forum mud pump parts made in china

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

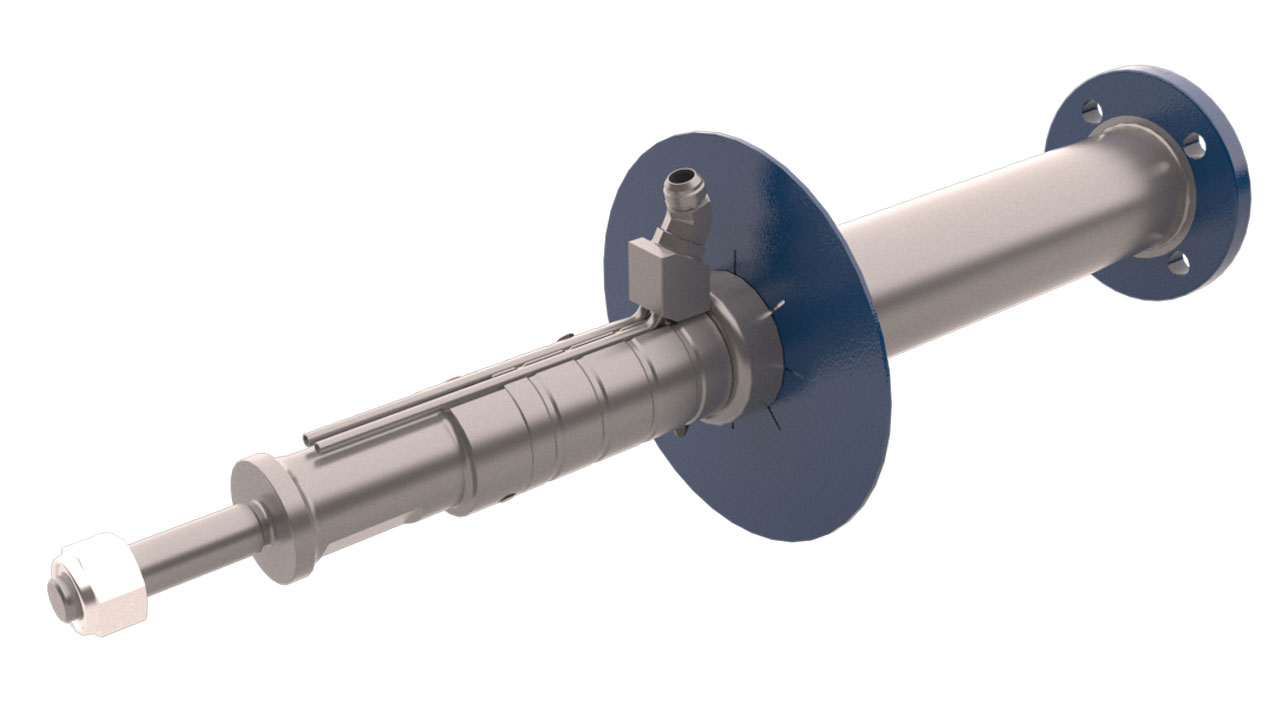

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

One of Forum’s most committed core values is that “no one gets hurt,” and the P-Quip system is designed to support that principle. Streamlined and easy to use, it reduces or eliminates the need for manual force during maintenance, shrinking the time needed to replace high-use components and minimizing safety risks.

⊙Mud pump spare parts of abroad brand:Eg. Liner, piston, valve assembly, valve seat, valve spring, valve rubber could be alternative for original with lower price.

⊙Original brand:Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford.

Alibaba.com offers 3,418 the spare part of mud pump products. such as 1 year, not available, and 2 years. You can also choose from new. As well as from energy & mining, construction works , and machinery repair shops. And whether the spare part of mud pump is 1.5 years, 6 months, or unavailable.

Aisin is owned by Toyota and they make the mechanical parts such as transmissions, locking hubs, water pumps, diesel pumps, thermostats, clutch/pressureplate, clutch and brake pumps etc., for toyota. Denso is the Toyota"s electrical division.

Here is an example: Honda"s use Denso alternators and last 100K miles, the repair involves many new parts, however, a Toyota-Denso alternator can go easy 230K miles and the only failing part is brushes.

Always buy from a reputed seller. Chinese counterfeit parts are all over the internet. People who have bad experience with AISIN for sure went with the cheapest "aisin" availabe. I have AISIN on all 3 of my toyota"s and still works like a charm. No issue what so ever!

A couple of years ago I bought a cheap Amazon chinese fuel pump to rule out the fuel pump as a problem. It wasn"t the problem, then, after about six months it failed. I put the OEM one back in and all is well. Today, I was cleaning out my junk box (as if have only one) and came across the bad pump. I thought I"d tear into it because I wasn"t sure what the inside looked like. I would"ve guessed that the failure was the diaphragm or springs that failed but, the failure was actually much simpler. They apparently used cheap metal to build the rod, it deformed, and slipped out of the fork.

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

8613371530291

8613371530291