f1600 mud pump piston in stock

A wide variety of bomco f1600 mud pump piston options are available to you, such as 1 year, not available.You can also choose from new, bomco f1600 mud pump piston,as well as from energy & mining, construction works , and machinery repair shops bomco f1600 mud pump piston, and whether bomco f1600 mud pump piston is 1.5 years, 6 months, or unavailable.

A wide variety of f1600 mud pump parts options are available to you, such as 1 year, not available and 2 years.You can also choose from new, f1600 mud pump parts,as well as from energy & mining, construction works , and machinery repair shops f1600 mud pump parts, and whether f1600 mud pump parts is 1.5 years, 6 months, or unavailable.

Haihua F1600 Mud Pump Piston Rod, HH0628.207.019 HH11309A.05.017.162 is connected to extension rod through clamp, the piston and piston rod are connected by piston nut.

Check if any abnormal sound exist at connection clamp between piston rod and extension rod. Tighten the clamp bolts or replace qualified clamp, piton rod or extension rod if any abnormal sound occurred.

Dismantle the connection clamp between piston rod and extension rod, and crank mud pump to separate the extension rod from piston rod. Then use the lifting tool to hold liner inside.

There is no need to remove piston core from piston rod when replacing piston rubber. Replacing the rubber only needs to remove the retainer (circlip) and clamping plate at the front of piston core.

TENACITY produces a series of API 7K-compliant mud pumps ranging from F-500 to F-2200. F-2200 is atri-cylinder, single-action, heavy-duty, high-pressure drilling pump with amaximum power of 2,200HP, maximum working pressure of 52MPa, and maximum displacement of 77.65L/s.

F-1300, F-1600,F-1300L and F-1600 mud pumps have a Max Pump pressure of 34.5 MPa (5000Psi) and adisplacement of 46.5L/S with a liner of Φ180mm. These two models are the first choice for medium and deep drilling rig as an assortedcomponent.

F-1600, F-2200 mud pumps with high-power and high-pressure are developed to meet drilling requirements of offshore deep-water, terrestrial andhorizontal wells, especially in desert areas.

Our premium pistons are fully interchangeable with other API standard designedpistons and deliver maximum performance in almost all drilling conditions. Hightensile strength, resistance to chemicals, hydrocarbons, and abrasion, longService,and full interchangeability with other API designed pistons make our premiumpiston a sound value.

This one piece bonded constructed piston has no joints to leak. Eliminates abrasive fluids between piston and liner. The fluid expanded lip is not damaged by high pressure and fast pump strokes. This Fail-Safe piston seals off to greater diameter as liner wears.

Currently running in pumps using exotic muds and highest drilling pressures! Bonded construction - no joints, no leakage. Longer piston and liner life. This pistonwill run in higher-pressure, fast stroking pumps, and is resistant to oil basemuds and other additives currently being used. This Premium Piston has been inservice for years, providing unmatched performance under extreme drilling conditions. This one piece bonded unit provides the same series of advantages. being imprevious to oil and other chemicals

The piston rubber is made from specially formulated compounds which are resistant tothe effects of heat, oil and water. The multi-ply fabric reinforced backingsused in the production of the piston rubbers provide positive, wear resistantseals.

The piston rods are manufactured from high quality alloy steel. Surface is induction hardened for maximum case hardness and core strength - hard on the outside, tough on the inside. Precision ground mirror surfaces meet rigid quality control standards and minimize wear.

