pop off valve mud pump free sample

Created specifically for drilling equipment inspectors and others in the oil and gas industry, the Oil Rig Mud Pump Inspection app allows you to easily document the status and safety of your oil rigs using just a mobile device. Quickly resolve any damage or needed maintenance with photos and GPS locations and sync to the cloud for easy access. The app is completely customizable to fit your inspection needs and works even without an internet signal.Try Template

If you run a mud rig, you have probably figured out that the mud pump is the heart of the rig. Without it, drilling stops. Keeping your pump in good shape is key to productivity. There are some tricks I have learned over the years to keeping a pump running well.

First, you need a baseline to know how well your pump is doing. When it’s freshly rebuilt, it will be at the top efficiency. An easy way to establish this efficiency is to pump through an orifice at a known rate with a known fluid. When I rig up, I hook my water truck to my pump and pump through my mixing hopper at idle. My hopper has a ½-inch nozzle in it, so at idle I see about 80 psi on the pump when it’s fresh. Since I’m pumping clear water at a known rate, I do this on every job.

As time goes on and I drill more hole, and the pump wears, I start seeing a decrease in my initial pressure — 75, then 70, then 65, etc. This tells me I better order parts. Funny thing is, I don’t usually notice it when drilling. After all, I am running it a lot faster, and it’s hard to tell the difference in a few gallons a minute until it really goes south. This method has saved me quite a bit on parts over the years. When the swabs wear they start to leak. This bypass pushes mud around the swab, against the liners, greatly accelerating wear. By changing the swab at the first sign of bypass, I am able to get at least three sets of swabs before I have to change liners. This saves money.

Before I figured this out, I would sometimes have to run swabs to complete failure. (I was just a hand then, so it wasn’t my rig.) When I tore the pump down to put in swabs, lo-and-behold, the liners were cut so badly that they had to be changed too. That is false economy. Clean mud helps too. A desander will pay for itself in pump parts quicker than you think, and make a better hole to boot. Pump rods and packing last longer if they are washed and lubricated. In the oilfield, we use a petroleum-based lube, but that it not a good idea in the water well business. I generally use water and dish soap. Sometimes it tends to foam too much, so I add a few tablets of an over the counter, anti-gas product, like Di-Gel or Gas-Ex, to cut the foaming.

Maintenance on the gear end of your pump is important, too. Maintenance is WAY cheaper than repair. The first, and most important, thing is clean oil. On a duplex pump, there is a packing gland called an oil-stop on the gear end of the rod. This is often overlooked because the pump pumps just as well with a bad oil-stop. But as soon as the fluid end packing starts leaking, it pumps mud and abrasive sand into the gear end. This is a recipe for disaster. Eventually, all gear ends start knocking. The driller should notice this, and start planning. A lot of times, a driller will change the oil and go to a higher viscosity oil, thinking this will help cushion the knock. Wrong. Most smaller duplex pumps are splash lubricated. Thicker oil does not splash as well, and actually starves the bearings of lubrication and accelerates wear. I use 85W90 in my pumps. A thicker 90W140 weight wears them out a lot quicker. You can improve the “climbing” ability of the oil with an additive, like Lucas, if you want. That seems to help.

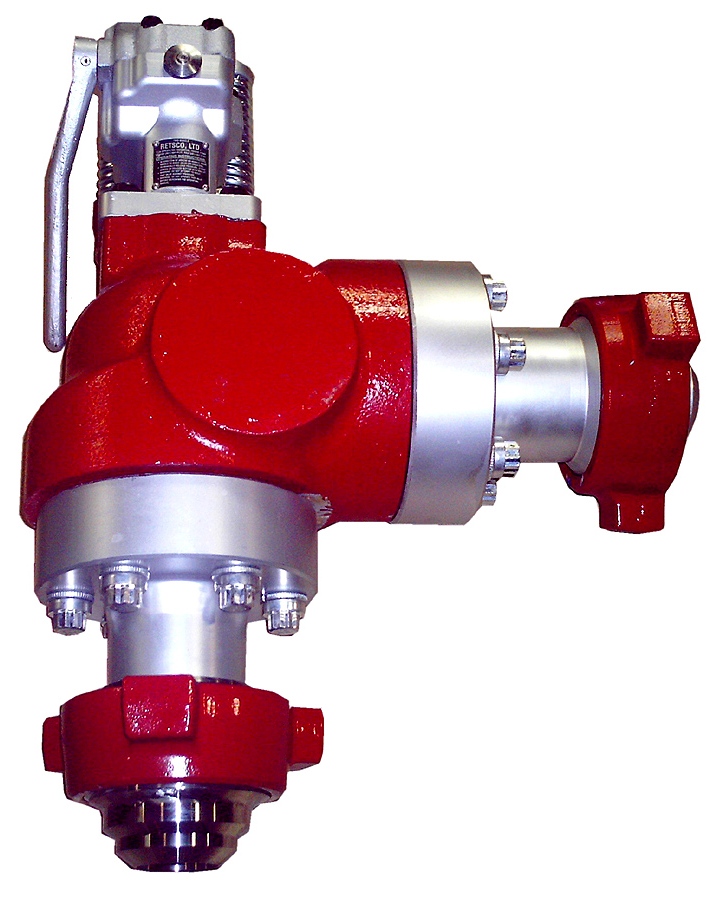

Outside the pump, but still an important part of the system, is the pop-off, or pressure relief valve. When you plug the bit, or your brother-in-law closes the discharge valve on a running pump, something has to give. Without a good, tested pop-off, the part that fails will be hard to fix, expensive and probably hurt somebody. Pop-off valve are easily overlooked. If you pump cement through your rig pump, it should be a standard part of the cleanup procedure. Remove the shear pin and wash through the valve. In the old days, these valves were made to use a common nail as the shear pin, but now nails come in so many grades that they are no longer a reliable tool. Rated shear pins are available for this. In no case should you ever run an Allen wrench! They are hardened steel and will hurt somebody or destroy your pump.

One last thing that helps pump maintenance is a good pulsation dampener. It should be close to the pump discharge, properly sized and drained after every job. Bet you never thought of that one. If your pump discharge goes straight to the standpipe, when you finish the job your standpipe is still full of fluid. Eventually the pulsation dampener will water-log and become useless. This is hard on the gear end of the pump. Open a valve that drains it at the end of every job. It’ll make your pump run smoother and longer.

