efficient mud pump replacement motors in stock

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Our motors meet the toughest industry specifications and standards and are built to the highest quality for our valued customers. We sell our motors individually, in combination with your pump as a bundle, or as a comprehensive package (including pump(s), motor(s), and control panel) to meet the needs of your specific application for the ultimate in cost-effectiveness no matter what your industrial automation needs entail. The future of the commodities markets lies in improving efficiency. Whether you are extracting, transporting, or refining energy, or operating a small to commercial-scale agricultural business, Replicate Pumps can assist you by dramatically improving your productivity level. Let us help you reach the heights that can place your business into the global market with a total industrial or agricultural automation system.

All of our motors and control panels are available completely assembled and ready to ship. In fact, we offer the fastest delivery in the industry. Our logistics team will work with you to ensure that you have the power you need, when and where you need it. We can also ship replacement parts. We sell most types of motors and pumps. If you don’t see what you need, contact us. We offer complete customization services for all industries throughout the world.

Replicate Pumps is a trusted pump and motor supplier for the oil and gas industry in Odessa, TX, across the nation, and around the world. We carry some of the most powerful and reliable pumps to provide clean water on oil platforms, as well as mix and transport all petrochemicals both on and off-shore. We offer a selection of stock pumps and motors or can custom-build exactly what your business needs to get the job completed safely and efficiently. A range of pumps and motors designed specifically to handle a wide range of needs specific to the oil and gas industry are available. Safety, extreme durability, corrosion resistance, and superior power are standard for all of our energy industry pumps and motors. Some of our most requested products include:

All motors, panels, and components are tested prior to shipment and very carefully packaged to virtually eliminate the possibility of damage during transport. Distribution centers are located throughout the United States for prompt nationwide and global shipping.

If you have already placed your order and require customer support, or are ready to order, contact Replicate Pumps directly. Our customers are our main priority and we are waiting to provide you with exceptional customer service. Call our friendly and knowledgeable staff at: (432) 258-3092. Expedited shipping is available for all in-stock parts.

As part of Experience 360, our Parts on Demand program lets you manage your replacement parts inventory at your regional location, pump site, or even via GD Energy Products Parts on Demand mobile trailers.

These Frac and Mud Pump Consumables are OEM-certified parts, designed, manufactured and tested by our Pump experts, and proven to maximize the performance on your operation. Our parts are always available, ensuring you have what you need, whenever and wherever you need it.

GE manufactures rugged electric drilling motors for the toughest applications in the oil and gas industry. The company has pioneered the electrification of the drilling rig and continues today to lead the way in manufacturing DC and AC drilling motors for land and offshore drilling rigs.

GE engineers, manufactures, and tests GE drilling motors to withstand the harshest requirements. They are used today driving drawworks, mud pumps, cement pumps, rotary tables, top drives, and anchor-handling winches on all types of drilling rigs, all over the world.

GE’s ongoing research and development efforts provide innovative and increasingly efficient technology continue to produce electric motors that are a more reliable and efficient power supply – especially in extreme weather conditions – and able to decrease noise on the rig, making a safer working environment. Combined with a potentially smaller “envelope,” this makes GE motors a better solution to meeting your rigs’ power supply requirements.

GE drilling motors are performing worldwide on all types of drill rigs, providing dependable operations of the rig’s primary equipment. GE drilling motors have been reported by rig operators to run for years without service or failure.

The company has a worldwide network of authorized service facilities such as, Gulf Electroquip in Houston, Texas, USA, for both its AC and DC drilling motors. These service facilities are audited and GE’s personnel have been trained to assure that they meet the quality standards required to repair GE’s drilling motors.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

