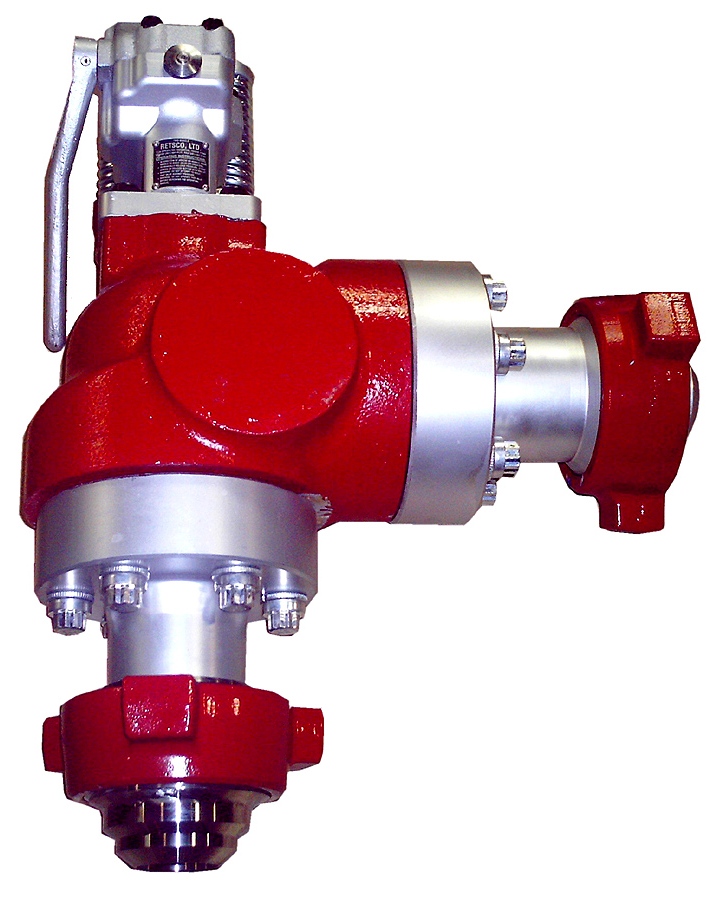

pop off valve mud pump in stock

Over-pressurization is a looming factor that can cause significant damage to drills and machinery, making quality drilling pop-off valves a must. Drillmax, Inc. specializes in pop-off and relief valves, ensuring that your equipment is adequately protected during the course of your application.

In fact, since 1996, Drillmax, Inc. has specialized in a wide range of quality gate, float, relief and drilling mud valves. We have built strong ties working with a wide range of clients, including:

We our proud of the fact that our drilling pop-off valves are used all across the world in the industry, providing superior performance and longevity for the clients we service. As an aftermarket manufacturer of drilling mud valves and other components, we are able to offer superior service at a lower price point than OEM.

We offer drilling valve 2” aftermarket replacement parts, along with a wide range of other essentials that ensure your machinery and equipment runs efficiently and with minimal downtime. We offer:

All rig mud pump systems use pop-off valves to protect the pump from over pressurization. The best that can be achived with a pop or relief valve is approximately +/- 10% repeatability. On a high pressure system, this can be a significant variance. Although the valves are resettable, they generally go at a lover pressure once tripped and reset. Not WOM’s Pump Saver.

Available up to 10.000 psi, and is more accurate that pop/relief valves. WOM’s Pump Saver features +/- 3% above 3.500 psi. New rupture discs can be easily and quickly replaced.