Spheroidal cast iron crankcase with sight glass and vented dipstick; forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; solid ceramic plungers; nitrile seals with fabric reinforcing; stainless steel valves with plastic retainer and nickel-plated Spheroidal cast iron manifold.

Spheroidal cast iron crankcase with sight glass and vented dipstick; forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; solid ceramic plungers; nitrile seals with fabric reinforcing; stainless steel valves and nickel-plated Spheroidal cast iron manifold.

30 pressure relief valve for mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 36%, pumps accounts for 23%.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

Safety is of the utmost importance when dealing with pressure relief valves. The valve is designed to limit system pressure, and it is critical that they remain in working order to prevent an explosion. Explosions have caused far too much damage in companies over the years, and though pressurized tanks and vessels are equipped with pressure relief vales to enhance safety, they can fail and result in disaster.

That’s also why knowing the correct way to test the valves is important. Ongoing maintenance and periodic testing of pressurized tanks and vessels and their pressure relief valves keeps them in working order and keep employees and their work environments safe. Pressure relief valves must be in good condition in order to automatically lower tank and vessel pressure; working valves open slowly when the pressure gets high enough to exceed the pressure threshold and then closes slowly until the unit reaches the low, safe threshold. To ensure the pressure relief valve is in good working condition, employees must follow best practices for testing them including:

If you consider testing pressure relief valves a maintenance task, you’ll be more likely to carry out regular testing and ensure the safety of your organization and the longevity of your

It’s important to note, however, that the American Society of Mechanical Engineers (ASME) and National Board Inspection Code (NBIC), as well as state and local jurisdictions, may set requirements for testing frequency. Companies are responsible for checking with these organizations to become familiar with the testing requirements. Consider the following NBIC recommendations on the frequency for testing relief valves:

When testing the pressure relief valve, raise and lower the test lever several times. The lever will come away from the brass stem and allow hot water to come out of the end of the drainpipe. The water should flow through the pipe, and then you should turn down the pressure to stop the leak, replace the lever, and then increase the pressure.

One of the most common problems you can address with regular testing is the buildup of mineral salt, rust, and corrosion. When buildup occurs, the valve will become non-operational; the result can be an explosion. Regular testing helps you discover these issues sooner so you can combat them and keep your boiler and valve functioning properly. If no water flows through the pipe, or if there is a trickle instead of a rush of water, look for debris that is preventing the valve from seating properly. You may be able to operate the test lever a few times to correct the issue. You will need to replace the valve if this test fails.

When testing relief valves, keep in mind that they have two basic functions. First, they will pop off when the pressure exceeds its safety threshold. The valve will pop off and open to exhaust the excess pressure until the tank’s pressure decreases to reach the set minimum pressure. After this blowdown process occurs, the valve should reset and automatically close. One important testing safety measure is to use a pressure indicator with a full-scale range higher than the pop-off pressure.

Thus, you need to be aware of the pop-off pressure point of whatever tank or vessel you test. You always should remain within the pressure limits of the test stand and ensure the test stand is assembled properly and proof pressure tested. Then, take steps to ensure the escaping pressure from the valve is directed away from the operator and that everyone involved in the test uses safety shields and wears safety eye protection.

After discharge – Because pressure relief valves are designed to open automatically to relieve pressure in your system and then close, they may be able to open and close multiple times during normal operation and testing. However, when a valve opens, debris may get into the valve seat and prevent the valve from closing properly. After discharge, check the valve for leakage. If the leakage exceeds the original settings, you need to repair the valve.

According to local jurisdictional requirements – Regulations are in place for various locations and industries that stipulate how long valves may operate before needing to be repair or replaced. State inspectors may require valves to be disassembled, inspected, repaired, and tested every five years, for instance. If you have smaller valves and applications, you can test the valve by lifting the test lever. However, you should do this approximately once a year. It’s important to note that ASME UG136A Section 3 requires valves to have a minimum of 75% operating pressure versus the set pressure of the valve for hand lifting to be performed for these types of tests.

Depending on their service and application– The service and application of a valve affect its lifespan. Valves used for clean service like steam typically last at least 20 years if they are not operated too close to the set point and are part of a preventive maintenance program. Conversely, valves used for services such as acid service, those that are operated too close to the set point, and those exposed to dirt or debris need to be replaced more often.

Pressure relief valves serve a critical role in protecting organizations and employees from explosions. Knowing how and when to test and repair or replace them is essential.

RM2CD8621–Crude oil stack valve, blowout preventer, gas flare, flare stack, pressure relief valve, stack valve, crude oil, valve, crude oil tank valve, valves

RMCYXCDA–A very well detailed model triple expansion vertical reversing condensing marine engine,Built by H.Wall 1970 ¦S.D.S.M.E with brass bound,blued steel clad cylinders 1.5in,1.75in and 2.25in bores x 1.75in stroke,cylinder head lubricators and pressure relief valves,piston HP and slide IP and LP valves with hand wheel operated Stephenson"s link reverse,main stop and sampling valves,oil boxes and fine pipe work,crankshaft with six main bearings and marine type big ends,barring gear and disc flywheel.Further details include rear frame incorporated surface ,Additional-Rights-Clearences-Not Available

RM2CNPY75–. Railway and locomotive engineering : a practical journal of railway motive power and rolling stock . ible) block intercepting valve incompound position by slipping piece ofgas pipe over stem of intercepting valve March, 1904. RAILWAY AND LOCOMOTIVE ENGINEERING and fasten with a nut; leave separateexhaust valve shut. If the valve onhigh pressure side is broken steam willpass to high pressure cylinder thenthrough the receiver to low pressureside. As the pressure relief valves onlow pressure cylinder will only allowabout 45 per cent, boiler pressure tostay in cylinder, regulate opening ofthrott

RMCYXCDJ–A very well detailed model triple expansion vertical reversing condensing marine engine,Built by H.Wall 1970 ¦S.D.S.M.E with brass bound,blued steel clad cylinders 1.5in,1.75in and 2.25in bores x 1.75in stroke,cylinder head lubricators and pressure relief valves,piston HP and slide IP and LP valves with hand wheel operated Stephenson"s link reverse,main stop and sampling valves,oil boxes and fine pipe work,crankshaft with six main bearings and marine type big ends,barring gear and disc flywheel.Further details include rear frame incorporated surface ,Additional-Rights-Clearences-Not Available

