mud pump function for sale

The Baoji/Bomco F1000 Triplex mud pump has a max. working pressure of 5,000PSI and a 6-3/4" liner size. This model is the first choice for the medium and deep dr... More Info

The Baoji/Bomco F1600HL Triplex mud pump has a max. working pressure of 7,5000PSI and a displacement of 46.5L/S with 6" liner size. This model is the f... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - 1 - Rebuilt Gardner Denver PZ-9 Mud Pump Package, New Caterpillar C-27, 1050 HP diesel engine. Belt-driven. comes with pulsation dampener, discharge block, precharge, li... More Info

Mud Pumps - 1 of 3 used Gardner Denver PZ-8 triplex mud pumps. This would be a good rebuildable core. We also have new, rebuilt and good used pumps and packages available for sale ... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

All Categories2 phase separator (6)Separator (6)3 yard dump truck (3)Dump (2)Dump truck (1)Agitator (1)Mixing (1)Air Compressor (3)Compressor (2)Oil Free Compressor (1)Backhoe (14)710 (1)Back hoe (2)Digger (3)Excavator (2)Extenda hoe (2)Loader (1)Rear Actor (1)Tractor (2)Boom (14)Aerial work platform (1)Basket crane (2)Boom Lift (1)Cherry picker (2)Elevating platform (1)Lift (2)Man lift (1)Manlift (1)Mobile elevating work platforms (2)Reachlift (1)Boom Lift (4)Boom (1)Cherry picker (1)Man lift (1)Reach lift (1)Bucket Truck (2)Lift Truck (1)Man lift (1)Cart (3)Mule (1)Side by side (1)UTV (1)Centrifugal Pump (7)Centrifugal Pump (4)Centrifuge (260)Centrifuge (22)Decanter (88)Dewatering (24)Disc Stack (1)Drilling Equipment (36)Processing Equipment (35)Solids Removal (25)Trailer (1)Water Treatment (26)Centrifuge Stand (2)Centrifuge (2)Compactors (3)Double Drum Roller (3)Construction (1)Backhoe Loaders (1)Control Panel (3)Centrifuge (3)Conventional Trucks (2)Day Cab Trucks (2)Conveyor (1)Screw Conveyor (1)Crane (9)Crane (1)Crane Truck (1)Crawler crane (1)Telescopic Crane (2)Truck Mounted Cranes (4)Cryogenic Tank (1)LNG Tank (1)Cuttings Dryer (10)Centrifuge (1)Control Panel (2)Drilling Equipment (1)Dryer (4)Solids control (1)Solids Removal (1)Degasser (2)Atmospheric Degasser (1)Vacuum Degasser (1)Desander (2)Drilling Equipment (1)Solids Removal (1)Desilter (2)Drilling Equipment (1)Solids Removal (1)Diesel Engine (4)Caterpillar (1)Diesel (1)Diesel Engine (1)Engine (1)Drilling (1)Swivels (1)Drilling Equipment (36)Blowout Preventer (1)Centrifuge (5)Cuttings Dryer (1)Degasser (1)Drilling (1)Dryer (1)Mud Cleaning (1)Mud Pump (1)Mud Recycling (1)Power Swivel (2)Processing Equipment (4)Shale Shaker (9)Solids control (6)Solids Removal (1)Tanks (1)Drilling Rigs (6)Drilling Equipment (1)Workover Rig (5)DUMP TRUCK (3)10yard (1)DUMP (1)HAULER (1)Electrical & Electronic Components (1)Wire (1)Engine (1)Natural Gas (1)Excavator (4)145 Excavator (1)30,000 LBS Excavator (1)Digger (1)Heavy machinery (1)Filtration (3)Filtration (1)Forklift (8)Case (1)Fork Lift (1)Lift (1)Rough Terrain (1)Rough Terrain Forklift (1)Toyota (1)Warehouse Forklift (2)Fuel & Lube Trucks (1)GENERATOR (3)POWER (1)TEMP POWER (2)Heater (2)Electric (2)Hydraulic Screen Vibrator (1)Shale Shaker (1)Inline Heater (1)Heater (1)Kill Truck (1)Vacuum Truck (1)Light Tower (7)Disel Engine (3)Generator (1)Light (1)Light Plant (1)Tower (1)Liner hangers (1)Mini Excavator (2)Excavator (1)Mini Ex (1)Mixing Tank (13)Centrifugal Pumps (1)Diesel Driven (1)Diesel Engine (1)Drilling Equipment (1)Mix Tank (1)Mixing (1)Mud Recycling (1)Mud Tank (1)Shaker Tank (1)Tank (4)Mud Guns (1)Mixing (1)Mud Hopper (1)Shearing (1)Mud Pumps (14)Drilling Equipment (2)Gardener Denver (2)Mud Pump (4)Processing Equipment (2)Triplex (2)Triplex pump (2)Oil, Gas and Mining (50)Coiled Tubing (14)Cuttings Dryer (1)Drilling Rigs (5)Fishing Tools (1)Frac blender (1)Frac Pumps (24)Hydraulic Rig (1)Separation Equipment (1)Transmission (1)Triplex Pump (1)Oilfield Equipment (7)Power Swivel (7)Parts (1)Dryer (1)Pressure Washer (7)Processing Equipment (93)Air Stripper (1)Artificial Lift System (1)Centrifuge (48)Cuttings Dryer (2)Dewatering (1)Dryer (1)Filter Press (1)Hopper (1)Mix Tank (2)Oil Water Separation (3)Pump Jack (1)Remediation (1)Rod Pump (1)Separator (2)Shale Shaker (14)Solids Control (2)Tanks and vessels (1)Vessels (2)Water Filtration (1)Water Softener (1)Water Treatment (4)Wemco (2)Production Equipment (2)Combustor (1)Flare (1)Progressing Cavity Pumps (1)Positive Displacement Pumps (1)Pump (14)Centrifugal Pump (3)Centrifuge Feed Pump (1)Diesel Driven (1)Lobe Pump (1)Mulitstage Pump (1)Positive Displacement Pumps (4)Rotary Lobe Pump (1)Self Priming (1)Trash Pump (1)Reach Forklift (3)Forklift (1)Reachlift (1)Up and over (1)Reach Lift (9)FORKLIFT VARIABLE REACH (3)Lift (3)Telehandler (3)SCISSOR LIFT (20)Boom Lift (2)Cherry picker (3)Lift (4)MAN LIFT (2)Manlift (3)REACHLIFT (1)Rough Terrain (1)Scissor (4)Shaker Screen Cleaner (1)Shaker Screens (1)Shaker Screens (1)Screens (1)Shale Shaker (9)Centrifuge (1)Screens (1)Shaker (4)Shaker Screens (1)Shale Shaker (1)Solids Removal (1)Skid steer (6)Bobcat (2)Skidsteer (2)Track (1)Track Skid steer (1)Stand Centrifuge (7)Centrifuge Stand (7)Submersible Pump (1)Pump (1)Tanks & Kettles (1)Coalescer (1)Three phase separator (7)Separator (7)Top Drive (6)Drilling Equipment (2)Drilling Rig (1)Hydraulic (1)TOP DRIVE (1)Well Service Equipment (1)Trash Pump (5)Centrifugal Pump (1)Diesel Driven (1)Diesel Engine (1)Trash Pump (1)Water pump (1)Truck (6)Crew Cab (1)Kill Truck (1)Pickup (1)Reefer Trucks (1)Service & Utility Trucks (2)Vacuum trailer (2)Vac trailer (1)Vacuum (1)Vessels (8)Acid Tank (1)Frac Gel (1)Frac Tank (1)Mix Tank (1)Mud Tank (1)Tank (1)Truck (1)Water tank (1)Warehouse Forklift (2)6k Forklift (1)Forklift (1)Water Treatment (2)Reverse Osmosis (2)WATER TRUCK (3)Tank (1)TANK TRUCK (1)WATER (1)Welder (2)300Amp welder (1)Big Blue (1)WHEEL LOADER (1)3 YARD WHEEL LOADER (1)Winch Trucks (1)

