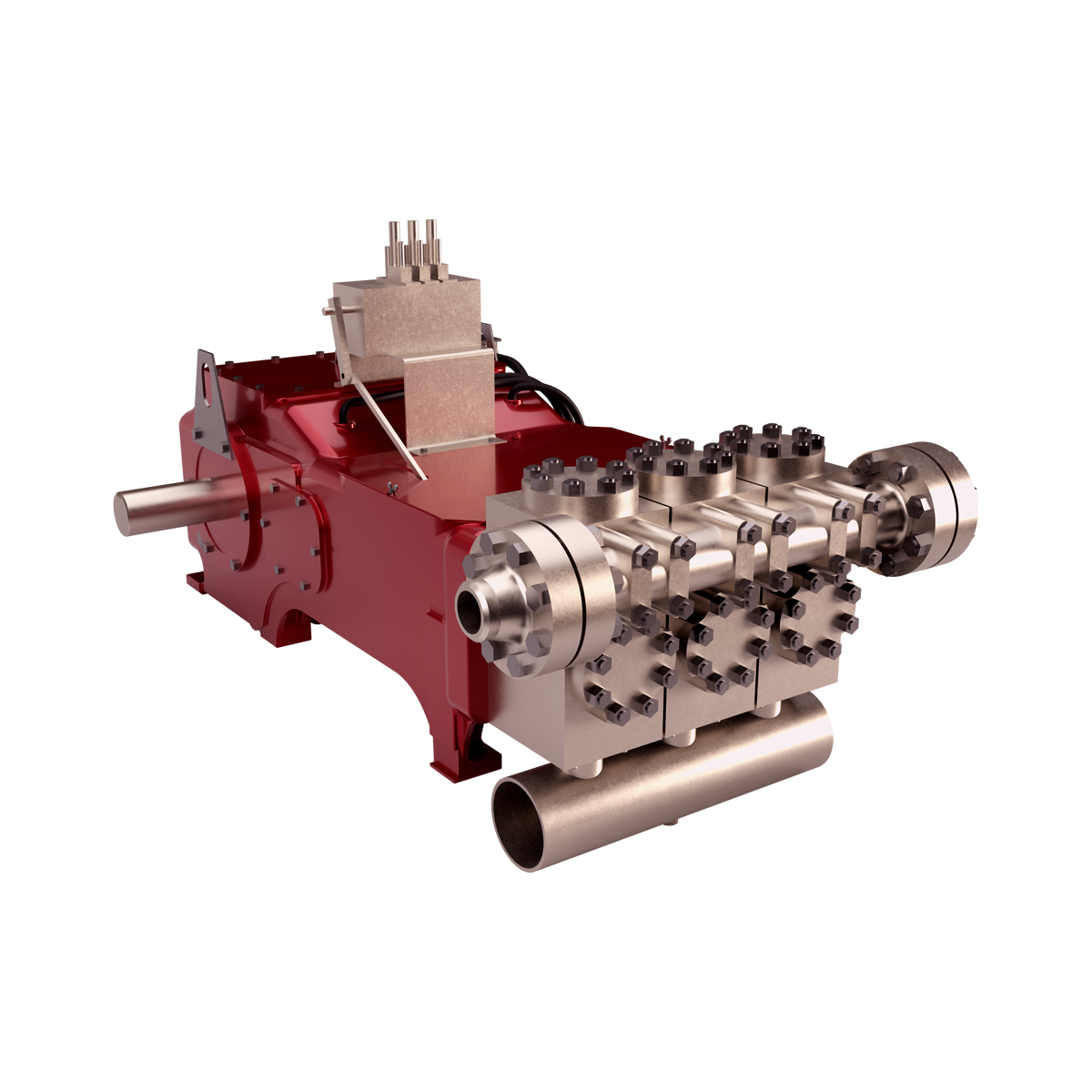

heavy duty mud pump in stock

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

A wide variety of heavy duty mud pump options are available to you, such as 1 year, 2 years and 3 years.You can also choose from new, used heavy duty mud pump,as well as from energy & mining, construction works , and machinery repair shops heavy duty mud pump,And whether heavy duty mud pump is 1.5 years, {2}, or {3}.

Our high-head pumps are specially designed for industrial and commercial applications where high heat and high pressure are required. Whether you need to pump water, chemicals, or other liquids over long distances, our high-head pumps are up to the task.

