mud pump relief valve in stock

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

A wide variety of mud pump relief valve options are available to you, such as 1 year, not available.You can also choose from new, mud pump relief valve,as well as from energy & mining, construction works , and machinery repair shops mud pump relief valve, and whether mud pump relief valve is 1.5 years, 6 months, or unavailable.

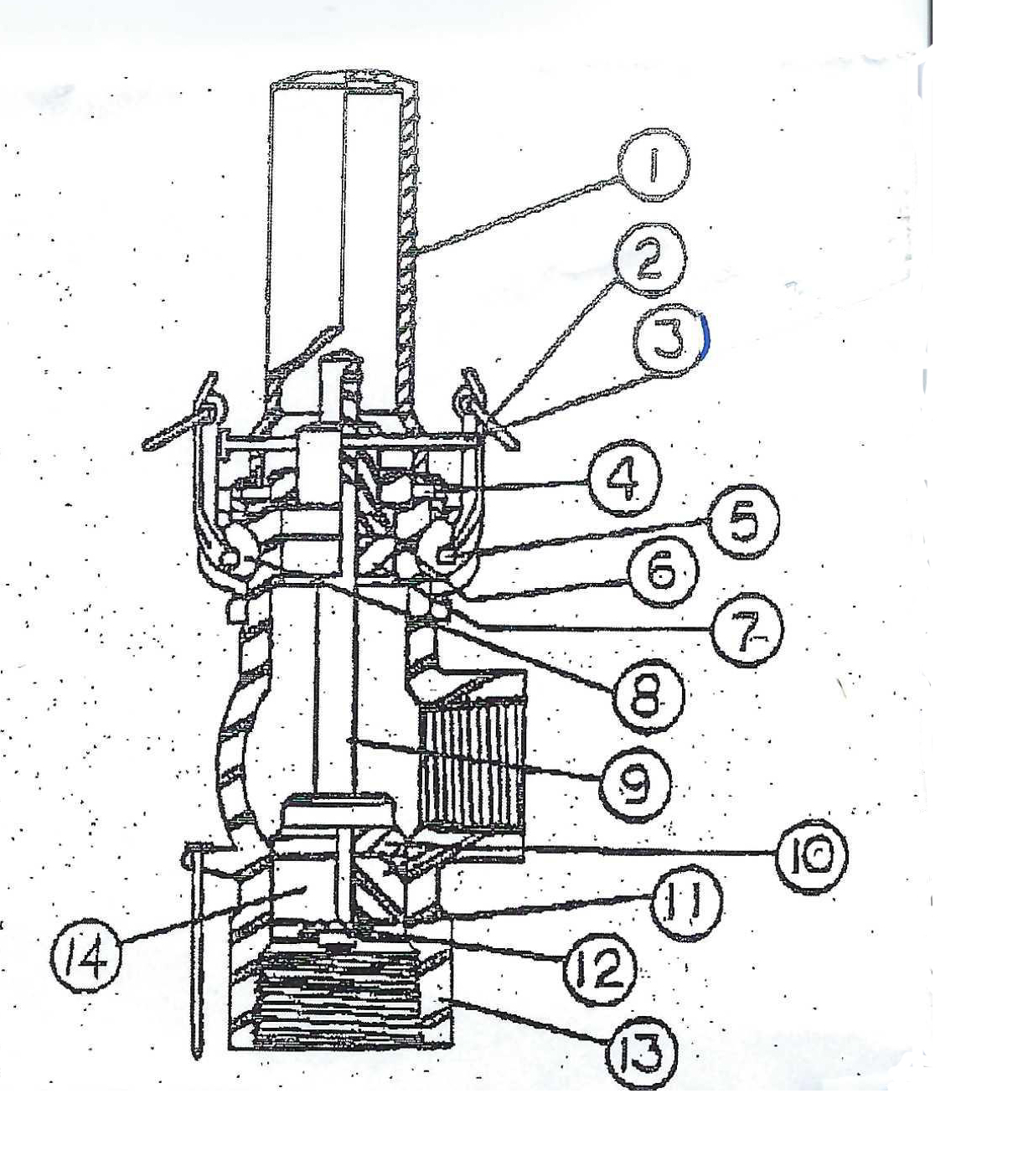

Drillmax Shear Relief valves are known for their dependability and effectiveness and are usually installed on the discharge end of the mud pump. When pressure exceeds the preset limit, the pin is sheared allowing the excess pressure to escape and be re-directed, preventing costly repairs. Different pin diameters are used to set the desired shear pressure. Once the problem is corrected, a new pin can be inserted to reactivate the valve.