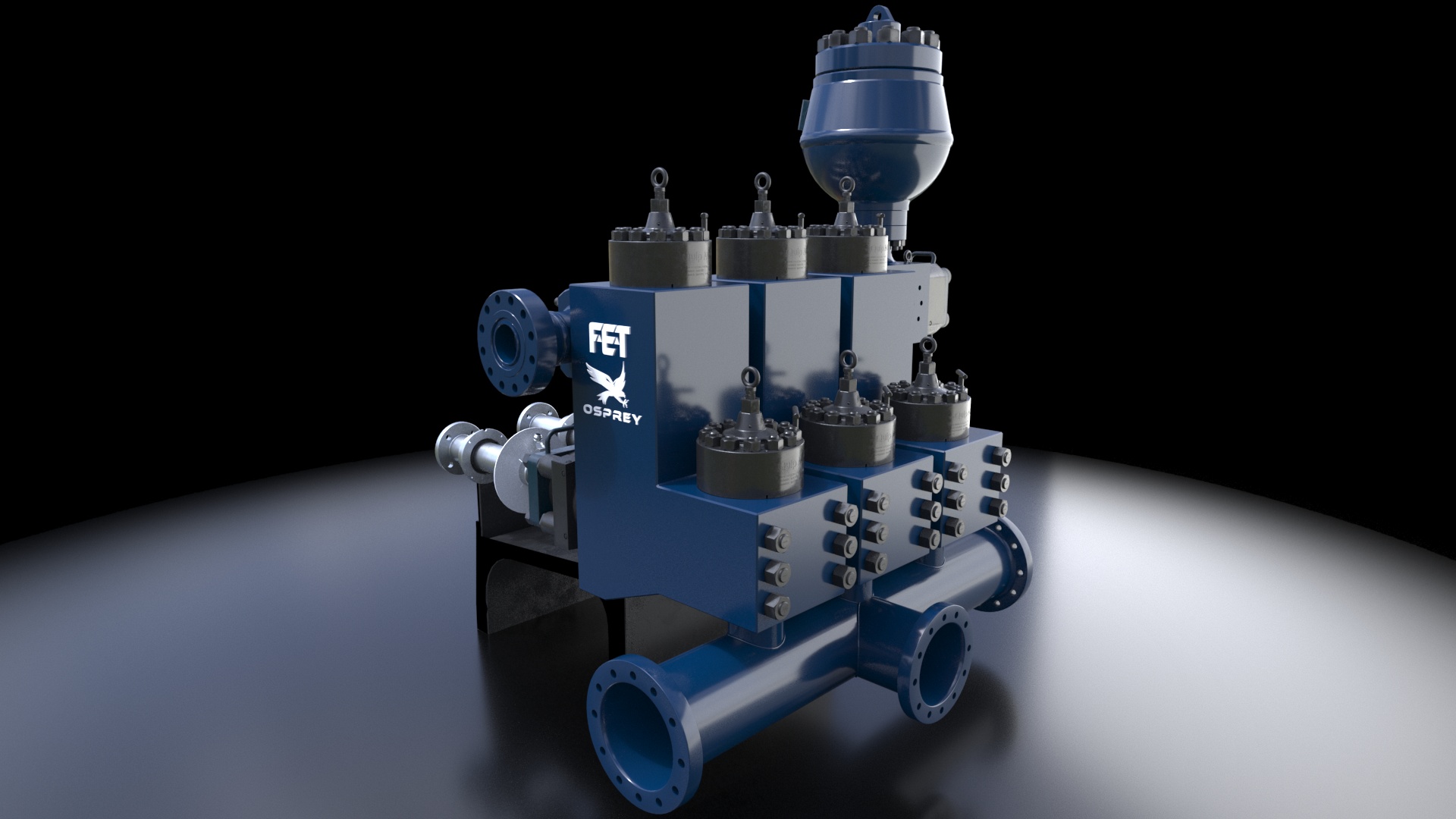

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

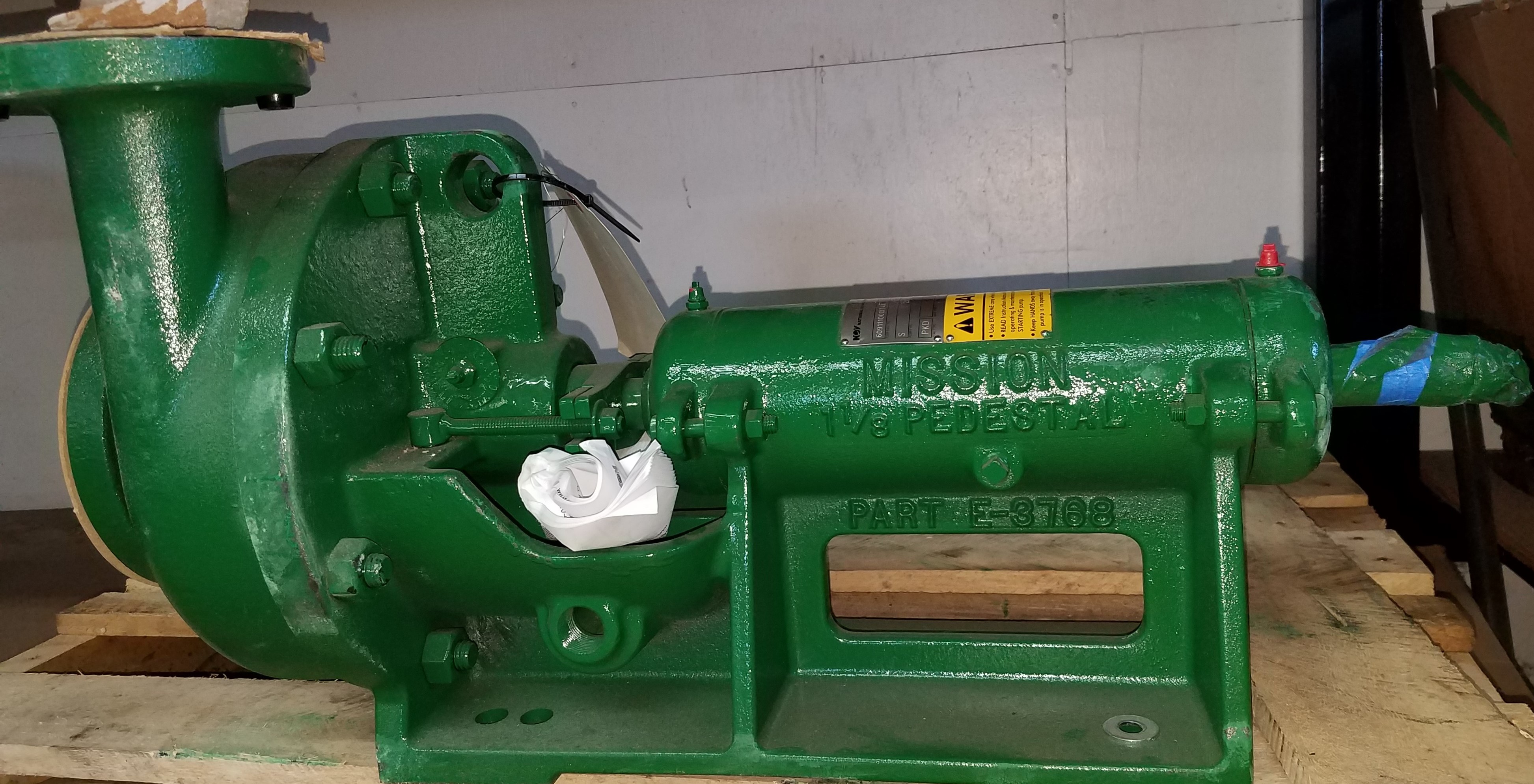

We provide oilfield spares and spare parts for many major U.S. manufacturers and equipment, including: Airesearch, Elliott, Emerson Process, Continental Emsco Mud Pumps, Gardner Denver Triplex Pumps, Gaso Mud Pumps , Garrett, Harrisburg , Centrifugal Pump, Honeywell, Mission Centrifugal mud pumps, Mud Pump Expendables, National Mud Pump , NOV, Pratt & Whitney, Trico, Rosemount Analytical, Union Pump, Varco, Veritrak, Web Wilson, Wilson Snyder, Wheatley Mud Pumps, and Westinghouse Transmitters and obsolete and hard to source items.

From annular blowout preventer’s parts to RAM BOPs, from mud pump parts to Drawworks spares our goal is to provide our customers with the best quality and value in aftermarket, OEM, and reverse engineered replacement parts for such commodities as oil field equipment, refineries, and pipelines.

