gorman rupp mud pump quotation

Since 1933, Gorman-Rupp has manufactured the high-performance, high-quality pumps and pumping systems required for lasting service in the municipal, water, wastewater, sewage, industrial, construction, petroleum, mining, fire, and OEM markets.

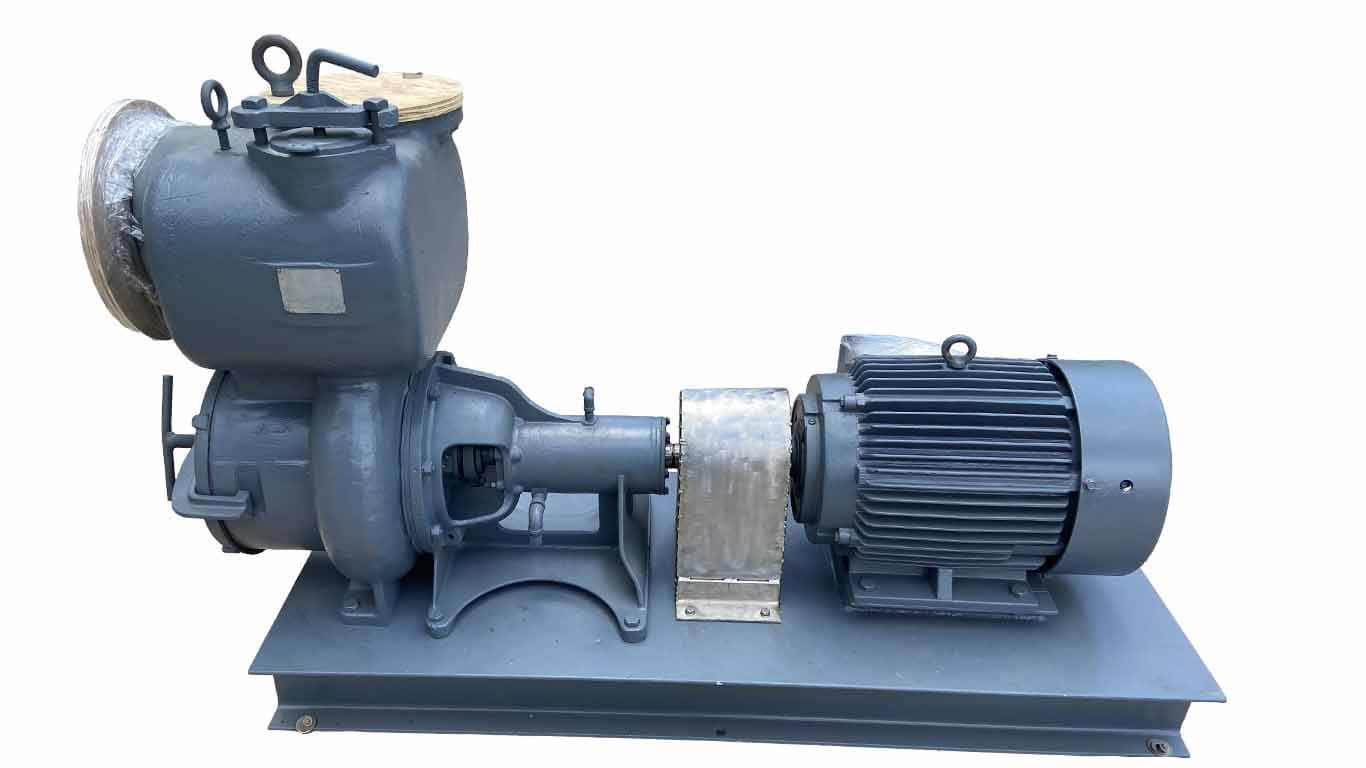

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for medium to high head contractor and bypass applications

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for high head/high flow contractor and bypass applications

Gorman Rupp Pump manufactures of all types of trash pumps, submersible pumps, portable pumps, high-pressure fire pumps, and self-priming pumps. Centrifugal and diaphragm pumps. Electric Gas Diesel powered. Mansfield, OH. OTS Off-The-Shelf & IPT pumps program.

Gorman Rupp pumps will meet any pumping situation you may have. For more than 80 years, Gorman-Rupp has manufactured the high-performance, high-quality pumps required for lasting service in the contractor and industrial fields. Complete line of AMT pumps. Made in America

In addition to the electric motor, many pumps are powered by Honda engines. If you need durability and reliability, these GR Pumps with Honda gas powered engines are just what you are looking for.

Designed for the harshest environments, the Gorman-Rupp line of EXPlosion Proof pumps have a long history of quality and reliability. These self-priming pumps handle flammable and hazardous liquid material.