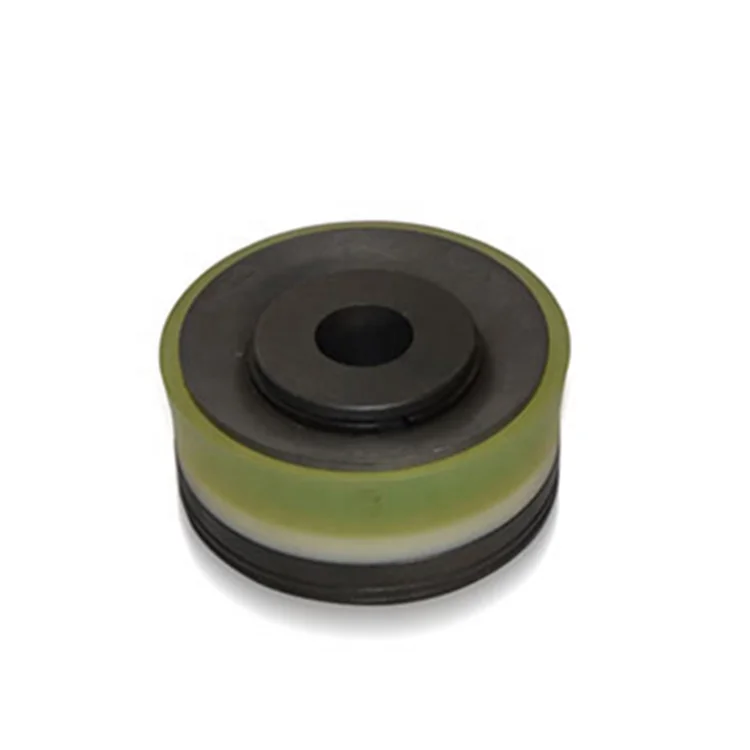

The piston assembly is one of the main parts of the hydraulic end system of the mud pump, and it is also one of the vulnerable parts in the drilling work. The discharge pressure of the mud pump is generated by the reciprocating linear movement of the piston assembly in the piston. The piston assembly is composed of piston core, rubber, circlip, pressure plate, etc. The material of the piston core is 42CrMo, and the material of the piston rubber is nitrile rubber or polyurethane rubber

Has excellent oil resistance and wear resistance. The working temperature is not higher than 120℃, which is suitable for oil-based mud with working pressure below 35Mpa and working environment with high sand content.

Quick DetailsModel Number:All sizePlace of Origin:Shandong, ChinaPressure:High PressureStructure:PISTON PUMPMaterial:NBR/PolyurethaneName:mud pump pistonType:NormalWarranty:1 YearKeywords:pistonColor:black, yellowPump Type:piston pumpDelivery time:25 DaysMOQ:2 pcPower:HydraulicFuel:DieselUsage:Mud PumpApplication:drilling mud pumpSupply AbilitySupply Ability:1000 Piece/Pieces per MonthPackaging & DeliveryPackaging Detailswooden box or according to clients requirement.Port:QINGDAO, SHANGHAI, TIANJIN

KINGWELL produces a series of API7K-compliant mud pumps ranging from F-500 to F-2200. F-2200 is a tri-cylinder, single-action, heavy-duty, high-pressure drilling pump with a maximum power of 2,200HP, maximum working pressure of 52MPa, and maximum displacement of 77.65L/s.

F-1300, F-1600, F-1300L and F-1600 mud pumps have a Max Pump pressure of 34.5MPa (5000Psi) and a displacement of 46.5L/S with a liner of Φ180mm. These two models are the first choice for medium and deep drilling rig as an assorted component.

F-1600,F-2200 mud pumps with high-power and high-pressure are developed to meet drilling requirements of offshore deep-water, terrestrial and horizontal wells, especially in desert areas.

Our premium pistons are fully interchangeable with other API standard designed pistons and deliver maximum performance in almost all drilling conditions. High tensile strength, resistance to chemicals, hydrocarbons, and abrasion, long Service, and full interchangeability with other API designed pistons make our premium piston a sound value.

This one piece bonded constructed piston has no joints to leak. Eliminates abrasive fluids between piston and liner. The fluid expanded lip is not damaged by high pressure and fast pump strokes. This Fail-Safe piston seals off to greater diameter as liner wears

Currently running in pumps using exotic muds and highest drilling pressures! Bonded construction - no joints, no leakage. Longer piston and liner life. This piston will run in higher-pressure, fast stroking pumps, and is resistant to oil base muds and other additives currently being used. This Premium Piston has been in service for years, providing unmatched performance under extreme drilling conditions. This one piece bonded unit provides the same series of advantages., being imprevious to oil and other chemicals

The piston rubber is made from specially formulated compounds which are resistant to the effects of heat, oil and water. The multi-ply fabric reinforced backings used in the production of the piston rubbers provide positive, wear resistant seals.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

8613371530291

8613371530291