Titan Oil Tools understands our customer"s critical need for high-quality USA made oil tools and parts, delivered on time, when and where you need them. Titan Oil Tools will provide the highest quality oil tools and oilfield parts and equipment made in the USA. We offer a complete line of oilfield supplies; equivalent repair parts and used equipment for Garret, Mission, Elliott, Varco, Airesearch, Continental, Guiberson type replacement parts and more.

Mud Pump Spares; Mud Pump Consumables - "L" Modules - We sell high quality mud pumps spares, mud pump parts, and mud pump expendables including; mud pump liners and mud pumps pistons. They are competitively priced and have an outstanding service life. Manufactures include; Brewster, Continental Emsco, Ellis Williams, Gaso, Gardner Denver, IDECO, National, Oilwell, OPI, Wheatley, and Wilson.

Mission type mud pump liners. We are one of the few companies worldwide specializing in; and stocking “Mission” type high temperature mud pump liners. Our "Mission" type liners are formulated with two rare metals not found in common everyday liners. All of our "Mission" type mud pump liners include the seal ring and are individually packed for immediate export, offshore or domestic oilfield use. Manufactured to OEM specifications, our Mission type Discharge Module and Mission type Suction Module come complete with studs and nuts installed.

Titan Oil Tools is major supplier of expendables for mud pumps. We stock pistons, seats, valves for popular brand duplex mud pump parts and triplex mud pump parts. Call us for all your mud pump expendables.

We supply Wheatley mud pump parts, Ideco mud pump parts, Emsco mud pump spares and Gardner Denver mud pump parts and many more manufacturers. Call us for quality and the best prices.

We supply quality swabbing equipment which may include the swabbing assembly, shut-off valve on the well, also called a swabbing valve and also the lubricator. Parts may include Guiberson style oil tools replacement parts under the Titan name. Titan brand has equal specifications to Guiberson oil tools and is made in the USA. We can provide replacements for Guiberson Rope Sockets, Guiberson Hydraulic Oil Savers, Guiberson Safety Tools, Guiberson Sinker Bars, and Guiberson Tubular Jars.

Blowout preventer parts, Blowout preventer spares and blowout preventer replacement parts made in the USA. Our BOP parts , BOP spares, feature outstanding quality. We have Cameron BOP parts, Hydril BOP parts and Shaffer BOP parts.

Downhole tools for high-performance torque reduction and hole enlargement. These tools also will provide a major resistance reduction. Call us for genuine GE drilling motors, motor optimizers, mud motors, shock subs, drilling jars, downhole tool data loggers and more.

OIlfield supply parts include: Hydraulic gate valves, hydraulic check valves, blowout preventer parts, BOP parts, mud pump parts, mud pump spares, drawworks parts, drawworks tubing drum, drawworks bearings, drawworks seals.

Titan Oil Tools can provide AiResearch gas turbine parts and AiResearch gas turbine industrial turbochargers. Make your gas turbine the most efficient combustion turbine with our AiResearch turbochargers and gas turbine parts. AiResearch Gas turbine turbocharger parts achieve a higher degree of efficiency than other types of gas turbines.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

A mud motor is no more effective than the volume of fluid that is pumped through it, which generates power. If the mudflow is on the low side of specifications, the mud motor will have low bit speed and a slower penetration rate. As the pumping rate increases toward the maximum of the flow specification the motor is more powerful and efficient. This is why it is essential to match your mud motor size with the available deliverable mudflow from the pump.

Most mud pumps used in the directional boring industry run at higher speeds to operate mud motors. The draw back is that the mud pumps lose operating efficiency, particularly as mud viscosity increases and the effect of entrained air in the mud magnifies. The pumps experience incomplete filling on the suction phase of the stroke, causing a drop in the volume of fluid actually being pumped.

