mud pump piston rod supplier

The products we produce are oriented by user"s demand, improve performance cost, reduce production cost, save labor cost and improve production efficiency.

Thereby, the corrosion resistance of the surface is improved, and the generation or expansion of fatigue cracks can be delayed, thereby increasing the fatigue strength of the cylinder rod. Through roll forming, a cold hardened layer is formed on the rolled surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the abrasion resistance of the cylinder rod surface and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced, which can improve the mating properties. At the same time, the friction damage to the seal ring or seal during the movement of the cylinder rod piston is reduced, and the overall service life of the cylinder is improved. Rolling process is an efficient and high-quality process measure.

Piston rods are mainly used in hydraulic and pneumatic, engineering machinery, automobile manufacturing piston rods, plastic machinery guide posts, packaging machinery, printing machinery rollers, textile machinery, conveying machinery axis, linear optical axis for linear movement.

A wide variety of mud pump piston rod options are available to you, such as 1 year, not available and 2 years.You can also choose from new, mud pump piston rod,as well as from energy & mining, construction works , and machinery repair shops mud pump piston rod, and whether mud pump piston rod is 1.5 years, 6 months, or unavailable.

A wide variety of mud pump piston rods api standard options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mud pump piston rods api standard,as well as from energy & mining, construction works , and machinery repair shops mud pump piston rods api standard, and whether mud pump piston rods api standard is 6 months, unavailable, or 3 months.

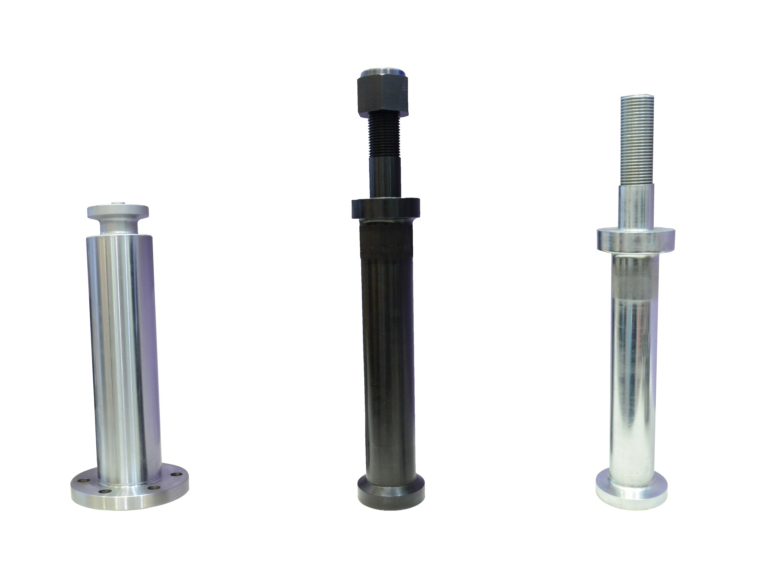

Application: The big end of the piston rod is connected to the power end of the mud pump through clamp, for power transmission purposes. The small end is installed with s piston which is in reciprocating rectilinear movement in the cylinder to generate pressure.

pump bimetal liner ,mud pump piston,mud pump piston assembly ,mud pump piston rod ,mud pump valve assembly ,mud pump valve,mud pump valve body and valve seat,mud pump valve rubber,,valve and seats,Plug Board Assembly,Clamp Assembly,Cylinder Head Plug,Cylinder Liner Gland ,Low guide,Oil Seal Ring,Wear Plate,Shear Safety Valve,Hoisting Device,Piston Rod,Pulsation Dampener Assembly,Steel Ring,Hydraulic Cylinder

Application: The big end of the piston rod is connected to the power end of the mud pump through clamp, for power transmission purposes. The small end is installed with s piston which is in reciprocating rectilinear movement in the cylinder to generate pressure.

