airlift mud pump brands

The pumps PM are made of corrosion-proof materials conforming to conditions for conveying potable water (GENOVA system). During air flow cut-off the pump’s construction provides separation of the supply system from the media pumping zone by means of a diaphgram perforated valve, closed by hydrostatic pressure.

The pumps are highly reliable and easy to assemble owing to the use of PVC hose as an intake end. The hose can be formed depending on the shape of the tank.

The capasities of the pumps (specyfied in laboratory conditions for clean water and constant depth Hz=1,5 m) are presented in the diagram showing the dependance of air demand supplied to the pump on the lifting height “H” of the medium being pumped (see data sent by fax).

The capasity of PM 110, at immersion depth Hz= 4m, is 15-20m3 (at H=0,5 m). The pumps can operate in a complex system allowing for multiplication of capasity. The lenghts of ends, intake L2 and exhaust L1, and air supply hose are specyfied by the buyer. We suggest the purchase of the very “heart” for individual assembly.

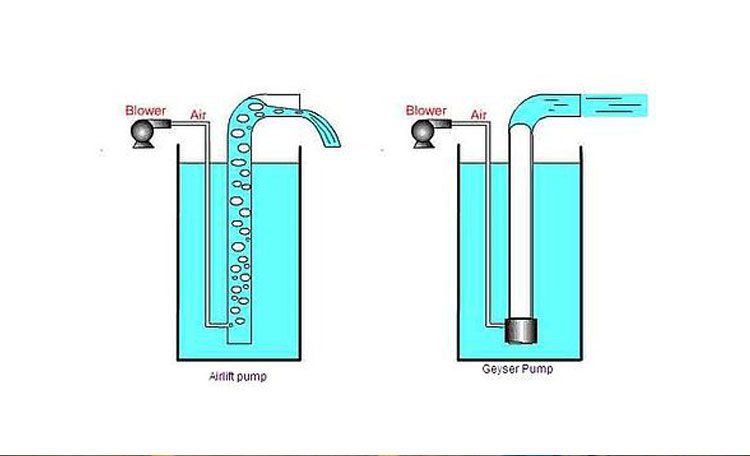

Air Lift pump or Air Lift pump is one of the simplest equipment in the field of wastewater treatment and aeration of aquaculture pools, which with the help of air pressure, tries to transfer fluid to the top of the ponds. Airlift pumps or air pumps are designed on the basis that the presence of air bubbles in the fluid will reduce their density and eventually lead to their upward movement. Seven Industrial Group; Manufacturer of airlift pumps and other water treatment equipment designs and manufactures this group of products in compliance with various standards. In the following, we will provide a comprehensive guide including how air pumps work, standards and important points in the design, production and manufacture of airlift pumps and everything you need to know about the price of Air Lift pumps and their purchase.

An airlift pump is a pump with low suction power that consists of two very simple pipes that are transferred from a compressed air pipe by a compressor or blower to the lowest point of the pond or treatment plant or pool and in the next pipe water droplets or Sewage moves up with the air. This type of pump actually reduces the density of the fluid by moving air into the sewage and fluid in the ponds and moves easily to the highest level of the pond.

To better understand and become more familiar with the Air Lift pump, it is better to first describe how this type of pump works and introduce each of the steps that go through it. The operation of the airlift pump is as follows:

The entry of air into the fluid or sewage creates multiple bubbles that reduce the density of the fluid and move upwards through the second pipe of the pump.

Due to aeration and bubbling in the sewage and its transfer to the top, solid particles deposited in the floor may also move upwards. A very important issue in aeration or transfer of sediments by this pump is the non-use of mechanical or electronic energy, which is a great advantage for it.

Due to their simple structure, Air Lift pumps have low suction power and low fluid transfer speed upwards. Therefore, different types of this pump are designed. We introduced its common type in the first part of the text and explained how it works. In order to improve and increase the efficiency of the device, changes were made in its structure and another type called geyser pump was designed and produced.