[fusion_builder_container type=”flex” hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” overlay_color=”” video_preview_image=”” border_color=”” border_style=”solid” padding_top=”” padding_bottom=”” padding_left=”” padding_right=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” background_color=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”true” min_height=”” hover_type=”none” link=”” border_sizes_top=”” border_sizes_bottom=”” border_sizes_left=”” border_sizes_right=”” first=”true”][fusion_text]Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

The NV-7500 Mud Gate Valve is a full metal to metal sealing gate valve for use in applications up to 7500 psi. The NV-7500 uses single piece seat rings creating an upstream metal to metal seal. The upstream design helps eliminate debris contamination into the valve body and reduces wear on the internal components.

MTM Hydro"s MG1000 Pressure Relief Valve is a must-have for all triplex pump owners. This valve effectively monitors pressure of your pump and if the limit is exceded, the 6mm side port is opened to alleviate accrued pressure within the line. This accessory will save you hundreds, and even thousands of dollars by keeping your pumps safe from pressure spikes and keeping your crew at work by avoiding downtime due to a blown pump. The MTM Hydro Pressure Relief Valve has 3/8" Male NPT thread for fast install on a a "T" fitting between the pump and the unloader. "T" Fitting not included.

AKO UK recommend that the valves are de-pressurised every 8 weeks for a period of 15 minutes. This will ensure maximum life from the sleeve. During the same period the valve should be visually checked to ensure all parts are working. AKO advise checking the PRV evry 4 weeks to make sure it is holding pressure. It is possible that the PRV can lose up to 0.5 BAR within a 4 week period, if this occurs use the foot pump to inflate the PRV to desired pressure.

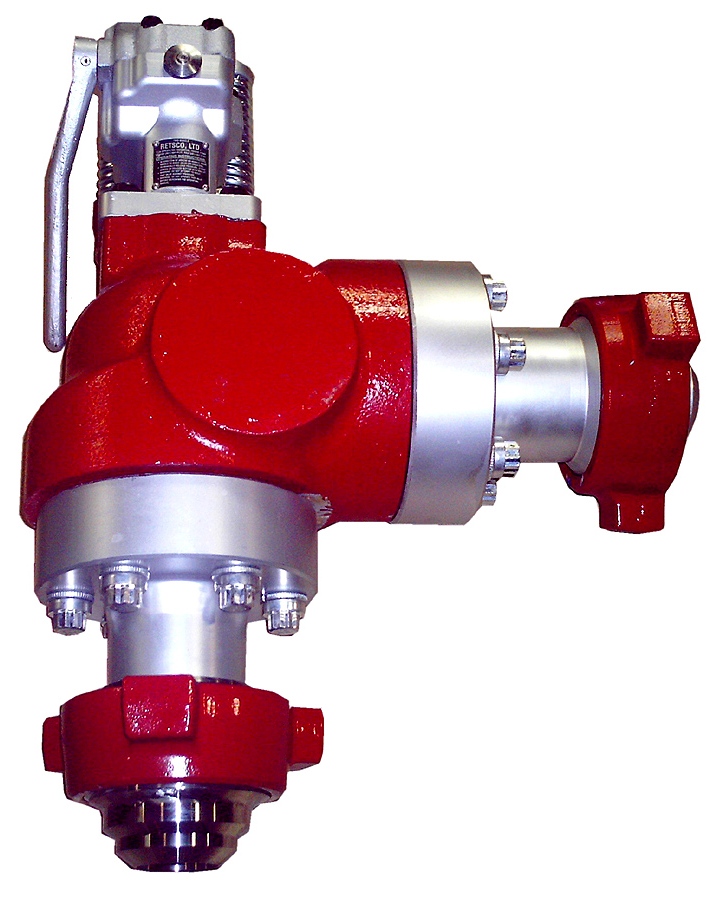

The CRV26 PRV is a product of the CORTEC Fluid Control division of CORTEC, which provides a complete line of high-end valves designed and manufactured according to specific project specifications. CRV26 PRV is engineered to protect drilling systems against the dangers of over pressurization and is the first of its kind to be rated to 10,000 PSI systems.

Stephen Corte, Vice President, CORTEC, said, “Automated PRVs provide the highest level of accuracy and reliability and are automatic or manually resettable for thousands of cycles. Our CRV26 PRV offers a competitively priced alternative to other remotely-operated PRV models, along with a degree of service life, precision and repeatability that conventional burst disks and manual spring reset valves cannot provide.”

