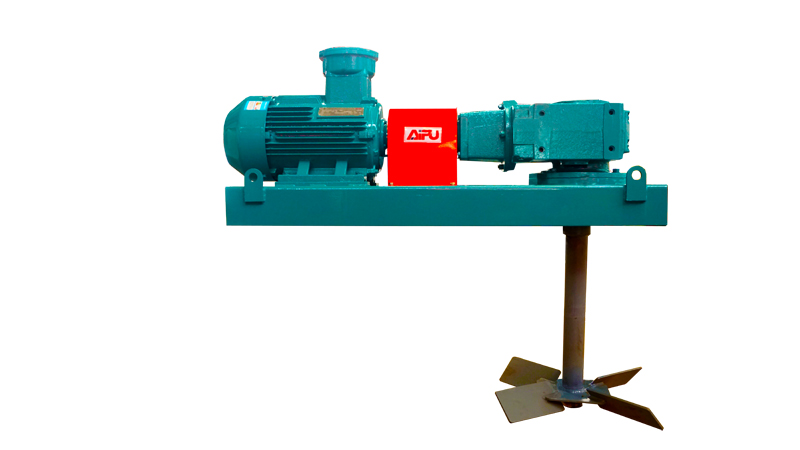

DC mud agitator is used for the mixing and agitation of drilling fluid, preventing the settlement of solid phase particles in the tank recycling system.

(2) Customers can choose single layer or double layers impellers according to site conditions.Agitator shaft centering guide can be added according to the increase of tank depth.

KOSUN oilfield drilling mud decanter centrifuge can meet with different requirements of mud treatment under various drilling condition, that can do sedimentation and separation for particles more than 2 um. After treatment, the mud can achieve ideal viscosity and proportion, results in better recycling, high efficiency, saving and environment protection.

The mud separation process between solid phase and liquid phase is completed in the roller. Decanter centrifuge separation principle is to use high-speed rotating roller driven into the mud in the high speed rotating drum, mud was dumped into the wall to form a liquid circle, solid phased particles of liquid ring get greater than its own gravity for undreds or even thousands of times the effect of centrifugal force, will overcome the resistance of the slurry viscosity to the roller on the inner wall of rapid subsidence formed solid layer, liquid forming liquid layer.

In order to fully understand how a decanter centrifuge operates, we must first define what a centrifuge does. In many industrial jobs, solid material often mixes with liquids, contaminating water supplies or turning mud into sludge. A decanting centrifuge is useful in that it separates solids and liquids, and has become an essential component of water waste facilities and the chemical, oil, and food processing industries. Moreover, without a centrifuge, many of these companies would become so inefficient they could not function.

KOSUN is capable of providing customers with such three series as oil & gas drilling solids control equipment, decanter centrifuges, shale shaker, mud gun, mud agitator, vacuum degasser, jet mud mixer, mud cleaner, desander, desilter and drilling waste treatment equipment(DWM), including 25 categories of products, which are extensively used in oil & gas drilling and workover, coalbed methane drilling, shale gas drilling, water well, geothermal well drilling, trenchless horizontal directional crossing projects, mine gravel staged treatment, tailings treatment, rive dredging works, industrial wastewater treatment, environmentally friendly sewage treatment, waste oil recovery, purification treatment, etc.

