efficient mud pump replacement motors price

Explore a wide variety of electric mud pump price on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These electric mud pump price are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these electric mud pump price is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right electric mud pump price for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of electric mud pump price to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

TR provides high quality Mud Pump replacement parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve & Seat etc. We are dedicated to assisting worldwide clients with most cost-effective and quality guaranteed mud pump liners, pistons and other mud pump replacement parts. Reducing the mud pump production cost is our priority so that significant saving can be achieved for our valuable clients and end users.

TR liners offer both ceramic mud pump liners and high-chrome mud pump liners (bimetal liner) with excellent resistance to abrasion, erosion and corrosion for most mud pumps in worldwide. Advanced anti-wear measures are adopted and highest-grade materials are selected in our mud pump liners production to increase their service life, which can reduce our clients’ investment cost of the project, and improve their production efficiency.Replacement Mud Pump Liners for Gardner Denver PZ 6/7/8/9/10/11

TR provides a wide series mud pump liners for all major brand mud pumps. We also offer custom design-built service per our clients’ drawings and specifications

TR also offers high quality replacement parts for all major brand mud pumps including valve module, piston/extension rods, pistons, valves and seats etc.

Powered by Honda GX120 Commercial Engine gas. Replaced by newer model 338G-96. AMT 2" Diaphragm pumps features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps, mudhog or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick water liquids that have the ability to flow. AMT IPT Diaphragm pumps are available with a choice of drivers to meet your application requirements. Phelps HoneyWagon Wastecorp

Honda gasoline engines. Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Heavy duty gear box is designed to operate pumps at 60 strokes per minute. Each unit includes a 2" NPT steel suction strainer, two 2" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Mud Trash pumps Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

Is it time to replace the fuel pump? The fuel pump is responsible for transferring fuel from the gas tank to the vehicle’s engine. With a malfunctioning fuel pump, the engine won’t have fuel to keep the vehicle running. If this necessary component is failing, it can cause severe drivability and performance issues and has to be dealt with if you want a reliable, driveable vehicle. So how much will it cost to fix the fuel pump? As per yourmechanic.com, a completefuel pump replacement cost at a mechanic shop can land anywhere between $532.97 and $1,187.35 depending on factors such as the vehicle’s make and model and where the vehicle is fixed.

We will explain the types of fuel pumps, the signs of a bad fuel pump, and how a good mechanic will replace the fuel pump. We will also go through fuel pump repair cost breakdown.

As per repairpal.com data – “The average fuel pump replacement cost is between $834 and $874 with about 80% of the cost being the cost of the parts“.You may be able to find fuel pump parts for $50. Good quality fuel pump sets can cost between $200 to $1000. Labor costs are $150-$350. More expensive vehicles with complex designs can cost $2,500 to have a fuel pump replaced.

Here is a chart from YourMechanic.com that shows the average cost of fuel pump replacement for different vehicles. Cars Parts Cost Labor Cost Average Dealer Price

Automotive fuel pumps are either mechanically or electronically operated. Modern-day vehicles that require more pressurized fuel supply than mechanical fuel pumps can deliver will have an electronically operated fuel pump or fuel module that is mounted on or in the gas tank.

Fuel pumps have various components that work together to send fuel from the gas tank, through the fuel filter, to the fuel rail, distributed into the injectors, and sprayed into each engine cylinder combustion chamber. The pump must produce a certain pressure specified by the manufacturer.

Older vehicles that have a carburetor will have a mechanical fuel pump with either a diaphragm or plunger-type pump. Automobiles with engines rated under 450hp work well with them. Mechanical fuel pumps may be the more convenient and less costly of the pumps to choose from. They can be easier to access and would, in turn, have a lowered labor cost.

Mechanical fuel pumps use a pulling force to get the gasoline through the different components. They are normally mounted on the engine block with the engine’s camshaft operating the pump. The fuel is regulated with an inlet valve closing when fuel in the float bowl of the carburetor is filled and opening when more fuel is needed.

Common issues of mechanical fuel pumps includefuel leakage from the diaphragm into the crankcase, vapor lock in the pump, faulty diaphragm spring, and too low fuel pressure.

Modern vehicles with a fuel injection system have electric fuel pumps. These pumps do not have diaphragms or plungers that pull the gasoline but instead pushes gasoline through the different components with an electric motor.

Electrical fuel pumps can be mounted inside the fuel tank on a bracket that can be accessed from an access port on top of the tank. These pumps are designed to be submerged in gasoline. External electric fuel pumps sit outside the fuel tank.

Electric fuel pumps are powered and receive instructions from the Powertrain Control Module (PCM) and Engine Control Unit (ECU). It regulates fuel with pressure regulators.

