china heavy duty mud pump supplier

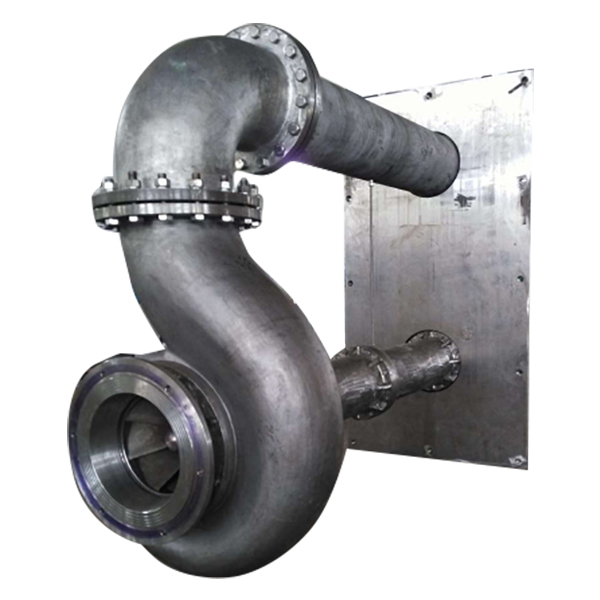

MCM 250 Mud Master Cantilevered Mud Pump MCM 250 Mud Pump is cantilevered pumps, used for handling strong abrasive and corrosive slurries. It is widely applied in 1.Mining (solids fluid transferring and dewatering) 2.Metallurgy 3.Coal washery 4.Power plant 5.Dredging 6.Building material 7.Waste and sewage treatment 8.Paper and pulp 9.Chemical process industry 10.Cement and blender 11.Water well drilling Materials of Construction The main wear parts of MCM 250 Centrifual Pump are wet parts. Quality Inspection The Quality Control Center is equipped with advanced precise quality testing instruments We have experienced wok team

BW320 Horizontal three cylinder single action reciprocating plunger pump Type Horizontal three cylinder single action reciprocating plunger pump Travel 110 Cylinder Diameter(mm) 80 60 Pump Speed(min-1) 214 153 109 78 214 153 109 78 Displacement(L/min) 320 230 165 118 180 130 92 66 Pressure(MPa) 4 5 6 8 6 8 9 10 Volumetric Efficiency(%) 90 Total Efficiency(%) 78 Power Needed(kw) 30 Large Belt Nodal Diameter(mm) φ480(C×5) φ480(C×5) Speed Input(r/min) 535 Suction Height(m) 2.5 Suction Pipe Diameter(mm) φ76 Discharging Pipe Diameter(mm) φ51 Dimension(LxWxH)(mm) 1280×855×720 Single Pump(Without Engine and Air Chamber) 1905×1100×1200 Entire Pump( Without Engine and Air Chamber) Weight(kg) 650 Single Pump(Without Engine and Air Chamber) 1000 Entire Pump( Without Engine and Air Chamber) BW160/10 horizontal triplex reciprocating acting Mud pump Name BW-160/10 Type horizontal triplex reciprocating acting Cylinder diameter 70mm Stroke 70mm Speed(r/min) 200 132 83 55 Displacement(l/min) 160 107 67 44 Pressure(Mpa) 2.5 4 6.5 10 Input torque 150N*m output speed 610r/min Power(KW) 11(electric motor) Power(KW) 14.7(diesel engine) Suction pipe diameter 51mm Drain pipe diameter 25mm Weight(Kg) 500(include electric motor) 560(include diesel engine) Dimengsion 1920×830×1000mm BW160 Horizontal type single-cylinder double-acting Mud pump BW250 Horizontal, Three-cylinder single-acting, reciprocal piston pump

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Professional China China Heavy Duty Submersible Slurry Pump Mud Pump, We welcome new and previous customers from all walks of everyday living to get hold of us for foreseeable future business enterprise interactions and mutual achievements.

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for 60Hz Submersible Pump, China Hydraulic Submersible Pump, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our items. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires you should do not hesitate to contact us.

Heavy construction and advanced design techniques throughout insure high performance and long, trouble-free service life. Vertical pumps are self- priming and self-venting. Hazards of bottom tank openings are eliminated. Space is conserved. Fugitive emissions are effectively controlled with various options and accessories.

Every Taber pump has a thrust bearing to carry the dynamic thrust generated during pump operation. Since pump thrust is not transferred to the motor, standard motors and fl exible couplings can be used.

The impeller adjustment/locking mecha-nism is located above the support plate.This positioning permits convenient and safe access for ease of accurate adjustment with pump in the installed position.

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

For Heavy Duty Mud Pump Suppliers, everyone has different special concerns about it, and what we do is to maximize the product requirements of each customer, so the quality of our Heavy Duty Mud Pump Suppliers has been well received by many customers and enjoyed a good reputation in many countries. Muyuan Pump Heavy Duty Mud Pump Suppliers have characteristic design & practical performance & competitive price, for more information on the Heavy Duty Mud Pump Suppliers, please feel free to contact us.