The unique design of our high-head pumps allows them to generate high head and pressure while still maintaining a high flow rate, making them ideal for a wide range of applications including irrigation, water treatment, and industrial processing.

Our high-head pumps are also highly customizable, with a variety of options available to suit your specific needs. Whether you require a high flow rate, a high head, or a combination of both, our team of experts can work with you to create a pump that meets your requirements.

The 4-Inch heavy-duty slurry pump by EDDY Pump. Close coupled or flex coupled version pumps available in extra heavy-duty (HD) class. Depending on your needs, all of our pumps can be setup horizontal or vertical.

Our industrial pumps are non-clog pumps with no critical tolerances designed for high solids pumping applications. Our patented pump technology outperforms all centrifugal, vortex and positive displacement pumps in a variety of the most difficult pumping applications.

In harsh conditions with sand, sludge, rocks, slurry, normal dredge pumps clog, wear and fail more often. This leads to downtime for maintenance, hurting your bottom line. This is not the case with EDDY Pump since we have the tolerance to pump objects up to 12 inches!

Whether you’re transferring waste oil mixtures, bio waste, sewage, mud or lime slurries, there’s one thing you can be sure of, and that’s that you need a heavy duty, high pressure sludge pump. Capable of efficiently handling viscous fluids containing solids, Castle Pumps’ range of slurry pumps has been built up over the years to provide you with a non-clogging solution to your waste transfer applications. Not all pump designs can do the job, but that’s where we are there to help you. Our technical sales engineers are on hand to help you to select the right solution for your requirements.

Ideal for moving underwater sludge, abrasive slurries, and rocks, the submersible slurry pumps sit at the bottom of a tank, lagoon, pond, well, or another water-filled environment. Submersible pumps suction out solids and liquids right at the pump itself. The materials are taken in at the intake and pass through a hose connected to its discharge valve. DAE Pumps submersible pumps include a watertight enclosure with the industry’s best o-rings seals for worry-free operations.

With the hose head in the water and the other end connected to the pump, self-priming slurry pumps suction the material to the pump, then out through the discharge valve. Self-priming pumps get prime at the pump by electric or diesel motors drawing water to it. They mount to a portable trailer for easy transportation or on a stationary skid.

The flooded suction slurry pump is located outside of a tank or hopper, typically below or as low as possible. Gravity forces the sludge and liquids to the pump, then passes the materials out through the pipe or hose on the discharge end. The flooded suction pump does not require priming because it uses gravity to prime, and it doesn’t use as much power to operate as the other types of slurry pumps because it does not have to draw the material to it. However, a flooded suction slurry pump can get corrosion and require more repairs because there is always liquid filling the pump.

Gear pumps are one of the most common types of positive displacement pumps. They provide a constant volume of fluid that passes between the teeth of two meshing gears and the casing. Rotating gears and separation of teeth create a suction that pulls fluid in through the inlet. The gears then trap the liquid and move it around the casing to the discharge or outlet. Each revolution creates consistency in the flow of fluid.

Lobe pumps are like gear pumps in that fluid flows around the interior of the casing, but they use lobes instead of the gears with teeth. The lobes do not touch each other, thus reducing wear, and they are driven by external timing gear that allows the lobe pump to operate in either direction.

Vane pumps use blades, know as vanes, that slide in and out of rotor slots to move fluids. This action creates a suction that pumps fluids. The vane pumps use multiple sets of vanes that mount on an off-center rotor that sits close to the cam wall creating a crescent-shaped cavity on the other side. These blades, which are always in contact with the cam wall, turn with the rotor. With the spinning of the rotor, the vanes slide out when they reach the cavity, trapping fluid. As the vanes reach the end of the open space, they slide back in, and the trapped fluid thus moves to the outlet or discharge valve.

Screw pumps and twin-screw pumps use rotating screws to move liquids and solids from one end of the pump to the other. Because of the rotating, turning action, the spinning motion is what pumps the material. The twin-screw pumps are identical to the screw pump, but with a dual screw for more power. Screw pumps are capable of high flow rates with very little to no vibration. They provide excellent usage in irrigation, oil production, fuel injection, and fuel transfer applications.

The piston pump uses a piston or pistons to draw in liquids and solids by creating a vacuum in the chamber to suction in the materials, then pushing them out the other end. Pistons repeatedly move up and down inside the pump chamber to pump the material. DAE Pumps piston pumps use high-quality O-rings to ensure reliable performance. These pumps are used for high-pressure washing, oil production, paint spraying, and other low viscosity liquids.

