china heavy duty mud pump manufacturer

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Professional China China Heavy Duty Submersible Slurry Pump Mud Pump, We welcome new and previous customers from all walks of everyday living to get hold of us for foreseeable future business enterprise interactions and mutual achievements.

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for 60Hz Submersible Pump, China Hydraulic Submersible Pump, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our items. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires you should do not hesitate to contact us.

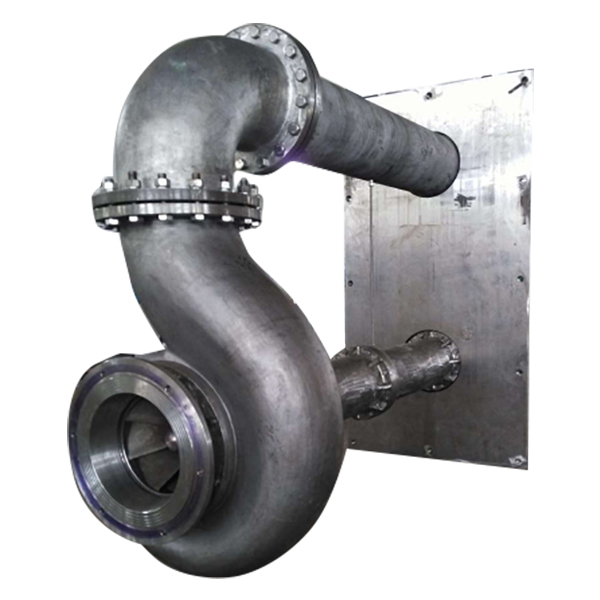

Heavy construction and advanced design techniques throughout insure high performance and long, trouble-free service life. Vertical pumps are self- priming and self-venting. Hazards of bottom tank openings are eliminated. Space is conserved. Fugitive emissions are effectively controlled with various options and accessories.

Every Taber pump has a thrust bearing to carry the dynamic thrust generated during pump operation. Since pump thrust is not transferred to the motor, standard motors and fl exible couplings can be used.

The impeller adjustment/locking mecha-nism is located above the support plate.This positioning permits convenient and safe access for ease of accurate adjustment with pump in the installed position.

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

Trades to drain off the sewage, waste water, rainwater and living water in cities containing solid grains and various long fabrics. Cooling: The built in cooling system can make the pump normally work whether the motor is on or under the liquid surface. Oil chamber: Oil can lubricate and cool the mechanical seal and realize the attached function of safety by preventing liquid from penetrating into the motor.

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for PriceList for China Heavy Duty Industrial Horizontal Mining Mineral Sand Pump Metal Wear-Resisting Chrome Water Pump Mud Pump Slurry Pump, Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided.

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for Affordable, China Customized, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

WX(R) & WXA(R) hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or corrosive slurries. Extra thick sections at the critical wear points and superior Impeller structure ensures improved performance with extended wear and minimised maintenance, thus improving cost of ownership.

Rubber lined pumps expand applications to chemical products handling, several different rubber options are available to meet different application requirements.Best fitted in aggressive applications, like mill discharge and tailing transfer

WXA( R ) pumps are improved version of WX(R) pumps, in that it has an adjustable wear plate seated in at the Throatbush. This can be adjusted while the pump is running.

Usage of versatile wear-resistant and corrosion-resistant materials allows WX(R)/ WXA( R ) series slurry pumps to service in various industries, such as mining mill discharge, delivery of tailings, ash removal in power plant, FGD and coal washing in coal plant, etc.,resulting in low operating cost, as well as minimized maintenance and down time.

BW850/2 heavy duty slurry pump is a horizontal, triplex reciprocating plunger pump. It has the advantages of compact construction, light weight, readily movable and easy to be operated etc. The pump can be driven by electric motor or diesel engine according to the requirement of the customer in order.

Sunbo slurry pump manufactures high quality heavy-duty horizontal slurry pumps, vertical slurry pumps, replacement pump parts, and provides pump services to a wide array of markets worldwide.we serve global industries that supply valuable raw materials to the marketplace with trustworthy and reliable pumps, parts, and service. We exist to provide unmatched engineering excellence, ...

Sunbo Pump supports the success of our customers and representatives by delivering quality slurry pumps and parts in a timely and conscientious manner, and maintaining a trustworthy and courteous relationship with each partners.

Hydroman was founded by Tobee in 2008"s as a manufacturer of heavy duty submersible slurry pumps in North of China. Hydroman mainly specialized in submersible slurry pumps, submersible sand pumps, submersible dredging pumps, Submersible agitator slurry pumps, Submersible Dewatering Pumps, Submersible sludge pumps, Submersible sewage pumps, hydraulic slurry pumps, hydraulic submersible dredge pumps, Excavator mounted hydraulic dredge pumps and all accessories like cutterheads, agitators, strainers, cooling jackets, excavator, sparge rings and hydraulic oil station etc.

Hydroman offers Heavy duty agitator submersible pumps and accessories in the Industry for handling slurries, rocks, gravels, sands, stones, sludge, mud,slag, minerals, bentonite, sewage, waste water and all other kinds of solids, with the shortest delivery times to world markets.

Over the past 20 years, Hydroman Pumps has been evolving based on our customer"s excellent ideas and feedback. Tobee Pumps have been investing heavily in ourselves; attracting top talent from all over the world, streamlining our processes and our systems, partnering with top universities for cutting edge research in hydraulics, hydra-efficiencies, mechatronics and corrosion and abrasive material handling, becoming ISO 9001 certified and designing a new range of modular submersible slurry pumps.