In order to improve the suction power and transfer of air and fluid flow upwards to sedimentation ponds or aquaculture ponds, changes were made in the structure of conventional air-pump pumps. geyser pump is actually an improvement of old pumps that in their general structure, in addition to air transfer pipes, a kind of pipe is also considered as an air supplier. This pipe eventually causes fluid and air in the transfer pipe create larger bubbles. The formation of larger bubbles and their presence in the sewage or water in the ponds and the liquid source greatly affects the density reduction and therefore the speed of their transfer to the highest level of the pond increases.

In designing an airlift pump, it is necessary to consider several very important issues in order to increase the efficiency of this group of equipment. One of the most important things in designing an air lift pump is the height and length of the pipes. The air transfer pipe should be considered at the height of the pond and the liquid source in order to perform aeration and fluid transfer from the lowest point. In addition, it is necessary to determine the material of the pipes according to the organic matter in the wastewater to prevent corrosion and decay. Stainless steel and fiberglass, cast iron and composite are among the materials that can be selected according to the conditions of sewage and the environment of installation and use of Air Lift pump.

Seven Industrial Group, as the oldest manufacturer of water and wastewater treatment equipment, has designed and manufactured Airlift pumps in its activities. It should be noted that in the process of manufacturing the airlift pump, the environmental conditions and the treatment plant are considered and the required standards are determined by the development and research team and a group of professional engineers, and finally the design is done. To know the features of each of the products in this collection, experts are ready to provide the necessary advice before buying an airlift pump.

The price of airlift pumps, like other water and wastewater treatment equipment, is determined by various factors, and that is why the variety of these pumps is high. Pipe body material, pipe height and size, type of pump and compressor, etc. are among the factors that affect the price of the airlift pump. To inquire about the price of Air Lift pump, all you have to do is contact the experts of Seven Industrial Group through the communication channels mentioned at the bottom of the page.

The reasons for using air pumps are so varied that in some cases they may be used to transfer sludge deposited in sedimentation ponds or to aerate aquaculture ponds. It is very important to note that if you use this pump to transfer sludge and sediment from the bottom of the ponds, it is necessary to consider the diameter of the fluid transfer pipes up large enough.

The use and purchase of airlift pumps in the field of water and wastewater treatment is very high, the main reason for its great popularity is the numerous advantages of this equipment, some of which are:

Despite the many advantages of this type of air pump, there are limitations in their use, in other words, like other equipment, it has disadvantages, some of which are:

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes air lift pump wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A air lift pump comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the air lift pump of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of air lift pump for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of air lif pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

According to relevant research, it is clear that for a traditional mud pump, there will be blockage and wear during the dredging process because the flow cross-section of the blade is so large that its concentration is limited. Compressed air serves as the power source for air transportation, which can pump and transport liquid or mud through the combination of buoyancy, friction, and vacuum effects (Fu and Yan, 2004; Pei and Liao, 2010). To the best of our knowledge, the airlift system has many advantages, such as low cost, easy operation, simple configuration, no pollution to the environment, and less blockage (Chen et al., 2009; Pei and Tang, 2015). Therefore, it can be considered that the air transportation system has great potential for river and lake dredging.