GR Pumps meet the needs of virtually any industry. From circulator pumps to hazardous material, GR Pump move water, chemicals, sludge, trash, mud, and more. Contact us to discuss your application and we will be sure your GR Pump meets your needs.

The AMT 335Z-96 diaphragm trash pump is designed to move thick liquids like sewage and sludge. Features a heavy duty 2 stage forged gear driven transmission that operates pump at 60 strokes per minute. Modular component design permits easy maintenance and cleanout. Wheel kit and handle are included.

Diaphragm pumps by Gorman-Rupp help you pump muddy, mucky, sand-laden liquids and slow seepage for construction, agricultural and industrial applications that require the pumps to run dry for extended lengths of time. Available basic or electric driven.

Designed for economical, trouble-free operation, the superior solids-handling capabilities of Super T Series® pumps make them ideally suited for a variety of applications including solids-laden liquids and slurries. The large volute design allows automatic repriming in a completely open system without the need for suction or discharge check valves. This self priming centrifugal pump comes packed with advanced features. Gorman-Rupp offers a wide selection of pumps and pumping systems for many fluid-handling applications. Ranging in diverse sizes from fractional horsepower pumps to the largest of flood control pumps, Gorman-Rupp pumps are in continuous duty around the globe.

Gorman-Rupp’s extensive line of hard-working, dependable priming assisted (dry prime) pumps will tackle everything, including clear liquids, tough solids, and slurry applications. For sewage bypass operations, construction site dewatering and remediation or other applications where intermittent flow can be a problem, these dependable, versatile performers help contractors move large volumes of water rapidly, even when sticks, stones, and debris would normally present a problem.

In addition, Gorman-Rupp manufactures a complete line of state-of-the-art packaged lift stations and booster stations that include pumps, motors, controls, piping, accessories and enclosures.

Effective immediately, due to supply chain challenges, Gorman-Rupp Pumps (Engineered Systems) is temporarily substituting Allen-Bradley PowerFlex 753 Variable Frequency Drives (VFD) with the Allen-Bradley PowerFlex 755 Variable Frequency Drives (VFD). At this time, there is no additional cost for the substitution. We will continue to monitor availability, and will provide notification when availability returns for

Gorman Rupp pumps are known throughout the world as some of the highest quality, best-performing pumps on the market. Gorman Rupp pump housings are manufactured from a variety of high strength materials, including aluminum, bronze, stainless steel, and numerous engineered plastics. Buna-N, polyethylene, Teflon, and Viton elastomer materials provide reliable, durable seals. Electric, piston, and rotary drives (varies by model) provide outstanding performance in any fluid handling application.

Gorman Rupp has been manufacturing pumps and pumping systems since 1933, and many of their innovations have since become industry standards. Gorman Rupp pumps are popular around the world thanks to the company’s overriding philosophy of “Innovation, Improvement, and Superior Products.”

Gorman Rupp utilizes state-of-the-art manufacturing technology, including fully automated machining centers, to ensure that each and every one of their pumps meets their own high standards of quality and precision. Advanced pump designs and superior quality materials have made Gorman Rupp pumps the equipment of choice anywhere dependability and high performance is essential.

Order your Gorman Rupp pump online today, send us a Request for Quote, give us a call at800-603-0399 or contact Pumping Solutions for more information on Gorman Rupp pumps.

The Gorman-Rupp Super T-Series pumps have been the “Best in Class” centrifugal wastewater/sewage pump technology since 1963. They are designed for economical, trouble-free operation, with superior solids handling capability and low cost of ownership. Operators love the T-Series pumps because they are easy to maintain, they include a large inspection cover to access pump internals for service or clog removal, and parts are readily available.

Even the best and most dependable pumps require basic attention and periodic maintenance to ensure they provide an exceptionally long service life and unmatched performance. Here is a list of ten ways to extend the life of the Gorman-Rupp T-Series pumps. These also apply to the Gorman-Rupp V-Series pumps.

Envirep’s service staff is factory-trained in the operation, maintenance, and troubleshooting of Gorman-Rupp pumping equipment and electrical controls. They are equipped with proper tools and testing instruments and arrive at your site with common replacement parts enabling them to solve potential problems quickly and economically. We will work with you to keep your pumping equipment operating reliably and efficiently.

Envirep/TLC is the exclusive distributor for Gorman-Rupp municipal water and wastewater pumps and pumping systems in Eastern Pennsylvania, Delaware, Maryland, Northern Virginia, and the District of Columbia.

