mud pump suction strainer factory

Mud pump is a reciprocating plunger pump, through the crank connecting rod mechanism to convert the rotating motion into the reciprocating straight motion of the crosshead and piston, the low pressure mud compression into high pressure mud.

Traditionally, mud pumps are divided into the liquid end and the power end, which transmits power and changes motion patterns and speeds. Provide appropriate power to the liquid end; The liquid end is used to convert mechanical energy into liquid internal energy to transport mud.

Suction and discharge valves conform to ASA and API specifications, and the piston rod and the intermediate rod are connected with a clamp. The seat hole has a bottom shoulder to prevent seat subsidence. The piston and cylinder liner are lubricated and cooled by spray for extended service life.Easy to realize quick assembly, disassembly and installation.

Explore a wide variety of pump strainer mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These pump strainer mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these pump strainer mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right pump strainer mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of pump strainer mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

Flange-blind, National, #5912392, for Strainer cleanout, 5-1/8”, 5000PSI, API 6BX blind flange, BX-169, API 60K Material, 4130 steel, PSL-1, T/C-U, M/C-DD

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

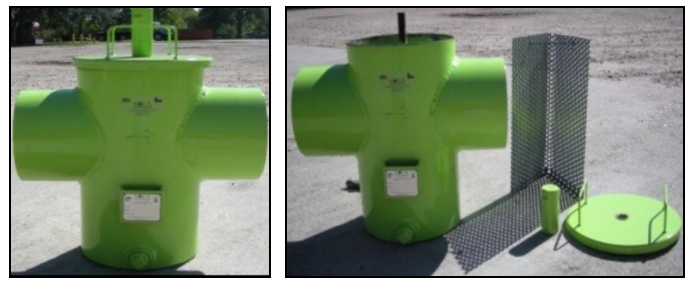

We have a complete industrial chain, which can guarantee sufficient and stable output of the Stem guided valve, Full Open Valve Seat, bi metal lner.We have established a comprehensive pre-sales and after-sales service standards for our Discharge Strainer Cross. Our company"s "careful, attentive, quality is always satisfactory" is the spirit of our company, which is reflected in the pace of our company"s sustainable progress and in the relationship with customers, partners, internal staff and competitors. In order to remain invincible in the market competition, our company has established brand awareness and broken the monopoly. The company"s products and reputation are the symbol of the company, embodying the spirit of the company and the connotation of the company"s culture, and directly affect the customer"s purchase experience. We insist on continuous innovation around customer needs, continue to provide excellent products and services, and create value for customers. We persist in openness, tolerance, sincere cooperation, mutual benefit and harmony.

WebDec 13, 2022 · NATIONAL 12P-160 TRIPLEX MUD PUMP (Ref#5586T) 3 available in India. 1600 HP, rated pump speed 140 strokes per minute, maximum fluid cylinder liner bore 6¾”, stroke 10", 10,000 PSI...

WebMay 27, 2016 · What r the advantages and disadvantages of strainer at pump discharge vs at suction. We have a double diaphragm pump. Application is slurry service with very low flow rate 3 to 7 kg...

WebCompletely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation...

WebWhat Is A Pipe Strainer? A pipe strainer is a device that serves as a means to remove solids from a flow of the fluid mechanically. This is achieved by using a straining element of perforated...

WebSpecial Discharge Strainer Design. Featured here is a specially designed 3-inch 316. Stainless Steel Spool Type Strainer. This flow-through style. Strainer was custom engineered with a 316SS...

Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for Piston Rod and Pony Rod, Module Accessories, Mud Pump Expendables, Stuffing Box and Oil Seal. We"re professional Discharge Strainer Cross manufacturers and suppliers in China, specialized in providing high quality products and service. We warmly welcome you to buy high-grade Discharge Strainer Cross at competitive price from our factory.