Many scholars have carried out research, such as numerical simulation of the mixed fluid in the airlift system and analysis of the relationship between the injection parameter and the performance so that it has a higher matching, and thus, the performance of mud airlift is improved. Huang et al. (2017) performed a numerical simulation to study the effect of the nozzle type, injection depth, and injection hole diameter on the airlift pump, thereby improving the performance of the airlift pump. Alasadi and Habeeb (2017) then performed a numerical simulation study on the airlift pump with traditional and improved air injection devices under different intake flow rates, and the results show that the airlift pump with an improved air injection device can improve performance at higher intake flow rates. In actual operation, sufficient attention should be paid to the critical point of the solid particles carried in the bottom layer. If this is not given, it will cause blockage in the pump which will affect the performance and cause safety accidents in severe cases. When researchers study critical characteristics, they are mainly conducted from the perspective of experiments and rarely involve theoretical models. Taleb and Al-Jarrah (2017) performed an experiment to study the effect of the submergence ratio and air injection hole diameter on the performance of the airlift pump. The results showed that the performance of the airlift pump increased as the submergence ratio increased, while an injection hole diameter of 4 mm gave the highest performance. Oueslati A performed an experiment under many operating conditions, and proposed a theoretical model taking into account the air humidification and liquid temperature. The results showed that the proposed model is in good agreement with the experimental results. Fujimoto and Murakami studied the critical conditions of a mud airlift pump and obtained a model of the critical water flow rate for lifting solid particles at the bottom of the pump. By using this model, results that are consistent with reality can be obtained (Fujimoto et al., 2004). On this basis, our research team expanded the suction distance and obtained the rule of critical particle detonation. It needs to be clear that the aforementioned studies are only for water–solid two-phase flow (Tang et al., 2012). Fujimoto and Nagatani then used the aforementioned working conditions to analyze the critical conditions of particles transported in the three-phase flow. The research results show that in the three-phase flow, the starting of particles is easier, but the corresponding theoretical model is not proved (Fujimoto et al., 2005). In application, because of the constraint pressure (Pei et al., 2010; Hu et al., 2013), the particles are often compressed when they are deposited at the bottom, which makes it difficult to start the particles. At the same time, the airlift is caused to fail, but scholars rarely conduct research on this aspect.

In this study, the research is carried out. The interface selects the inlet of the airlift pump to divide the mixed water into two fluid phases, one is a water–solid two-phase flow, and the other is a gas–water–solid three-phase flow. To satisfy the actual dredging, the medium used in this study is round river sand. Based on this, the critical conditions of the three-phase flow and two-phase flow are analyzed, and the relationship between the key condition and chip compaction is analyzed. For discussion, the research result of this study can provide a reference for other researchers to study related theories.

Analyzing Figure 3, it is clear that when JG,cri is increased, JL,3,cri will be reduced. After reaching the inflection point, JL,3,cri will decrease as JG,cri decreases. Therefore, by increasing JG,cri, the density of the mixed fluid can be reduced, so that the start of the particles becomes easier. Near the inflection point, because the gas value is large, the movement of the particles is mainly controlled by the water phase. From this, it can be clear that the performance of the airlift will be affected by working conditions, and it is necessary to reduce the air mass and then change the flow pattern in the tube, so that it can change from circular flow to elastic flow. It needs to be clear that this change is irreversible, that is, after reaching the inflection point, JL,3,cri will decrease with the decrease of JG,cri. According to the related research results (Hanafizadeh et al., 2011; Tang et al., 2016), the critical airlift of mud is opposite to the existence of the inflection point. In engineering applications, the inflection point needs to be moved down as much as possible. Comparing and analyzing the critical strength of particles with different diameters can be clear (Figure 3A). When the particle diameter is increased, JL,LS,cri and JL,3,cri will rise accordingly. The reason for this phenomenon is that increasing the particle diameter will increase the solid phase slip. In Figure 3B, it is clear that when the particle density increases, JL,LS,cri and JL,3,cri will rise accordingly. The reason for this phenomenon is that increasing the average density of the mixed water will reduce buoyancy. In addition, when increasing the particle density and diameter, the inflection point will move to the right (Kassab et al., 2007).

In the aforementioned model, particles need to be placed in the tube. However, in practical application, the particles will first deposit at the bottom of the water, and then they will be affected by the static chip retention effect. Obviously, the working conditions are different from those assumed by previous research. To be consistent with the practical situation, the research object selected in this study is particle B which is closest to the bottom of the pump. Figure 4 shows the force acting on particle B.

