what is mud agitator in drilling free sample

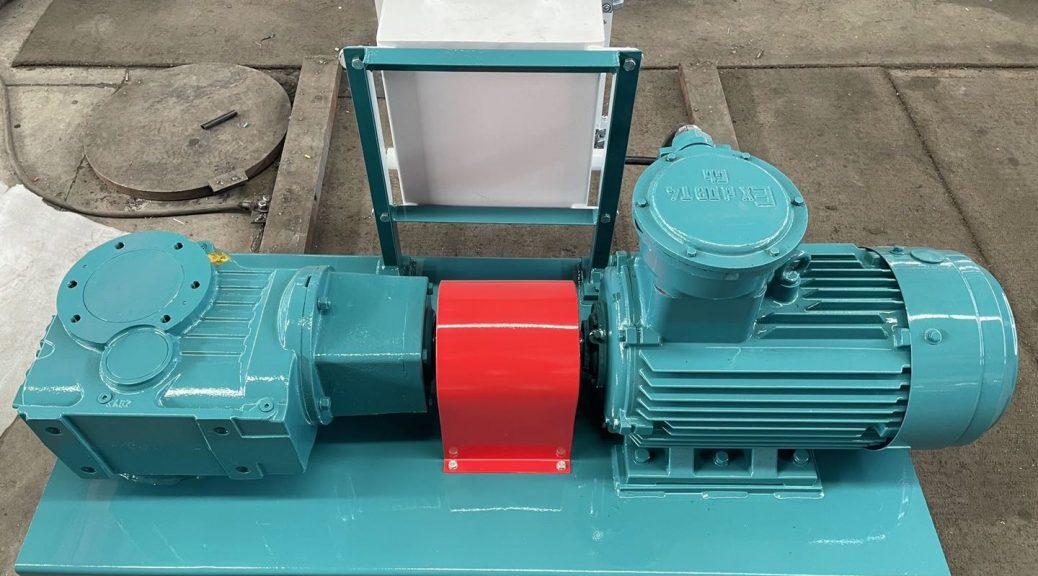

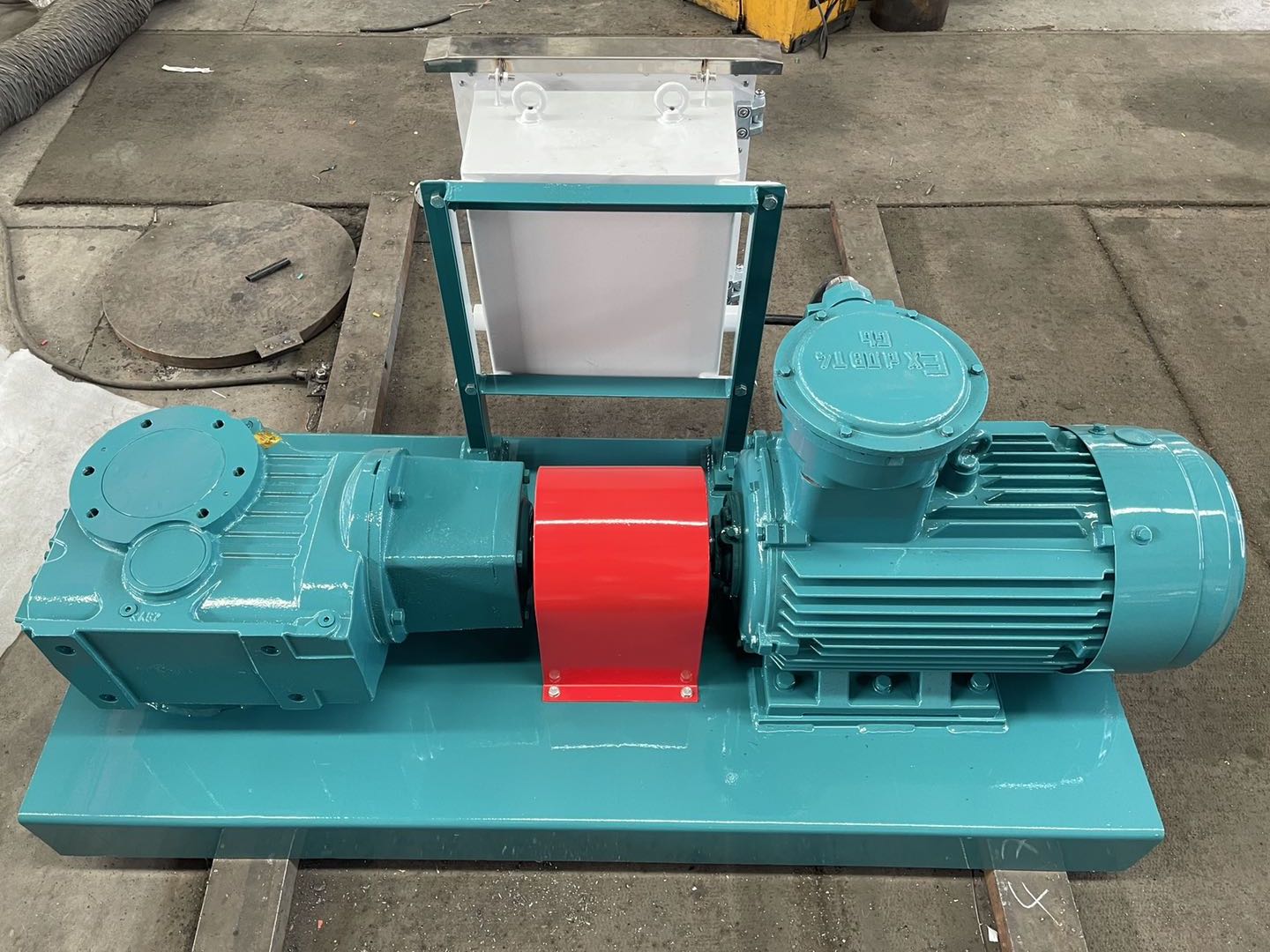

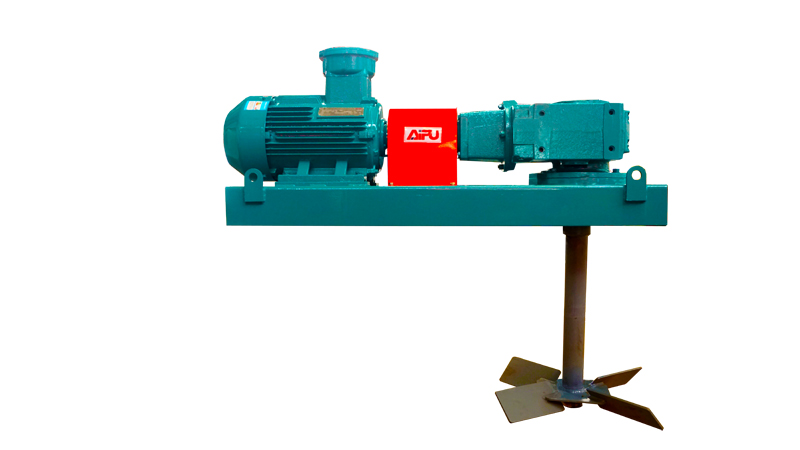

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation. The objective is to obtain a uniform suspension of all solids.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

After 5 days operation please discharge all of the oil out of the gearbox and clean gearbox feed clean lubrication oil in it. Then do the same work every 6 months.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Motors are available with horizontal or vertical mounts. The motors generally have shafts that rotate much faster than the impellers need to rotate. A large gearbox, or gear reducer, used to turn the shaft, is mounted at the end of the motor. The motor size depends upon the diameter of the impeller blades and the density of the slurry.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

canted blade, and proprietary. Generally, Materials determine the price of shaft and impeller. Stainless steel is more expensive than common carbon steel.

Mud agitator combined with motor and gear box. Mud agitators do agitation in drilling fluid make the solids suspend. Help drilling fluid property achieve better. Shaft will be connected with gear box coupled on motor. Under a certain ratio the shaft mounted with impeller rotate at uniform speed and lead an upward stream in drilling mud. This will benefit drilling mud mixture completely with sufficient viscosity, etc.

Onshore and offshore oil&gas drilling, CBM exploration, HDD,waste management, etc. process system. Mud agitators make drilling fluid property more even and stable.

3)Before running please check if impeller rotation direction is same as marked direction 4)Inspect oil height via observation window make sure the level always be at center.

6)After 5 days operation please discharge all of the oil out of gear box and clean gear box feed clean lubrication oil in it. Then do same work every 6 month

The present invention relates generally to the field of drilling mud systems and, more particularly, to a drilling mud agitator assembly including a shaft retainer that permits disassembly of the agitator shaft from outside the agitator tank.

The present invention relates to a device for agitating drilling mud having particulate solids entrained therein, such as for example drill cuttings and various drilling mud additives. In operation, such a device is typically mounted atop a mud tank in which one or a plurality of agitating devices may extend.