RM2AM3J7B–The Locomotive . the safety valves soon began to blow. Thesevalves were said to have been set to relieve the pressure at no lbs.In spite of the relief afiforded by the safety valves, the pressure on theboilers continued to rise, 140 lbs. having been noted shortly beforethe explosion by one of the survivors. A few moments after thisobservation both boilers exploded. The foregoing evidence, togetherwith the violence of the explosion, would seem to indicate over-pressure,resulting from insufficient safety valve capacity, as the cause of theaccident. As all of the mill employees were at work at th

RM2AKNG6F–National boilers, radiators, and specialties: catalog no26 . The Honeywell Vapor Relief is designed andconstructed to be placed on atmospheric vaporheating boilers. This extremely simple and inexpensive devicecontains no valves or mechanical parts of anykind —just three open tubes through whichvapor and water circulate when the relief isoperating. It is made entirely of cast iron intwo parts and will last indefinitely, With the Honeywell Vapor Relief properlyinstalled it is unnecessary to place check valvesin the return mains near the boiler to preventwater from backing out under pressure, ast

RM2AN1YHE–Handbook for heating and ventilating engineers . purpose oftaking up the expansion. It will be noticed that the two-pipe steam systems have sealed returns where they enterthe main return above the water line of the boiler. In some steam systems where atmospheric pressure ismaintained, special valves with graduated control admit steamto the upper part of the radiator. The returns enter into areceiver near the boiler with a vapor and air relief to theatmosphere through some form of condenser, having an out-let pipe leading to an air shaft or to a chimney. The pres-sure upon this return is mainta

RM2AG7YTN–. Mechanical appliances, mechanical movements and novelties of construction; a complete work and a continuation, as a second volume, of the author"s book entitled "Mechanical movements, powers and devices" ... including an explanatory chapter on the leading conceptions of perpetual motion existing during the past three centuries. 160. FRICTION RELIEF IN DVALVES. This novel method of relievingthe friction of slide valves consists in cuttingdiagonal grooves in the outer bearings of theport face of the steam chest, as shown at a, a.This relieves the pressure of the valve andfacilitates lubricatio

RM2AM5NGP–Steam turbines; a practical and theoretical treatise for engineers and students, including a discussion of the gas turbine . g bar running in the bearing housing so as toinsure a concentric bore. Manholes are provided at each endof the cylinder to permit access for interior examination, andauxiliary relief valves are fitted in each of the manhole covers toprevent the pressure in the exhaust passages from rising to adangerous point in case of failure of the condensing apparatusor the sticking of the atmospheric relief valve in the exhaustpiping as otherwise dangerous pressure would result in th

RM2AWEKAF–Handbook for architects and builders . G.M.DAVIS REGULATOR CO. 422 MILWAUKEE AVE., CHICAGO Manufacturers of Steam Heatipg and Power Plant Specialties Pressure Regulators Balanced Valve Back Pressure Valve Float Valve Exhaust J^elief Valves Damper RegulatorSteam Trap Pump Governor Stop and Check Valves Water Relief ValveRadiator JUr Valves Receiver and Pump Governor Vacuum Pump GovernorESTABLISHED 1875 CATALOG ON APPLICATION DAVIS PRESSURE REGULATOR Specifications should read G. M. Davis Valves. OUR WORK IS OUR SUCCESS. The Chas. D. Ranney Co. STEAM AND HOT WATERHEATING Phone Edgevvater 2731513

RM2AFXRHE–. Hot water supply and kitchen boiler connections : a text book on the installation of hot water service in residences and other buildings and methods of connecting range boilers, steam and gas water heaters. Pig. 5 34. Two Types of Relief Valves. and lack of pressure in the supply. From the top of the boilerto the level of the water in the tank, as shown in the illustra-tion, would hardly be over 6 feet. Using the thumb rule ofwater pressure of % pound to each foot in height, a pressureof only 3 pounds would be exerted at the top of the boiler bythe supply. The large water heating surface exp

RM2AKNM49–National boilers, radiators, and specialties: catalog no26 . Nov us Pop Safety ValveLow Pressure List Price, Pop Safety Valves Nov us Water Relief Valve Size, Inches ] 1M 1M 2 m 3 3V2 4 Price, each $6.00 $6.75 $8.2£ $11 75 $26.0C $37.5C $50.0C >$80.00 List Price, Water Relief Valves Size, Inches.. , 1 m m 2 2V2 3 3H 4 Price, each.... $12 00 $15.00 $18.00 $27.00 $43.00 $72.00 $95.00 $120.00 Brass Water Gauges Self-Cleaning 4

RM2AKNKXM–National boilers, radiators, and specialties: catalog no26 . Nov us Pop Safety ValveLow Pressure List Price, Pop Safety Valves Nov us Water Relief Valve Size, Inches ] 1M 1M 2 m 3 3V2 4 Price, each $6.00 $6.75 $8.2£ $11 75 $26.0C $37.5C $50.0C >$80.00 List Price, Water Relief Valves Size, Inches.. , 1 m m 2 2V2 3 3H 4 Price, each.... $12 00 $15.00 $18.00 $27.00 $43.00 $72.00 $95.00 $120.00 Brass Water Gauges Self-Cleaning 4. Size, Y2 Gauge Glass, % x 12List Price 12.60 Size, Y2 Gauge Glass, % x 12List Price $3.00 71 NATIONAL HEATING SPECIALTIES Bronze and Bronzing Liquid

RM2AM46J5–The Locomotive . S. Sre/fM Bo/LEK^ II <& Fig. I. The heater was not equipped with the regulation water relief valvenor had it a pressure gauge, thermometer or temperature regulator.However, there was a relief valve fitted on the inlet pipe leading to thepipe coil in the firebox of the steam boiler. The relief valve was stampedto release at 125 lbs. pressure, while the normal city water pressure was85 lbs. It will be observed that stop valves are fitted in all pipe connec-tions between the boiler and the relief valve. The hot water supply heater was installed during the fall of 1925and, as p

RM2CGWWR6–. American engineer and railroad journal . Section Through Cylinders and Steam Chests.. LLJ LU UJ Combination By-Pass and Relief Valves for High Pressure Cylinders.Four-Cvlinder Tandem Compound Locomotive—Northern Pacific Railwav. September, 1901. AMERICAN ENGINEER AND RAILROAD JOURNAL. 277 J :; • -L—4=— i - I. t> -7 n Sectionot OilCv/>. -v, U^VJ i. H7P • -

