efficient mud pump replacement motors brands

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

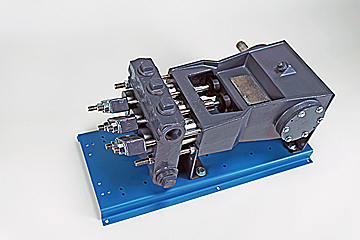

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

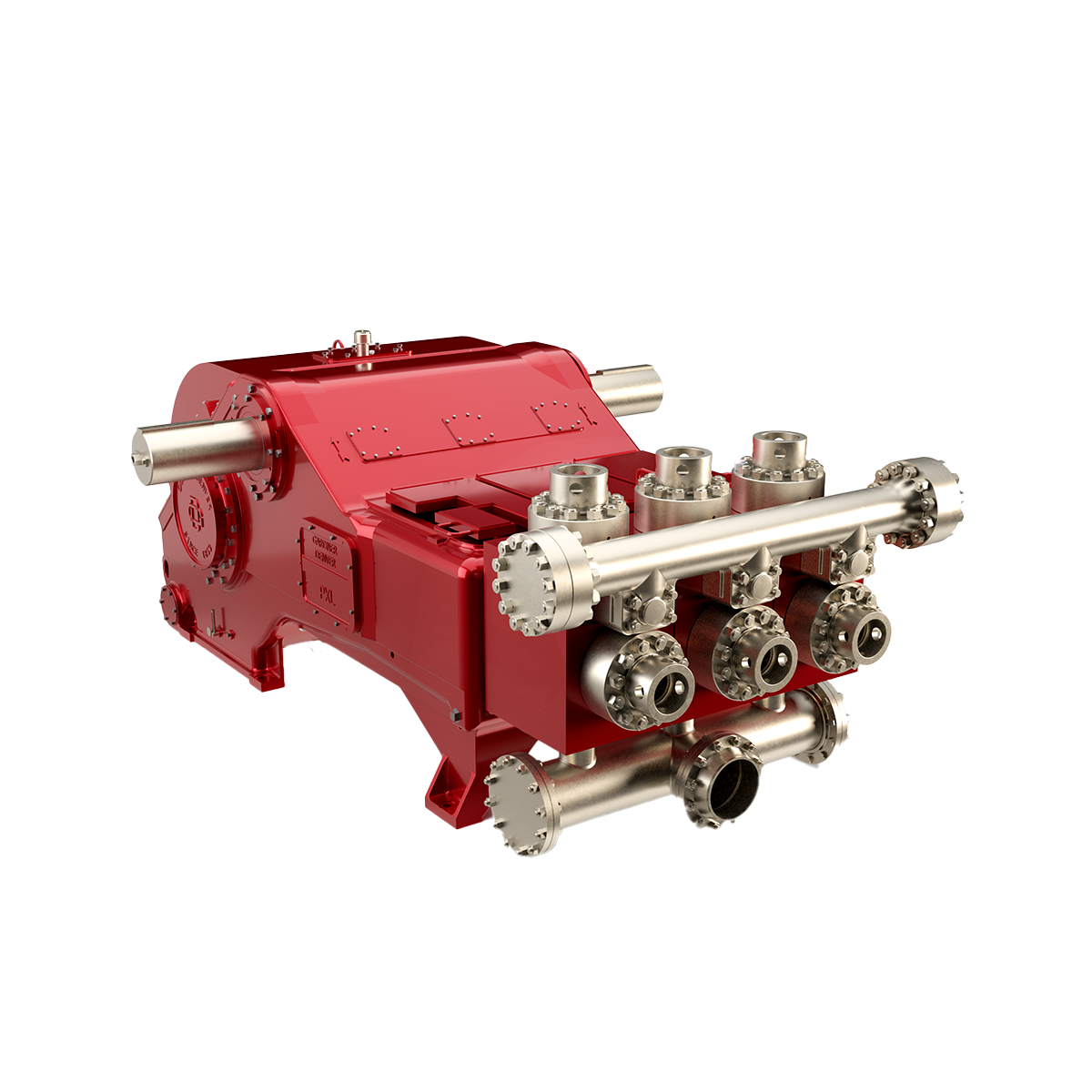

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

Oil Baron Supply provides a unique value to our customers by offering a one-stop shop solution for packaged systems. We work with customers to define the package, design the system, procure the materials and construct the complete package. We manage the entire process to minimize the design and project risks. Working with our suppliers to provide innovative components such as lightweight, high pressure pumps, efficient motors and auxiliary components.

Oil Baron Supply is also leader in supplying mud pump fluid-end and consumable parts trusted by drilling companies across the Asia Pacific Region. We provide a full-portfolio of parts to keep your mud system performing efficiently and reliably. We have a large warehouse of comprehensive stock where most of the interchangeable mud pump expendables and spares parts can be found which covers a wide range of brands, such as; Emsco, Bomco, Gardner Denver, Ideco, NOV, TSM, Weatherford and Wheatley.

