mud pump pulsation dampener precharge brands

Our custom-designed systems will absorb excess energy pulsing through the pump and piping system by creating a low-pressure area to dampen the excess shocks and vibrations. Because a pulsation dampener regulates the release of energy, your system will be better protected and run more smoothly. After installing a pulsation dampener, customers notice that their system:

A properly serviced pulsation dampener is critical for your mud pumps’ efficiency, safety, and performance. Unfortunately, there aren’t many resources available to educate personnel on executing safe and effective servicing procedures. Please review the following steps with your personnel for safe pulsation dampener maintenance.

Should you or your personnel have any questions regarding pulsation dampener maintenance, please don’t hesitate to ask. Sigma is more than happy to help you to ensure safe and proper care is being completed on your pulsation dampening equipment.

The Pulsation Dampener 3375-0015-3 from the Hypro series assures smooth discharge from piston and plunger pumps. It also reduces peak loading on pump bearings and other internal parts. The Pulsation Dampener 3375-0015-3 extends the system life and minimizes maintenance costs.

As a general guideline, when using two cylinder or four cylinder piston pumps, the dampener charge should be approximantely 1/2 of the pump operating pressure. When using a three or six cylinder pump, te dampener charge should be approximately 2/3 of the pump operating pressure. This pump is rated for up to 1500 psi.

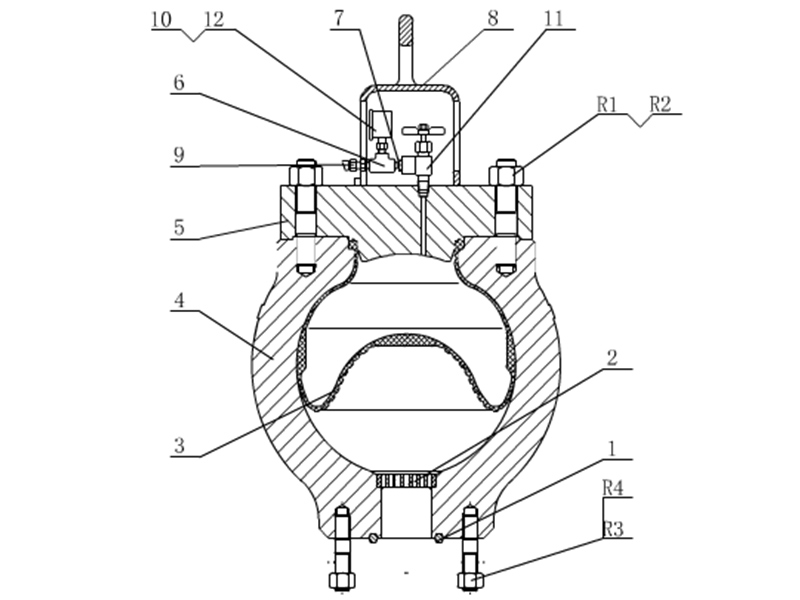

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

Mud pump pulsation dampeneris the mud pump discharge end main component, installs in the hydraulic end discharge pipe one end, plays the stable pressure and the pressure compensation function, the air bag work pressure is the mud pump work pressure 80%.Attention should be paid to the use of air bag, must be the first pressure relief.The mud pump of F500/F800 USES kb-45 air bag, and the mud pump of F1000/F1300/F1600 USES kb-75 air bag.The middle tie rod produced by our company is made of 35CrMo material, which has a smooth surface after chrome plating and fine grinding, greatly improving the wear resistance and corrosion resistance.

Proper installation and use of pulsation dampener can effectively reduce pressure fluctuations in the discharge system, thus achieving a more uniform fluid flow.In order to achieve a high service life of the air bag, always maintain the recommended ratio between the pump pressure and the air bag precharge pressure (generally not more than 2/3 of the pump discharge pressure, the maximum should not exceed 4.5mpa).

2. In the maintenance of air bag, air bag pressure must be zero, the pump pressure must be zero.Cannot rely on the pressure gauge to judge, because the residual pressure is small, the pressure gauge can not be displayed, but this low pressure will also lead to accidents!

The pulsation dampeners shall be installed properly to reduce the pressure fluctuation and smooth the liquid flow. In order to extend the lifespan of the air bag, it is highly recommended to maintain the suggested proportion of the pump pressure to the pre-charge pressure of the air bag for the pulsation dampeners. Generally, the pump pressure shall be 2/3 that of the discharge pressure and no more than 4.5MPa.