GN General Brochure (2017) Content Part 1: Company Profile…………………………………………… 3 Part 2: Decanter Centrifuge………………………………………… 8 Part 3: Shaker Screen……………………………………………… 17 Part 4:Solids Control Equipment………………………………… 22 4.1 Shale Shaker………………………………………………… 22 4.2 Desander & Desilter………………………………………… 24 4.3 Degasser …………………………………………………… 27 4.4 Mud Agitator & Mud Gun…………………………………… 30 4.5 Mud Mixing Hopper………………………………………… 31 4.6 Mud Tank…………………………………………………… 32 4.7 Flare Ignition Device………………………………………… 33 Part 5: Waste Management Equipment…………………………… 34 5.1 Vertical Cuttings Dryer……………………………………… 34 5.2 High G Drying Shaker……………………………………… 35 5.3 Screw Conveyor…………………………………………… 36 5.4 Inclined Plate Clarifier……………………………………… 37 5.5 Oil Water Separator………………………………………… 38 5.6 Chemical Dosing Equipment……………………………… 39 5.7 Waste Solidification Unit…………………………………… 40 5.8 Thermal Desorption Unit…………………………………… 41 Part 6: Transfer Pumps…………………………………………… 42 6.1 Centrifugal Pump…………………………………………… 42 6.2 Shear Pump………………………………………………… 43 6.3 Screw Pump………………………………………………… 44 6.4 Submersible Slurry Pump…………………………………… 45 6.5 Vacuum Pump……………………………………………… 46 Part 7: Electrical Control Equipment……………………………… 47 Part 8: Application………………………………………………… 50 8.1 Oil Gas Drilling Solids Control……………………………… 50 8.2 Drilling Waste Management ………………………………… 51 8.3 Oil Sludge Treatment ……………………………………… 53 8.4 HDD Mud Recycling System……………………………… 54 8.5 TBM & Bored Piling Mud Cleaning………………………… 55 8.6 Industry Solids & Liquid Separation………………………… 56

Main Function of GN Industry Centrifuges GN Centrifuge Main Application Industry ● Dewatering sludge / mud and suspensions ● Oil Gas Drilling Mud Solids Control ● Thickening sludge or mud ● Drilling Waste Management ● Clarifying different type liquids ● Oil Sludge Treatment ● Separating 3-phase mixtures, i.e. two immiscible fluid ● HDD trenchless mud cleaning phases and a solid phase ● Bored Pile and TBM mud dewatering ● Classifying solids in a wet suspension by grain size ● Waste water treatment ● Separation of solids according to various densities ● Chemical and Pharmaceutical separation ● Mining industry separation ● Food and Beverage industry separation

The mud distribution port is made from Tungsten carbide inserts, the anti-abrasion will extend the life for heavy mud.

The advantage of the FHD centrifuge is for use in high temperature ambient for heavy mud with flexible bowl and differ-ential speed. The compact one skid design makes it easier for rig up.

12 Decanter Centrifuge2.6 14inch (360mm) Decanter CentrifugeGN 14inch (360mm)decanter centrifuge is the most popular centrifuge for oil gas industry, it is popular for drilling mudtreatment, and also it can be used for industry waste water treatment, oil sludge treatment, mining water treatment, chem-ical industry separation.GN 14 inch decanter centrifuge is optional in three types includes: fixed gear box drive, fullyhydraulic drive, and variable frequency drive.

13 Decanter Centrifuge2.7 18inch (450mm) Decanter CentrifugeGN 18inch(450mm) decanter centrifuge is optional with 3 different bowl length.GNLW452 is an economic centrifuge,popular for drilling mud treatment. To meet different applications, the GNLW453 and GNLW454 is designed with longerbowl.GN 18 inch decanter centrifuge is optional in three types includes: fixed gear box drive, fully hydraulic drive, and vari-able frequency drive.

14 Decanter Centrifuge2.8 22inch(550mm) Decanter CentrifugeGN 22inch(550mm) decanter centrifuge is widely used for different industry .It is the medium size centrifuge which hasthe normal capacity requirement for most of the applications. It is popular for drilling mud treatment, and also it can beused for industry waste water treatment, oil sludge treatment, mining water treatment, chemical industry and food indus-try separation.