In the submersible pump design and manufacturing industry, Hydroman could make a durable, high quality slurry pump capable of tackling the toughest abrasive applications that any industry could throw at it. Hydroman is a manufacturer that thrives on a good challenge, applying common sense, solid experience, and a sense of what"s right to guide our problem-solving and practices.

Hydroman"s proprietary advanced Computational Fluid Dynamics (CFD) program allows us the accurately design the most efficient impeller vane and volute profiles to ensure longer wear life and more efficient operation of your submersible pump.

Hydroman® Pump has a wealth of experience in the manufacturing and service of pumps and accessories; in fact Hydroman® Pump has machinery manufacturing experience of over 45 years having achieved great success with R&D and manufacturing of Pumps for more than 20 years. The annual production capacity of pumps in our factory surpasses 10,000 easily. Hydroman® Pump has a tremendous market share that covers more than 120 cities in China including many provinces and autonomous regions and more than 80 countries.

Hydroman® Pump has over 80 sophisticated equipment such as CNC, Director reading Spectrometer, CMM (Coordinate Measuring Machine), Rapid typing Machine and etc. Based on these facilities, Hydroman® Pump has the abilities of material inspection, casting, welding, machining, assembling and the performance test of pump unit. The maximum weight of the casting by Hydroman® Pump is about 5 tons, the maximum diameter of the casting can be machined by Hydroman® pump is over 5 meters and the maximum flow rate of Hydroman"s Pump product is more than 1,000 cubic meters per hour. With an annual production of 1000~1200 pumps, Presently, Hydroman® Pump is the top 10 pump manufacturer with high comprehensive capacity of design and producing.

As a High & New Tech enterprise, Hydroman® Pump owns a municipal research center with strong R & D research capability and a team of more than 120 technicians along with 25 senior engineers and 17 experts etc. There are material laboratory, physical lab, chemical lab, 3D scanning equipment, MAXUM, 3D coordinate measure machine, metallographic analysis software, casting simulation software, CFD computer aided design, PLM (product lifecycle management), CAPP and etc. hardware and software in Hydroman® factory. In addition to these, Hydroman® Pump continually introduce new technology technologies to improve the products comprehensive performance, like Lost Foam Casting and Vacuum Casting technology.

Hydroman® pump"s humongous market share and its unrelenting competitiveness in the pump market have made us rank Top 10 in China for many years and were also selected as the Pacesetter Enterprise in the Chinese Industrial Pump Industry. This warrants enough proof of our distinctive position in the pump market today.

Since ours is a high tech enterprise of North of China, Hydroman® Pump has a municipal level research centre and has strong abilities in product research and development because of our powerful research team. We also like to profess that we have a long standing technical cooperative relationship with many renowned research institutions which only shows the strength of Hydroman"s R&D capabilities.

All the products manufactured by Hydroman® Pump are well received by our customers and have gained high appraisal from the society noting certain qualities of our products like energy saving, overall efficiency, stable operation and long service life. Some of our customers refer to Hydroman® Pumps simply as "Permanent Pumps" because of our quality and defect-free manufacturing ability.

Hebei Delin Machinery Co., Ltd. is one of the largest slurry pump manufacturers in China. Our products are sold widely throughout China and export to the world.

Hebei Delin Machinery Co., Ltd. is one of the mayors mud pumps manufacturers in China, with an area of over 40,000 square meters and a building area of over 22,000 square meters. The Delin mud pumps are widely used in mining processes and minerals, metallurgy, power, coal, petroleum, chemical in...

The construction of this DG series gravel pump is single stage, single suction, cantilevered and horizontal. This is a single casing pump. According to the driving type, it can be classified into two kinds of typical structures: self carrying bracket type, and gear box with pump together. Lubricatin...

DF (DHF) series vertical froth pump or centrifugal foam pump are designed with double casing design, including rubber lined froth pump, centrifugal pump, mining froth pump. These centrifugal foam pumps feature high efficiency, wear-resistance, stable performance and great interchangeability....

We provide various pumping solutions in China. The sump slurry pumps are designed for vertical cantilever type with single casing, double suction and semi-open impeller design. The impeller is made of high-chromium alloy or rubber. The gap between impeller and liner is adjustable, to assure the high...

Delin Machinery specializes in manufacturing slurry pumps, desulfurization pumps and dredging pumps in China. The pump designation Dredge DG series is based on research on dredge pump used domestically and abroad. We have done a lot of statistical analysis of dredging pumps and mud pumps....

Hebei Delin Machinery is one of the largest pump company specializing in the manufacture of mud pumps in China, with land area of over 40,000m2 and building area more than 22,000m2. The products are mainly used in the course of the river diversion, mining, metallurgy, urban planning, energy, coal,...

single stage slurry pump is also a type of centrifugal horizontal slurry pump. As one of the largest manufacturers of centrifugal pumps in China, we are committed to providing our customers with superior quality products and better customer service. Slurry single stage pump is designed for high pres...

Longteng Machinery have gained certification of ISO 9001:2000, and holds a compelte line for metal lined slurry pumps, like casting workshop, heat treatment, machining, assembling, quality testing etc.

Longteng machinery mainly produce 100% Interchangeable Warman slurry pumps and spare parts, such as Cr27 alloy A05 casting parts, slurry pump, dredging pump, gravel pump, submersible pump, rubber pump and spare parts.

8613371530291

8613371530291