pop off valve mud pump brands

Over-pressurization is a looming factor that can cause significant damage to drills and machinery, making quality drilling pop-off valves a must. Drillmax, Inc. specializes in pop-off and relief valves, ensuring that your equipment is adequately protected during the course of your application.

In fact, since 1996, Drillmax, Inc. has specialized in a wide range of quality gate, float, relief and drilling mud valves. We have built strong ties working with a wide range of clients, including:

We our proud of the fact that our drilling pop-off valves are used all across the world in the industry, providing superior performance and longevity for the clients we service. As an aftermarket manufacturer of drilling mud valves and other components, we are able to offer superior service at a lower price point than OEM.

We offer drilling valve 2” aftermarket replacement parts, along with a wide range of other essentials that ensure your machinery and equipment runs efficiently and with minimal downtime. We offer:

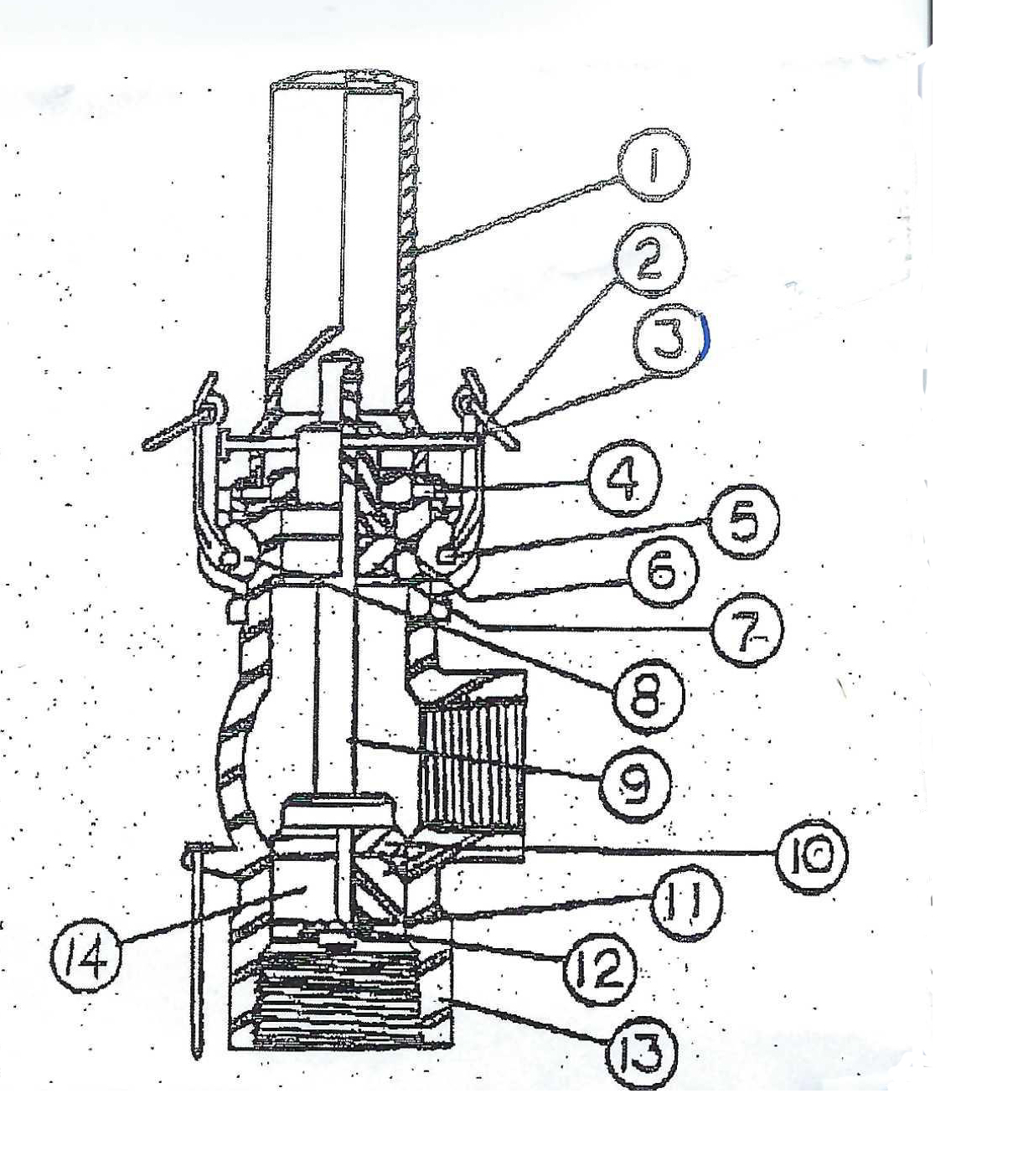

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

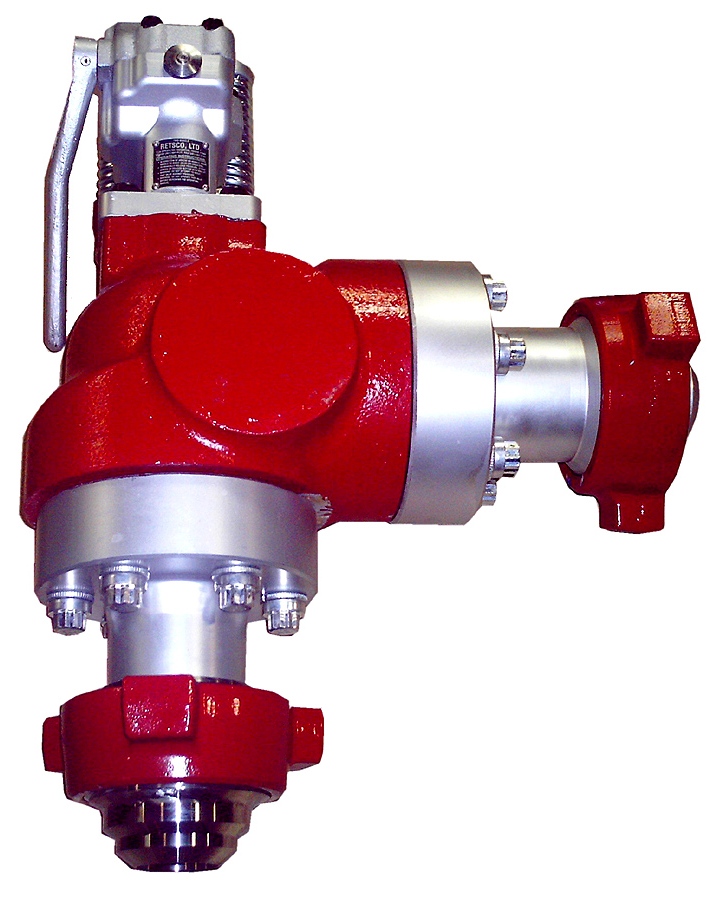

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

The patented X8000 SERIES II™ Reset Relief Valve is designed to protect equipment from high pressure spikes and automatically “pop off” to a full open position when the set pressure is reached.

The X8000 Series II™ Reset Relief Valve is easy to adjust, easy to set triggering pressure, and easy to reset. The bonnet, top-loaded piston, and seals can be removed while the body remains in line.

The X8000 Series II™ minimizes downtime and is easily repaired or rebuilt in the field. Our valves are DNV certified to 10,000 PSI. With computer modeling, high technology engineering, metallurgical and mechanical enhancements, RR Valve, Inc. has solved many of the industry’s frustrations with temperamental and unreliable Reset Relief Valves.

Our technical advances have replaced the commodity valve with a proven advanced engineered flow control device. Our valves are competitively priced and relatively maintenance free, resulting in negligible rebuild costs and downtime. At half the weight of the commodity valves, The X8000 Series II™ is safer to install and service, thus reducing the time and labor cost during maintenance.

The Sur-Lock™ Valve Cover System was designed to eliminate the unsafe practices of using cheater pipes and sledge hammers to tighten and loosen valve covers. In current practice, one rig hand will hold a pipe in the valve cover holes and another will swing a large sledge hammer at the pipe in order to loosen or tighten the assembly.

The new Sur-Lock system eliminates this unsafe practice and radically decreases the time it takes to remove valve covers, and replace valves and seats. The new system requires no special tooling and weighs about the same as a conventional valve cover assembly.

30 pressure relief valve for mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 36%, pumps accounts for 23%.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

