mud agitator vs desander quotation

Fluid Systems uses an impeller to mix and suspend the solids using both axial and radial flows, and by utilizing low shear mixers to suspend and mix mud additives particle size degradation and polymer shear. Unlike centrifugal pumps or mud guns. The FSI Agitator is relatively low shear and low energy device, so it’s easy to operate and inexpensive to maintain.

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

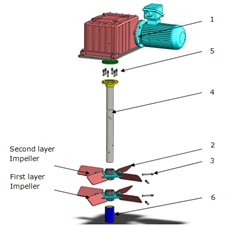

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

• The Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high

• Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the Agitator is the lower bearing, which can

The VIDA BEM 10” hydrocyclone desander is a cost-effective equipment upgrade designed to efficiently remove sand-size (40-100 micron) particles from drilling fluids. Operating at 75 ft lbs of pressure, the unit processes approximately 500 gallons of fluid per minute, per cone.

Easy installation and maintenance, long-wearing durability and dependable performance make the VIDA BEM 10” hydrocyclone desander the ideal equipment upgrade for demanding drilling projects.

Most water-based muds (WBMs) are disposed of when the drilling job is finished. In contrast, many oil-based muds (OBMs) and synthetic-based muds (SBMs) cuttings are recycled when possible. Sometimes the physical and chemical properties of the used muds have degraded somewhat, and the cuttings must be processed to rejuvenate the necessary properties. In other cases, the cuttings have been degraded sufficiently that they cannot economically be reused as new muds, and they must be put to a different type of reuse or final fate.You can consult GN Solids about the drilling cutting treament business.

Dachuan are a desander factory with ten years of production experience, we have our own factory and a complete and professional production line, so we will provide you with the best price and the most reliable quality products. If you need it, please contact us immediately!

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

Oil ang gas drilling (Drilling mud recycling system, drilling waste management, comprehensive disposal for oil sludge, mud comprehensive treatment station, barite recovery system etc.)

Infrastructure construction (HDD mud purification, pipe jacking / TBM slurry circulation, slurry for continuous wall construction’s separation, and mud of pile foundation engineering’s treatment, etc.);

A mud tank is an open-top container that is made of square-shaped steel tubes and plates with a cone-shaped bottom. These are used to mix and store drilling fluid on a drilling rig or for boring operations. The earliest concept of a mud tank was made by digging pits into the earth and using them to store products. For that reason, they can also be referred to as mud pits.

Mud tanks are able to mix, treat, and store drilling fluids, which makes them extremely important to the oil and gas industries. They are also used in applications to remove unwanted solids and sediments from the drilling and boring systems.

Mud tanks have different capacities for different storage functions attached to the oil and gas industries. For land rigs, mud tanks have an estimated capacity of 240 barrels.

The shale shaker is used to separate big solids while the desander separates relatively smaller solids. The desilter also segregates smaller kinds of solids from the drilling fluid. The vacuum degasser separates air from the drilling fluid. The centrifugal pump is used to move this drilling fluid from one component into another for further purification. The vertical slurry pump is used to pump the drilling fluid up to the centrifuge. The mud pump is used to pump the drilling fluids from the mud tank into the borehole after it is treated by centrifuge.

This circulation process repeats as a cycle. Normally the shale shaker, the vacuum degasser, and the desander are mounted together on the same mud tank. The desilter and the centrifuge are mounted on the second tank.

Adler Tank Rentals provides 10,080 gallon (240 bbl) open-top mud storage tanks, which are the top-performing solution for the oil and gas industries. With their sloped V-shaped bottoms for easy drainage, smooth interiors, top-mounted sidewall support braces, and durable one-quarter-inch steel-plate floors, these mud tanks make solids control extremely reliable and convenient.

All our mud tanks meet the highest standards of safety inspections and offer highly efficient containment and treatment solutions for your drilling projects.

Mud agitator combined with motor and gear box. Mud agitators do agitation in drilling fluid make the solids suspend. Help drilling fluid property achieve better. Shaft will be connected with gear box coupled on motor. Under a certain ratio the shaft mounted with impeller rotate at uniform speed and lead an upward stream in drilling mud. This will benefit drilling mud mixture completely with sufficient viscosity, etc.

Onshore and offshore oil&gas drilling, CBM exploration, HDD,waste management, etc. process system. Mud agitators make drilling fluid property more even and stable.

Leading Manufacturer of Drilling Mud Cleaner, Hydrocyclone Desander, Mud Agitator, Balanced Elliptical Motion / Linear Motion Shale Shaker and Shale Shaker Screen from Jodhpur.

JOT manufacture Mud Cleaner which is the first-stage solids control equipment in the drilling fluid solids phase control system, and separates a large amount of cuttings carried by mud from wellhead, facilitating mud to enter the second-stage separation equipment. JOT manufacture both two stage (Shale Shaker + Desilter) and three stage (Shale Shaker + Desander + Desilter) mechanical process Mud Cleaner.

Desanders are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter.

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation.

Vacuum Degasser is adapted to get rid of various cut-in gases in the drilling fluids. Vacuum degasser is very important for returning mud gravity, stabilizing mud viscosity and reducing drilling cost. Therefore, it works as one type mud cleaning equipment. As it is placed after the shale shaker, so we call it second stage mud cleaning equipment in mud recycling system. At the same time vacuum degasser can be used as a heavy-power agitator.

8613371530291

8613371530291