Here are warning signs that can signify your vehicle needs a fuel pump repair and other culprits that cause the same symptoms. Rule out these other causes before paying for a fuel pump replacement that you may not need.

Sputtering– While trying to accelerate, the engine starts sputtering. Engine sputtering sounds like humming or purring from under the hood. This happens when there is not enough fuel pressure or inconsistent amount of fuel reaching the combustion chamber. Slow acceleration may be felt, too. This is a sincere sign there is something wrong with the fuel system. The fuel system includes the pump, fuel filter and injectors.

Low Gas Mileage – Less miles for your gas. If the relief valve in the fuel pump is not opening at the right time, your engine will be getting excess fuel and thus you will have lower fuel efficiency.

Driving regularly on a low tank of gas – While driving on an empty gas tank, the fuel pump can overheat and cause it to run dry. This stresses out the fuel pump and can cause it to malfunction.

Age– Time does not help rejuvenate anything, even fuel pumps. Over time there will be an accumulation of contamination and wear and tear. Fuel pumps can start hiccuping around 7 or 8 years old or after 100,000 miles.

Check the fuel pressure. Look up the figures for the year and model of the vehicle and connect the pressure gauge to the fuel system. First, measure the pressure with the vehicle turned on but the engine off. Then get a second pressure reading with the engine idling. For a healthy fuel pump, you should get a reading near specifications and then see a drop of 4 to 6 psi when you start the engine.

A good mechanic will go through a few extra procedures apart from just replacing the fuel pump. With other replacement parts, these extra charges are necessary for the new fuel pump to run efficiently. The mechanic will first ensure the fuel pump is actually malfunctioning.

Keep your gas tank at least a quarter full. This will cause less stress on the fuel pump. Ensure your gasoline has no impurities. Avoid getting dirt and debris in or around the gas tank opening. Less contamination equals less fuel filter blockage.

⊙Mud pump spare parts of abroad brand:Eg. Liner, piston, valve assembly, valve seat, valve spring, valve rubber could be alternative for original with lower price.

⊙Original brand:Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford.

From industrial wastewater to fire suppression systems or commercial pools, ABB"s Baldor-Reliance® Pump motors provide value by increasing system reliability and reducing maintenance costs. Utilizing energy efficient designs, our inverter duty pump motors meet the NEMA Premium® efficiency standard with wide variable torque speed ranges. Pump motor construction can be tailored for specific applications and industries such as food processing, washdown applications or explosion proof enclosures for pumps in hazardous areas.

A mud motor is no more effective than the volume of fluid that is pumped through it, which generates power. If the mudflow is on the low side of specifications, the mud motor will have low bit speed and a slower penetration rate. As the pumping rate increases toward the maximum of the flow specification the motor is more powerful and efficient. This is why it is essential to match your mud motor size with the available deliverable mudflow from the pump.

Most mud pumps used in the directional boring industry run at higher speeds to operate mud motors. The draw back is that the mud pumps lose operating efficiency, particularly as mud viscosity increases and the effect of entrained air in the mud magnifies. The pumps experience incomplete filling on the suction phase of the stroke, causing a drop in the volume of fluid actually being pumped.

A properly designed, pressure-fed piston or plunger pump generally has a 96 to 97 percent volumetric efficiency. The loss is due to valves not opening and closing instantly. This efficiency goes down as mud viscosity increases and drops like a rock, if air is in the mud. Air is a hidden monster that can drop the pump efficiency to 50 percent or less. The biggest cause of entrained air in the mud is the cleaning system and its design. By the very nature of cleaning mud, agitation occurs which mixes air into the mud. Higher viscosity mud makes air entrapment worse. The design of the cleaning system must give time for the mud to expel this air before it enters the suction manifold of the pressure pump and cause cavitation damage and loss of pump efficiency. A cleaning system that eliminates sand from the mud will also reduce repair costs to mud motors and pumps.

Small internal diameters of the piping and hoses cause pressure losses as pumping rates increase. This robs available pressure away from the motor, causing a decrease in motor torque and slower boring. The smaller I.D. of the drill pipe of some rigs also tends to require a higher surface mud system pressure to off set piping losses.

When talking about mud pump capabilities, you have to keep in mind that when flow rates are represented by manufactures, it is usually a calculated volume based on pumping water at 100 percent efficiency. Air in the mud, the size of the restricted passages, mud viscosity and the length of the various restrictions reduce the true working efficiency of the pumps.

It almost goes without saying, but any leaks on the pressured side of the pump, including a leaking piston or plunger packing, reduce efficiency. Sonde housings that have broken windows and allow mudflow to divert out of them reduce efficiency. Leaks in the suction hoses can allow air to enter the system or allow cleaned mud to be lost. What can be done to help eliminate some of the inherent problems so that more mud can get to the motor and bit and do the best job for the work at hand?