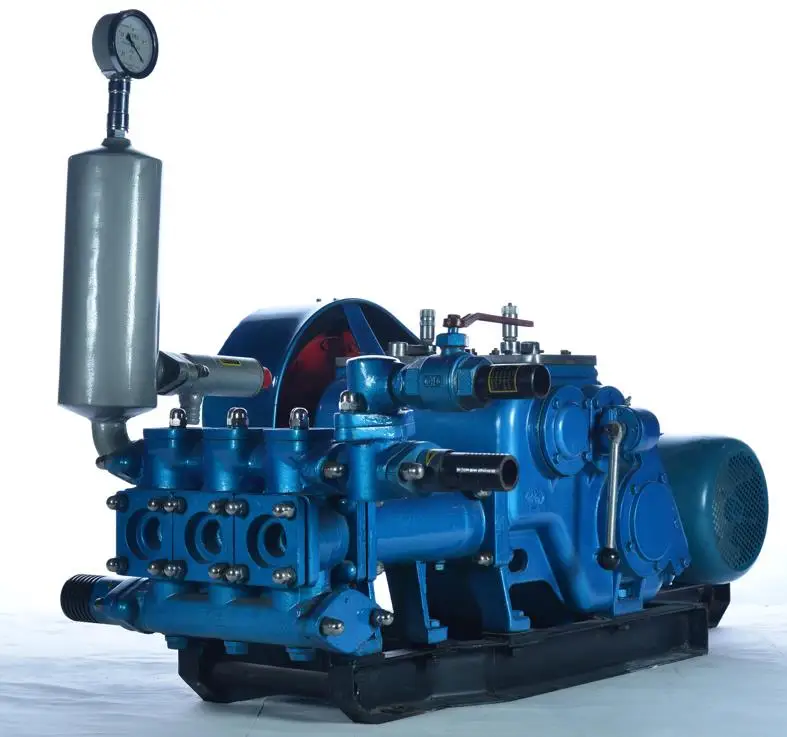

Mud pumps are large reciprocating pumps that are used to move heavy drilling fluid within the hole during oil drilling. The pump works by circulating the mud; it pushes the fluid down into the hole and then moves it back up again. Being reciprocating by design, they use plungers or oscillating pistons in order to displace the drilling fluid. Mud pumps are single acting pumps, which means that the fluid moves only in one direction.

The mud pump them pushes the mud down the piping and into the bottom of the well, and the pressure forces the mud up the space surrounding the piping (called the annulus). During oil and gas explorations, the mud used consists of clay, emulsified oil or water, and chemicals. It’s tailor-made for the particular conditions of the drilling for safety reasons. The purpose of this mud is to float clean the bottom of the well by floating out rock cuttings. It also cools the drilling equipment and functions as a barrier should there be a blowout.

Mud pumps, such as a Gardner Denver PZ 11, are crucial equipment for drilling oil. As drills cut through rocks, mud pumps move cuttings up the hole. These rock cuttings are then put through shakers that remove them from the drilling fluid or mud, which is them reused by the mud pumps. The process continues until the hole is drilled to the full depth. Modern mud pumps are typically triplex-style with three cylinders. Duplex pumps are still used sometimes in older oil rigs. Some of the newest mud pumps have six cylinders.

If you need a mud pump for sale, don’t hesitate to contact Henderson where we specialize in the procurement and brokerage of capital drilling equipment. Known for the transparency of their procurement process, if we don’t have what you need in stock we can recommend alternative sourcing options to help you cut costs as well as increase efficiency.

Mud pump is mainly used for geological drilling, geological engineering construction and foundation treatment of low and medium pressure grouting pump, etc. Mud pump is a machine that sends mud or water to the borehole during the drilling process. Mud pump is an important part of drilling equipment. All major businesses have mud pump parts for sale.

The main function of mud pump is to inject mud into the well along with the bit during the drilling process. It plays the role of cooling the drill bit, cleaning the drilling tool, fixing the well wall, driving drilling, and bringing the cuttings back to the surface after drilling.

In the commonly used positive circulation drilling, the mud pump sends the surface flushing medium-- clean water, mud or polymer flushing fluid to the end of the drill bit through the high pressure hose faucet and the center hole of the drill string under a certain pressure. Therefore, the purpose of cooling the drill bit and removing and conveying the cuttings to the surface is achieved.