15 Decanter Centrifuge2.9 30inch(760mm) Decanter CentrifugeThe GN 30 inch (760mm) bowl diameter decanter centrifuge is a big bowl centrifuge. GN 30inch centrifuge iswith bowl length and diameter ration of 4.4:1. This bowl size allows client to handle big volume fluids with onesingle unit. Because of GN unique design for the screw and bowl, the GN 30 inch decanter centrifuge is designfor best performance in Tunnel Boring Project Mud Cleaning, Dredging Slurry Separation, and Municipal SewageSludge in Purification Plants, Industry Waste Water Treatment. The tungsten carbide protection in the slurry distri-bution port or solids discharge port as well as the screw conveyor inside the bowl makes the GN 30 inch decantercentrifuge lasts longer.

Model GNLW764A-VFD Bowl Diameter 760mm Bowl Length 3328mm 528GPM/120m3/h Designed Capacity (Mud with 20% Solids Content) Max Bowl Speed 2650RPM Typical Bowl Speed 0-2200RPM Max G Force 3000G Typical G Force 0~2060G Cut Point 2-5µm Differential Speed 5~28RPM Gearbox Torch 25000 N·M Gearbox Ratio 38:1 Main Motor 132KW(180HP) Back Drive Motor 90KW(120HP) Above Max capacity is for reference only, the treating capacity would be various as Remarks per different material conditions and customer required treating results.

● Automatic Robot Welding of the steel frame to have better quality and consistency. ● High quality fiber glass to improve plastic quality and screen temperature resistant to 140 C degree. ● Four side tension of mesh during the heat press to minimize the gap between the top screen and support screens, in a result extending the screen life. Our competitors normally do not use any tension for heat press. ● GN 3 layer wire mesh for API 60 and above for longer screen life, our competitor normally use 3 layer only for API 120 and above. ● GN high performance wire mesh configuration is compliant to API RP 13C with normally longer screen life. ● GN comprehensive line composite frame replacement screen for GN shakers, MI-Swaco Mongoose, MI-Swaco MD-3/MD-2, Nov Brandt Cobra, Venom, VSM-300, FSI screen, Derrick FLC 2000 FLC 500 etc. And we can customize the In¬jection mold for your screen dimension. ● The composite frame screen is repairable to save cost. ● Compared to metal frame, the composite frame useable area is 10% to 20 % larger. ● Since the composite frame is covered by plastic, it is rust resistant for long time storage up to over 5 years.

19 Shale Shaker Screen3.4 GN Shaker Screen Types3.4.1 GN OEM ScreenGN Solids Control sells around 200 shale shakers a year, we have shale shakers operate around the world. To use GNOEM screen will improve your shaker performance and save your operational cost.OEM Shaker Screen for GNZSseries shale shaker include screen for GNZS703, GNZS752, GNZS594 shale shaker and screen for GNZJ703,GNZ-J752,GNZJ594 mud cleaners.

3.4.2 Replacement Screen for MI-Swaco ShakerReplacement Shaker Screen for MI-Swaco MONGOOSE PRO, MONGOOSE PT & MEERKAT, ALS, BEM, MD-3 se-ries shale shaker or mud cleaner. Available in Steel frame or composite frame.

20 Shale Shaker Screen3.4.3 Replacement Screen for Derrick ShakerReplacement Shaker Screen for Derrick FLC 2000, FLC 500 , DP 600 and Hyperpool series shale shaker and mud clean-er. The screens are available in flat screen or pyramid screen. Composite screen is available for high quality and longerscreen life.

3.4.4 Replacement Screen for NOV BrandtReplacement Shaker Screen for NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D, VSM 300series and D380/D285P shale shaker and mud cleaner. Available in steel frame or composite frame.

