mud pump suction strainer in stock

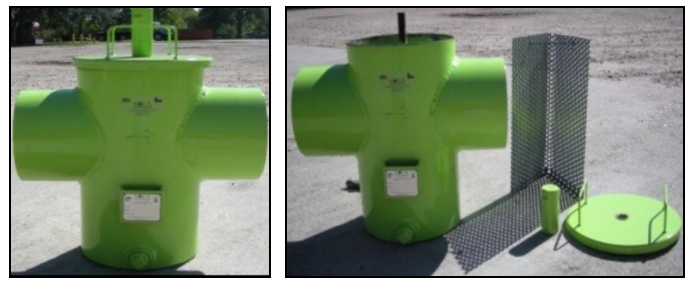

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

Explore a wide variety of pump strainer mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These pump strainer mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these pump strainer mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right pump strainer mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of pump strainer mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

Flange-blind, National, #5912392, for Strainer cleanout, 5-1/8”, 5000PSI, API 6BX blind flange, BX-169, API 60K Material, 4130 steel, PSL-1, T/C-U, M/C-DD

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

1-1/2 inch FNPT Suction Strainer with 1/2 inch round holes. 1.5" Irrigation or sprinkler pump strainer. Also comes in the 1/8" size holes SRHS-200-SM Zinc plated steel. Good for use with sprinkler pumps, irrigation pumps and other centrifugal and semi-trash pumps which can accept limited debris.

These zinc plated round hole strainers can be used with all popular makes of centrifugal pumps for use with hoses and pipes. Drop in to liquid to be suctioned. An "open" area of 50% allows filtering out large damaging debris, yet permits sufficient water passage to keep pumps functioning at full capacity.

For Top Hole skimmer strainers see SSKS-TH or SSKS-BH for Bottom Hole series or SRHS for barrel suction strainers. Image tab belows shows some of the various strainers available from PumpBiz. Please let us know if you do not see what you are looking for or for complete hose kits.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

The Tsurumi two-pole to six-pole agitator slurry pump is capable of handling sandy liquids in quarries and concrete plants. The Megator Dolphin floating suction strainer can draw clean water from below the surface, bypassing sand, mud, other floating matter and contaminated liquid (eg oil slicks).

Tsurumi is one of the world’s largest submersible slurry pump manufacturers, with a wide range of pumps suitable for handling everything from sandy, salty water, to heavy-duty slurry found in the quarrying, mining and concrete manufacturing sectors.

The high chrome, cast iron agitators ensure the smooth suction of the settled matter. This same philosophy is used in single- and three-phase pumps alike, providing the ability to move solids in suspension that conventional pumps can’t handle.

{{image2-a:r-w:300}}The ultimate extension of the product range is the four-pole and six-pole pumps, with huge flows, capable of pumping thick slurry. Tsurumi’s four-pole GSZ series will handle flows of up to 18,000 litres per minute (LPM) and heads of up to 54m.

The impeller, agitator and suction plate are made of high chrome cast iron to resist abrasion. Even if the impeller and suction plate wear down to the point of diminishing pump performance, the plate can be easily replaced or its gap from the impeller adjusted, giving users an easy, inexpensive means of extending use.

Tsurumi’s GSD series, a new range of heavy-duty, high-powered agitator pumps, feature power ratings of up to 75kW. The pumps feature high heads and volumes, and may change the way the international market thinks about mining, quarrying and heavy mineral movement.

The impeller, agitator and mouth ring are made of high chrome cast iron to ensure long use. Tsurumi has developed an innovative mechanism for this series that continuously adjusts the clearance between the mouth ring and the impeller. The pumps in this new series are also equipped with pressure relief ports that release pump pressure applied to the mechanical seals. This enhances reliability in extended use applications.

Like all Tsurumi pumps, the GSZ and the GSD series offer Tsurumi’s anti-wicking cable entry. This prevents water incursion due to wicking, should the power cable be damaged or the end submerged.

Tsurumi also offers two double silicon carbide mechanical seals. These are located in an oil chamber fitted with a unique “oil lifter”. The guide vanes on the oil lifter ensure the seals are continuously lubricated and cooled during operation of the pump.

Developed by Megator to be compatible with its positive displacement “sliding shoe” pump, the Dolphin is equally at home in dewatering or oil disbursement applications.

{{image3-a:r-w:300}}The Dolphin strainer is considered unique in that it always floats upright. It can’t lose buoyancy and is tough and shockproof. The materials of construction make it corrosion-proof. The products are available in 1.5-inch to six-inch ports.

The suction strainer will draw clean water from just below the surface, avoiding sand, mud and any floating matter. That also makes it ideal for emergency services in flood waters or for pumping contaminated liquids where the surface has to deal with floating debris or oil slicks.

The strainers cannot get buried when grounded in shallow water. They are made entirely of very tough corrosion resistant plastic materials and stainless steel.

The Megator Dolphin can reduce the wear on pumps and prevent pump damage. They prevent stoppages, and can substantially lessen the risk of cavitation.

The six-inch version can handle flows up to 3000 LPM. That unit, the largest in the range, has a perforated body constructed entirely of 18/80 stainless steel. Smaller sizes have replaceable strainer screens made of Darvic black PVC.

The rounded shape of the cover is strong and resistant to rough handling. The strainer also includes an “eye” for mooring or the attaching of extra weight if used in choppy seas or fast flowing flood water.

The patented construction includes a free-turning tube that eliminates the twisting effects of the hose and ensures the correct “attitude” of the strainer at all times. Detachable strainer plates are mounted in the sides and the bottom of the Dolphin. They are strongly ribbed to prevent the unit from being sucked down into mud if stranded in shallow water.

Megator has even included an access port that enables the strainer to be cleaned out in the event of it being choked with sediment. This can be cleaned without having to disconnect the suction hose connected to the pump!

According to Hales, Dolphin strainers are not limited to use with sliding shoe positive displacement pumps. They can function in any pumping application, including on construction mining sites.

“Pump cavitation is a huge issue, not only in pump performance but also in premature wear,” Hales said. “The Dolphin reduces the risk of cavitation, prevents pump damage and can save its purchase cost many times over.”

Early pump wear and consequent failure is often generated by the entry of solvents to the pump chamber that are not compatible with the pump’s design. It is that abrasive wear, coupled with cavitation issues, that can result in massive pump failure with consequential downtime and expensive repairs.

8613371530291

8613371530291