RM2CEMJF9–. The story of the exposition; being the official history of the international celebration held at San Francisco in 1915 to commemorate the discovery of the Pacific Ocean and the construction of the Panama Canal. THE 20,000-HOESE-POWEE TURBINE. STORAGE-BATTERY TRUCKS WATER AND ELECTRICITY i79 The important thing about this wheel was that it was equipped with anoil-pressure governor and the latest pattern of water-economizing needlenozzle and relief valves; for two of the serious problems of the hydro-electricengineer were regulation of speed under fluctuating loads, and water econ-omy under th

RM2CH0PKW–. The science of railways . any kind, steam orwater. The spring in the water relief valves onthese engines is made to carry a pressure enoughgreater than the boiler pressure to prevent theirdischarging steam and water ordinarily in start-ing the engine simple. In all other respects the locomotive is the sameas the ordinary single expansion locomotive. Operation of the Baldichi Four-Cylinder Com-pound.—When starting the locomotive, the engi-neer should, ordinarily, pull the cylinder cocklever way back and thus open the cylinder cocksin order to relieve the cylinders of condensation,and, as the

RM2CH10EY–. American engineer and railroad journal . r. The extraction of air and water from each radiatorand coil is controlled by special Webster thermostatic waterand air relief valves, attached to the return end of the unitin place of the ordinary air valves. By the use of the Webster system, exhaust steam is usedto the fullest extent, and when not sufficient is supplementedbj live steam from the boilers under a reduced pressure. Thecirculation is accomplished under a pressure below that of theatmosphere, all air and water being extracted, the formerescaping to the atmosphere and the latter entering

RM2CH5B8D–. Railway age . g so as to Insure a truly con-centric bore. Manholes are provided at eaxh end of the cylinderfor Interior examination, and relief valves are fitted In each of themanhole covers to prevent the pressure In the exhaust passagesrising to a dangerous point in case of failure of the condensingapparatus and sticking of the atmospheric relief valve. A Y-connectlon fitted with two corrugated copper expansionjoints below the base of the turbine connects the separate exhauststo the main exhaust nozzle. An atmospheric exhaust nozzle opensout ot the side of the exhaust Y to permit non-conde

RM2CEJFX9–. A manual of marine engineering: comprising the design, construction, and working of marine machinery. Fig. 94.—Martin and Andrews Valve Relief.. Fig. 94a.—Transverse Section of Martin and Andrews Valve. There are many other plans for preventing slide-valves from pressingunduly on the cylinder face, some by means of springs, and some by pistonsacting perpendicularly to the direction of motion of the valves, but none ofthem are free from objection, nor have any given greater satisfaction thanChurchs (fig. 95) very ingenious arrangement. Through Exhaust Valve.—Fig. 96 shows a low-pressure doubl

RM2CR47TN–. American engineer and railroad journal . ssation of the injection water supply, the exhauststeam from the engine accumulates in the condenser and ex-haust pipe, increasing the pressure and shortly stopping theengine. Also the hot steam passing into the air pump de-stroys the rubber valves and removes the load from the airpump, causing it to race and do serious damage. To preventthis and give the accumulated steam free admission to the at-mosphere, the Knowles automatic exhaust relief valve wasdesigned. The valve proper is practically a cheek valve com-posed of a material unaffected by steam

RM2CEHD31–. Mechanical appliances, mechanical movements and novelties of construction; a complete work and a continuation, as a second volume, of the author"s book entitled "Mechanical movements, powers and devices" ... including an explanatory chapter on the leading conceptions of perpetual motion existing during the past three centuries. 160. FRICTION RELIEF IN DVALVES. This novel method of relievingthe friction of slide valves consists in cuttingdiagonal grooves in the outer bearings of theport face of the steam chest, as shown at a, a.This relieves the pressure of the valve andfacilitates lubricatio

RM2CH6GJR–. Railway mechanical engineer . inders arefitted with the Robinson pressure release valve, the two valvesat each end of the cylinder being combined in a single casting; thai is to say, there are two such castings, each containing two valves which communicate by means of a perforated connecting pipe. These pressure release valves combine thefunctions Of air valves, water relief valves and compression release valves when running without steam. The valve spindle packing, which is exposed to the super-heated steam, is composed of a special bronze instead of theusual lead and antimony white metal.

RM2CRDXTF–. American engineer and railroad journal . s much ingenuity, sincethe whole cage and valve were arranged to lift inside the chest,to give relief in the same manner as the slide valve. It was notuntil several years later that the Brooks Works commencedbuilding bona-fide piston valve engines, which became increas-ingly popular. Those concerns interested in cross-compounds soon adaptedthe piston valve for the high-pressure cylinder, because of the difficulty experienced in balancing the large slide valve neces-sary against the high pressure used. These valves were of theoutside admission type, be

RM2CEHD9J–. Mechanical appliances, mechanical movements and novelties of construction; a complete work and a continuation, as a second volume, of the author"s book entitled "Mechanical movements, powers and devices" ... including an explanatory chapter on the leading conceptions of perpetual motion existing during the past three centuries. 160. FRICTION RELIEF IN DVALVES. This novel method of relievingthe friction of slide valves consists in cuttingdiagonal grooves in the outer bearings of theport face of the steam chest, as shown at a, a.This relieves the pressure of the valve andfacilitates lubricatio

RM2CH39FT–. Locomotive engineering : a practical journal of railway motive power and rolling stock . s. The standard throughout the world. Crosby Pop Safety Valves For all kinds of boilers. Crosby Water Relief Valves For pumps, hydrants, hose, etc. Crosby Improved Steam Gages, And all other pressure and vacuum gages. Crosby Single Bell Chime Whistles For railroads, mills, factories, marine buoys, etc. Crosby Spring-Seat Valves, Globe and angle, for high pressures. Warranted. Crosby Patent Gage Testers. Accurate and altogether reliable. Revolution Counters, Pressure Recorders,Blow-Off Valves. The Crosby

RM2CGWWYX–. The street railway review . owing the companys 2S-kv.set. This set consists of a Sliirtcvant g.xS-in. single, vertical, en-closed automatic engine, direct connected to a Sturtevant 9-100M. P. 8 compound wound generator; the engine operates at 350r. p. m. with go lb. steam pressure at the throttle. The vertical single engines are designed for continuous operation,it high speed. Relief valves of large diameter, adjustable to openautomatically at any desired pressure, are provided at each end ofthe cylinder. The piston is cored out and provided with internalribbing. The guides are cast in one