Mud pumps consume more than 60% of all the horsepower used in rotary drilling. Mud pumps are used to circulate drilling fluid through the mud circulation system while drilling. A pump with two fluid cylinders, as shown in Figure 4-99, is called a duplex pump. A three-fluid-cylinder pump, as shown in Figure 4-100, is called a triplex pump. Duplex pumps are usually double action, and triplex pumps are usually single action.

Mud pumps consist of a power input end and a fluid output end. The power input end, shown in Figure 4-101, transfers power from the driving engine (usually diesel or electric) to the pump crankshaft. The fluid end does the actual work of pumping the fluid. A cross-section of the fluid end is shown in Figure 4-102.

The hydraulic horsepower produced by mud pumps depends mainly on the geometric and mechanical arrangement of the suction piping. If suction-charging centrifugal pumps (e.g., auxiliary pumps that help move the mud to the mud pump) are not used, the pump cylinders have to be filled by the hydrostatic head.

suction pipe. Minimizing the effect of inertia requires a reduction of the suction velocity and mud weight. It is generally practical to use a short suction pipe with a large diameter.

Mud temperatures of 150° can present critical suction problems. Under low pressure or vacuum existing in the cylinder on the suction stroke, the mud can boil, hence decreasing the suction effectiveness. Furthermore, hot mud accelerates the deterioration of rubber parts, particularly when oil is present. Large mud tanks with cooling surfaces usually solve the problem.

Entrained gas and air expands under the reduced pressure of the suction stroke, lowering the suction efficiency. Gas in water-base mud may also deteriorate the natural rubber parts used. Gases are usually separated with baffles or by changing mud composition.

The normally good lubricating qualities of mud can be lost if cuttings, particularly fine sand, are not effectively separated from the mud. Adequate settling pits and shale shakers usually eliminate this trouble. Desanders are used occasionally.

A poorly designed discharge manifold can cause shock waves and excessive pressure peaks. This manifold should be as short and direct as possible, avoiding any sharps turns. The conventional small atmospheric air chamber, often furnished with pumps, supplies only a moderate cushioning effect. For best results, this air chamber should be supplemented by a large atmospheric air chamber or by a precharged pulsation dampener.

A few strokes of the piston in a dry liner may ruin the liner. When the pump does not fill by gravity or when the cylinders have been emptied by standing too long or by replacement of the piston and liner, it is essential to prime the pump through the suction valve cap openings.

Suction lines are often partly filled by settled sand and by debris from the pits, causing the pump to hammer at abnormally low speeds. Frequent inspection and cleaning of the suction manifold is required. The suction strainer can also be a liability if it is not cleaned frequently.

The discharge strainer often becomes clogged with pieces of piston and valve rubber. This may increase the pump pressure that is not shown by the pressure gauge beyond the strainer. The strainer should be inspected and cleaned frequently to prevent a pressure buildup.

Usually special solids, such as nut shells, limestone, expanded perlite, etc., are added to the drilling muds to fill or clog rock fractures in the open hole of a well. Most of these lost circulation materials can shorten the life of pump parts. They are especially hard on valves and seats when they accumulate on the seats or between the valve body and the valve disc.

Pump parts for high-pressure service are made of precisely manufactured materials and should be treated accordingly. In storage at the rig, metal parts should be protected from rusting and physical damage, and rubber parts should be protected from distortion and from exposure to heat, light, and oil. In general, parts should remain in their original packages where they are usually protected with rust-inhibiting coatings and wrappings and are properly supported to avoid damage. Careless stacking of pistons may distort or cut the sealing lips and result in early failures. Hanging lip-type or O-ring packings on a hook or throwing them carelessly into a bin may ruin them. Metal parts temporarily removed from pumps should be thoroughly cleaned, greased, and stored like new parts.

The charts showing the performance of duplex pumps are shown in Table 4-38 [17]. The charts showing the performance of triplex pumps are shown in Table 4-39 [17]. A chart listing the pump output required for a given annular velocity is shown in Table 4-40 [18]. A chart listing the power input horsepower required for a given pump working pressure is shown in Table 4-41 [19].

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

8613371530291

8613371530291