Model GNZS752F-MDZF GNZS703F-SDZF GNZS703F-SHBF GNZS594F-SHBF GNZS706F-SHBF Vibration Mode Linear Motion Capacity(m³/h) 45(200GPM) 120(528GPM) 140(616GPM) 140(616GPM) Vibration 2×1.0 2×1.72 2×1.94 Motor(Kw) Screen Qty(Pcs) 2 3 4 6 Up:750×900 Screen Size(mm) 750×900 700×1250×29 585×1165×40 Down:700×1250 Up:2.03 Screen Area(m2) 1.35 2.63 2.73 Down:2.63 Adjustable G Force ≤7.5G ≤7.3G Vibration 4.14~5.96 4.04~5.82 Amplitude(mm) Deck Angle Range +2° -1°~+5° Feeding Type Top Box Feeder Weir FeederWeir Height(mm) 714 1060 895 EX Standard ExdIIBt4 / IEC EX/ ATEX Weight(Kg) 929 1665 1571 1624 1795 L×W×H(mm) 1816×1657×1083 2462×2007×1476 2744×1968×1435 2989×1968×1435 2744×1968×1435 Above capacity only for reference, actual capacity will be various as per screen API No. and mud Remarks conditions

Model GNZJ703F-D1S8NF GNZJ703F-S2S12NF GNZJ594F-S2S12NF GNZJ703F-S3S16NF GNZJ594F-S3S16NF Capacity(m³/h) 120(528GPM) 240(1056GPM) 360(1584GPM) Desander Size(Inch) 10 Desander Qty(PCS) 1 2 3 Desilter Size(Inch) 4 Desilter Qty(PCS) 8 12 16 Working Pressure(Mpa) 0.25 ~ 0.4 Inlet Size(Inch) 6 Outlet Size(Inch) 8 Shaker Model GNZS703F GNZS594F GNZS703F GNZS594F Vibration Mode Linear Motion Motor(Kw) 2×1.72 Screen Qty(Pcs) 3 4 3 4 Bottom Screen Size(mm) 700×1250 585×1165 700×1250 585×1165 Shaker Specs. Screen Area(m2) 2.63 2.73 2.63 2.73 Adjust G Force ≤7.5G Vibration Amplitude(mm) 4.14 ~ 5.96 Deck Angle Range -1 ~ +5° EX Standard ExdIIBT4/IECEX/ATEX Weight(Kg) 1930 2235 2285 2328 2378 Dimension: L×W×H(mm) 2462×2042×1848 2462×2042×2147 2707×2042×2147 2462×2042×2147 2707×2042×2147

Features● Desander & Desilter & Shale Shaker 3 in one unit for compact footprint.● Polyurethane Material hydro cyclone for long life.● Removable hydro cyclone assembly for adjusting to be a shale shaker.● Mechanical shaker deck angle adjustable while working.● Patented tighten rubber sealing for shaker deck and screen, long life and easy replacement.● Shaker bottom deck made from Stainless Steel for long service life.● Heat treatment on complete shaker deck for High G force operation.● Pretensioned Shaker screen for fast screen replacement.● Famous Brand Vibration Motors : IEC Ex, ATEX and UL Certified

Type: Desander without downstream drying shale shaker Model: GNWS-2S / GNWS-3S Application: For oil gas drilling un-weighted drilling mud. Features:Small footprint, economic choice, no consumable screens. Result: Wet cuttings, not recommended for Weighted mud and drying solids.

Type: Desander with GNZS752 Series Mini Shale Shaker Screen Area:1.4m2 Model: GNZJ752E-1S / GNZJ752E-2S Application: For oil gas drilling small drilling rig, CBM drilling, HDD, Water Well drilling. Features:Small footprint, economic choice, acceptable drying solids.

Type: Desander with GNZS703 Series 3 Panel Shale Shaker Screen Area:2.6m2 Model: GNZJ703F-D2S / GNZJ703F-3S Application: For oil gas drilling big drilling rig , large HDD rig, Tunneling Boring Machine etc. Features:Big capacity,,drying solids.

