mud pump pony rod manufacturer

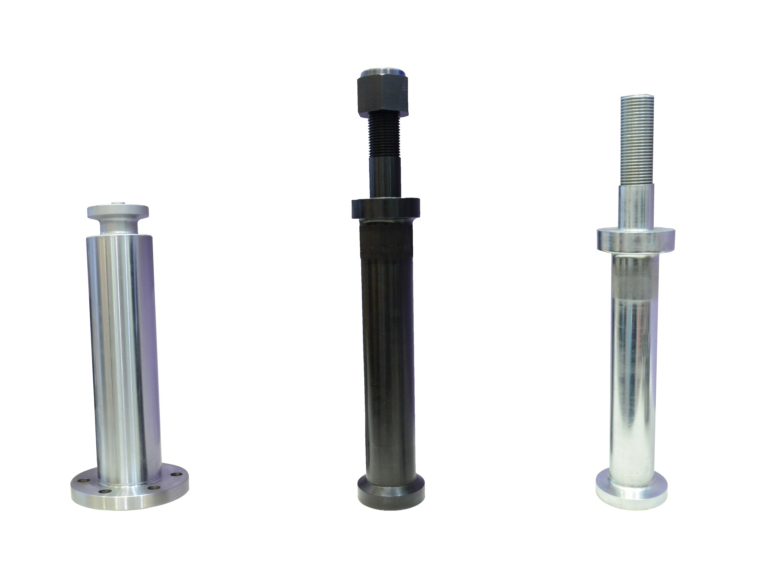

Pony rod also called the intermediate rod, is an important part of the connection between the crosshead and the piston rod. It is the key component that connects the power end and the hydraulic end of the mud pump. One end is connected to the crosshead and the other end is connected to the piston rod by a clamp. Its outer circumference is filled with a packing box assembly. In the reciprocating motion, the outer circle of the intermediate tie rod and the sealing member in the packing box rub against each other. To ensure it"s wear resistance, the outer surface of the intermediate rod is hard chrome-plated.

We can offer a wide range of extension (pony) rods for triplex mud pumps that are made of high quality alloy steel (40Cr). After strict heat treatment of quenching and high temperature, the rods have the features of high intensity on surface and high tough inside. The surface is treated with galvanization or nitrogen for high intensity and low abrasion.

31 mud pump pony rod products are offered for sale by suppliers on Alibaba.comAbout 70% % of these are mud pump, 12%% are pumps, and 9%% are mining machine parts.

A wide variety of mud pump pony rod options are available to you, You can also choose from new, mud pump pony rod,as well as from energy & mining, construction works , and machinery repair shops mud pump pony rod, and whether mud pump pony rod is 1.5 years, 6 months, or 3 months.

8 pony rod for emsco mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 75%, mining machine parts accounts for 25%.

A wide variety of pony rod for emsco mud pump options are available to you, You can also choose from new, pony rod for emsco mud pump,as well as from energy & mining, machinery repair shops, and manufacturing plant pony rod for emsco mud pump,And whether pony rod for emsco mud pump is 3 months, {2}, or {3}.

Our piston rods are manufactured from high quality alloy steel. Surface is induction hardened for maximum case hardness and core strength - hard on the outside, tough on the inside. Precision ground mirror surfaces meet rigid quality control standards and minimize wear.

High quality Grayloy material is used on all HNA Duplex Piston Rods. This corrosion-resistant, high-density, long-wearing surface results in fewer packing changes and longer life for gland bushings and junk rings. HNA rods are furnished with a heavy duty Piston Lock Nut.

HNA offers a full range of clamps for mating the piston rod to the crosshead extension (pony) rod. Machining tolerances are tightly held to assure proper fit and alignment of the adjoining components. HNA clamps are furnished complete with all required hardware.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

Schlumberger sucker rods are available in 25- and 30-ft lengths. Pony rods are available in lengths of 2, 4, 6, 8, and 10 ft. Rods are manufactured, heat-treated, and tested at a facility that follows our stringent quality assurance procedures. They exceed the requirements for API Spec 11B certification for applicable grades.

Sucker rods are used in multiple artificial lift applications, including rod lift and progressing cavity pumps (PCPs). You can choose among several certified materials—depending on both the depth and corrosion level of your well—to best fit your application.