Powered by Honda GX120 Commercial Engine gas. Replaced by newer model 338G-96. AMT 2" Diaphragm pumps features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps, mudhog or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick water liquids that have the ability to flow. AMT IPT Diaphragm pumps are available with a choice of drivers to meet your application requirements. Phelps HoneyWagon Wastecorp

Honda gasoline engines. Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Heavy duty gear box is designed to operate pumps at 60 strokes per minute. Each unit includes a 2" NPT steel suction strainer, two 2" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Mud Trash pumps Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

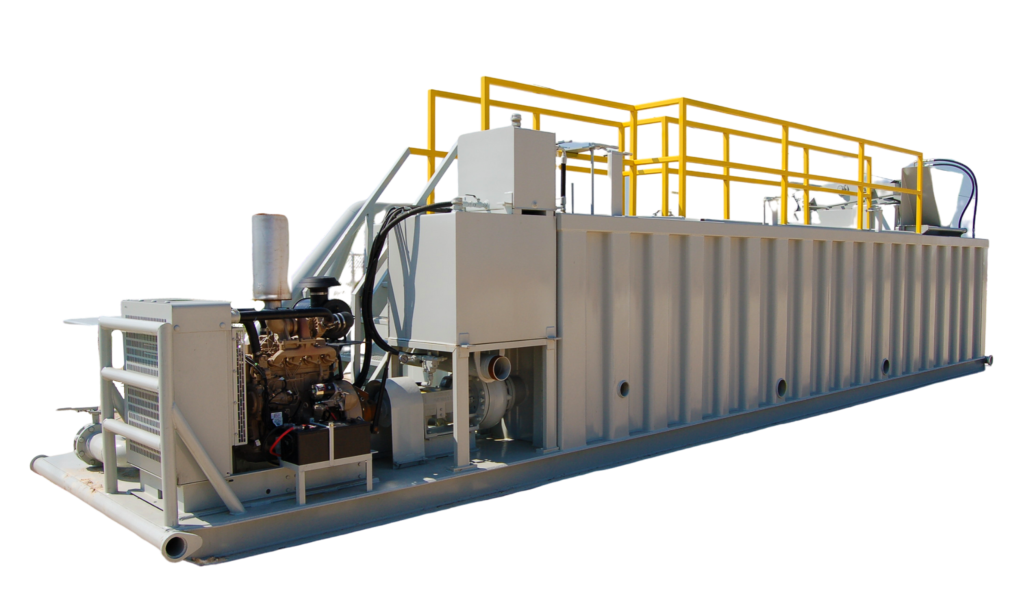

Castle Pumps were approached by an oil and natural gas company installing a new piece of drilling equipment aboard their offshore platform. They required high viscosity pumps to transfer the oil based mud which is a fluid used during the drilling process. The viscosity of oil based mud can vary and it contains both soft and hard solids. There were various special requirements for these oil based mud pumps including explosion proof ATEX motors, dry running protection devices and variable speed drives.

We have experience with transferring viscous slurries and knew our range of progressive cavity pumps would be well suited for the application. The Diamond series can handle up to 1,000,000CP and is able to transfer both soft and hard solids in suspension.

We supplied progressive cavity pumps complete with ATEX motors, planetary variable speed drives and thermic probes that protect the pumps against dry running. To ensure the pumps were as reliable as possible and to avoid any down time, we also supplied two years operational spares for the pumps including stators and rotors. Further to that, we supplied counter flanges for the pumps to allow them to be installed immediately when they arrived at site.

These progressive cavity pumps were manufactured in under five working weeks and packed in wooden crates according to ISPM 15 and delivered directly to site in Angola. This project is another example of Castle Pumps’ flexibility in ensuring all of the customer’s requirements are met.

⊙Mud pump spare parts of abroad brand:Eg. Liner, piston, valve assembly, valve seat, valve spring, valve rubber could be alternative for original with lower price.

⊙Original brand:Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford.

TR provides high quality Mud Pump replacement parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve & Seat etc. We are dedicated to assisting worldwide clients with most cost-effective and quality guaranteed mud pump liners, pistons and other mud pump replacement parts. Reducing the mud pump production cost is our priority so that significant saving can be achieved for our valuable clients and end users.

TR liners offer both ceramic mud pump liners and high-chrome mud pump liners (bimetal liner) with excellent resistance to abrasion, erosion and corrosion for most mud pumps in worldwide. Advanced anti-wear measures are adopted and highest-grade materials are selected in our mud pump liners production to increase their service life, which can reduce our clients’ investment cost of the project, and improve their production efficiency.Replacement Mud Pump Liners for Gardner Denver PZ 6/7/8/9/10/11

TR provides a wide series mud pump liners for all major brand mud pumps. We also offer custom design-built service per our clients’ drawings and specifications

TR also offers high quality replacement parts for all major brand mud pumps including valve module, piston/extension rods, pistons, valves and seats etc.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

UDS International designs and manufactures heavy-duty centrifugal mud pump parts and equipment with innovative designs for optimum output and reliability.