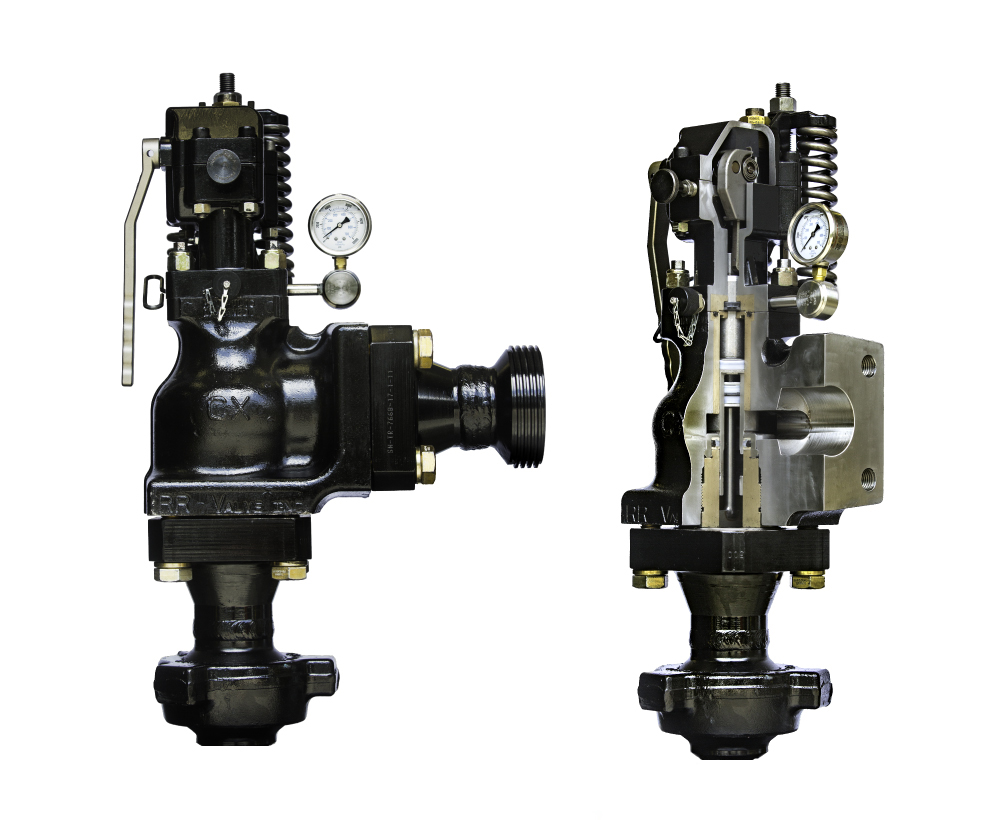

Marathon Valve designs and manufactures high-pressure safety reset relief valves for installation on heavy duty mud pumps to protect the pumps against over-pressurized conditions and damaging pressure surges. As the OEM for the Guardian® valve line, Marathon Valve ensures all specifications and tolerances are met. Our valves are highly effective at holding high pressures and deliver exceptional repeatable performance. To meet the drilling industry’s operating and safety standards, material traceability and specialized material testing is maintained throughout the manufacturing process. A primary drilling industry objective is all equipment utilized on vessels and installations meet rigorous industry operating and safety standards. This focus on equipment safety and integrity is how Marathon Valve’s Guardian® valve line can deliver the proven performance and reliability our customers expect.

The Guardian® reset relief valve series underwent rigorous R&D to produce impressive results and successfully obtained multiple U.S. patents. The primary focus was engineering out all the field problems that were prevalent with other relief valves, also known as pop-off valves in the industry. Our valves have the 3″ industry standard connectors to facilitate swap outs, are simple to operate, and utilize the systems pressure to fully open when a pre-set relief pressure is reached. Marathon Valve’s line of reset relief valves are the only valves on the market today with unique patented technology that is making our valves the new standard in high-pressure relief valves.

We offer a product line of land and offshore pressure control safety valves, to learn more about how our reset relief valves can help your success, contact us today.

A Relief Valve, or Pop-Off Valve, is a secondary pressure regulating device used to back up the primary regulating device. If the primary regulating device fails to by-pass at a set system pressure, the relief valve will open and allow liquid to flow freely. A relief valve can save costly pump and system damage, and more importantly it’s an added safety feature to protect those working around the equipment.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

Poor maintenance — such as improper valve and seat installation — is another factor. Improper cleaning when replacing a valve seat can leave sand or debris in the valve seat area; preventing the new seat from properly forming a seal with the fluid cylinder, causing a pathway for a washout to occur. It is important to pull up on a seat firmly by hand and make sure it doesn’t pop out and is properly seated. The seats must be seated well, before resuming repairs. You should never reuse a valve seat if at all possible.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

A washout occurs when fluid and solids enter the area behind or underneath a valve seat and erode the sealing surface. Washouts are usually caused by one of three issues: a worn or cracked valve seat, improper cleaning of the valve seat and deck which creates a poor seat seal, and excessive sand content in your drilling fluid. Worn or cracked valve seats can allow fluid to enter the area around the valve seat and seat deck, creating a wash point on the valve seat and causing it to cut into the fluid cylinder and seat deck.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

8613371530291

8613371530291