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

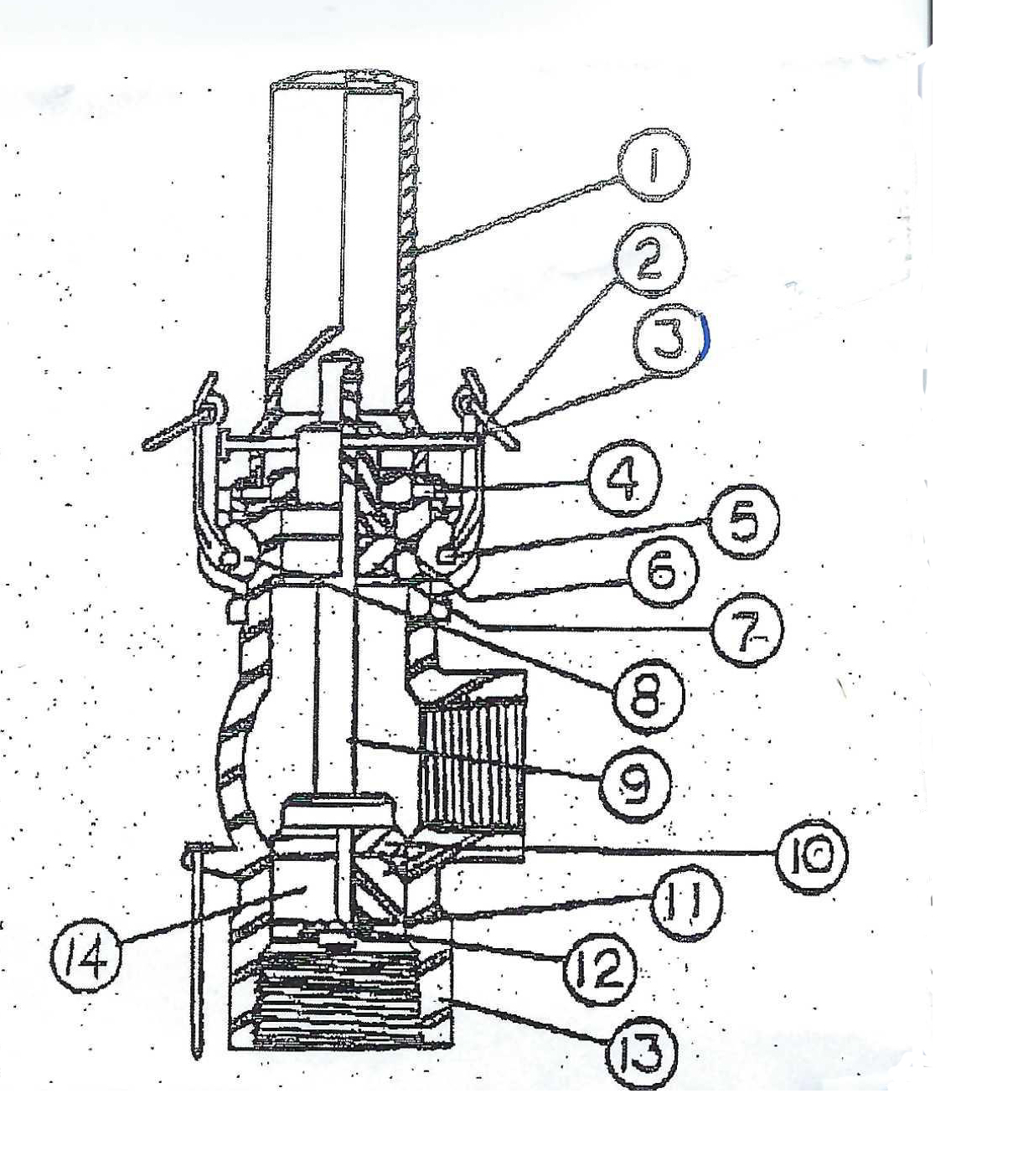

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

Poor maintenance — such as improper valve and seat installation — is another factor. Improper cleaning when replacing a valve seat can leave sand or debris in the valve seat area; preventing the new seat from properly forming a seal with the fluid cylinder, causing a pathway for a washout to occur. It is important to pull up on a seat firmly by hand and make sure it doesn’t pop out and is properly seated. The seats must be seated well, before resuming repairs. You should never reuse a valve seat if at all possible.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