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for PriceList for China Heavy Duty Industrial Horizontal Mining Mineral Sand Pump Metal Wear-Resisting Chrome Water Pump Mud Pump Slurry Pump, Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided.

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for Affordable, China Customized, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

WX(R) & WXA(R) hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or corrosive slurries. Extra thick sections at the critical wear points and superior Impeller structure ensures improved performance with extended wear and minimised maintenance, thus improving cost of ownership.

Rubber lined pumps expand applications to chemical products handling, several different rubber options are available to meet different application requirements.Best fitted in aggressive applications, like mill discharge and tailing transfer

WXA( R ) pumps are improved version of WX(R) pumps, in that it has an adjustable wear plate seated in at the Throatbush. This can be adjusted while the pump is running.

Usage of versatile wear-resistant and corrosion-resistant materials allows WX(R)/ WXA( R ) series slurry pumps to service in various industries, such as mining mill discharge, delivery of tailings, ash removal in power plant, FGD and coal washing in coal plant, etc.,resulting in low operating cost, as well as minimized maintenance and down time.

Shijiazhuang Minerals Equipment Co., Ltd. is a professional Slurry Pump supplier in China. We are engaged in the manufacturing and producing of heavy duty and severe duty slurry pumps and spare parts.

If you need a sludge pump that can handle heavy-duty applications, look no further than our assortment of high-quality Jack Scaffolding pumps. All of our pumps are self-priming, which means that once the pump casing has been initially filled, the pumps will restart themselves automatically. These pumps are simple to set up and require only a little amount of maintenance on a yearly basis.

Judge the market for heavy-duty pumps around the world can be broken down into distinct submarkets based on the sludge pump type, product type, end-user industry, and geographic location. The market can be broken down into the centrifugal pump market and the positive displacement pump market based on the different types of pumps available. During the time period under research, it is anticipated that the segment comprised of centrifugal pumps will hold the largest share of the global market. The market can be broken down into segments such as crude oil, fuel oil, bitumen, and others on the basis of the product type. During the course of the research period, it is anticipated that the crude oil industry would lead the market for heavy-duty pumps worldwide. The oil and gas sector, the power industry, the processing industry, and other end-user industries make up the different segments of the market. The most significant portion of the market is held by the processing industrial sector. A centrifugal type pump and a positive displacement type pump together make up this sort of pump. Because of its extended service life and low maintenance cost, the centrifugal segment is anticipated to develop at a considerable growth rate over the projected period. This growth is predicted to contribute significantly to the overall market size. In addition, population growth, rapid urbanization and industrialization, and increased oil, gas, and electricity production are expected to drive the growth of the service centrifugal pumps market. These factors all drive water and wastewater management, which in turn drives the growth of the market for service centrifugal pumps. hefty. Heavy-duty centrifugal pumps are used in a variety of industries because of their high efficiency, high resistance to wear, and high flow capacity. Some examples of these types of businesses are power generation, the food and beverage industry, and others.

The application known as Quizlet contains a great number of flashcards pertaining to the sludge pump heavy-duty model. Quizlet is a web-based program for learning languages, and its website allows users to manage their accounts and review previously learned vocabulary. A user account can be created in this program by anyone, anywhere in the globe, and flashcards can be created on any subject under the sun. The sludge pump is a type of industrial pump that is typically used in municipal wastewater treatment applications as well as in mining, construction, agriculture, or industrial applications where heavy waste fluids are processed. Other common applications include mining, construction, and industrial applications. To begin, sludge is a distinct mixture that is typically made up of water as the liquid component and a variety of crushed solids as the solid component. This material is frequently used in a wide variety of industries, including the production of steel, mining, and power generation, amongst others. A strong sludge pump is an absolute necessity due to the fact that sludge acts similarly to a thick and viscous fluid. The experts classify sludge into two distinct groups: those that settle and those that do not settle. When the sludge is allowed to settle, coarse particles are produced. This leads to the creation of an unstable mixture, which in turn necessitates the use of a greater amount of pumping power. In the case of sludge that does not settle, the sludge in question is made up of particles that are relatively small and have low abrasion properties. However, selecting the appropriate pump for this category is also of critical significance.

Whether you handle oily mixes, bio waste, sewage, sludge, or lime slurry, one thing is certain: you"ll need a heavy-duty, high-pressure slurry pump. These sludge pumps are designed to provide a clog-free means of transporting sewage and are capable of handling viscous fluids containing solids. These pumps are used for high-pressure suction and contain a separate motor and inter-bearing impellers that allow for high heads to be achieved. Vertical sludge pumps and floating sludge pumps are the two categories of sludge pumps that can be distinguished by their installation orientations, respectively.