Compared with the critical water flow model[30] we constructed, it is clear that in this model, we only consider the static chip retention force (static chip retention effect) of the particles, which is in line with the actual engineering. Using the relevant parameters shown in Table 2 to calculate, the results of the model can be clarified (Figure 5). It is clear that with the increase of particle diameter dS and density ρS, the JL,LS,cri only shows a slight upward. On the contrary, when the immersion rate γ is continuously increased, JL,LS,cri will be significantly increased. If the particle density and size are smaller, then the immersion rate γ will control the start of the particle. Analyzing Figure 5, it can be clear that if the static chip retention effect is maintained, JL,LS,cri will be increased quickly. It is concluded that for small and medium particles, the airlift performance will be affected by the static chip retention effect.

It can be considered that in areas such as oceans and lakes, because of their greater depth, the particles have a larger static chip retention force, which causes the start to fail. If the particles are compacted, then it will prevent airlift dredging. Therefore, it is necessary to impact the sand layer before airlift, so that the static chip retention effect can be reduced.

Comparing the experimental results and the calculated results, it is clear (as shown in Figure 7) that the experimental value of the critical water flow rate for lifting the solid is lower than that of the calculation result when only lifting the particles. This situation occurs because the tube and the pump will coalesce, expand, rupture, and re-aggregate. The bubbles will move periodically, causing mixed fluid instability along the axial direction when it rises. Ascending, its oscillation characteristic is ascending-descending-ascending, and compared with descending motion, the ascending motion is more intense. According to the results of other researchers and ours, it can be inferred (Hu et al., 2012; Hu et al., 2015) that the basic feature of a slurry airlift is the oscillating upward motion of the mixed fluid, which will cause a transient vacuum, so there will be resistance. If the particle’s fluctuation reaches its peak, then the particle’s activation state can be advanced. Figure 7 also shows that if the immersion rate is lower, the mixed fluid will have more prominent oscillation characteristics, which will result in a higher instantaneous vacuum. To confirm these phenomena, high-speed cameras can be used.

Due to the effect of gravity, the particles will be affected by the static chip retention effect when they are deposited at the bottom of the water. When we are conducting research, we put sand particles on the bottom of the pump in advance (Figure 4). At this time, the sand will be closely arranged and in a double-stacked state. To maintain the static chip retention effect, the particles need to be placed in the water continuously for 7 days. Then we adjusted the water tank and preset the immersion rate. The particles in the center of the upper layer are the object, and the key experimental steps are repeated. Based on this, we can get JG, L, LS, Cri, JG, S, LS, Cri, and JL, LS, Cri. The research results show that the particles cannot start when the air compressor valve is adjusted from close to the maximum gas flow. Therefore, it can be considered that the static chip retention effect is obvious at the bottom. Even if the pump has a large water value and the resistance imposed on the particles is small, the static chip retention force cannot be overcome, thus making it impossible to carry out an airlift. To clarify the experimental results of JL,LS,Cri, we connected the outlet of the airlift pump to a high-power centrifugal pump. Table 4 shows the comparison results of theoretical and experimental critical values. Research on the table can be clear, and the calculation results show that the experimental results of JL,LS,Cri are low. Therefore, it can be considered that the fluctuation of water flow and surface defects between adjacent particles (Figure 4) will reduce the compactness, which finally weakens the static retention effect of the chips. Therefore, it can be considered that as long as the static chip retention effect exists, it will affect air transportation, so it is necessary to take measures to eliminate it.

2) In a water-solid two-phase flow, the physical properties of the water and particles will affect the critical water rate. However, in the gas–water–solid three-phase flow, not only will the physical properties of water and particles affect the critical water rate but so will the air rate. Before the inflection point, as the air critical flow increases, the water flow will decrease. After the inflection point, as the air critical flow increases, the water flow will increase. In addition, the existence of the inflection point is not conducive to airlift.