Diaphragm pumps use a flexible membrane that expands the volume of the pumping chamber bringing in the fluid by opening the inlet valve, then compresses to push out the materials through the outlet valve. The hermetically sealed diaphragm pumps are safe for pumping hazardous and corrosive liquids.

Agitator series submersible pump designed for slurry, mud & sand pumping with hard iron adjustable wear parts & bottom side discharge up to 6-inch size.

Constructed for maximum durability, our dewatering pumps are compact and lightweight, built with the contractor in mind. Trash pump with 2", 3" and 4" designs with Honda GX engine.

Constructed for maximum durability, our dewatering pumps are compact and lightweight, built with the contractor in mind. Centrifugal pump with 1", 2", 3" and 4" designs with Honda engine.

Dewatering - Direct across the line starting - Automatic series control panels are heavy duty, UL listed control panels used for dewatering applications

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

For industrial, mining, milling, power plant, water treatment, sewage, organic waste, or anywhere slurry solids have a tendency to accumulate, agitator pumps are the answer. Since water always flows to the path of least resistance, a pump without mechanical agitation will only pump the water, leaving the solids behind to accumulate around your pump intake, and eventually starving the pump by blocking the intake. Agitator pumps deliver kinetic energy (energy of motion) to slurry solids surrounding the pump intake, re-suspending them into a fluid state. These solids, which would have otherwise buried and starved the pump of liquid, are pulled into the pump and pushed on through the discharge keeping the intake clear and free of slurry accumulation.

Submersible pumps, which are more efficient than jet pumps, contain a hermetically sealed motor and are used for pushing fluid to the surface. We offer submersible pumps for several applications, including mines, manholes, construction sites, sewage and other areas with a high concentration of solids. Our submersible pumps come in several different varieties in order to handle the different conditions you may face in the field:

Dewatering Pumps – Heavy duty abrasion resistant pumps for dewatering: mines, power plant sumps, manholes, and construction sites. Also as water supply pumps (3/4 to 45 hp).

Corrosion Resistant Pumps – For severe corrosion: all 316 stainless-steel recessed impeller pumps. (1 to 10 hp)For moderate corrosion: Rhino Coated aluminum with stainless steel impellers, shafts, and hardware (1.5 to 45 hp).

No matter what pump you’re looking for, Piranha Pumps will deliver on your expectations, however high they may be. When it comes to the best heavy-duty submersible pumps in the business, look no further than Piranha Pumps.

If you’d like to learn more about our submersible pump systems, don’t hesitate to contact us. An experienced Piranha Pumps team member will be happy to answer any questions you have. At Piranha Pumps, you can rest assured knowing that our dredging and pumping machines are powerful, efficient, and reliable.

As a "Woman Owned" business, we have successfully developed our business from small dewatering pumps to large industrial dredges and have dotted the world with our business products. We have a strong market demand on almost every continent and a continuous demand for all of our quality products. It is our mission here at Piranha Pumps to evolve and improve our products and services to accommodate the ever-changing global market and unique needs of our diverse customer base. We aim to lead the market with our competitive pricing and industrially advanced equipment while maintaining growth and customer satisfaction.

JBSP Series pumps take on the toughest applications of sewage water handing and get the job well done. Every component and parts are designed and manufactured to deliver highly efficient performance. Design of impeller is such that most solid objects entering the pump will pass through the impeller between the impeller vanes.

We are JB Pumps-The flow of Happiness manufacturer of Sewage Pumps in Ahmedabad, Gujarat. We have total in house manufacturing facilities. The JB pumps follow Make in India concept. We provide 24×7 after sales service.

Pump Power1HP TO 2HPWe are successfully ranked as the renowned Manufacturer, Trader, and Exporter of a wide collection of Pressure Pump, Sludge Pump, Multi Stage Pump, Booster System etc. We also provide Installation, Repairing, and Maintenance services for these products.

Prominent & Leading Authorized Wholesale Dealer from Ahmedabad, we offer Lubi Sewage Mud Pumps 0.5 to 30 HP, LUBI Sewage Pumps, Lubi/SMC Sewage Pumps Submersible Heavy Duty, LUBI Drainage Pump and Lubi Drainage Mud Pump Low Weight.

Established in the year 1971 at Ahmedabad (Gujarat, India), we “Paras Engineering Company” are a renowned Authorized Wholesale Dealer of an excellent quality range of Submersible Pump, Monoblock Pump, etc.

8613371530291

8613371530291