As described in U.S. Pat. No. 4,516,860 to van der Laan et al., drilling mud is commonly used in oil and gas drilling operations to cool and lubricate the drill bit and flush drill cuttings from the bore hole back up to the surface. Drilling mud must have an adequately high specific weight so that the column of drilling mud controls the liquids and/or gases in the formation on the corresponding depth without danger of blow outs. Further, viscosity of the drilling mud should be higher than that of water, so that the drill cuttings can be entrained in the rising flow of drilling mud in the annulus around the drill pipe. At the surface, the drill cuttings are removed from the drilling mud in a several-step operation. In one step in this operation, it is essential to agitate the drilling mud to keep the drill cuttings from separating out of suspension in the drilling which would clog up the operation.

For this step, drilling systems commonly include a mud tank provided with an agitator. The agitator typically comprises a motor mounted on a mounting plate on top of the mud tank. A shaft is coupled to the motor and extends down through the mounting plate into the mud tank to a level sufficient to be immersed in the mud/drill cuttings suspension. An impeller is mounted to the end of the shaft so that by rotating the impeller, the mud is agitated and the drill cuttings are prevented from settling out.

The agitator system shown and described in U.S. Pat. No. 5,944,418 to Orr et al. illustrates one structure of the coupling of the motor, shaft, and impeller. In that system, a motor is mounted on the top of a cover. Various types of motors might be employed, such as an electric motor. Extending from the motor is an agitator shaft which passes through the cover and is rotated by the motor. The agitator shaft lies generally along the axis of the cylindrical tank. Extending radially outward from the agitator shaft is a plurality of impeller blades.

Orr et al. purport to keep the drilling mud the drill cuttings in good mixture without any problems, and without the high viscosity and the high specific weight of the drilling mud, and the high weight of the for instance heavy clay and/or rock particles of the drill cuttings could cause a separation of the drill cuttings and the drilling mud.

A difficulty arises when maintenance must be performed on the system within the mud tank or repair or replacement of the agitator motor. The typical system, as shown in described in Orr et al., requires access into the mud tank if maintenance is to be performed on the agitator. This requires draining the mud from the mud tank and then permitting a workman to enter the mud tank to perform the required operation. Or, if the agitator motor is to be repaired or replacement, access must be made into the mud tank to de-couple the impeller blades from the end of the shaft so that the shaft can be withdrawn through the cover. This is not only time consuming, it places the workman in danger.

Thus, there remains a need for a system that allows the system to be secured so that the maintenance operation can be performed on the outside the tank. The present invention is directed to fulfilling that need in the art.

The present invention addresses these and other needs in the art by providing a mechanism for securing the agitator motor on top of the man-way cover for the mud tank. The mechanism includes a retractable shaft retainer arranged to engage a retainer block affixed to the agitator shaft. A pair of hemi-cylindrical coupling halves couple the agitator motor shaft to the agitator shaft.

The retractable shaft retainer, once engaged with the retain block, secures the agitator shaft. The coupling halves can then be quickly and easily removed, and the motor can then be removed for repair or replacement.

These and other features and advantages of the present invention will be apparent to those of skill in the art from a review of the following detailed description.

So that the manner in which the above recited features, advantages and objects of the present invention are attained and can be understood in detail, more particular description of the invention, briefly summarized above, may be had by reference to embodiments thereof which are illustrated in the appended drawings.

FIG. 2 is a detail perspective view of the agitator of FIG. 1, with the shaft retainer withdrawn so that the agitator system is free to operate normally.

FIGS. 1, 2, and 3 depict an agitator system 10 in accordance with the teachings of the present invention. The system primarily comprises a gearbox/motor assembly 12, an impeller 14, both coupled together with an agitator shaft 16. The gearbox/motor assembly 12 is mounted on an open work pedestal 18 which is affixed to a cover plate 20. The cover plate is secured to the top of a mud tank 22, which is shown in FIG. 1 as having flat rectangular sides for illustration purposes only. Preferably, the mud tank 22 is a cylindrical tank with a round bottom so that the tank does not present any dead zones for the free flow of agitated mud within the tank. The cover plate 20 is preferably removably mounted to the top of the tank 22 with a set of screws 24, for example.

The gearbox/motor assembly 12 is preferably secured to the agitator shaft 16 with a shaft coupling 26, shown more clearly in FIGS. 2 and 3. The agitator shaft 16 extends through a hole 28 in the cover plate 20. Thus, without the present invention, decoupling the gearbox/motor assembly 12 from the agitator shaft 16 by removing the coupling would result in the agitator shaft falling through the hole 28 into the tank. To alleviate this problem, a shaft retainer comprising a first retainer half 30 and a second retainer half 32, are operationally mounted onto the cover plate 20. Each of the first and second retainer halves comprises a substantially semi-circular element with an upwardly depending notch 34 formed therein to mate with a retainer block 36. The retainer block 36 is affixed to the agitator shaft 16 such as for example by welding, or it may be otherwise secured to the shaft 16.