Gorman-Rupp’s extensive line of pump products includes self-priming centrifugal pumps, standard centrifugal pumps, submersible pumps, solids passing pumps, portable engine-driven pumps, and priming-assisted pumps. In addition, Gorman-Rupp manufactures a complete line of packaged wastewater pumping stations and potable water booster stations that include pumps, motors, controls, piping, accessories, and enclosures.

Gorman-Rupp is the industry leader and innovator in high-quality pump design. At Envirep/TLC, we will help you choose the best Gorman-Rupp® pump parts for your needs. Our goal is to provide you with easy-to-operate, low-maintenance pump parts to ensure you are being as cost-effective as possible.

Envirep/TLC is an authorized distributor of Gorman-Rupp pump products, and we carry a huge inventory of spare parts so our customers receive the best service possible.

Gorman-Rupp 10 Series Self-Priming Pumps are specifically designed for handling solids, corrosive liquids and slurries. They have few moving parts, so maintenance is minimal. If a clog occurs, it can be removed easily through the cover plate opening without disturbing piping or the use of any special tools. The 10 Series offers a variety of seal configurations to choose from to handle a number of different liquids, they make for great corrosive liquid pumps.

–Solids Handling Impeller:Two-vane, semi-open, solids handling impeller handles up to 3″ (76 mm) diameter solids, depending on pump model. Pump out vanes on impeller shroud reduce foreign material buildup behind impeller and reduce pressure on seal and bearings for extended pump life.

– Multiple Seal Options: 10 Series pumps are available with Gorman-Rupp double mechanical grease lubricated seals, self-lubricated mechanical seals and Gorman-Rupp’s exclusive tungsten titanium carbide double floating, self-aligning oil Lubricated seals. Fluorocarbon Elastomers (DuPont Viton® or equivalent) and PTFE Elastomers (DuPont Teflon or equivalent) are also available.

– Removable Cover Plate:Removable cover plate provides quick and easy access to pump interior without disconnecting piping. Clogs can be removed and pump returned to service in minutes. Impeller, seal and replaceable wearplate can also be easily accessed through cover plate opening for inspection or service.

– Replaceable Wearplate:10 Series pumps feature replaceable wearplates which fasten to the cover plate and can be removed for inspection or service. No expensive castings to replace. 10 Series pumps are available as basic units for connection to customers’ power source or may be flex-coupled or V-belt driven by an electric motor. Pumps can also be powered by gasoline or diesel engines.

D.J. Gongol and Associates, Inc. are the exclusive manufacturer"s representatives for the Gorman-Rupp lines of municipal water and wastewater treatment systems in the states of Iowa and Nebraska. The Gorman-Rupp Company is the world"s leading manufacturer of self-priming centrifugal pumps, and we are their proud representatives for municipal water and wastewater treatment applications in Iowa and Nebraska. Gorman-Rupp pumps are reliable and easy to maintain.

Wet on the inside, dry on the outside. Self-priming centrifugal pumps keep the fluids on the inside. Any pump can clog from time to time -- so why make life more difficult for the operator? Gorman-Rupp pumps stay high and dry above the sump, so maintenance and repairs are easy and safe. The easy-access coverplate on a Gorman-Rupp T-Series pump means you don"t have to disturb piping or move the pump just to clear it out. Every Gorman-Rupp pump 4" or larger will clear a 3" solid anywhere in the pump -- that"s the size of a baseball. Solids-clearing capacity like that is a huge advantage to you as an operator.

Reliability. Dozens of Gorman-Rupp applications are still working here in Iowa and Nebraska more than a decade after we first put them into place. Your operators have better things to do than fix pumps all day. Go with the reliability of a Gorman-Rupp application! See for yourself!

Our exclusive five-year guarantee. We"re so certain that your Gorman-Rupp self-priming pumps will give you trouble-free operation that we"ll offer you a five-year guarantee on service. That"s more reliability than you can expect from your own car or truck!

Proven results. We"ll put Gorman-Rupp pumps side-by-side with any competitor"s and let you make the decision. Once you see how a Gorman-Rupp self-priming pump outperforms any other pump on the market, you"ll know why we"ve earned the trust of scores of municipalities across Iowa and Nebraska.

Hands-free operation. Why spend your time doing what a reliable Gorman-Rupp system can do for you? Gorman-Rupp stations are available with auto-start controls, so when the power goes out, your system keeps working.

It gets even better: Gorman-Rupp has taken the industry-leading T-Series pump and made it even better with the Super-T! The Super-T combines classic T-Series pump performance with features designed to make maintenance even easier. Contact us for custom specifications and calculations - use our contact page.

8613371530291

8613371530291