Mud pumps are an important part of your drilling, tunneling and/or mining dynamics, helping to maintain drilling mud circulation through your drilling rig column, which improves the efficiency of drilling operations and reduces wear on your equipment.

UDS effective mud pump parts and equipment have the durability to meet the demands of high pressures, a range of ground conditions and are easy to maintain.

The Mount Wilson Solar Observatory was first funded by the Carnegie Institution of Washington in 1904. The site is an astronomical observatory in Los Angeles, California and contains two historically important telescopes: the 60-inch Hale telescope built in 1908 and the 100-inch Hooker telescope. The facility is used for astronomical research and offers visitors guided tours. In 1911, A Deming Triplex pump with a 15 HP motor was installed to supply the pressure for the fire hydrant system. It operated continuously for an estimated 50 years until an entire system upgrade in the 1960’s obsoleted the pump. In 2008, there was a need for a backup firefighting unit while the new system was being serviced. The 1911 Deming Triplex pump was resurrected for the application. After routine servicing the pump operated without any issues. The Deming brand was the first pump line manufactured by Crane Pumps & Systems and offers a full line of highly regarded municipal and industrial pumps today.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

From industrial wastewater to fire suppression systems or commercial pools, ABB"s Baldor-Reliance® Pump motors provide value by increasing system reliability and reducing maintenance costs. Utilizing energy efficient designs, our inverter duty pump motors meet the NEMA Premium® efficiency standard with wide variable torque speed ranges. Pump motor construction can be tailored for specific applications and industries such as food processing, washdown applications or explosion proof enclosures for pumps in hazardous areas.

Incorporated in 2002, White Star"s triplex mud pumps and replacement parts for Ideco pumps are found offshore and on land rigs around the world, providing oil and gas drilling contractors with industry-proven solutions that not only meet but exceed their operational requirements. Realizing the increasing availability of low-cost, inferior mud pumps on the market today, White Star Pump has renewed its commitment to delivering mud pumps with a focus on quality, superior design, in-stock replacement parts for Ideco pumps, and dependable field service.

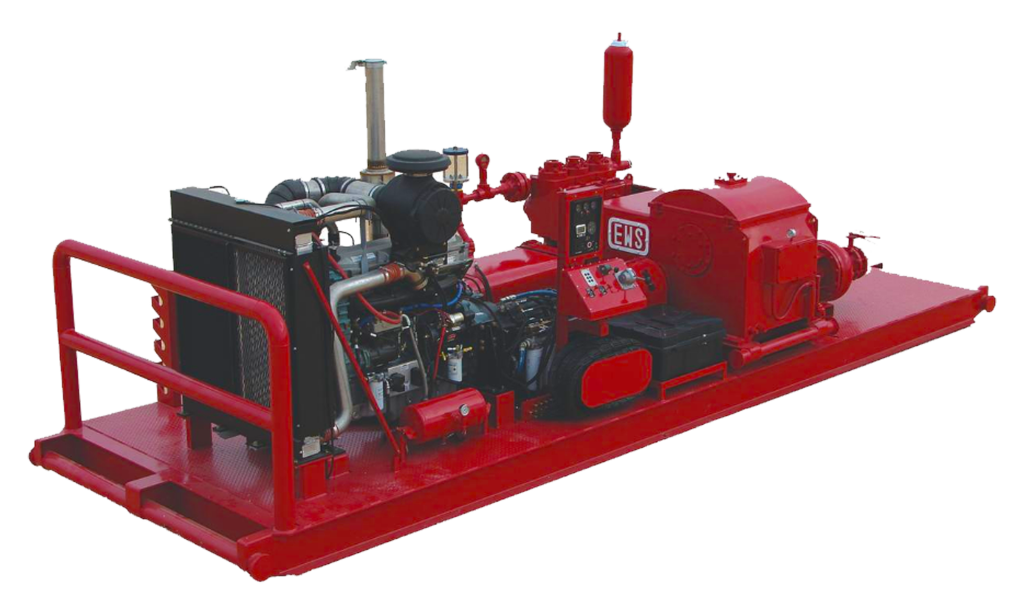

The Quadraplex "Quatro" is a low-maintenance, high-performance mud pump that boasts up to 1597 GPM and , when unitized, is the narrowest in its category on the market today.

With this unprecedented, space-efficient design, White Star has introduced in 2009 a fully self-powered, hydraulically unitized trailer-mounted model of the Quatro that requires no rig power. This highly mobile unit serves as a perfect emergency back-up or supplementary pump on critical well sections.

White Star Pump designs, manufactures, and services high-performance mud pumps for oil and gas-drilling operations worldwide. From Ideco-interchangeable parts to ready-to-ship, fully unitized mud pumps, White Star has the solution you need to increase operational efficiency and maximize profits

8613371530291

8613371530291