The CRV26 PRV is suitable for frac system relief, mud pump relief and managed pressure drilling (MPD) and is compatible with API 6A and NACE MR0175 requirements.

The CORTEC Model CRV Choke Relief Valve (CRV) line offers users the safety, reliability and quick response function required to meet the demands of today’s drilling operations. Our robust designs are manufactured with superior performance and field serviceability in mind. CORTEC Model CRV Choke Relief Valves are compatible with API 6A and NACE MR0175 requirements. Full third-party review is available upon request.

Available with a range of options for orifice sizes, end connections and control methods, CORTEC is certain to have a CRV model to suit your application needs. Whether you’re configuring a deepwater Managed Pressure Drilling (MPD) system, protecting mud pumps or relieving frac systems CORTEC’s CRV line is designed and proven to provide the highest level of reliability in the industry. Hydraulic and pneumatic control packages are configurable to suit customer and project specifications

Piston Rod Of JA-3 Relief Valve, JA-3 Shear Relief Valve 3”-5000psi, which is popular used in BOMCO Mud Pump F1300/1600, HHF1300/1600 and 3NB1300/1600. There is Threaded and Flanged connection, union is available upon request.

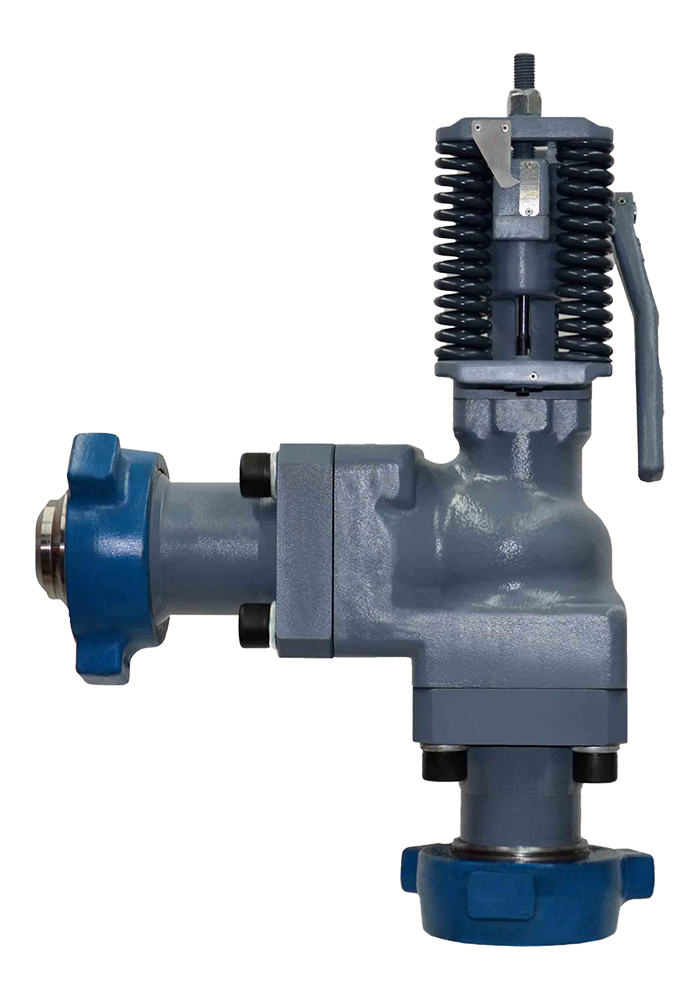

Manual Reset Relief Valve is mainly used as mud pump relief valve, with the same function as shear relief valve; but Reset Relief Valve can automatically snap to a full open position when the preset pressure is exceed. Once the pressure released, the reset was done to recover to work within several minutes when to operate the reset handle.

From the raw water intake to the filtration plant to the finished waster distribution and storage system, GA Industries valves have been providing dependable service in large and small water systems. GA Industries pump control, check and relief valves mitigate damaging pressure surges and eliminate slam and bang that can result from the operation of water pumps.

Air trapped in water pipelines can reduce system efficiency and exacerbate pressure surges. Our wide range of automatic air valves ensures we have the right valve to maintain an air free system.

And when it’s necessary to isolate a pump, process or section of pipeline, you can depend on GA Industries butterfly valves for reliable flow shutoff.

8613371530291

8613371530291