mud pump valve insert pricelist

We can supply many kinds of mud pump spare parts to fit your drilling needs, suiting to almost all popular mud pumps in the world.. Such as valve, valve seats, liner, piston, fluid end parts, crankshaft Assembly, Pinionshaft assembly, valve cover, liner cage, liner nut, valve seat puller, extension rod and piston rod, bearing, cylinder etc.

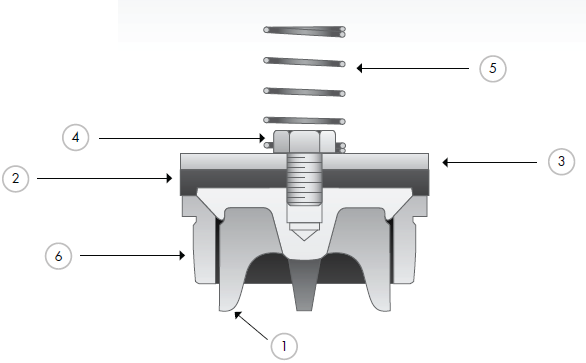

The valve and seat are made of forged alloy steel with deep carburized wear surface. We offer a full range of valves and seats which include full open valve and seat, 3 web / 4 web design valve and seat.

The valve comes with full open seat features four guide wings. They are either inertia welded to the valve body or uniformly forged with valve body. The urethane insert can be easily snapped on.

The 3 web / 4 web seat comes with stem guided valve. The urethane insert is tightened by steel plate and nut. It can be easily replaced with minimum down time. They offer long lasting service life under harsh service conditions.

A wide variety of mud pump valve inserts options are available to you, such as 1 year, not available.You can also choose from new, mud pump valve inserts,as well as from energy & mining, construction works , and machinery repair shops mud pump valve inserts, and whether mud pump valve inserts is 1.5 years, 6 months, or 3 months.

Being a customer focused organization; we are engaged in offering a wide assortment of Mud Pump Valve Inserts. All our products are provided to clients in different sizes and specifications at most competitive prices. Further, these products are thoroughly checked by expert quality controllers on various parameters to determine flawlessness.

G.D. TEE-BJA / TEE BFB : Valve assembly (PT. No. 200 PEE 482B) 5” stroke 3.1/2” triplex plunger mud pump spares : Valve body, valve, PU insert, washer, spring, spacer lantern, 3.1/2” Hardchrome plunger & packing set (60bu73)

Triplex plunger mud pump spares : Valve assembly complete (B-73991), fluid valve body, seat, polyurethane insert, self lock nut, spring are ready stock. 4” & 4.1/2” plunger (Hardchrome)

Full-Open Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

Outer Diameter2 TO 7 INCHWe are one of the leading manufacturers and suppliers of a quality-approved range of Mud Pump Piston Cup. Precisely designed, these products are made using quality components that are obtained from the authorized vendors of the market. Moreover, our products can be customized as per the specifications laid down by the customers.

ShapeROUNDBeing a customer focused organization; we are engaged in offering a wide assortment of Mud Pump Valve Inserts. All our products are provided to clients in different sizes and specifications at most competitive prices. Further, these products are thoroughly checked by expert quality controllers on various parameters to determine flawlessness.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

8613371530291

8613371530291