pump bimetal liner ,mud pump piston,mud pump piston assembly ,mud pump piston rod ,mud pump valve assembly ,mud pump valve,mud pump valve body and valve seat,mud pump valve rubber,,valve and seats,Plug Board Assembly,Clamp Assembly,Cylinder Head Plug,Cylinder Liner Gland ,Low guide,Oil Seal Ring,Wear Plate,Shear Safety Valve,Hoisting Device,Piston Rod,Pulsation Dampener Assembly,Steel Ring,Hydraulic Cylinder

Customers said they wanted long-lasting, easy-to-use pistons, and we delivered. Made from domestically sourced steel, GD Energy Products’ pistons feature proprietary bonded inserts and innovative geometry to deliver significantly longer life. This field proven design meets API Standards, and comes with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our pistons, along with our new valves and seats, are designed for use in GD Energy Products PZ, F-Series, Bomco, HHA, Emsco and National 12P lines of triplex drilling pumps. Let GD Energy Products be your one-stop shop for your whole fleet of pumps.

High quality Heat Treated Alloy Triplex Mud Pump Piston Rod AH1001010516 AH33001-05.21A from China, China"s leading Mud Pump Parts product market, With strict quality control Mu...

Mud pump is the "heart" of oil drilling system while mud pump liner an important disposable quick-wearing part of the fluid end. Therefore, the quality of mud pump liner will directly affect the normal operation of the drilling rig and thus the drilling costs.

Bi-metal liner is one of the most widely used types of liner. Our product combines the virtue of high strength forged steel shell and the advantage of anti-abrasive corrosion-resistant high-chromium sleeve together. The shell, including lip sleeve, is forged with high-quality carbon steel. The inner sleeve made of high-chromium cast iron is processed by centrifugal casting, the hardness of which is up to HRC 62 after heat treatment, could withstand a mud pressure of 7000 psi.

Ceramic liner is applied to well drilling operations for deep reservoir and complicated geologic situations, and is also used for offshore oil and gas development. The hardness of the working surface of the inner sleeve can reach HRC89 or more while the bending strength can be up to 1000-1200Mpa. Our ceramic liner is able to withstand a maximum pump pressure of 70Mpa. It is anti-abrasive, corrosion-resistant, heat-resistant, pressure-resistance, and is of high strength and high rigidity.

Piston assembly is one of the main parts of the fluid end of the mud pump. The volume of the working chamber alters with the reciprocating of piston, and thus realize a liquid suction and discharge through the pump valve. We are able to provide superior replaceable rubber piston and bonded piston.

Piston assembly, as a vulnerable part, is mainly composed of piston hub, rubber etc. Forged with alloy steel according to strict processing control and heat treatment, the piston hub is of high strength and rigidity, and of long lifespan. In addition, there are several selections for piston rubber under different operating conditions, like Nitrile Rubber, Polyurethane (PU) and Hydrogenated Nitrile (HNBR) etc.

Piston assembly, as a vulnerable part, is mainly composed of piston hub, rubber etc. Forged with alloy steel according to strict processing control and heat treatment, the piston hub is of high strength and rigidity, and of long lifespan. In addition, there are several selections for piston rubber under different operating conditions, like Nitrile Rubber, Polyurethane (PU) and Hydrogenated Nitrile (HNBR) etc.

Valve and seat make up a valve assembly that is the major component of the fluid end of the mud pump. It is also one of the most consumed vulnerable part during drilling.

Valve assembly is made of high-quality forged alloy steel. It has an enhanced strength by a process of carbonization at the working surface. Through precise calculation and advanced NC machining, our product can realize a favorable match between the valve body and the seat. Moreover, material is selectable as per different working situations. Thus, the lifespan of the product can be prolonged.

Valve assembly is made of high-quality forged alloy steel. It has an enhanced strength by a process of carbonization at the working surface. Through precise calculation and advanced NC machining, our product can realize a favorable match between the valve body and the seat. Moreover, material is selectable as per different working situations. Thus, the lifespan of the product can be prolonged.

8613371530291

8613371530291