The Amazon website features products from a significant number of heavy-duty pump manufacturers from all around the world. Each of these factories is in the business of producing sludge pumps and selling them in significant quantities. Suctioning sludge, industrial effluent, or sewage using a self-priming sludge pump, which is also known as a sewage pump or thickening pump, is a common application for this type of pump. These pumps are classified as centrifugal pumps and are utilized for pumping fluids that contain solid particles. Their category describes their primary purpose. There is a movable diaphragm present in self-priming pumps; this diaphragm is responsible for the release of air, which is why these pumps are referred to as self-priming pumps. The decanter, which performs the same function as a centrifuge tube, is sometimes referred to as a solid screw centrifuge because it features a horizontal screw that revolves at a slow pace in relation to the bowl. Throughout the course of this procedure, solids are continually extracted and disposed of. As a consequence, this leads to great separation performance in a relatively compact space. Sludge decanters from GEA offer a solution that is both energy- and cost-efficient for industrial and hydraulic engineering. Decanters are devices that can be used to clean and treat sludge in addition to wastewater production procedures with costs that are minimized while achieving the highest possible levels of availability, quality, and efficiency. The cantilever in design, horizontal in orientation, and either lined with natural rubber or hard metal, the heavy-duty slurry pumps in the WA series are centrifugal. It is meant to be used in industries such as metallurgy, mining, coal, electricity, construction materials, and others that deal with high-density abrasive mud.

Made of aluminum and cast iron, this lightweight and efficient submersible sludge pump is durable enough for heavy-duty industrial strength and high performance and harbor freight, yet remains extremely portable with its slim design, ideal for a sewage pump that mixes sludge and water with solids and can run in any vertical, horizontal or upside-down position. The robust design provides a robust pump coupling ideal for harsh conditions while protecting the engine and being ready for use when delivered to the field. Whether you work in mining, tunneling, or construction, this pump is your best insurance against water-related breakdowns. From purchase to service, you can turn to DanPumps for dewatering solutions that work in the real world. Mud Pump Features

The frame plates of the WA series pumps have interchangeable solid metal or pressed rubber bushings. Impellers are made of solid metal or pressure-molded rubber bushings

Under harsh conditions such as sand, mud, stone, and mud, ordinary slurry pumps are prone to blockage, corrosion, and frequent failures. But heavy-duty slurry pumps are highly abrasion and corrosion resistant, meaning the pump will last better than pumps from other manufacturers.

Xtreme Pumps supplies a large number of pumps to the mining industry and heavy duties, both domestically and worldwide, which helps to cut down on consumption and maintenance costs. The impeller of the centrifugal sludge pump is one of the essential components of this type of pump. The selection of the mud pump impeller is extremely important to the performance of the mud pump, and this choice is dependent on the application. Due to the abrasive nature of mud pump impellers, mud applications present an extremely difficult set of challenges. It is imperative that the correct impeller be selected for a mud pump in order for the device to function effectively and endure the test of time.

There are three distinct kinds of impellers that can be found in mud pumps: open, closed, and semi-open. The specific use determines both the benefits and the drawbacks associated with each option. Some are more adept at managing solids, while others are more adept at operating at high efficiencies.

To ensure that the impeller of the slurry pump is resistant to wear, its size must be considered. For less abrasive fluids, slurry pump impellers are typically larger than mud pump impellers. The more "meat" in the impeller, the more effectively it can pump abrasive mud mixtures. Consider the impeller of the mud pump to be the offensive line of a football team. Typically, these players are older and slower. They were repeatedly beaten throughout the entire game, but they deserved it. This mode does not require a small player, just as a mud pump does not require a small pusher.

Tobee Pump TG Dredge Pump are the most comprehensive range of centrifugal gravel sand pumps for use in mining, chemical and general industry applications. The horizontal dredge pump are designed for heavy duty ... Read More

Tobee AH slurry pump are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee AH slurry pump are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee AH slurry pump are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee AH slurry pump are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee AH slurry pumps are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee AH slurry pump are the most comprehensive range of centrifugal slurry pumps for use in mining, chemical and general industry applications. The horizontal slurry pumps are designed for heavy duty ... Read More

Tobee G centrifugal sand mud pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently ... Read More

Tobee G Type Horizontal Centrifugal Gravel Pump for Sand Dredging is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling ... Read More

Polyuretahne Spare Parts for Centrifugal Slurry Pump are directly connection with slurries, It is very crucial to the service life of slurry pumps. The worklife of Polyurethane parts is longer than Rubber ... Read More

BW850/2 heavy duty slurry pump is a horizontal, triplex reciprocating plunger pump. It has the advantages of compact construction, light weight, readily movable and easy to be operated etc. The pump can be driven by electric motor or diesel engine according to the requirement of the customer in order.

Shijiazhuang Minerals Equipment Co., Ltd. is a professional slurry pump supplier in China. We are engaged in heavy duty and severe duty pumps. Being manufactured at the highest standards, our pumps ...

8613371530291

8613371530291