ceramic plunger mud pump in stock

Explore a wide variety of ceramics plunger pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These ceramics plunger pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these ceramics plunger pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right ceramics plunger pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of ceramics plunger pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Explore a wide variety of ceramic slurry plunger pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These ceramic slurry plunger pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these ceramic slurry plunger pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right ceramic slurry plunger pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of ceramic slurry plunger pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Choose a used Plunger Pump from our inventory selection and save yourself some money on your next oilfield project. This equipment is used and may show some minor wear. Please contact us for additional information about its condition.

We offer wholesale pricing on new Plunger Pump and pass the savings on to you. Contact us to compare prices. This equipment is brand new and has never been used.

Our large network often has surplus Plunger Pump that go unused. Contact us to see what we have in inventory. This equipment is considered new but may have some weathering depending on wear it was stored. Surplus equipment is usually stored at a yard or warehouse.

We have refurbished Plunger Pump that have been used and brought up to functional standards. It is considered a working unit. Please contact us for more information about the product. This equipment has been used and brought up to functional standards. It is considered a working unit. Please contact us for more information about the product.

1. Wear resistance: The plunger is made of alumina ceramics and is finely ground. The hardness is above HLC8.5 and the surface roughness is 0.4um. The plunger and the conveyed materials have no shearing movement. It is suitable for conveying materials with sand and solid particles.

2. Strong self-priming ability: plunger-type vacuuming method, self-priming capacity 4-8 meters (the specific gravity of the material determines the change of the suction range).

3. Adjustable constant pressure automatic variable: the working pressure of the plunger mud pump is adjustable, and it can be adjusted arbitrarily within the range of 0-2MPa. The adjusted pressure will not change due to the change of the pump output flow, and the set pressure will remain unchanged , Even if the outlet of the running pump is shut down, the pressure will not change. (The change cannot exceed the maximum flow rate of the pump, the flow rate can be zero).

4. High pressure and high efficiency: The maximum pressure of ordinary models is 2MPa. When the pressure is ≥0.5MPa and the flow rate is the same, the power of the plunger mud pump motor is 1 to 2 models smaller than other types of pumps.

6. Low cost of use: The vulnerable parts of the pump are valve and plunger seal. The replacement cycle of ceramic slurry is 3-6 months, and the municipal sludge is 6-12 months.

8. Customized production of mud pump: The company can flexibly configure according to the actual industrial and mining requirements of each user, and customize various plunger mud pumps that are most suitable for the customers" needs.

K-S has put many engineering hours into its patented packing design, which involves stabilizing the plunger to move in only the vertical direction. This, in turn, allows for better sealing of the packing against the plunger.

Grit is still the biggest problem to the life of the packing and the plunger but this can usually be overcome by enhancing the materials of construction to more abrasion resistant materials such as ceramic or tungsten carbide coating plungers.

Replacement pressure washer pump pistons and plungers, we offer replacement plunger and piston kits for all major brands of pressure washer pumps, including Karcher, Annovi Reverberi (AR), General Pump, Hotsy, Hawk, Landa, Legacy, Comet and more!

Standard Industrial Manufacturing started in 1979. Our mission was to manufacture and supply pump parts to a few select pump retailers and OEMs. During the 1980s the company expanded its customer base to include all pump retailers and OEMs. Today, Standard has broadened its product lines to include most fluid-end expendables for all major pump brands.

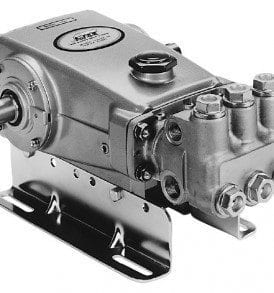

Aluminum crankcase with sight glass and vented dipstick; forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; solid ceramic plungers; nitrile seals (with fabric reinforcing); stainless steel valves and machined brass manifold.

Or maybe you’re going to be using a pressure washer for lower-pressure applications? Washing the sides of your house? Washing the family car? Washing the mud off your kids in the backyard—okay, that one is probably a criminal act, so don’t do it. Soft washing your roof?

Different types of pumps have different applications they work best for. The text below describes the differences and similarities between types of pumps, and the different applications each is best suited for.

For the most part, these two types of pumps function the same way. Both are reciprocating positive displacement pumps which pull water through an intake valve and into a chamber and push it—pressurized—back out through an outflow valve. These valves are engineered to be one-way only, meaning the intake valve will only open under negative pressure and the outflow valve will only open under positive pressure.

Duplex pumps have two pistons or plungers while triplex pumps contain three. This means duplex pumps must move faster to generate the same pressure levels as triplex pumps, consequently wearing their parts faster, and often causing a pulsating effect.

Triplex pumps last longer because each individual component has to do less work. Furthermore, the flow of water from triplex pumps is more constant, lessening the components’ strain even more.

Plunger pumps use a reciprocating plunger to pressurize water and force it through the outlet valve. The plunger is normally made out of hard ceramic, which is very durable and resistant to wear.

The plunger is attached via connecting rod to a rotor. As the ceramic plunger reciprocates out, it creates suction pressure drawing fluid through the intake. As the rotor turns, the plunger is pushed back down to send fluid through the outflow valve.

Similar to plunger pumps, piston pumps use reciprocating pistons to pressurize water and force it through the outlet valve. The difference between a piston and plunger pumps is the high-pressure seal. In a piston pump, the seal is attached to and reciprocates along with the piston.

Because of this, piston pump seals wear out faster and cannot handle as much pressure compared to plunger pumps. As the seal wears out, the power washer will suffer from reduced pressure buildup, resulting in a weakened stream and inefficient operation.

Pump failure is rarely the cause of power washer problems. The leading causes of pressure washer problems are system restrictions, which cause the pump to fail.

If the inlet hose or valve is not getting enough water to the pump, air is sucked in—this is called cavitation. When this mixture of water and air bubbles is pressurized it creates small explosions, damaging the pump and its components.

The easiest way to combat cavitation is to install a quality inlet valve and filter. This is especially true if the inlet source is a water tank, where many larger particles may sit and settle. If you are using particulates, such as sand, to assist with surface cleaning, make sure to use an appropriately-sized filter mesh to prevent clogging; you must also make sure your pressure washer has enough power to make sure the sand does not wash back into the machine, whereby ruining the pump.

Taken care of properly, with regular maintenance checkups, your pressure washer pump should last at least as long as the hour-rating it’s supposed to last for as per the owner’s manual. As we’ve said, actual pump failure is rarely the cause of the problem, but rather the result. Give us a call or submit a contact form with your questions, and we’ll do our very best to give you the right answer.

Unused Surplus Aplex MA-40M triplex pump. Aluminum bronze fluid end, 1 1/2" white ceramic plungers, gland adjustable 838 bronze packing, abrasion resistant valve assembly.

8613371530291

8613371530291