forum mud pump parts brands

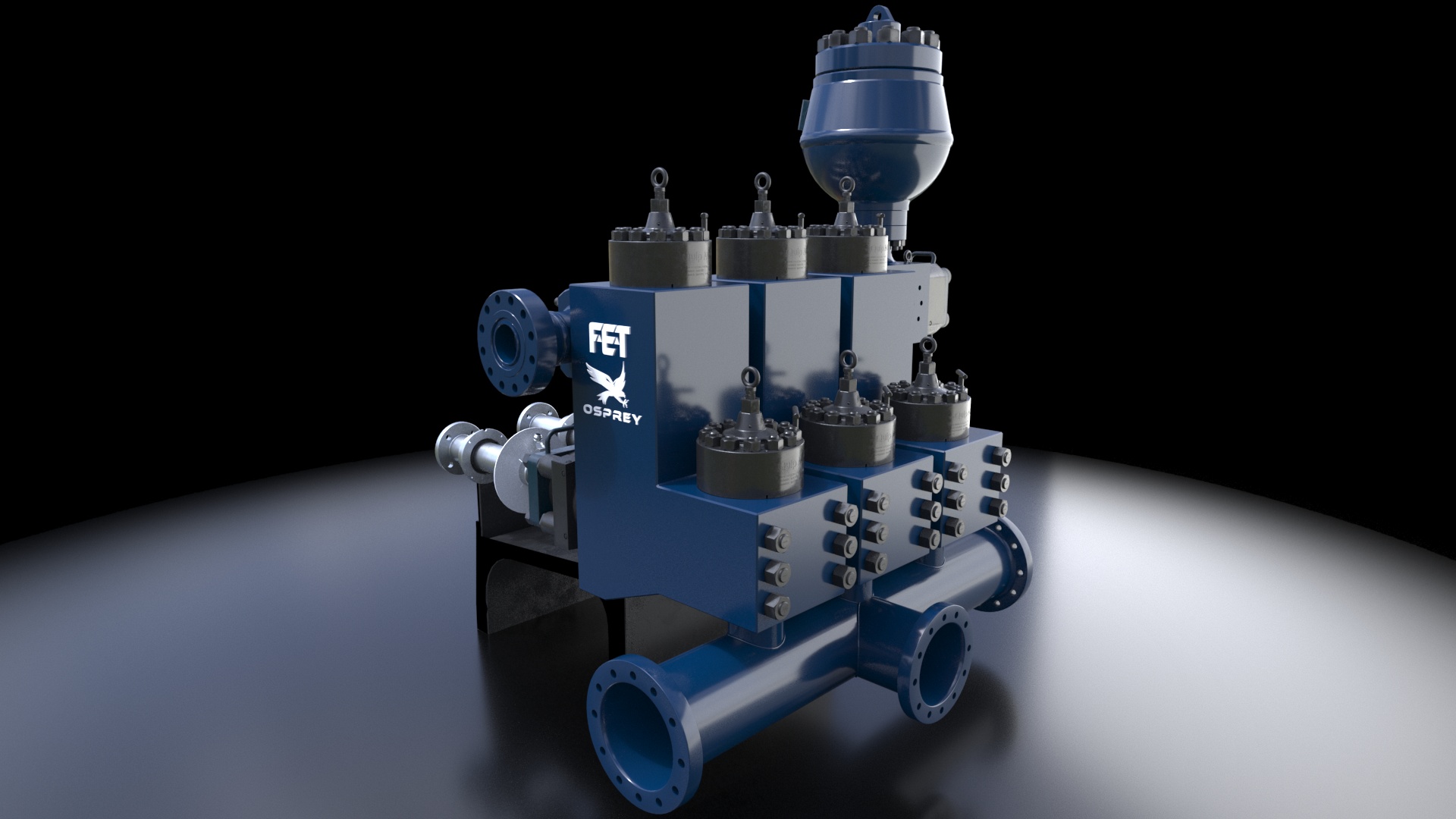

Mud systems are essential to every oil and gas rig. To successfully transfer fluid throughout your circulating system at pressures up to 7,500 pounds per square inch you need proven and reliable products. FET’s products have 30 years of innovation and field experience in providing industry-leading technology for your mud system operations.

Our industry-recognized centrifugal pumps, gate valves, drill pipe float valves, and wash pipes provide you with robust systems that meet the high-pressure demands of today’s drilling landscape.

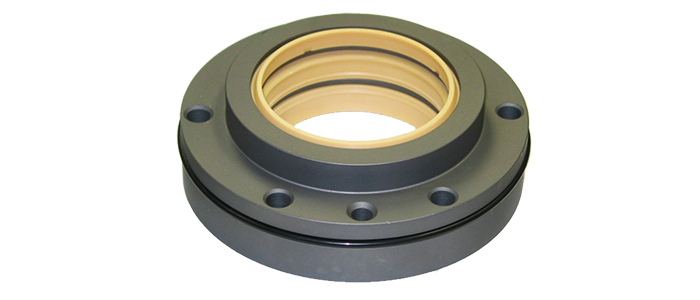

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Smart solutions. Powerful products. All Forum Energy Technologies products are reliable and easy to use; every piece designed with you in mind ─ ensuring that servicing your products is quick and stress-free.

Forum has a comprehensive offering in addition to their own high-quality product lines, by bringing together some of the most trusted brands in the industry. Their legacy includes recognizable brands like Baker SPD, Blohm + Voss, CraneSafe, Merrimac, OBI, P-quip and Pipe Wranglers.

JL Offshore AS are the Exclusive Representative for Worldwide Oilfield Machine (WOM) in Norway. Gate Valves, Pump Savers, Manifolds and Subsea Valves are among their products.

JL Offshore AS keep inventory and provide a full range of Fluid End Expendable Pump Parts for every drilling condition and different Mud Pumps from well known manufacturers.

JL Offshore AS have inventory of OEM MHWirth TPK-2200 Mud Pump Parts such as Crankshaft, Drive Shaft, Gear Wheel, Pulsation Dampener, Gearbox, Connection Rod, Bearings, Suction Module, Discharge Module, Valves, Valve Seats, Piston, Zirconia Liners etc. In attached pdf you will find list and pictures on some of the parts. Please contact us for additional information or quote.

JL Offshore AS keep inventory and provide a full range of Fluid End Expendable Pump Parts for every drilling condition and different Mud Pumps from well known manufacturers.

JL Offshore AS are the Exclusive Representative for Worldwide Oilfield Machine (WOM) in Norway. Gate Valves, Pump Savers, Manifolds and Subsea Valves are among their products.

JL Offshore AS keep inventory and provide a full range of Fluid End Expendable Pump Parts for every drilling condition and different Mud Pumps from well known manufacturers.

JL Offshore AS have inventory of OEM MHWirth TPK-2200 Mud Pump Parts such as Crankshaft, Drive Shaft, Gear Wheel, Pulsation Dampener, Gearbox, Connection Rod, Bearings, Suction Module, Discharge Module, Valves, Valve Seats, Piston, Zirconia Liners etc. In attached pdf you will find list and pictures on some of the parts. Please contact us for additional information or quote.

The NV-7500 Mud Gate Valve is a full metal to metal sealing gate valve for use in applications up to 7500 psi. The NV-7500 uses single piece seat rings creating an upstream metal to metal seal. The upstream design helps eliminate debris contamination into the valve body and reduces wear on the internal components.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

8613371530291

8613371530291