For applications in particularly harsh conditions, you can also rely on our highly corrosion- and abrasion-resistant coatings for D-Alloy (DA) and H-Alloy (HA) rods.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

Engineered to last, our rods are the best performing sucker rods on the market today, allowing wells to produce at optimum levels longer. As a sucker rod manufacturer, our steel sucker rods, and pony rods are manufactured to the highest quality standards to ensure reliable, consistent operation in every well application. Norris, UPCO, and Alberta Oil Tool provide full sucker rod service, with experienced rod specialists ready to assist with in-depth product selection knowledge and a commitment to ongoing technical support.

Ideco is one of the parts of a mud pump that is complete with high quality parts. This is a name that is a leading manufacturer of high quality parts of the fluid end such as the following:Modules

The products of this brand are designed in the United States as well as manufactured according to the strict processes that ensure the perfect quality so that customers get nothing short of the best. The ingredients of Ideco consist of the following components:Liners

The Ideco pumps allow an addition in the quality trading of the replacements parts of the mud pumps and their parts that also take into account the following varieties such as:Centrifugal pumps

All of the above mentioned ingredients are found in the market and are available for better oil drilling and extraction. There are more than 1000000 varieties of inter changeable mud pump constituents and all the previously mentioned types like centrifugal pumps, parts of a rig and swivel components for the majority of the manufacturers and this includes Ideco. Their components include:Duplex pump spares

Parts of Ideco are provided with a full series of pistons for the triplex as well as duplex mud pumps. This is done for ensuring their popularity among the customers. All the manufacturers of the mud pumps and their parts make sure or try to make sure that their products and constituents are made under the certification of the American Petroleum Institute, the API. Some of them include:Bonded rubber pistons

The Bonded premium urethane piston is a single piece bonded constructed piston that does not have any joints which guarantees the prevention of leaking. The Ideco components like these eliminate the possibility of the abrasive fluids to accumulate between the liner and the piston. The expanded lip of the fluid is not damaged by faster strokes of the pump or high pressure actions. It is a fail proof piston that seals off to increased diameters as the liner keep wearing.

Parts of the mud pump like the pistons with replacement rubbers are currently running for drilling mud in the highest of pressures. It has a bonded construction as well as build without using leakage and joints. The longer size of the piston helps in guaranteeing the longevity of the equipment. The Ideco component helps the piston to function in higher pressure for ensuring a faster stroke. It is additionally resistant to the mud of the oil base as well as other additives that are put to use.

Pistons with replacement rubbers are actually the premium Ideco pistons or mud pump parts that have been serving the industry for a number of years with excellent and unparalleled performance records to suit extreme drilling conditions. This is a single piece bonded unit that has a number of benefits as it is impermeable to different kinds of chemicals as well as other kinds of oil.

Being able to garner the trust of our valued customers, we manufacture (Down Hole Tolls i.e. Cross over, Sub Saver, Lifting Sub. etc.), import, trade and supply best quality Steel Products. Having an experience of almost a decade, we offer a wide range of products that includes Drilling Bits (for Oil & Gas), C.S and M.S. Pipes & TubesandRotary Substitutes (Down Hole Tools for Oil & Gas). These products are generally used in exploring mine and gas or drilling wells, sugar industries, chemical plants, fertilizer plants, pharmaceutical, railway coaches, refrigeration and metallurgical industries. Known for their dimensional accuracy, high tensile strength and durability, these products are made by experts in compliance with the industry standards.

We have a strong infrastructure base that is equipped with latest technological tools and machines. We are powered with a trained and experienced team of professionals, who have expertise in their respective domains and work areas. These experts work with dedication and efficiency on our set standards to maintain the trust of our clients. Therefore, our clients trust us for offering top quality products and making their timely deliveries at clients" end.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

The Sur-Lock Rod Link System was developed to provide a safer and faster way to unfasten the piston rod and remove the piston from the liner. The sub rod contains a proprietary “wedge lock” mechanism that allows the piston and pony rods to be connected by simply inserting pins and turning a bolt. No hydraulic fitting, seals, or pumps are necessary.

The system uses rods and rod extensions that are 100% compatible with the same parts from the P-Quip system. Additionally, our torque module can completely replace the P-Quip hydraulic module in plug-and-play fashion.

8613371530291

8613371530291