Model GNZJ752E-1S/2S GNZJ703F-D2S GNZJ703F-3S GNWSE-2S/3S 3 3 3 120/240m /h 240m /h 360m /h 240/360m3/hCapacity (528/1056GPM) (1056GPM) (1584GPM) (1056/1584GPM)Desander Size(Inch) 10″Desander Qty 1/2 Pc 2 Pcs 3 Pcs 2/3 PcsWorking Pressure 0.25~0.4MpaFeeding Size DN150Output Size DN200 Shaker Model GNZS752E GNZS703F Vibration Mode Linear Motion Vibration Motor 2×0.75Kw 2×1.72Kw Screen Qty 2 Panels 3 PanelsBottom Screen Size 750×900mm 700×1250mmShaker N/ASpecs. Screen Area 1.35m2 2.63m2 Adjust G Force ≤7.1G(Adjustable) ≤7.5G(Adjustable) Vibration Amplitude 3.92~5.62mm 4.14~5.96mm Deck Angle Range +2° -1~+5° EX Standard ExdIIBt4/IECEX/A-TEXWeight(Kg) 1059/1114kg 1835kg 1924kg 502/559kgDimension:mm 1676×1754×1822 2419×2131×1656 2419×2135×2066 2177×1000×1901

Type: Desilter without downstream drying shale shaker Model: GNWS-12N / GNWS-16N Application: For oil gas drilling un-weighted drilling mud. Features:Small footprint, economic choice, no consumable screens. Result: Wet cuttings, not recommended for Weighted mud and drying solids.

FeaturesGNZCQ Series Vacuum Degassers that are able to service the needs of any application. It is usually installed after theshakers. Each degasser effectively and efficiently removes gases from gas-cut mud, thus ensuring that the proper mudweight is pumped downhole. In doing so, the degassers are able to aid in the prevention of potential blowouts. Unlike thetraditional vacuum degasser, GNZCQ vacuum degasser is a self-contained unit, GN Vacuum Degasser is monitored bylevel sensor to protect over suction of the fluids. The gas-cut mud is drawn into the degasser by a vacuum created by a re-generative vacuum without needing centrifugal pump . GN degasser can act as a big agitator for the drilling mud, whichhelps the treatment for desander and desilter.

Features Model GNLCQ300AGNLCQ300A centrifugal degasser is a new type degasser, Liquid Inlet Size 20″specialized in processing gas cut drilling fluid. Normally it is Liquid Outlet Size 8″installed after shale shaker and widely used in various solids Gas Outlet Size 2″control system, and it is very important for recovering mud Max Liquid Throughput 300m3/hweight, stabilize mud viscosity performance, reduce drilling Max Gas Removed 30m3/hcost. Meantime it can be used as a big power blender. Its Main Motor 22Kwad¬vantages are large capacity, high rate of degassing, less Fan Motor 1.1Kwarea required, low energy consumption, easy operation and Gearbox Ratio 1: 3.78main¬tenance. Weight 1375kg Dimension 1150×1055×2885mm

FeaturesGN Mud Gas Separator is designed for continued drilling in underbalanced conditions where dramatic pressure surgesare normal. The GN Mud Gas Separator is manufacturing according to API and ISO Standard.In dangerous “kick” conditions, the Mud Gas Separator allows operators to circulate the drilling fluid by removing largepockets of gas. The gas cut mud enters the flow line of the unit, where it hits a series of baffle plates. These baffle platesprovide surface area for the dispersion of the gas cut mud. The mud is routed to solids control equipment for further pro-cessing while the separated gas travels to the flare line at the top of the unit to be vented at a safe distance from the rigand rig personnel.

GN solids control designs and manufactures various types of tank including mud tank, wa- ter tank, oil tank, etc. GN solid control mud tanks are usually used to install solids control equipment, storage mud, mixing mud, etc. It meets utility request of the drilling solid con- trol system, mud plant and solid-liquid sepa- ration system. According to different working conditions, mud tanks can be customized into horizontal mud tank, vertical mud tank and trailer mounted mud tank.