Petroleum drilling mud pump is a kind of volumetric mud pump. Its basic working principle is that the volume of the sealed working chamber (mud pump cylinder liner) is periodically changed to convert the original mechanical energy into the pressure energy of the liquid to complete the operation.

The specific process relies on the reciprocating motion of the mud pump piston in the cylinder liner to make the volume of the working chamber in the cylinder liner change periodically. The mud pump cylinder liner is isolated from the outside world by means of a sealing device such as a seal ring, and communicates or closes with the pipeline through the pump valve (suction valve or discharge valve), which shows the importance of the mud pump cylinder liner. The three-cylinder mud pumps currently on the market are equipped with three cylinder sleeves.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

- The pump skid weighs only 2450 kg (wet) and only covers an area of 2.4 m x 1.92 m making it very easy to move into restricted areas due to its compact abilities.

The effectiveness of triplex mud pumps for sale determines the success of drilling operations in rigs. Circulation of the drilling fluid or mud is a continuous process that calls for uninterrupted operations of the mud pumps. Finicky about how our equipment work, we at ShalePumps, go to extreme lengths before engineering modern beasts for continuous drilling operations in rigs.

Our state of the art Houston facility develops high performing mud pumps for drillings rigs by a combination of the best materials, and structural dynamics to put together some of the best equipment. Designed to be adapted for various drilling applications in rigs through designs that incorporate various liner sizes, the triplex mud pumps for sale that leave the assembly line at ShalePumps are mean and mighty workhorses. The triplex mud pumps feature high performance steel power ends, balanced forged steel crankshaft, steel herringbone gears and anti-friction roller bearings. Striking the right balance between weight and performance, the triplex mud pumps for sale we make are best for drilling operations in rigs.

The triplex mud pumps manufactured at ShalePumps have extended continuous duty cycles, and foolproof lubrication systems for smooth drilling operations in rigs. With mud pumps from ShalePumps the drilling operations in rigs will never be the weak link, but a pivot that spells success.

ShalePumps, LLC is proud to introduce the SP-1614 1600 HP Continuous Duty Triplex Drilling Pump. Engineering and rated for 1600 horse power at 110 strokes per minute with a 14” stroke capable of 7500 PSI. Manufactured in our Houston Texas facility, this pump defines longevity, quality and capability. The SP-1614 is designed to incorporate minimum weight and maximum performance using a high performance steel power end, a balanced forged steel crank shaft, steel herringbone gears and anti friction roller bearing throughout. Multiple liner sizes are available to allow variance in pressure and output volume for a variety of drilling applications. Download the performance chart for more detailed information.

Oil well drilling depends on many equipment and drilling rig mud pumps form an intrinsic part of operations. Reciprocating pumps that basically circulate mud, the drilling rig mud pumps offer continuous service to contractors with robust and rugged build. At Waters International, Inc our mission of featuring only the very best equipment on our site continues, with satisfied customers vouching for the build quality and performance of drilling rig mud pumps that we put up on offer. Here is a brief outline on the different types that are available in the market.

Triplex mud pump – At Waters International, Inc we have always believed in offering the right suggestions to clients. Hence, for drilling applications that require very high pump pressures, the triplex mud pump would be the most suitable. The most commonly used applications of triplex mud pumps are oil drilling, where it works by reducing the volume of the working fluid so as to generate adequate pressure for the purpose of producing the flow. The triplex mud pump comprises three pistons, and the middle piston generates more pressure to a crankshaft. But, operators need to be cautious of high piston load, where the application of disproportionate pressure can result in the failure of the crankshaft.

Quintuplex mud pumps – Quintuplex mud pumps are typically used in operations where the fluid needs to be pumped during drilling operations. The pumps function in what is called as continuous duty return piston mode. By virtue of being a quintuplex or five sheave models, the pump requires crankshaft support, which is provided by external bearings.

Duplex mud pump – Duplex mud pumps are generally used by contractors and operators to facilitate the circulation of mud that is drilled. The supply of liquid needs to reach the bottom of the well from its source, viz., the mud cleaning system. Duplex mud pumps are considered as technology that is old, however, the feature of the pumps that can work on either electricity or diesel, makes it a good choice. At Waters International, Inc we have always looked at equipment that require less maintenance and this fits the bill as one that demands the least maintenance.

8613371530291

8613371530291