Use larger pumps than are needed so that the mud pump does not have to be operated at 100 percent. Seventy-five percent of rated speed is a good maximum operating rpm.

Automatic Taping Tools are more powerful and efficient than traditional hand tools. Whether you"re a drywall professional, remodeler, or DIY, automatic taping tools achieve better results in half the time. Drywall Loading Pumps (mud pumps) are compound pumps that use Gooseneck and Box Fillers Adaptors to fill drywall taping and finishing tools. All-Wall offers the largest selection of Loading Pumps from top brands such as TapeTech, Columbia, Asgard, Graco, and Drywall Master.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

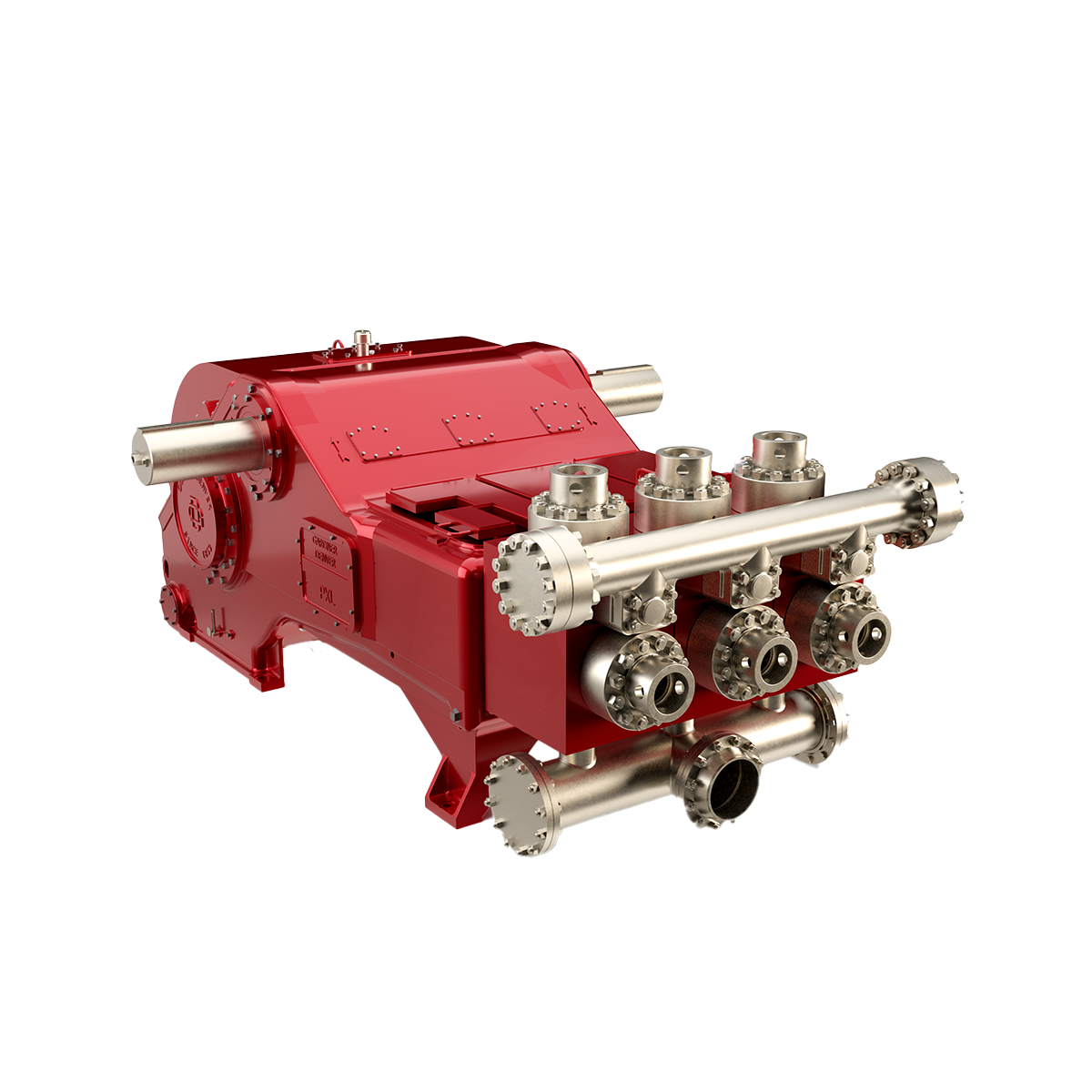

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

8613371530291

8613371530291