The first retainer half 30 is affixed to a threaded rod 36. The threaded rod passes through a flange 38 and is held in place by a pair of nuts 40. Similarly, the second retainer half 32 is affixed to a threaded rod 42, which passes through a flange 44 and is held in place by a pair of nuts 46. To operate the shaft retaining mechanism, the nuts 40 and 46 are loosened, the retainer halves 30 and 32 are moved inward into engagement with the retainer block 36, and the nuts are then re-tightened. This is the position of the shaft retaining mechanism shown in FIG. 3.

It will be apparent to those of skill in the art that many different kinds of mechanisms may be used to move the retainers back and forth within the scope and spirit of this invention. Further, many different kinds of mechanisms may be employed to engage the retainers with the retainer block. The preferred embodiment, described above, has the advantage of being simple, inexpensive, easy to use, and robust.

Once the shaft retaining mechanism is engaged as just described, the shaft coupling 26 can be removed. The shaft coupling 26 preferably comprises a first, hemi-cylindrical coupling half 48 and a second, hemi-cylindrical coupling half 50, preferably releasably held together with a set of screws 52. The pedestal 18 is made in an open-work arrangement to provide adequate room for the workman to gain access to the shaft coupling with tools.

The principles, preferred embodiment, and mode of operation of the present invention have been described in the foregoing specification. This invention is not to be construed as limited to the particular forms disclosed, since these are regarded as illustrative rather than restrictive. Moreover, variations and changes may be made by those skilled in the art without departing from the spirit of the invention.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

APMA series Mud agitator is combination of gear box and motor. It"s important to drilling mud process and fit on mud tanks as 3 meters per set. Except the shaker tank/compartment every tank and compartment will be fit with mud agitator. Mud agiators help to maintain mud property and keep the solids suspend for necessary mud propery and further mud process. Almost of agitator for drilling fluids system are horizontal design. On mud tanks, the separated control panel for each agitator is a good design.

Mud tank size defines agitator number and model, besides, mud property will affect agitators selection. For example, usually we put one set agitator per 3 meters on tank. According to tank width and height, the agitator can be APMA7.5, or APMA15. And if the tanks are same size, then we"ll consider the mud property. Such as mud gravity is 1.8sg we may need 7.5kw, while mud gravity is 2.4sg, we may need APMA15 driven by 20hp motor. Agitator speed defined by motor and gear box. For example, if we use APMA7.5 agitator, the motor is 10hp and speed is 1450rpm. The gear box reduce ratio is 25:1, then the agitator shaft/impller speed is 58rpm. If we use 10hp motor under 60Hz condition, its speed is 1740rpm then, and the reduction ratio is 25:1 still, then the shaft speed is about 70rpm

In a complete mud system, how many sets agitator do we need? For oil and gas drilling, there are different configuration on tanks number, tanks size, so it"s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9mX2.2mX2.3m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of agitator. And the agitators are APM7.5 driven by 7.5kw motor.

How to select agitators? As we said just now, according to mud tank size and mud tank property. And before confirmation on agitator selection, we"d better to inquire professional engineer or consultant. There is a formula for agitator selection or design. Aipu will help user to get right solution at the best cost

Is there any other configuration on agitator type or drive system? Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need the vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different application and industry will request equipment much different If you have question or demand on mud mixers, please let us know and we"ll help you to get ideal solution

Moreover, APMA series agitator are flexible on gear box and motor configuration. Such as worm and worm wheel reducer, helical bevel reducer. The motor certified by IEC, ATEX, and so on

For any interet or demand, please feel free to contact AIPU. You will get free offer on optimal solution, you will get professional proposal very soon.

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

When you need to gain rapid access to the essential wholesale mud agitator supplies that your business relies on, head to Alibaba.com where you"ll find thousands of Chinese wholesalers ready to provide the equipment, materials, consumables and products that you need to run your business. From mud agitator supplies that cover all technical specifications through to associated products and office consumables, you can buy everything that your business needs in one place at Alibaba.com.

Simply use the search filters and categories to swiftly find details of mud agitator prices, specifications, order volumes, lead times, discounting arrangements and more. See what other customers thought of individual wholesalers with the customer review feature and see images of operations, markets served and more. You can even chat instantly with sales and support or send an email at any time of day.

Ready to make your mud agitator order? Just do so in a few clicks in your private account area and you"ll receive regular updates on your shipment so that you know exactly where it"s at in the world until it arrives at your business! It"s swift, convenient and cost-effective to shop at Alibaba.com where you"ll find everything that your business needs to operate smoothly and without delay.

8613371530291

8613371530291