2. During maintenance, the pump pressure and the pressure inside the pulsation dampeners shall be zero. Since the residual pressure is generally small and can not be indicated on the pressure gauge, user shall confirm the pressure carefully to avoid accident caused by low pressure.

· Integrated production line: Premium delivers F series triplex single acting piston mud pump from 500HP up to 2200 HP with time-tested high performance.

· Diversified drive options: Through belt, chain or gearbox, pumps could be operated by multiple brand AC/DC motor, diesel engine, or simply couple the pinion shaft with one of our premium Direct Drive motors.

· Upgrade a 1300HP or 1600HP mud pump to achieve higher discharge pressure (7500 psi) simply by changing to an "L" type fluid end, site service optional (extra charge).

A Pulsation Dampener is an inline dampening device used to smooth out pulsations in a pump’s output. They are used alongside a pump as a mounted accessory to help achieve certain flow rates for an application. They can be used with a variety of Positive Displacement Pumps which typically generate a pulsed flow (Diaphragm Pumps, Peristaltic Pumps, Dosing Pumps, Piston Pumps etc)

Pulsation Dampeners are required in some process applications when the customer needs smooth flow into the next phase of the production line, for example, to get an accurate reading through a flow meter or to fill a hopper consistently. On the flip side, Dampeners can be used to reduce water hammer effects through pipework. Water hammer is where the pump causes the pipes to vibrate and potentially fail, a smooth flow from a Pulsation Dampener reduces this.

For example, Diaphragm Pumps inherently produce a very turbulent discharge flow meaning that in some instances a Pulsation Dampeners are required to give a smooth pulse-free flow.

In the Tapflo UK range, we focus on Pulsation Dampeners for Diaphragm and Peristaltic Pumps, although we can also supply them for other pump technologies.

The Active Pulsation Dampener works by supplying an equal pressure to the pulsation supplied by the pump. The Dampener supplies this pressure during the low-pressure points of the pump’s operation, as the pressure drops between pump strokes creating a pulsating flow. The pressure supplied by the dampener decreases pressure variations, therefore producing a steady flow from your Diaphragm Pump. You can see the pressure drops and Pulsation Dampener benefits in action in the diagram below.

Tapflo supplied a 2” Air Operated Diaphragm Pump to a bleach factory, the customer used the T400 PTT for a couple of days and then called us to explain that the bleach line, running along the roof of his production facility, was shaking. Due to the nature of the product being pumped health and safety on site could not allow this to continue.

To support our Peristaltic Pump customers, Tapflo offers an in-line Pulsation Dampener for our PT and PTL Series’. They can reduce the pulsation of your PT Pump by as much as 90% to reduce the vibration and water hammer effects on pipework. Another benefit of this accessory is its ability to be installed on-site horizontally or vertically for flexible installation.

The EQUAFLUX 100 pulsation dampener is installed downstream of the pump to reduce pulsations and create a smooth and laminar flow. The casing can be manufactured in many materials, including; polypropylene, PVDF, PPS-V and stainless steel 316. The diaphragms come in PTFE as standard, the combinations of material options make this pulsation dampener suitable for use with a wide range of fluids.

A pulsation dampener works by creating an area of low pressure that absorbs the pulsations emitted by the pump. A diaphragm is fitted that has a cushion of compressed air, this flexes and absorbs the pulsations. The EQUAFLUX 100 is connected to the air line and fed with compressed air, the diaphragm and air work in conjunction and automatically adjust the pressure to minimise pulsations in the pipework.

The EQUAFLUX 100 pulsation dampener can be utilised for many fluids in the industrial and marine markets, including; fuels, oils, chemicals, acids, waste water, glues, resins, paints and inks. Applications for this pulsation dampener include; mechanical and metalworking industry, ceramic industry, petrochemical, waste water treatment, biofuels, marine (bilge, slop, sewage), mining, textile industry, automotive industry, paint industry, cosmetic industry, cleaning industry and ink and print industry

This pulsation dampener is Atex zone 2 as standard meaning it is suitable for operation in non safe potentially flammable environments. As an option, this can can come in an Atex zone 1 version if required.

Designed with a broader bladder design to provide even greater pulsation reduction for smooth performance. Engineered to reduce pressure fluctuations and pulsation found in positive displacement pump system. Install on the discharge side of the pump to prolong pump and system component life. Nitrogen is used to pre-charge the dampener to 250 PSI for system operating pressures of 300-600 PSI.

8613371530291

8613371530291