FeaturesThe GN Flare Igniters used for connecting to the gas discharge line of Mud Gas Separator, which fire the dangerous gasfrom the drilling mud like H2S.GN Flare Igniters have options for electrical power charge or Solar Energy charged.The upper part of the flare ignition system is stainless steel, and it is designed for rain proof in the oilfield. The majorcomponents for the electrics are from famous Brand like SIEMENS or Schneider. The power for the electric can be di-rectly from industry normal power, or users can charge the battery and take the unit for remote areas application.GN flaredevice is with remote control, and PLC is optional available for less manpower notice for continually and automaticallyworking.

Features● More Application: Working for OBM, WBM, and SBM.● High G Force: Normal 420G @ 900RPM, super high speed with 750G @ 1200RPM● FAG Brand premium bearing.● The Flights on the rotor is hard facing to HRC 65, longer life than our competitors.● Special high pressure air knife design to clean the basket screen automatically to avoid the screen blinding especially for high viscosity mud and water based mud.

GNDU2000 series 20ft container chemical dosing equipment is mainly used for mixing of flocculation, coagulation or de-emulsifier. It works together with dewatering centrifuge to separate the ultra-fine solids from the mud or waste water, to get clean water for industry applications; or support the separation of waste sludge.

Model: GNDU-2000A Chemical Dosing System Include 20ft container with decoration, include electric control system, exhaust system, lighting system. Max powder adding capacity:1-6 Kg/Hr( Speed Adjustable) Tank Material: SS304 Hopper Volume:45 L Three Chamber automatic Tank Capacity:2000L Dosing Unit Output for concentration 0.1%:2000L/Hr, if aging time is 45 Min. Mud agitator: 3 sets Model: GN-2000S Dosing pump: 2 sets, single pump capacity:2000L/h(adjustable) Dimension:2000×1400×1500mm Including Ex liquid level meter, Ex electromagnetic flow meter, Ex solenoid valve, relief valve, buffer, filter and pressure gauge, etc accessories. Tank Material: Outer material is carbon steel, inner material is PE Dissolving Tank Volume: 2000LSingle tank chemical Dosing Dissolving Tank Dimension 1400×2200mm(Agitator included) Unit Mud agitator: 1 set Dosing pump: 2 sets, single pump capacity:530L/h(adjustable) Model: GN-2000L Attached with Magnetism rolling board level meter, relief valve, buffer, filter and pressure gauge, etc accessories.

The GN SB Series Centrifugal pumps are used for transferring slurry or mud or water. They can be used as the feed pump for a desander or desilter, or used as a mixing pump for a Jet mud mixer. They can also be used as a trip pump or supercharging pump for the rig mud pump. All GN model centrifugal pumps use tungsten carbide mechanical seals and use bearings from first tier international suppliers. Spare parts are interchangeable with the commonly used international brand pumps which helps the customer to source spare parts easily. The open impeller design lowers axial thrust loads and make it easier for installation, repair and maintenance.

Features:The GN shear pump reduces the cost of mixing polymers and clays while improving mud properties. Shearing the poly-mers eliminates fish eyes and prevents polymer chaining (long strings), which cannot pass through the shaker screens.The GN shear pump is available as a belt-driven or diesel-driven package including a hopper, mud gun, and transfer lineorifice plate. A complete system with skid, tanks, and piping are also available.GN Shear Pump impeller is specially designed to have a wider flow pass and smooth vanes, with larger flow area andsmooth fluid pass, making the shear pump reach the internationally advanced level in shear pump efficiency and ener-gy-saving, 10% higher than similar products.The shear pump has adopted a shell thicker than normal one, with rationalpass and less turbulence.GN Shear pump Impeller and shell are made of high wear resistant cast irons, with longer servicing life. The shear pumpshaft has high strength that can bear certain load, reducing shafts deflection and extending seals service life;The shaft islubricated with lubricants and lubricating grease and the oil seal is made of special structure and materials, suitable forhigh and low temperatures and complicated environment;Front opening structure is used for convenient installation, re-pair and maintenance.

