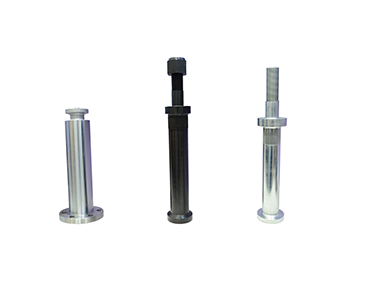

mud pump piston rod manufacturer

The products we produce are oriented by user"s demand, improve performance cost, reduce production cost, save labor cost and improve production efficiency.

Thereby, the corrosion resistance of the surface is improved, and the generation or expansion of fatigue cracks can be delayed, thereby increasing the fatigue strength of the cylinder rod. Through roll forming, a cold hardened layer is formed on the rolled surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the abrasion resistance of the cylinder rod surface and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced, which can improve the mating properties. At the same time, the friction damage to the seal ring or seal during the movement of the cylinder rod piston is reduced, and the overall service life of the cylinder is improved. Rolling process is an efficient and high-quality process measure.

Piston rods are mainly used in hydraulic and pneumatic, engineering machinery, automobile manufacturing piston rods, plastic machinery guide posts, packaging machinery, printing machinery rollers, textile machinery, conveying machinery axis, linear optical axis for linear movement.

A wide variety of mud pump piston rod options are available to you, such as 1 year, not available and 2 years.You can also choose from new, mud pump piston rod,as well as from energy & mining, construction works , and machinery repair shops mud pump piston rod, and whether mud pump piston rod is 1.5 years, 6 months, or unavailable.

8613371530291

8613371530291