RM2CGWT62–. Science of railways . Sectional View of a Syracuse Packless High Pressure Valve. This top disc also screws into the bonnet, forming a lock-nut feature that prevents its getting loose. In case of renewals, this top disc can be replaced withpressure on the valve. 580 LOCOMOTIVE APPLIANCES. STEAM CHEST VACUUM VALVES. The purpose of these valves is to permit air toenter the steam chest and thence the locomotivecyhnder when the engine is drifting or running withsteam shut off. These valves are often termed relief valves, butshould more properly be known as vacuum relief. Fig. 4.Steam Chest Vacuum

RM2CGXYHP–. Railway and locomotive engineering : a practical journal of railway motive power and rolling stock . /i ins. at thethreaded ends. The piston valves havecast-iron bodies and L-shaped pack-ing rings, and the drifting valves are ofPennsylvania Railroad style with flatplati over the relief ports. Vacuum re-hef valves are placed in the live 5ti ampassages and a safety valve, set for 225pounds pressure is screwed into each cyl-inder head. The cylinder heads arc ofcast steel, and the steam-chest heads ofcast iron. I he frames, where they are secured to teel. Each link 1i by two longitudinal castbea

RM2CR6TEE–. American engineer and railroad journal . Intercepting Valve for Compound Locomotives.—Great Southern & Western Railway, Ireland, of the high-pressure cylinder; at the same time it closes the com-munication from the high pressure exhaust to the low-pressuresteam chest, and opens a connection for live steam from the steampipe to the low-pressure steam chest. This supply of live steam iswiredrawn so as not to exceed about 75 pounds pressure on the low-pressure side, and low-pressure cylinder and steam chest are, asusual, provided with relief valves, set to blow at 75 pounds in casethe pressure

RM2CGXKWP–. Locomotive text for engineers and firemen; a complete treatise on the engine, electric head-light and standard code of train rules . PLATE 77. Cracked or Broken Steam-Chest. A cracked orbroken steam-chest is usually caused by reversing theengine when running at a high rate of speed, with thethrottle closed. This causes the cylinders to becomeair compressors. High pressure is forced into thesteam-chest, and, having no means of escape, accumu-lates at a higher pressure than the steam-chest is de-signed to withstand. Modern locomotives are pro-vided with steam-chest relief valves for the purpos

RM2CGWR42–. Electric railway journal . exhaust lines are connected. Anatmospheric relief valve is in each linenear the receiver. This is a stand-ard relief valve weighted to open on about 28 lb. persquare inch absolute pressure by means of a hydraulicpiston and standpipe accumulator. The three lines leadinto a tapered header, from which two 30-in. risers,sealed with back pressure valves, extend above theroof. From the header a 42-in. pipe leads to the feed-water heater. This is also protected with a riser andvalve. Between the receiver and the feed-water heater isa thermal or heat-balance valve for equa

RM2CGWW8B–. Locomotive engineering : a practical journal of railway motive power and rolling stock . ater Relief Valves For pumps, hydrants, hose, etc. Crosby Improved Steam Gages, And all other pressure and vacuum gages. Crosby Single Bell Chime Whistles For railroads, mills, factories, marine buoys, etc. Crosby Spring-Seat Valves, Globe and angle, for high pressures. Warranted. Crosby Patent Gage Testers. Accurate and altogether reliable. Revolution Counters, Pressure Recorders,Blow-Off Valves. The Crosby Locomotive Pop Safety Valve. Our claims for merit in a Locomotive Poj> Safety Valve are as fol

RM2CGXM5W–. Railway track and track work . BE* m NO TANKS required with PATENT COUNTER-BALANCED Valve and Water Column Connected direct to High Pressure Mains flFrilKP {t is the only SINGLE CHAMBER VALVEDLUfiU JL that will close with absolutely NO SHOCK. Requires no relief-valve. We also make Gulland 13« Valves HESTON BLOW-OFF VALVES BEST GATE VALVES for all Purposes Best Manufacturing Co. Correspondence Solicited Pittsburg, Pa. WWOOOOOOOOOOOOCKKKX Why Not Use a Gasoline Engine In Your Repair Shops and Save Money ?. We would like to correspond with you in regard to your pumping plants. We make a speci

RM2CF5WM1–. Boston register and business directory. THE ASHTON VALVE CO, i Manufacturers of the Highest Grade I Pop Safety Valves I CO— Water Relief Valves 9 Casting* Pressure and Recording9 Gages „ on ^ , -^teeZ Coil Springs No. 20 Valve ^ * etatiocery Boiler, THE ASHTON VALVE CO. 161 FIRST STREET .. .. CAMBRIDGE C, BOSTON, MASS.. Steam Specialties—Stenographers—Storage—Store Fixtures BOSTON BUSINESS DIRECTORY G. P. ANDERSON & CO. Dealers in Steam Specialties, Engineers and Mill SuppliesVacuum and Vapor Specialties Steam Traps, Return Traps, Damper Regulators, Steam Pressure RegulatorsFeed Water Heater

RM2CGWWKA–. American engineer and railroad journal . LLJ LU UJ Combination By-Pass and Relief Valves for High Pressure Cylinders.Four-Cvlinder Tandem Compound Locomotive—Northern Pacific Railwav. September, 1901. AMERICAN ENGINEER AND RAILROAD JOURNAL. 277 J :; • -L—4=— i - I. t> -7 n Sectionot OilCv/>. -v, U^VJ i. H7P • -. Upper and Lower Guides. boilers have two firedoors and sloping back heads. They aresupported from the mud ring, as indicated in the elevationdrawing. From having followed this development in the drawing roomand the shops it is evident that the greatest care has beenexercised in

RM2CRB3RK–. The street railway review . line. ENGINES. Ihere are three vertical cross-compound condens-ing engines of the .llis-Chalmers Cos. latest type,with high pressure cylinder 28 in. in diameter, lowpressure cylinder 60 in. in diameter, and a commonstroke of 48 in. These engines run at 94 r. p. m.with 160 lb. steam pressure and are each directly con-nected to a i,ooo-kw. General Electric alternatingcurrent generator. Water relief valves are placed ineach cylinder and the steam e.xhaust valves of bothcylinders are operated by separate eccentrics pro-viding for automatic cut-off of from zero to J^

RM2CJ60JD–. Railway and Locomotive Engineering . necan not start the train in this way, open A. Willi cither engine, if tlie speedi.- below three or four miles per hour,proceed the same as when starting aheavy train. Q. In what position would you carrythe reverse lever when drifting? A. At about three-quarters stroke orrrore. Q. What attention should be giventhe power reversing gear? -A. Keep the oil cylinder full of oil,and the piston rod packing on the oil andair cylinders tight. Always sec that thelatches of both reverse levers mesh in the relief valves on low pressure steam chestsand cylinders? A. T