A properly designed, pressure-fed piston or plunger pump generally has a 96 to 97 percent volumetric efficiency. The loss is due to valves not opening and closing instantly. This efficiency goes down as mud viscosity increases and drops like a rock, if air is in the mud. Air is a hidden monster that can drop the pump efficiency to 50 percent or less. The biggest cause of entrained air in the mud is the cleaning system and its design. By the very nature of cleaning mud, agitation occurs which mixes air into the mud. Higher viscosity mud makes air entrapment worse. The design of the cleaning system must give time for the mud to expel this air before it enters the suction manifold of the pressure pump and cause cavitation damage and loss of pump efficiency. A cleaning system that eliminates sand from the mud will also reduce repair costs to mud motors and pumps.

Small internal diameters of the piping and hoses cause pressure losses as pumping rates increase. This robs available pressure away from the motor, causing a decrease in motor torque and slower boring. The smaller I.D. of the drill pipe of some rigs also tends to require a higher surface mud system pressure to off set piping losses.

When talking about mud pump capabilities, you have to keep in mind that when flow rates are represented by manufactures, it is usually a calculated volume based on pumping water at 100 percent efficiency. Air in the mud, the size of the restricted passages, mud viscosity and the length of the various restrictions reduce the true working efficiency of the pumps.

It almost goes without saying, but any leaks on the pressured side of the pump, including a leaking piston or plunger packing, reduce efficiency. Sonde housings that have broken windows and allow mudflow to divert out of them reduce efficiency. Leaks in the suction hoses can allow air to enter the system or allow cleaned mud to be lost. What can be done to help eliminate some of the inherent problems so that more mud can get to the motor and bit and do the best job for the work at hand?

Use larger pumps than are needed so that the mud pump does not have to be operated at 100 percent. Seventy-five percent of rated speed is a good maximum operating rpm.

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes, and why it is important? In order to understand that, you’ll need to know some basic information about mud pumps.

Knowing how a mud pump functions is important in understanding the role a pump stroke counter plays in rig operations. Mud pumps act as the heart of the drilling rig, similar to how our heart works. Just as our heart circulates blood throughout our bodies, a mud pump circulates essential drilling mud down the hole and back up to the surface. Mud tanks house drilling mud, and a mud pump draws the fluid from the mud pump. A piston draws mud in on the backstroke through the open intake valve and pushes mud through the discharge valve and sends it towards the rig. By circulating fluid, the mud pump ensures that the drill bit is cool and lubricated and that cuttings are flushed from the hole. The two main kinds of pumps used are duplex and triplex pumps, where the duplex pump has two pistons and the triplex pump has three. Whether the rig is using a duplex or triplex pump, it is important to know how many strokes per second the pistons are moving. The driller monitors strokes per minute to determine how much costly, yet essential, mud is being pumped into the system with the use of a mud pump stroke counter system. Now, that you know about mud pumps, you’ll need to know what’s in a stroke counter system.

Stroke Counter — The stroke counter stainless steel box is mounted on the driller’s console and is either square or rectangular in shape, depending on the number of pumps it is monitoring. Stroke counters will show strokes per minute and total strokes, and when a particular mud pump is operating the strokes/minute and total strokes will be displayed. Power is supplied by a 3.6 volt lithium battery, and the counter contains a crystal-controlled real time clock with 100 parts per million accuracy or better. Each counter is mounted to the console with 1/4” stainless steel hex head bolts, lock washers and nuts.

Micro Limit Switch — The micro switch is connected to a c clamp near the mud pump piston. The micro switch stainless steel rod (sometimes called a whisker) sticks out in the piston housing near the piston. As the piston passes the rod, it moves the rod and the switch sends an electronic signal back to the counter. The counter increases by one each time the piston moves the rod, counting the mud pump’s strokes. The switch’s signal is then transmitted to the stroke counter. These micro switches are built to stand up to demanding outdoor conditions. They can withstand shock, equipment vibration, extreme temperatures, water and dust.

Cable and Junction Box – A cable is connected to the back of the pump stroke counter and then to the junction box. From the junction box, the cables travel to the limit switches.