A washout occurs when fluid and solids enter the area behind or underneath a valve seat and erode the sealing surface. Washouts are usually caused by one of three issues: a worn or cracked valve seat, improper cleaning of the valve seat and deck which creates a poor seat seal, and excessive sand content in your drilling fluid. Worn or cracked valve seats can allow fluid to enter the area around the valve seat and seat deck, creating a wash point on the valve seat and causing it to cut into the fluid cylinder and seat deck.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

Mud & Slurry 5 21

2 At an exact set point, the pin buckles and the valve opens in milliseconds for immediate pressure relief.

Relieves pressure to prevent pump, hose and INLET system damage on mud and slurry pumpOUTLET systems - ideal for pulsating pressure.

Other Connections Available Advanced Custom and Standard Valves for Pressure Relief

• Alloy • Valve Size • Type • Set Point

“POCO” Pin Design Variation This intelligent design allows the user to change the set pressure of the valve by simply changing pins. This is done by affixing pin spacers on each end of the Rupture Pin while keeping the overall length of the pin assembly constant.

Advantages COLOR CODED PINS2” and 3” FNPT or 602, 1002 and 1502 Pins for the Mud Valve are color coded to show each individual set pressure.hammer unions.Large seat orifices. MUD RELIEF VALVES - “POCO” PIN CHARTRelief settings from 1,000 to 10,000 PSI PART# PIN TYPE SIZE COLORwith POCO set pressure pins. 004895 IA & IB - 1,000 PSI 2” & 3” NEON GR.Change the settings by changing the pin. 760756 IA & IB - 1,500 PSI 2” & 3” AQUAThe set pressure is shown on the pin label. 393345 IA & IB - 2,000 PSI 2” & 3” LT. GREENThe 2” and 3” Model I-A and Model I-Bvalves use the same interchangeable pins. 813247 IA & IB - 2,500 PSI 2” & 3” GRAYIn addition, the pins are color-coded 589412 IA & IB - 3,000 PSI 2” & 3” GOLDaccordingly. 635040 IA & IB - 3,500 PSI 2” & 3” BLACKReliable settings. 791664 IA & IB - 3,800 PSI 2” & 3” WHITESimple dependable operation. 122301 IA & IB - 4,000 PSI 2” & 3” DK. BLUEOne moving part. 272338 IA & IB - 4,500 PSI 2” & 3” ORANGEFatigue and pulsation are not factors that 425354 IA & IB - 5,000 PSI 2”& 3” DK. GREENaffect the set pressure of the valve. 523661 IA & IB - 5,500 PSI 2” & 3” YELLOWReaches open position in milliseconds. 261998 IA & IB - 6,000 PSI 2” & 3” REDProvides a bubble-tight seal to set point.Stainless steel seat and piston arestandard. 848612 IB - 6,500 PSI 3” LT. BLUEGreater washout resistance with no direct 118400 IB - 7,000 PSI 3” TANimpingement on the seat, piston or seal. 582953 IB - 7,500 PSI 3” PINKField repairable. 450182 IB - 8,000 PSI 3” SILVER 111374 IB - 8,500 PSI 3” FUCHSIAVisual indication of opening. 584833 IB - 9,000 PSI 3” BROWNUnaffected by changing ambienttemperatures on the pin. 195800 IB - 9,500 PSI 3” OLIVE 198533 IB - 10,000 PSI 3” PURPLEPin cannot fatigue and buckle early. OPERATIONIn the closed position, an elastomer seal contacts a machined, When the pin buckles, the piston moves off seat in millisec-stainless steel piston seat for a bubble-tight shut off. onds to a protected position to allow full flow pressure relief.

STANDARD MATERIALS CONNECTIONSModel I-A: A105 Carbon Steel, Forged Body Standard and custom connections available.Model I-B: A105 Roll Stock, Carbon SteelWith stainless steel trim, other materials optional. VALVE SEALS(Standard T for the Model I-A and Custom for the Model I-B ). Available for high and low temperatures. Viton standard.

30 pressure relief valve for mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 36%, pumps accounts for 23%.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

8613371530291

8613371530291