RM2CR782K–. The street railway review . p 300h. p. at 200 r. p. m. The high pressure cylinder is 11 in. in diam-eter, the low pressure 22 in. and the stroke is 2 it. A fly-wheel gov-ernor gives very close speed regulation. To the exhaust pipe arefitted two Blake-Knowles automatic relief valves. The exhauststeam passes into a Worthington condenser, which has water cir-culating around it and is then conducted to the cooling tower. The 168 ^llM%ilvviai%vlcw tower is 12 ft. in diameter and 31 ft. high and filled with vitrifiedfireclay pipes. An air draught is produced by a -ft. fan driven bya lo-h. p. Brot

RM2CGPBT2–. The Street railway journal . Crosby Steam Engine Indicator IS FAMOUS THE WORLD OVER FOR ITSACCURACY. Perfect in Design. Faultless in Workmanship, Branden Pump Valve. Kubber with Wire Coil Insertion.THIS IS THE VALVE YOU WANT. Will outlast several ordinary rubber valves. Sole manufacturers also ofCrosby Pop Safety Valves, Water Relief Valves, WaterGages, Lubricators, Pressure and Vacuum Cages,Feed Water Regulators, Etc., Etc. CROSBY STEAM GAGE & VALVE CO. STOR ES* i93-97 Oliver St., 78 John St., 21-23 W. Lako St., OFFICE and WORKS:BOSTON. NEW YORK. CHICAGO. BOSTON, MASS LONDON, ENGLAND.. ❖ **

RM2CE3KKH–. Hardware merchandising (January-March 1908) . VALVES Air valves Back pressure valves Check Direct weight safety Engine valves in endless variety. We make a valve adapted for almost every service for which a valve is used.Air, Water, etc. Steam, Vacuum, Foot valves Globe and gate valves Hydraulic Index J.M.T. Key valves Lock shield valves Marine valves Needle Oil Peet valves Quick opening valves Relief Sliding Stem Throttle The James Morrison Brass Mfg. Co., Limited Union Jradiator valvesVacuum Water pressure Xtra heavyY gate 93-97 Adelaide St. W.TORONTO 30 HARDWARE AND METAL FENCE WIRE! It m

RMRGAN8E–. Bulletin of the U.S. Department of Agriculture. Agriculture; Agriculture. ^K.COPRER THIMBLE SET IN PIPE Fig. -Expansion joints for high pressure. number have been replaced by relief stands. Some air drums are equipped with an automatic air pump that keeps the chamber filled with the proper proportion of air, but as any such apparatus is liable to get out of order, the air drum may be worthless when needed the most. There are some instances on record where air pumps have de- livered an excess of air which has caused large bubbles of air to col- lect in the main. Relief valves have also been u

RMRHTHHY–. Better fruit. Fruit-culture. Page 24 BETTER FRUIT March. "CROWN" THE NAME THAT STANDS FOR SAFE, SIMPLE, EFFICIENT PRESSURE REGULATION "Crown" Relief Valves and "Crown" Pressure Regulators THE CROWN PRESSURE REGULATOR (shown in cut) designed by the late J. D. Wallace, and ToTuCTioN originally called the "Wallace Pressure Regulator" was practically the "pressure regulator" designed for spraying machines. As indicated, it is placed in the suction line. Pressure acts against the bottom of the plunger which moves upward against reaction of spring,

RMRHTK30–. Better fruit. Fruit-culture. The Alpha Pressure Governor auto- matically controls the pump pressure. It keeps it steady and uniform under all working conditions. No part of the mechanism is exposed to the clogging or corrosive action of the solution. No relief valves or diaphrams are required. No liquid is pumped except it is forced through the nozzles. All unnecessary wear and tear on both engine and pump is eliminated; safety is insured and a saving on fuel is made. The Alpha Engine—The dependability and satisfaction of Alpha Sprayers is further insured by the use of a really high-class, s

RMRHTJWW–. Better fruit. Fruit-culture. IQl6 BETTER FRUIT Page ig. "CROWN" The Name that Stands for Safe, Simple, Efficient Pressure Regulation "Crown" Relief Valves and "Crown" Pressure Regulatiors This cut shows the CROWN RELIEF VALVE, the result of years of study and intimate connection with the whole spraying machine problem. Eliminates the trouble features of the ordinary relief valve. Cannot clog and be held open, allowing the pressure to run down. No ground valve seats to be cut out, necessitating re-gringing. Only an inexpensive rubber cup or gasket to replace. An

RMRHTJPR–. Better fruit. Fruit-culture. The New Myers Automatic Pressure Governor Pump not only eliminates the Relief Valve but prolongs the life of the Pump. Plungers and Valves not in action unless spray is going through nozzles. The Myers Power Sprayer with the Stover Engine for Power is pos- itively the best Spraying Rig possible % / to build. Light Draft and Cutaway Harrows Myers Spray Pumps Mail us the Coupon so we can send you FREE BOOKLET.. PORTLAND or SPOKANE Here is my name for your FREE Sprayer Booklet Name P.O had many years" experience as a fruit broker and fruit dealer, and also in conn

RMRHTPW4–. Better fruit. Fruit-culture. ip 18 BETTER FRUIT Page 15 THE MYERS AUTOMATIC POWER SPRAY OUTFIT With Automatic Pressure Governor VERTICAL CYLINDERS —NO RELIEF VALVES —MACHINE CUT GEARS Automatic Control. Insures Safety. Secures Uniform Pressure and Eliminates Unnecessary Wear. Plunger Guide above Plunger Eliminates all Side Thrust and Reduces Wear. Belt Driven. Brass Fitted Throughout. Forged Steel Crankshaft. All Boxes Babbitted. Improved Oiling System. The Myers Power Spray Pump With patent Automatic Pressure Governor, has all the desirable features found in any Spray Pump, viz., vertical c

RMRHTP29–. Better fruit. Fruit-culture. ipi8 BETTER FRUIT Page 15 THE MYERS AUTOMATIC POWER SPRAY OUTFIT With Automatic Pressure Governor VERTICAL CYLINDERS —NO RELIEF VALVES — MACHINE CUT GEARS Automatic Control. Insures Safety. Secures Uniform Pressure and Eliminates Unnecessary Wear. Plunger Guide above Plunger Eliminates all Side Thrust and Reduces Wear. Belt Driven. Brass Fitted Throughout. Forged Steel Crankshaft. All Boxes Babbitted. Improved Oiling System. The Myers Power Spray Pump With patent Automatic Pressure Governor, has all the desirable features found in any Spray Pump, viz., vertical c

