ceramic plunger mud pump free sample

Explore a wide variety of ceramics plunger pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These ceramics plunger pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these ceramics plunger pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right ceramics plunger pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of ceramics plunger pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Explore a wide variety of ceramic slurry plunger pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These ceramic slurry plunger pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these ceramic slurry plunger pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right ceramic slurry plunger pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of ceramic slurry plunger pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

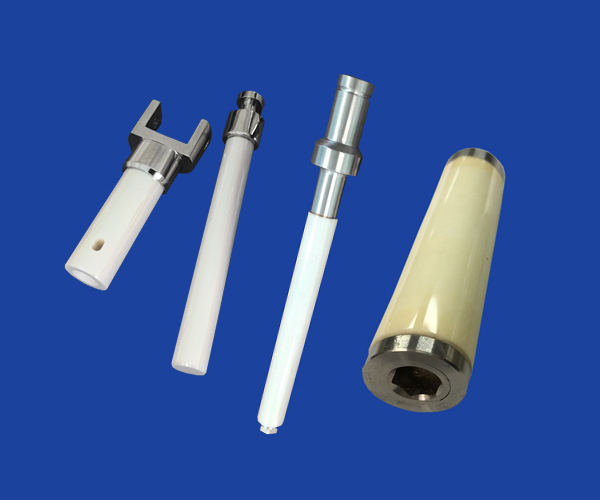

Spheroidal cast iron crankcase with sight glass and vented dipstick; forged, through-hardened, ground and polished crankshaft; bronze connecting rods; hardened stainless steel plunger bases; solid ceramic plungers; nitrile seals with fabric reinforcing; stainless steel valves and nickel-plated Spheroidal cast iron manifold.

Replacement pressure washer pump pistons and plungers, we offer replacement plunger and piston kits for all major brands of pressure washer pumps, including Karcher, Annovi Reverberi (AR), General Pump, Hotsy, Hawk, Landa, Legacy, Comet and more!

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... is a plunger metering pump with the option of adjusting the pump capacity in 0.2% increments. It offers a wide range of power end versions, such as three-phase or 1-phase AC motors, even ...

The plunger metering pump Makro/ 5 (M5ka) together with the Makro/ 5 hydraulic diaphragm and diaphragm metering pumps, form a range of drive mechanisms ...

... consumption of many other pumps on the market. Plus, the Python’s extreme duty plungers, seals and timing valve are designed for years of operation before replacement.

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

... pressure of 4,136 bar, KMT WATERJET SYSTEMS offers the STREAMLINE SL-VI STD high pressure pump as a lower priced alternative still featuring KMT"s advanced pump technology. The STD models can be operated ...

The NEOLINE pump has been developed with the aim of creating a robust, easy to operate pump. It is driven by a 40 hp (29 kW) three-phase motor which is equipped with vibration isolation pads ...

... to simple hand operated plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific ...

... to simple hand operated plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific ...

... to simple hand operated plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific ...

With operating pressures of up to 1,000 bar, the Y-series pumps are ideally suited to a wide variety of cleaning work, e.g. in the chemical industry, oil and gas industries as well as in the area of ship cleaning. Due ...

... high-pressure plunger pumps of the 2-series with operating pressures up to 750 bar and volumetric flow rates up to around 230 l/min are ideal for cleaning pipes and tube bundles, containers and containers. ...

... Abrasive Resistant Pump) high-pressure plunger pump series was developed specially for the conveyance of water contaminated with grainy or fibrous solids. The ARP high-pressure pumps ...

The “V” Series pump is a range of compact, self-contained, pneumatic metering pumps suitable for injecting a wide variety of chemicals that range from 0.07 gph to 9 gph (0.27 lph to 34 lph) and pressures ...

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... robust dimensioning of the pump drives, the determination of optimum clearance in the pump element and the application-oriented selection of high-strength steels with special heat treatment processes. ...

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

These models are equipped with a hydraulic motor-driven, triplex plunger pump; and include an unloader, gauge, and quick disconnect. Select models ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

Flojet Triplex Hi-Flow series pumps are designed for a wide range of applications and are constructed from a selection of materials suitable for handling a broad range of chemicals. ...

... cost-saving alternative to our diaphragm pump series: The LEWA plunger pump is a high-performance and versatile plunger pump for high-pressure applications in various industries.

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Triplex pump with connecting rod system. Pistons in ceramic-coated steel. Double gasket sealing system. Pump head in pressed brass. Automatic safety valve with pressure shut-off at pump ...

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small ...

... consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

JR500W pump is a horizontal single-acting reciprocating triplex plunger pump. Power end is self-lubricated by oil pump built onto the worm gear. Driven by worm pair, ...

... 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

Mystique Mud pump Coolant and Lubricant extends mud pump liner and piston life and provides internal lubrication and extra cooling to the coolant system of mud pumps. It extends the life of all liners, even ceramic. Mystique will not cause corrosion or rusting of iron, and is safe with all alloys. Recommened dilution rate of 12.5%. (25 gallons will treat a 200-gallon system.) For use on closed systems.

Other Industrial Pumps└ Pumps & Pump Accessories└ Hydraulics, Pneumatics, Pumps & Plumbing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Insufficient NPSH AvailableSuction pressure is incorrect meaning pump is cavitating. Ensure all valves are open, check liquid temperature. To correct increase fluid in tank, check for air ingress, remove unnecessary bends, increase pipe diameter, install feed pump.

Ensure all valves are open, check liquid temperature. To correct increase fluid in tank, check for air ingress, remove unnecessary bends, increase pipe diameter, reduce fluid temperature, install feed pump.

Bearing WearBearings can be worn by crankcase oil. Seal and packing wear results in liquid travelling along plunger rod allowing oil and water mix. Replace bearing as soon as oil leak noticed.

PulsationSuction pressure is incorrect meaning pump is cavitating. Ensure all valves are open, check liquid temperature. To correct increase fluid in tank, check for air ingress, remove unnecessary bends, increase pipe diameter, reduce fluid temperature, install feed pump.

Seals or CupsScored PlungersCheck for Chemical wear, hard water, and abrasive particles. Increase service intervals as high wear to lo and high pressure seals can cause male adapter to come into contact with plunger.

Inlet pressure too HighMaximum inlet pressure for piston pumps is 40psi (2.75 bar) and plunger pumps is 60-70psi (4-4.8bar). K Style pumps can accept higher inlet pressures.

Pump Dry RunningCheck Fluid level and that NPSHR is being met. Check inlet pipework, and filters for blockage, long suction lines, and presence of air ingress

Water in CrankcaseSpraying / Air CondensationProtect pump from direct spray with ventilated enclosure if necessary. Contaminated oil will damage bearings and other components within the drive.

Worn AdaptorSplit manifold designs of pumps have adapters within the pumps. Check O rings when servicing seals and valves and replace as required.

Damaged PlungerCan be caused by Thermal Shock, Chemicals or abrasives. Worn packings can allow the male adaptor to travel along plunger causing damage to it. Examine plunger when installing seals and replace if needed

Manifold Wear / DamageCheck chemical compatibility of fluid and any cleaning fluids used. Operation with worn seals and o rings can accelerate manifold wear. Erosion can be limited by freshwater flushing between pump use.

Manifolds can be damaged by over pressure which may be caused by high inlet pressure, relief valve or regulating valve failure or blockage within pump.

8613371530291

8613371530291