mud agitator vs desander price

Mud Agitator Price is composed of two parts, one is the Mud Agitator Power you will use, and the other is the material of the impeller and length of the impeller. So if you want the details of Mud Agitator Price, you need to provide your use and requirements. How much power is needed and your deepth of mud tanks.

Brightway is the famous mud agitator manufacturer and mud agitator supplier in China. and have more types mud agitators used in the mud tank of drilling mud system or other industry. such as 5.5KW 7.5kw 11kw 15kw mud agitators, or Horizontal Mud Agitator and Vertical Mud Agitator for Mud tank. Gear driven, Advanced impeller designs, Good Packed and delivered quickly. At present, Brightway BWJBQ series mud agitator had been exported to 40+ countries and service for many coustomers. Competitive Prices of Mud Agitator and good sevice is the importent factor.

If you want kown the Mud Agitator Price, please send your request to Brightway Email ( brightway@bwwell.com ) and our sales engineer will give you an Competitive Prices offer as soon as possible.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

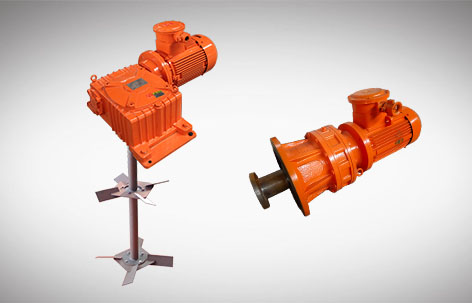

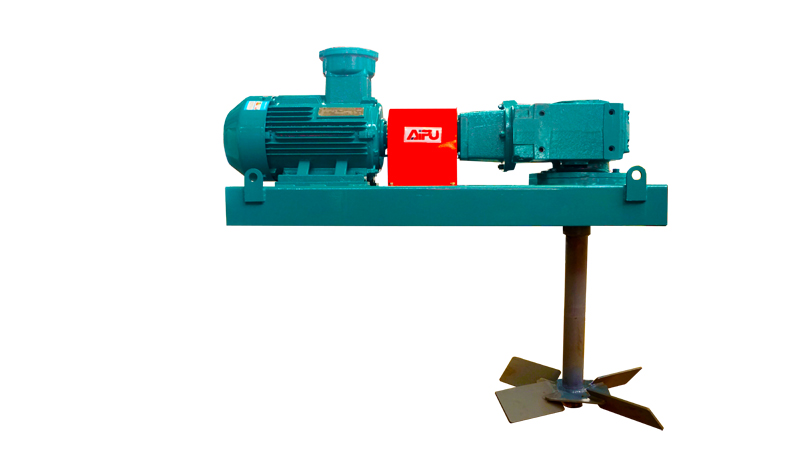

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

Mud gun are meant to provide supplemental or primary mixing in mud tanks depending on the number being used and the pit size. They are best used in tank corners to keep solids from settling and a mud agitator is placed in the tank center.

The mud agitators are high-efficiency mud-mixing units offered in a wide array of custom sizes and configurations to accommodate virtually any mud tank. Both horizontal and vertical drive configurations are available for all sizes of mud agitators. The horizontal drive is designed for installations having limited space above the mud tank.

The mud agitator stirs a mud slurry to maintain suspension of solids. The agitator is mounted on top of the mud tank and has one or two impeller(s) immersed in the mud slurry. The impeller shaft is directly coupled to an electric drive motor that is available in several horsepower ratings from 3 (50Hz only) to 30 (60Hz). Impellers are available in diameters ranging from 20″ to 52″ to meet the needs of various size mud tanks.

The mud agitator is operated by a 3-phase induction motor. Drive motors range from 5 to 30 horsepower for the 230/460Vac 60Hz power configuration and 3 to 25 horsepower for the 190/380 50Hz power configuration.

Though there are mud guns and mud agitator‘s, to activate the mud, there is certain portion in the mud tank which is not influenced by these activating devices. Hence this portion of mud tank is having in-activated mud. This in-activated mud promotes in settling of the chemicals at the bottom of the tank creating a differential chemical composition throughout the tank. This in-activated mud is carried to the drill string followed to the drill bit, where its functioning is severely affected. On observation, in mud tank there‘s a provision to run a horizontal shaft-blade assembly through the length of the tank. Such an arrangement at proper elevation can activate that portion of the tank which is generally a dead zone. This assembly runs horizontally along the length of the mud tank with three bearing supports at the partition. Each blade assembly consists of four blades and four such assemblies are located through out the length of the shaft.

On economic considerations, the amount of chemicals wasted due to this in-active mud is primarily calculated. The cost of chemicals wasted per tank for a location is amounting to around Rs.51,000/- (Rs. Fifty one thousand). If the drilling rig, works at least for a span of one year in five locations, the total cost of chemicals lost amounts to Rs.2,55,000/- (Rs. Two lakh fifty five thousand). To reduce this wastage of mud it is proposed in this paper to design a horizontal shaft-blade assembly

Mud with density 1668.1 kg/m3 is chosen in order to design the project for high mud weight. The Standard D.C Motor with speed reduction gear box used to mud-agitator is selected for calculation towards failure criterion.

Tags:mud desander, drilling fluids desander,oilfield drilling mud desander, desander manufacturers, D-SANDER, Desander Systems,desander cyclone, desander oil and gas, bentonite desander, desander cone, desander cyclone cone, desander filter, desander for bentonite, desander oil & gas, desander in drilling rig, desander in oil and gas, desanding machine, desanding equipment, desander price, specialized desanders, cyclone desander, desander hydrocyclone, mud desander price, desander separator.