Pump Stroke Counters are like a blood pressure machine. Each time our heart pumps, a blood pressure machine reads our systolic and diastolic blood pressure by way of our pulse. A mud pump stroke counter functions in much the same way. Just as a blood pressure machine detects our pulse so too does a limit switch rod detect the movement of the piston. When the stainless steel rod is moved, the micro limit switch detects the movement. The signal is sensed as a contact closure, and it is transmitted to the stroke counter where the contact closure is converted to a logic pulse. The pulse feeds two separate circuits. The total strokes circuit reads and displays the closures one at a time, totaling them up to reveal the total strokes in the LED window. The second pulse is sent along a separate circuit which is a rate circuit. This rate circuit will average the closures against the real time clock. The result is displayed as the total strokes per minute.

Pump stroke counters are essential to drilling rig operations because they measure the efficiency of mud pumps. Knowing strokes per minute and total strokes of the pistons helps the driller to determine if the correct amount of mud is going down hole. Having this information aids in running a drilling rig at peak efficiency, assists in extending drill bit life, and avoids costly overuse of drilling rig mud. Unsure which pump stroke counter is right for your application? Give our friendly, knowledgeable staff a call or email. We’ll keep you turning right.

A mud pump is a piston driven pump design that can produce high-pressure operations to safely transfer high viscosity fluids over an extended depth. The mud pump has many applications in industrial service, but it has proven to be invaluable in many drilling operations. Let"s take a look at mud pumps and why they are such a good fit for the industries they serve.

A Mud pump is a reciprocal pump design utilizing a piston in a cylinder to transfer fluids under high pressure. A mud pump can generate up to 7,500 psi (52,000 kPa) during normal operations. Mud pumps are a positive displacement design.

Mud pumps are available in a variety of configurations and sizes. However, mud pumps tend to be one of two main types: the duplex and the triplex. The duplex mud pump features two pistons (or plungers) in constant action to move the fluid.

The triplex mud pump has all but replaced the duplex version in most applications, although you will still find the latter in use in some smaller countries. The triplex mud pump features a triple piston (plunger) design that is more efficient than the duplex design.

The latest designs of the mud pump are the quintuplex and hex versions. As the name suggests, these designs feature five or six pistons in a reciprocating design. Although not in widespread use as compared to the triplex design, these mud pumps spread the pumping action across the rotational cycle, creating less mud noise. This allows for better measurements and logging to take place while in operation.

There are two main parts to a mud pump: the fluid end and the power end. The fluid end is where the actual pumping takes place. The components of the fluid end consist of valves, pistons (or plungers), and liners.

Since the fluid end is in constant contact with the material being pumped, most modern designs allow for quick replacement of worn components as needed. This dramatically extends the life of a unit without having to completely replace the pump.

The power end of a mud pump is responsible for taking the input power, typically through a driveshaft, and converting it into the reciprocating motion needed for the pistons. In most mud pump applications, the power end uses a crosshead crankshaft for this conversion.

Rotational power is supplied to the mud pump through an external power source. The power end of the pump converts this rotational energy through a crankshaft to a reciprocating motion that moves the pistons.

Due to the pressure and material being pumped, most mud pump applications can create a lot of vibration. To combat this, many mud pump applications incorporate pulsation dampeners. These are typically used on both suction and discharge sides of the pump.

In some cases, a positive displacement pump may pull the fluids at a pressure lower than its vapor pressure. When this happens, damaging cavitation can take place. In these cases, a charge pump might be required at the inlet side to maintain a positive pressure on the suction stream.

When selecting a mud pump, there are two main parameters to be used, pressure and displacement. Pressure is the net pumping pressure that the pump can safely provide. The requirement for pressure increases as the drilling depth and fluid (or slurry) viscosity increases.

Displacement is the volume of fluid that the pump can transfer within a given time period. In most applications, this is rated as discharged liters per minute.

Mud pumps are ideal wherever a lot of fluid needs to be pumped under high pressure. They are considered an essential part of most oil well drilling rigs. Mud pumps can deliver high concentration and high viscosity slurry in a stable flow, making them adaptable to many uses.

Mud pumps are an invaluable tool when high pressure and high viscosity fluids are needing to be transferred. Mader Electric, Inc. specializes in mud pump repair and installation, as well as pump training. Contact us to see how we can help with your pumping needs.

8613371530291

8613371530291