RMRHTKYF–. Better fruit. Fruit-culture. ic)i6 BETTER FRUIT Page 21 GOOD BYE-RELIEF VALVE! 100,150, 200-Gal. Tanks 114, 2 and 2J4-H.P. Engines ^. The New Myers Automatic Pressure Governor Pump not only eliminates the Relief Valve but prolongs the life of the Pump. Plungers and Valves not in"action unless spray is going through nozzles.. The Myers Power Sprayer with the Stover Engine for Power is pos itively the best Spraying Rig possible to build. L Mail us the Coupon so we can send you FREE BOOKLET. Light Draft and Cutaway Harrows Myers Spray Pumps. Please note that these images are extracted from scan

RMRHTJR3–. Better fruit. Fruit-culture. igi6 BETTER FRUIT PagL GOOD BYE-RELIEF VALVE! 100,150, 200-Gal. Tanks 114, 2 and 21/2-H.P. Engines. The New Myers Automatic Pressure Governor Pump not only eliminates the Relief Valve but prolongs the life of the Pump. Plungers and Valves not in action unless spray is going through nozzles. The Myers Power Sprayer with the Stover Engine for Power is pos- itively the best Spraying Rig possible % / to build. Light Draft and Cutaway Harrows Myers Spray Pumps Mail us the Coupon so we can send you FREE BOOKLET.. Please note that these images are extracted from scann

The disclosure relates generally to devices and methods for preventing a primary mud relief valve from incorrect opening. More particularly, the disclosure relates to devices and methods for preventing a primary relief valve in a mud system from incorrect opening.

Mud systems, as known from drilling rigs, normally include a mud pump, a pulsation dampener and a relief valve, the latter herein termed “primary relief valve”. The main pump is typically a triplex pump. This kind of pump delivers a flow rate which is far from constant and fluctuates much because of i) variable piston speed—the pump is crank shaft driven, ii) mud compressibility and iii) valve and fluid inertia. The pulsation dampener is therefore included to smoothen the flow rate and mitigate the resulting pressure fluctuations. The primary relief valve may be of a design known as a “pop-off valve” in the industry, or a rupture disk. Other types of relief valves are also known.

The primary relief valve is a safety valve that is designed to prevent excessive pressure and possible hazards in the case the pump pressure exceeds the certified pressure limit for the system. Normally the so-called trip pressure, at which the primary relief valve shall switch from a closed to an open state, is set slightly higher that the system pressure of typically 5000 psi (345 bar).

It is a well-known problem in the industry that the primary relief valve sometimes trips frequently even though the recorded pressure levels never reached the nominal trip pressure level.

Tripping of a primary relief valve represents a costly and highly undesired disruption of the drilling process, both because of the time it takes to refit a new rupture disk or to reset a resettable primary relief valve and because the well can be damaged during long periods of no circulation. To lower the risk for primary relief valve tripping one can therefore reduce maximum working pressure to say 80 per cent of the system pressure limit. This is also a costly solution because flow rate and pressure is often a limiting factor that can lead to slower drilling and even cause well stability problems. The opposite solution of increasing the nominal trip pressure to compensate for the dynamic effect is also a highly undesirable solution that may lead to damage in other parts of the mud system. It may even be illegal to raise the nominal relief valve pressure to more than a few per cent over the certified system pressure.

According to a first aspect of the invention there is provided a method for preventing a primary relief valve in a mud system from opening at a pressure lower than a nominal opening pressure, and where the mud system includes a mud pump, wherein the method includes: installing a flow restrictor between the mud pump and the primary relief valve; and

A field study of above stated problem has revealed that the reason for the tripping of the primary relief valve at a pressure lower than the nominal opening pressure, most likely is relatively large pressure fluctuations in a pop-off line. Despite of the damping action of a pulsation dampener, there are substantial residual pressure fluctuation present in a discharge pipe between the pump and the dampener. The pop-off line itself represents a hydraulic resonator that can significantly amplify these residual fluctuations at frequencies close to resonance frequencies. This explanation is supported by special pressure measurements just below the primary relief valve showing that the peak dynamic pressure can sometimes exceed 115 per cent of the mean pressure.

These pressure fluctuations can lead to undesired primary relief valve trips, both because the peak pressure are really higher than seen on the standard pressure sensors, and because they can lead to fatigue and lowering of the real trip pressure. This fatigue effect is especially relevant if the primary relief valve is a rupture disk.

It has thus been found that the opening of the primary relief valve is related to pressure variation at higher frequencies, typically in the region of 40 Hz. Pressure fluctuations at this frequency has been measured to be up to 40 bars. Such fluctuations are superimposed on the mean pressure and are believed to cause the tripping of the primary relief valve at a pressure lower than the nominal opening pressure.

The high frequency pressure fluctuation components appear to be generated by the mud pumps and are related to the pump valve action. Both mud compressibility and pump valve inertia tend to cause sudden changes in the pump flow rate when the pump discharge valves open and closes. The changes give rise to a pressure pulse that is enhanced at frequencies close to the resonance frequencies of the closed primary relief valve line.

By installing a flow restriction between the mud pump and the primary relief valve in combination with a cavity positioned between the flow restriction and the primary relief valve, these higher frequency pressure fluctuations are dampened. The pressure acting on the primary relief valve is then the mean operating pressure of the mud system. The relation between the size of the flow restrictor and the cavity volume should be calculated according to known principles, or it should be found experimentally by testing different size/volume ratios.

The method may include placing a second relief valve in parallel with the flow restrictor, preferably with a lower nominal trip pressure than the primary relief valve. This second relief valve will normally only experience the dynamic pressure difference as it receives the mud pump pressure on one side and the smoothed pressure at the cavity on the other side.

According to a second aspect of the invention there is provided device for preventing a primary relief valve in a mud system from opening at a pressure lower than a nominal opening pressure and where the mud system includes a mud pump, wherein a flow restrictor is positioned between the mud pump and the primary relief valve, and where a cavity is provided between the flow restrictor and the primary relief valve.

In a practical embodiment of the invention, the primary relief valve, the flow restriction, the second relief valve and the cavity may be produced as one unit that is fairly compact and suitable for installation in a mud system.