Features:The GNG Series Positive Displacement Pump is a single screw pump .The pump is an ideal pump for feeding to decantercentrifuge without shearing or agitating the drilling mud. The main parts are screw shaft (rotor) and screw shaft bushing(stator). Because of the special geometry shape of the two parts, they form pressurize capacity separately. The fluids flowalong with the shaft, inner flow speed is slow, capacity remains, pressure is steady, so it will not generate vortex and agi-tating. The shaft of the pump is made from Stainless steel, GNG series pump is available for option with complete stain-less steel body,It can drive by coupler, or adjust the speed by using variable speed motor, Triangle V-belt, gear box, etc G series positivedisplacement pump is with less accessories, compact structure, small volume, easy maintenance, rotor and stator are wearparts of this pump, it is convenient to replace.The stator is made of elastomeric material, so it has particular advantages than other pump to transfer the fluids of highviscosity and hard suspended particles included.

Features:GN YZ Series Submersible slurry pump is with structure of vertical single stage and single suction system overhungcentrifugal pump, it is made of abrasion-resistant alloy, it can transfer medium with high concentration particle. The nor-mal submersible length is 1.3m,customized length is available. There is no bearing and Gland Seal between impeller andpump body,so the slurry pump is maintenance-free and high temperature resistance, the slurry pump is the ideal centrifu-gal pump for feeding to decanter centrifuge, and feeding from mud pit for to the shale shakers on the mud system, it canalso be used as feeding pump for desander and desilter.

Material transfer applications1) Waste mud and waste solids discharged from shale shaker, mud cleaner and centrifuge transfer2) Drilling mud transfer3) Waste pit cleaning4)Hazardous waste recovery5) Oil sludge, tank bottoms residual removal and transfer6) Barge holdings and vessel bottom clean out7) Bulk tank and silo transfer of material8) Sand; Course, fine, conventional and frac sand9) Diatomaceous earth10) Animal waste etc.

8.1 Oil & Gas Drilling Solids Control SystemGN Solids Control manufactures all solids control equipment. Mud tanks are also designed and manufactured to composewhole mud systems to meet the demands of drilling rigs from 250HP to 3000HP. As a solids control manufacturer ownsUSA API and ISO certifications, GN Solids Control also certified by Europe CE for exporting to developed countries.

50 Industry Application8.2 Drilling Waste Management SystemGN Solids Control provides turnkey solutions for closed loop drilling mud and drilling waste management system. Keyequipment includes Hi-G Shaker, Cuttings Dryer, Decanter Centrifuge, Flocculating Dosing Unit, Sludge SolidificationUnit, and Thermal Desorption Unit. They can be used to treat WBM, OBM and SBM.

53 Industry Application8.4 Trenchless/HDD Mud Recycling SystemGN is committed to the research and development of trenchless mud recycling system, mud mixing system, decantercentrifuge etc. As a leading brand in the world, GN’s products have been exported to over 60 countries and regions, andset up branches & services stations in 8 countries. GN Solids America is GN’s USA brand.

Configuration Type High Configuration System Function Mud Recycling/Mixing/Strage GNMS- GNMS- GNMS- GNMS- Model GNMS-500B GNMS-500GL GNMS-1000G 200G 350G 500G 1000GL Capacity 50m³/h 80m³/h 120m³/h 120m³/h 120m³/h 240m³/h 240m³/h Cleaning Stage 2Stages 2Stages 2Stages 3Stages 3Stages 3Stages 3Stages Treating Precision 20μm 20μm 20μm 20μm 20μm 20μm 20μm System Volume 5m³ 9.5m³ 9.5m³ 15.5m³ 24.5m³ 30m³ 48m³

Advantages of GN Recycling Equipment● Preferred supplier of well-known rig manufacturers and contractors.● Leading capabilities on both hardware and software, welcome for facility site visiting.● Certified with US API, Europe CE and Russia CU-TR standard.● High level material selected: stainless steel shaker deck bottom frame, Italy OLI vibration motor and Siemens electric components.● Independent research and manufacturing on 4-Stage cleaning equipment: Shale Shaker, Desander, Desilter and Decanter Centrifuge.