JBQ series mud Agitator, Less than 5.5 kW drilling mud Agitator adopts the blender cycloid speed reducer, and it is applied to the drug liquids mixing tank. This mud agitator has the advantage of compact structure so it occupies small area. More than 7.5 kW Mud Agitator uses the turbo and worm gear speed reducer, with the large torque transmission、 the revolution is steady、it works reliablely and has great merit. Common model of mud agitator is JBQ5.5kW 、JBQ7.5kW 、JBQ11kW and JBQ15kW.The drilling mud agitator is an important components for GN Solids Control drilling fluids processing system.

GN Solids Control as a professional manufacturer for soilds control equipments, we have designed lots of high-quality products, and JBQ series Agitator is one of them. To keep both the mud uniformity and the suspension of solids, the mud agitator is used to agitate the mud consecutively and reliably.This agitator agitates the mud to make cuttings, silt and sand pass the solids control system without being precipitated onto the tank bottom. Due to the simplex turbine decelerator, this product is featured by compact construction, light weight, balanced transmission, low noise, high efficiency of transmission and strong agitating power. Therefore, it is a reliable product in the solids control system.

China manufacturer GN Solids Control offer the world with drilling mud agitator equipments.We are an exporter of drilling fluid mud agitator for Indian, Russian,middle east.etc..Our factory and company are Quality Management System ISO 9001-2000 certified.GN Solids Control operate international oil gas drilling mud separation system sales,service,manufacturing,distribution serivce.Buy drilling fluid mud agitatorfrom China manufacturer.Your best mud agitator for drilling mud circulation system.

The desander with underflow shaker is also called Mini desander cleaner which is applicable for both weighted and unweighted drilling mud, while traditional desander no underflow vibrating screen only for unweighted drilling fluids. And comparing with large size mud cleaner, the Mini Desander is cost-effective. For compact mud system used in HDD, CBM, water well drilling and Mining project, Mini desander is an Ideal choice.

Desander is placed after shakers and degasser but before desilter. Different from the Shale Shaker separating solids by screen, desander removes those abrasive solids from the drilling mud by centrifugal force. Due to different density of solid and liquid, the very fine solid which cannot be removed by shakers could be separated out by desander. Desander is also the first one equipment to separate by using centrifugal force.

The VIDA BEM 10” hydrocyclone desander is a cost-effective equipment upgrade designed to efficiently remove sand-size (40-100 micron) particles from drilling fluids. Operating at 75 ft lbs of pressure, the unit processes approximately 500 gallons of fluid per minute, per cone.

Easy installation and maintenance, long-wearing durability and dependable performance make the VIDA BEM 10” hydrocyclone desander the ideal equipment upgrade for demanding drilling projects.

Leading Manufacturer of Drilling Mud Cleaner, Hydrocyclone Desander, Mud Agitator, Balanced Elliptical Motion / Linear Motion Shale Shaker and Shale Shaker Screen from Jodhpur.

JOT manufacture Mud Cleaner which is the first-stage solids control equipment in the drilling fluid solids phase control system, and separates a large amount of cuttings carried by mud from wellhead, facilitating mud to enter the second-stage separation equipment. JOT manufacture both two stage (Shale Shaker + Desilter) and three stage (Shale Shaker + Desander + Desilter) mechanical process Mud Cleaner.

Desanders are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter.

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation.

Shale Shaker is first phase solids control equipment in drilling fluids processing system, also known as key solids control equipment in drilling mud system, shale shaker decides performance of the whole solids control system. We design double shakers and triplicate shakers on single skid according to clients special requirements and also supply relevant connecting manifold, according to current industry situation, provide both third generation linear motion shale shaker and fourth generation balanced elliptical shale shaker.

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. Our mud cleaner are combined from Desander, Desilter and an Underflow Screen, at the same time Mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. mud cleaner structure is compact, it occupy small space and the function is powerful. Mud cleaner is the ideal device of the second class and the third class solid control to treat the drilling mud. The hydrocyclones (desanders and desilters) make the primary separation with underflow directed onto the shaker’s vibrating screen. Used correctly, the drilling mud cleaner lower both drilling-fluid and disposal costs.

In oilfield solids control, drilling mud cleaners are very efficient for oil gas well drilling mud purification system. Mud Cleaners are one of the important equipments for solids liqiud separation system.

Degasser is a special-purpose device and a new type one for the treatment of gas in the drilling fluids. It can get rid of various gas of invasive drilling quickly. Degasser is very important for returning mud gravity, stabilizing mud viscosity and reducing drilling cost. Also, at the same time degasser can be used as a heavy-power agitator and supported applicable to all types of mud circulation purification system. The degasser design of the structure is scientific and rational. So we are able to achieve an effective gas-liquid separation, filter out impurities and to ensure that the exhaust pipe is always smooth.

Desander is the second class and the third class solid control equipment to treat the drilling fluid. Desanders are solid controls equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. so it is called Hydrocyclone Desander or Desander Unit. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. Desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Usually the cone diameter is more than 6″ is called Desander, and used as the second-control equipment in drilling operation. We commonly used 8" and 10" cones desander to separate solid-phase particle size 47-76μm in the drilling fluids.

Desilter is the third class solids control equipment to treat the drilling fluids, and to improve the performance of drilling mud, which can be combined with desander. According to the size of the cone diameter, they are divided into Desander and Desilter. Usually the cone diameter is less than 6″ is called Desilter, and used as the third-control equipment in drilling operation. We commonly used 5 "and 4" cone to separate solid-phase particle size 15-47μm in the drilling fluid. Based on customer requirements and capacity, we can select groups of cone into Desilter. Desilter works very well with Solids control system other equipments.

8613371530291

8613371530291