4) When there is a static chip retention effect under water, it is necessary to use auxiliary methods to impact the particle layer or to increase the resistance of the particles, otherwise, it will not be conducive to airlift.

Alasadi, A. A. M. H., and Habeeb, A. K. (2017). Experimental and numerical simulation of an airlift pump with conventional and modified air injection device. J. Eng. 23 (2), 62.

Fujimoto, H., Murakami, S., Omura, A., and Takuda, H. (2004). Effect of local pipe bends on pump performance of a small air-lift system in transporting solid particles. Int. J. Heat Fluid Flow 25 (6), 996–1005. doi:10.1016/j.ijheatfluidflow.2004.02.025

Fujimoto, H., Nagatani, T., and Takuda, H. (2005). Performance characteristics of a gas–liquid–solid airlift pump. Int. Jonalur Multiph. Flow 31 (10-11), 1116–1133. doi:10.1016/j.ijmultiphaseflow.2005.06.008

Hanafizadeh, P., Ghanbarzadeh, S., and Saidi, M. H. (2011). Visual technique for detection of gas–liquid two-phase flow regime in the airlift pump. J. Petroleum Sci. Eng. 75 (3-4), 327–335. doi:10.1016/j.petrol.2010.11.028

Hu, D., Kang, Y., Tang, C-L., and Wang, X-C. (2015). Modeling and analysis of airlift system operating in three-phase flow. China Ocean. Eng. 29 (1), 121–132. doi:10.1007/s13344-015-0009-z

Hu, D., Tang, C., Zhang, F., and Lin, Y. (2012). Theoretical model and experimental research of airlift device in borehole hydraulic jet mining[J]. J. China Coal Soc. 37 (3), 522. doi:10.13225/j.cnki.jccs.2012.03.014

Hu, D., Wu, X., Tang, C., and Liao, Z. (2013). Experimental study of airlift device for borehole hydraulic jet mining[J]. Mech. Sci. Technol. Aerosp. Eng. 32 (5), 756. doi:10.13433/j.cnki.1003-8728.2013.05.004

Kassab, S. Z., Kandil, H. A., Warda, H. A., and Ahmed, W. (2007). Experimental and analytical investigations of airlift pumps operating in three-phase flow. Chem. Eng. J. 131 (1–3), 273–281. doi:10.1016/j.cej.2006.12.009

Oueslati, A., and Megriche, A. (2017). The effect of liquid temperature on the performance of an airlift pump. Energy Procedia 119, 693–701. doi:10.1016/j.egypro.2017.07.096

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

In 1904, the company built its first mud pump, and since then, more than 1500 mud pumps in different designs have followed. MHWirth legacy of drawworks dates back to the 1950s, and also is history to deliver Pyramid masts and substructures for land rigs. In the following decades the firm added piston diaphragm pumps to its portfolio serving the mining industry as well as pile top drill rigs with Reversed Circulation Drilling (RCD) technology for the construction of foundation structures. That technology also laid the foundation for a later involvement in subsea mining. At that time, the Germany-based company was well-known in the industry under the name of “Wirth”.

During mining operation, a MHWirth drill bit with up to 7.2 m in diameter loosens the material from the seabed. The material is then transported vertically through a large diameter airlift drill string (up to 700 mm in diameter) to the drilling vessel for further processing. Core of this technology is MHWirth’s efficient and environmentally-friendly reverse circulation technology, also known as airlift technology. Compared to other solutions, MHWirth’s airlift technology uses only robust components with limited complexity under water, thus maximizing equipment availability and optimizing operational costs (OPEX). Thus, MHWirth drilling equipment allows the vessels to operate even under severe sea conditions.

An air lift pumps are a device used to lift water from a well or a sump using compressed air. These pumps are also called mammoth pumps. Airlift pumps have been used since the early 20th century. The first airlift pump was invented in 1797 by German engineer Karl Emanuel Loscher. Air lift pumps are commonly found in agricultural land.