The method and device according to the invention render it possible to overcome the long felt problem of incorrect opening of the primary relief valve of a mud system.

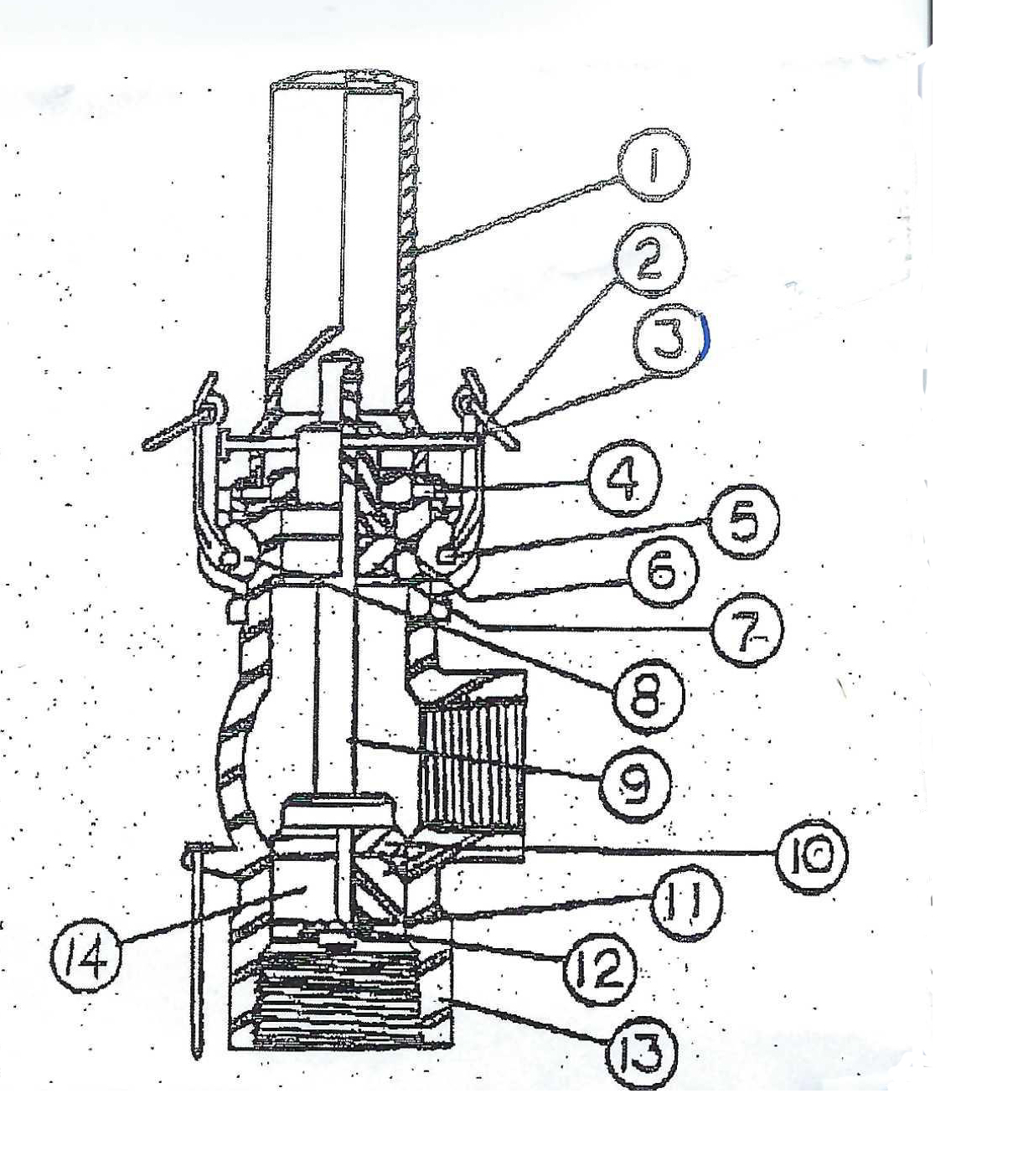

FIG. 2 is a cross-sectional view of an embodiment in accordance with the principles described herein where the flow restriction is placed in the second relief valve; and

On the drawings the reference number 1 denotes a part of a mud system that includes a mud pump 2 that draws mud from a mud reservoir 4 and discharge the mud via a discharge pipe 6 into a so-called stand pipe 8. A pulsation dampener 10 is connected to the discharge pipe 6. A primary relief valve 12 is connected to the discharge pipe 6 via a so-called pop-off line 14. In this exemplary embodiment, the primary relief valve 12 is a pop-off valve. However, in other embodiments, the primary relief valve 12 may be a rupture disk or another suitable valve.

In this embodiment, a flow restriction 16 is provided between the mud pump 2 and the primary relief valve 12, or more precisely between the discharge pipe 6 and the primary relief valve 12.

A second relief valve 18, which may be of a type similar to the primary relief valve 12, is positioned in parallel with the flow restriction 16. A cavity 20 is closed off in the pop-off line 14 between the primary relief valve 12 and the second relief valve 18. The cavity 20 communicates with the discharge pipe 6 through the flow restriction 16.

This done, as the mud pump 2 operates, the high frequency pressure fluctuation components are dampened in the flow restriction 16/cavity 20 dampener system. Thus, the primary relief valve 12 only experiences the average pressure present in the cavity 20.

The second relief valve 18 has the pressure from the mud pump 2 acting on the side facing the discharge pipe 6, while the average pressure is acting on the side of the second relief valve 18 facing the cavity 20. The resultant pressure across the second relief valve 18 equals the dynamic pressure fluctuations in the discharge line 6, normally with zero mean.

If the average pressure exceeds the trip pressure of the primary relief valve 12, the primary relief valve 12 opens. Then, as the flow through the flow restriction 16 is minute compared to that of the primary relief valve 12, the pressure over the second relief valve 18 will equal the full pressure from the mud pump 2. The second relief valve 18 will then also open if the high average pressure is still present. To ensure tripping of the second relief valve 18, its trip pressure may preferably be slightly lower than the trip pressure of the primary relief valve 12.

In an alternative embodiment shown in FIG. 2, the pressure sensing component of the second relief valve 18 is a rupture disk 22. A flow restriction 16 is incorporated in the rupture disk 22, see FIG. 3. Aside from the second relief valve 18 being a rupture disk in this embodiment, rather than a pop-off valve, mud system 1 and its functioning are as previously described.

8613371530291

8613371530291