54 Industry Application8.5 TBM & Bored Piling Mud CleaningGN Solids Control is providing the assembled-type mud cleaning system for piling and TBM projects. The productionline includes models with capacity of 120m³/h, 240m³/h, 360m³/h ,500m³/h, 1000m³/h,1500m³/h,2000m³/h,3000m³/h. Inaddition, GN also provides big bowl decanter centrifuge and chemical dosing system for treating the mud to discharge-able water.

Configuration Type Economic Configuration System Function Mud Cleaning/Recycling Model GNMS-200D GNMS-500D GNMS-1000D Capacity 50m³/h 120m³/h 240m³/h Cleaning Stage 2 Stages 2 Stages 2 Stages Treating Precision 20μm 40μm 40μm System Volume 1m³ 1.5m³ 1.5m³

Particle Size 0-2 2-5 5-20 20-40 40-60 60-1000 1000-2000 >2000 (Microns) Solids Control 4th Stage 3rd Stage 2nd Stage 1st Stage Stages Shale Shaker No API 270/325 ≤API 230 API 10/20 ≤API 10 Desander No Yes No Desilter No Yes No Decanter Middle Middle Flocculant High Speed Low Speed No Centrifuge Speed Speed Inclined Plate Flocculant Flocculant Yes ClarifierVertical Cuttings No Solids Should be above 250 microns Dryer Centrifugal Yes No Pump

Hoppers, mud guns, desanders, desilters,degassers, and triplex pumps requiring supercharging all have one thing in common: they require 76–80 feet of inlet head to operate as designed. Exceptions do exist, and the equipment manufacturer should be consulted. This simplifies the job of sizing centrifugal pumps. Since most applications in drilling systems require 80 feet of head at the inlet of the equipment, knowledge of volume needed by each piece of equipment is required. Following are standard flow rates when equipment has an 80-foot inlet head:

Take, for example, a contractor who wishes to operate a two-cone desander equipped with 10-inch cones and anticipates the maximum mud weight to be 16 lb/gal. The pump is mounted on the same deck as the desander and is 150 feet away. The inlet to the desander is 10 feet above the deck. The supply tank minimum liquid surface level is 8 feet above the pump centerline. Remember that two 10-inch cones will flow 1000 gpm and that the desander requires 80 feet of inlet head:

80 feet required by desander + 10 feet of discharge elevation − 8 feet of positive suction elevation + ? discharge friction loss + ? suction friction losses = TDH required at discharge of centrifugal pump.

Discharge elevation above pump centerline is 10 feet; supply tank liquid surface level is 8 feet above the pump centerline; and the required desander inlet head is 80 feet. Therefore, 80 = 10 – 8 +22.5 + 2.24 = 106.74 TDH required. Knowing the flow rate of 1000 gpm and TDH required at the pump to be 107 feet, an individual can begin the pump selection process.

Centrifugals must be sized using maximum values anticipated, to ensure that they can perform without cavitation and that the driver is adequately sized. If there is a possibility that the contractor would add a third cone and flow at 1500 gpm, the pump must be sized to handle up to 1500 gpm (this would also affect line velocities and friction losses). Motors must be sized for maximum mud weight. For this example, assume 1000 gpm to be the maximum flow rate and 16 lb/gal mud to be maximum mud weight. A pump to produce 1000 gpm at 107 feet TDH is required. This operating point is marked on attached curves (see Figure 1. – 6.).

5×4×14: Located at the end of the curve. NPSHR is very high. If this pump is used, cavitation is likely due to insufficient NPSHA. Even given sufficient NPSHA, if additional cones are added, mud temperatures rise, or if the desander cone wears, the pump could not handle the increased volume required. This would be an unacceptable sizing choice.

Knowing the SG of the fluid is necessary to determine the hp required. Maximum mud weight in this example is 16 lb/gal. To determine SG, use the following formula:

8613371530291

8613371530291