They are simple devices in which liquid enters from one end and a mixture of air and liquid discharge from the other end. Air is injected near the inlet. Almost without exceptions, the riser section of the airlift pumps has been a vertical pipe with a vertical cross-section.

Airlift pumps are typically used when maintenance needs to be kept to an absolute minimum. But this pump is not 100% maintenance-free because air is needed to deliver equipment to the pump that needs maintenance.

In air lift pumps, compressed air is mixed with water. We know that the density of water is much higher than the density of air. By buoyancy, the air that has a lower density than liquid rises quickly. By fluid pressure, the liquid is taken into the flow of the ascending air and moves in the same direction as the air.

The air is fed into the bottom of the riser pump, and this air freezes in water and form. As air mixes in water, the density of water decreases because the density of air and the mixture of water is less than the density of water.

So the mixture of air and water, also called froth, is much lower in density than water. Hence the main principle of air lift pump is the density difference between air and water mixture and water.

The velocity of the fluid through the pump and the velocity through the medium. The greater the difference between the respective velocities of fluid and air, the lower the overall efficiency of the pump.

For these pumps, the air injector system is in the form of an air jacket in which several holes are radially drilled through the pipe, and the air is supplied to them from the surrounding manifold.

An air pump is a device that uses the principles of gravity and inertia to move water by injecting a stream of compressed air into a pipe filled with a column of water.

An airlift pump is a pump that has low suction and moderate discharge of liquid and entrained solids. The pump injects compressed air into a pipe filled with a column of water.

The main advantage of the Husky double diaphragm air pump is that it can run dry for a limited time. A pump configuration in which the fluid source is located below the pump is called a pump stroke configuration. In other words, in a shock pump configuration, the pump draws from a fluid source located below the center line of the pump.

A major benefit of a Husky Air Operated Double Diaphragm pump is that it can run dry for a limited time. A pump layout in which the source of liquid is below the pump is called a suction lift configuration. In other words, in a suction lift configuration, a pump takes suction from a source of liquid located below the pump’s center line.

Halliburton HT400 pump is designed to handle various duty well applications including acidizing, cementing, fracturing and gravel packing. It features a compact and lightweight design; you can airlift it easily into remote areas.

The Halliburton twin-pump or flexibility concept is particularly useful when precise pumping ranges and controls are required. Halliburton exclusively manufactured the HT-400 pump power end, so that practically all parts are interchangeable.

It is ideal for a variety of cuttings injection projects. This time-proven technology can be adjusted for pressures ranging up to 20,000 psi (1379 bar) or pump rates of up to 19 barrels per minute (3 m3 per minute). The powerful HT-400 pump has a nominal rating of 800 hydraulic horsepower (hhp).

Yesterday I installed a set of Air Lift airbags, which is a pretty easy deal and took about 2 hours including some breaks. I’ve used them in the past on an old tow-rig as a teenager and was happy. I installed the air lines and schrader valves in the shield for the tow harness, they’re out of the way but easily accessible. As an avid cyclist, I always have a bicycle pump in the truck and ~10 quick pumps per side and the truck sits level with the boat on it. The nice thing about the air bags is that you don’t have to modify your suspension so that it’s stiff all the time. When not towing, just hit the schrader valves and let the air out and the truck drives normal.

I have used your product since 2009 Jan. I put a set in my Dodge 2009 ½ ton at 12,500 miles, and work in the oilfield where the conditions exceed the unacceptable, from 80% gravel and mud roads with excessive ruts, bumps and totally cruel conditions. I have since miled the truck out at 62,985 miles and now have got a new 2011 Dodge crew cab and installed the new set in at 745 miles. I am running these at 25 psi on air and will switch to nitrogen as soon as the opportunity arises. Your product works and works damn well—be proud of it. My next truck with rear coils will have them again.

8613371530291

8613371530291